Mielta Katana Manual instruction

Fuel level sensor

«Katana»

Setup and Operation Manual

Hardware version 12

Software version 2.2.2

Configuration program version 2.1.0

Amended on 13.08.2021

Tambov 2022

Table of contents

1. Description 3

2. Specification 4

2.1 Power supply 4

2.2 Frequency output 5

2.3 RS485 interface 5

3 Installation and Connection 7

4 Configuartion of the sensor 11

4.1 Connection to the sensor 12

4.2 Calibration 13

4.3 Taring 14

4.4 Other settings 15

5. Transportation and storage 18

6. Warranty terms 18

7. Package contents 18

2

1. Description

Fuel Level Sensor (FLS) Katana MIELTA is designed to measure the level of light

petroleum hydrocarbons (diesel fuel, gasoline, kerosene, etc.) in containers for various

purposes. Sensor can be installed both on stationary objects, and on vehicles and railway

transport.

Sensor uses the linear capacitor capacitance measuring method. Capacitance value

depends on the level of dipping into the dielectric liquid.

The sensor is made in a durable plastic housing with IP68 protection, equipped with

a flexible cable and a sealed connector. The sensor mounts in a hole in a container (tank)

and has a flange for mounting with screws.

3

2. Specification

Table 1.

Supply voltage

8 – 55 V

Average power consumption

0,5 W

Measurement period

1 sec

Average interval

1-60 sec

Relative level measurement error over the entire

range

1%

Frequency output: maximum frequency range

30-2047 Hz

Frequency output discreteness

1 Hz

Frequency output pull-up to the power supply

3.3 В, 470 kOhm

Frequency output current limitation

0,1 А

RS485 baud

9600, 19200, 38400, 57600, 115200

baud, 8n1

Measurement part length

990 mm

Cable length

0,7 m

Mounting kit cable length

7 m

Operating temperature

-40..+80 °С

Housing Ingress Protection

IP68

Sensor dimensions

82 х 86 х 1015 mm

2.1 Power supply

FLS is designed to work in the on-board power with a nominal voltage of 12 or 24

volts, has a reverse-polarity protection, over-voltage protection and a self-repairing fuse. A

wide range of operating voltage allows the sensor to work stably even in abnormal situations

- when the voltage is low up to 8 V or raised above the norm up to 55 V.

If the supply voltage exceeds 55 V, a protective diode and a self-repairing fuse in the

FLS circuit is triggered, and the sensor power is turned off. After reducing the supply voltage

level to the operating (normal) range, the sensor restores its operability.

2.2 Frequency output

The sensor`s frequency output is designed to transmit the data in a discrete signal

form of variable frequency and a 50% duty cycle. The positive signal potential is provided by

a pull-up to the sensor supply via resistor. The negative potential is formed by a transistor,

operating in a common-emitter circuit. The frequency output maximum current is limited to

100 mA. When the maximum current limit is exceeded, the high-speed protection is

triggered and deactivates the output. When the current is reduced to an acceptable value,

the frequency output continues to function.

The lower value of the output frequency is 30 Hz. The upper value is set

programmatically in the range of 500-2048 Hz.

If an error occurs, the sensor sets the frequency corresponding to the error code (see

Table 2). The error is also duplicated over the digital protocol.

Table 2.

4

Freq., Hz

Error code

Error description

20

20

Level is less than the minimum at calibration

Max +50

5000

The level is higher than the maximum at

calibration

Max +100

6000

Exceeding the measurement limits, short circuit

of the measuring system

If it is necessary to match the frequency output to a voltage level lower than the

sensor supply voltage, it is necessary to turn-off the inbuilt pull-up and use an external

pull-up resistor. The nominal value of the resistor is selected in such a way that, when

short-circuited to ground, it provides a current in the range of 5-10 mA (for example, a

resistor from 1200 to 2400 ohms is needed for 12V).

When connecting the sensor to the data reading system (tracker), it is necessary to

combine potentials (connection of negative power wires).

2.3 RS485 interface

The digital interface RS485 is made according to the international standard ANSI

EIA/TIA-485-A. The data is transmitted using a protocol developed by MIELTA, which is

compatible with the LLC protocol for receiving fuel level data.

The digital interface is designed to receive telemetric data from the sensor, configure

parameters and update the firmware. It is used to connect to a monitoring system or a

personal computer (PC) using a USB-RS485 adapter. To work with a PC, a configurator

program is used, which implements all possible functions of the sensor.

The RS485 interface allows you to connect several sensors to one terminal port (Pic.

1, 2). All MIELTA satellite terminals support the connection of up to 8 any sensors or

peripherals on the RS485 bus.

Picture No 1. Type "star" connection scheme.

5

When connecting several sensors at a distance less than 20 m from a tracker, the

"star" scheme is recommended. This scheme does not require additional terminal

resistors..

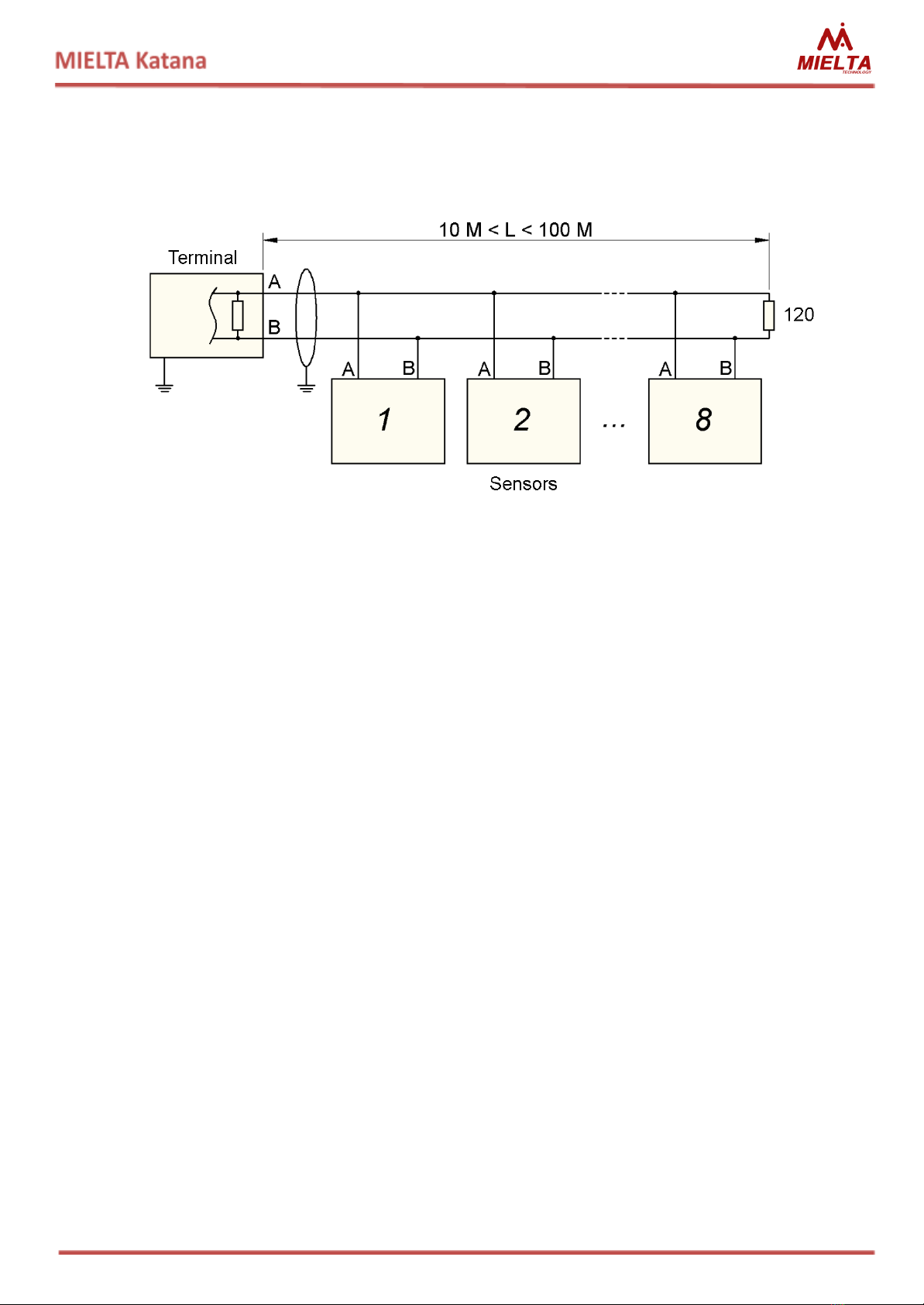

Picture No 2. Type "bus" connection scheme.

The "bus" scheme connection is used to connect several sensors at distances up to

100 m. In this case, an external termination resistor of 120 ohms 0.25 W is required, which is

connected at the location of the most remote sensor from the terminal.

If the length of the bus is more than 20 meters, it is recommended to use a shielded

twisted-pair. The cable shield is connected only from one side to the «-» terminal's contact

("-" supply). The connection of the cable shield to the sensor's «-» is not required. The

terminal and sensor power supplies must have a common «-» potential.

Before connecting several sensors to the common bus, it is necessary to configure

each of them individually. All devices on the bus are assigned a unique addresses.Then for

each sensor set the address, the transmission rate and the type of data requested (level,

output frequency or temperature) in tracker.

The digital value "level" is in the range 30 - 4095. Values of 20, 5000 and 6000 are

error codes in the sensor operation (Table 2). The digital value "frequency" is the frequency

formed at the sensor frequency output, the upper value of which is programmed (see

"Frequency output" section). The value "temperature" reflects the actual temperature in the

sensor housing.

3 Installation and Connection

The sensor is mounted at the top of the fuel tank and opposite to the lowest point of

the bottom of the tank. The surface for mounting the sensor must be horizontal and selected

with regard to the availability and ease of installation.

6

Picture No 3. Mounting dimensions of FLS.

The central hole has a Ø25 mm diameter (Pic. 3). The mounting holes diameter is

chosen based on the material of the fuel tank and the fixation method. Self-tapping screws

are used to fix the sensor. When the sensor is mounted on a metal tank, It is drilled 4 holes

with a diameter of 4-4.5 mm or It is used screws with a drill. When the sensor is installed in a

plastic tank, It is drilled 4 holes with a diameter of 3 mm and it is used self-tapping screws

without a drill.

7

Picture No 4.Dimension of FLS.

Installation procedures:

1. Select a location for installation, clean it of contamination.

2. Mark the holes according to the template, drill and remove the sawdust.

3. Measure the depth of the tank from the bottom to the mounting surface.

4. Measure the sensor length from the mounting flange 20 mm shorter than

the measured depth of the fuel tank.

5. Saw off the tube and the central electrode, clean off the burrs, put the remote

insulator into the end of the measuring tube.

6. Calibrate the sensor (section 4.2).

7. Clean and degrease the mounting surface of the fuel tank. Apply sealant to the

surface, glue a rubber gasket. Apply a sealant to the rubber gasket and install the

sensor.

8. Fixate the sensors with screws.

9. Connect the cable connector.

10. Seal the sensor mounting and connector.

If necessary, to avoid obstacles in tanks of complex shape, the measuring tube of the

sensor can be bent. Bending is performed by using specialized pipe bends with a bending

radius of at least 250 mm. The bend angle should not exceed 15 degrees. (Picture 5).

8

The operations sequence during bending:

1. Disconnect sensor from the power supply;

2. Calculate the location of the fold, mark it on

the sensor tube;

3. Place the sensor tube in the pipe bend with a

mark in the middle;

4. Connect the measuring device (multimeter)

in the continuity mode with probes to the

tube and the central electrode, respectively;

5. Bend the tube until the required angle is

reached, preventing the closure of the central

electrode and tube;

6. If there is an electrical shortage of the central

electrode and tube, it is necessary to reduce

the angle of the bend by applying force to the

folding position on the reverse side, until the

central electrode from the tube insulation

guaranteed;

7. Cut the pipe to the required length.

8. Calibrate, install and taring the sensor.

If necessary, the sensor tube can be

bent in two or more places to give it a complex

shape.

Please, note that the tube, after bending, loses its symmetry and linearity, which

directly affects the sensor readings. A sensor without taring can have non-linear distortions

in the readings at different levels. During sensor`s taring, it is recommended to do more

measurement points (30-50 points per meter) to compensate for nonlinearity.

Table 3.

№ Pin

Wire color

Purpose

1

Red

Plus power (“+”)

2

Black

Minus supply (“-“) (GROUND)

3

Yellow

RS485-A

4

Blue

RS485-B

5

White

Frequency output

6

-

-

9

Рисунок 6. Нумерация контактов в разъеме

жгута.

Рисунок 7. Нумерация контактов в

разъеме ДУТ.

●All electrical connections must be soldered or crimped. Seal the joints using a

heat-shrinkable adhesive tube.

4 Configuartion of the sensor

To configure the Sensor use the configurator program. Viewing Sensor information is

available without limitations, and to change the settings is required a password. By default,

the manufacturer sets the password «0000».

Picture 8. Main window of the configuration program

10

4.1 Connection to the sensor

Connection to the sensor is possible via the RS-485 interface with using a special

adapter. Before you start working with the sensor, you need to search for devices on the

RS-485 bus. To do this, click the "Sensor Select" button, which is located in the "General"

menu of the configuration program (Picture. 8).

In the window that opens, specify the serial port to which the RS-485 adapter is

connected, select the search mode (broadcast or by address range), and click the "Search"

button (Picture. 9). The search results will be displayed in the right part of the window in the

"Discovered sensors" block in the following format:

COM-port :RS-485 address : port speed

Picture 9. "Search and select sensor" window

For example, in the Picture 9, the program detected one sensor with address 3,

configured for a speed of 19200. To start working with the required sensor, click on the

corresponding line with the left mouse button. The program will connect to the sensor and

display its parameters in the main window.

4.2 Calibration

Before using the Sensor, it is necessary to calibrate it by the values "empty tank" and

"full tank". These values will match the sensor readings 0% and 100%, accordingly.

Sensor calibrating procedure:

1. Cut the sensor measuring tube at a distance from the mounting flange 20 mm

shorter than the depth of the fuel tank.

2. Connect the Sensor to the configuration program (section 4.1).

3. Sink the sensor tube into the fuel tank to the maximum depth (up to the drain

hole)

11

4. After stabilizing the readings in the program, perform calibration on a "full tank"

(Picture 10).

5. Remove the Sensor from the fuel tank, let the remaining fuel drain for 5

minutes.

6. After stabilizing the readings in the program, perform calibration on a "empty

tank” (Picture 10).

●Calibrate the sensor in the specified sequence. Calibration on the "empty tank"

value of a dry sensor (without filling the sensor tube into the fuel) causes incorrect

level readings. Fuel vapors in the tube significantly affect the sensor readings.

Picture 10. Calibration (Sensor is not calibrated)

The red color means that there is no calibration at the corresponding point. To calibrate the Sensor

at the required point, press the relevant "Calibrate" button. After the calibration, the line will change its

color to green. To calibrate the sensor again, press the “Calibrate” button again. To completely reset the

Sensor calibration (in two points), press the "Reset calibration" button.

4.3 Taring

Sensor taring is to create a table to link the sensor level readings to the actual volume

of fuel in the tank. Taring is done for each fuel tank individually and it is necessary to get

readings in liters with a certain accuracy and linearity. The more complex the shape of the

fuel tank, the more calibration points need to be made. Most often, 20-40 calibration points

are enough in practice.

The configuration program allows you to simplify the sensor taring process, using the

"Taring" program menu (Picture 11).

Before starting the taring process, select the required sensor parameter (level N or

frequency F) and set the taring step in liters. Fill the fuel tank with the required amount of

fuel, wait for the level to stabilize and press the "Add row" button - the program will

automatically fill the next line of the taring table in accordance with the selected parameters.

The Ready-made table can be saved to the Sensor memory (maximum 128 rows),exported

12

to an Excel file, printed out. Moreover, you can import a table from an Excel file. If a taring

table has already been recorded in the sensor, you can download it from the Sensor to the

configuration program using the "Read table" button (Picture 11).

Picture 11. Taring.

4.4 Other settings

Configuration program allows you to change the following Sensor settings.

●Sensor address on the RS-485 bus (valid values are 0...254);

●RS-485 bus speed (9600, 19200, 38400, 57600, 115200);

●Default Sensor data output mode operation:

⇨without automatic data output;

⇨automatic data output in binary form;

⇨automatic data output in symbolic form;

●Automatic data output interval (1..60 sec);

●Sensor data filtering interval (1..60 sec);

●The upper limit of the frequency output (500..2047 Hz);

●Turning on or off the frequency output pullup;

●User password for changing Sensor settings.

After changing the settings, click the "Write" button to save the new settings to the

sensor.

All changes made to the sensor settings are recorded in the configuration change log,

which is stored in the internal memory of the sensor. In addition, the sensor stores the total

13

operating time and the number of starts in the internal memory. To view the log of changing

settings, use the "Log" program menu (Picture 12).

Picture 12. Sensor settings change log.

To download a log from the Sensor, click the "Get log data" button. To save the log to

a text file, click the “Export to File” button.

The "Service" program menu contains the following functions:

●change the user password;

●reset the user password using the master password;

●sensor firmware update;

●sensor reset.

Picture 13. . "Service" program menu.

14

To change the user's password, click the "Change password" button, in the opened

window enter the current and new passwords and click "Change" (Picture.14).

Picture14. . Change user's password.

●If the user's password is lost, it is possible to reset the user's password.To get a

master password, contact your hardware vendor.

Picture 15. User password reset.

To update the Sensor firmware, click the "Firmware update" button in the "Service"

menu, select the firmware file and click the "Update" button (Picture 16). During the update

process, do not interrupt communication with the Sensor and do not turn off the Sensor

power.

Picture 16. Sensor firmware update.

15

To reboot the Sensor, click the "Reboot" button in the "Service" menu.

3. Transportation and storage

The fuel level sensor must be stored in a warehouse at a temperature from -20 ° C to

+50 ° C and a relative humidity of no more than 85 ° C. Water ingress and technical liquids

must be excluded.

The Sensor is transported in the original packing, by any kind of transport.

4. Warranty terms

The manufacturer guarantees the operation of the fuel level sensor within 3 years

from the date of sale, subject to the consumer's compliance with the conditions and rules of

transportation, storage, installation, and operation. The average service life is 10 years.

Warranty does not apply:

- for the sensors with mechanical damages and defects (cracks, chips, dents, traces of

impacts, thermal, electrical and chemical effects) caused by the fault of the consumer or

third parties due to violation of operating, storage or transportation conditions;

- for the sensors with traces of repair outside the manufacturer's service center;

-for the sensors with traces of electrical and/or other damages caused by

unacceptable changes in the parameters of the external electrical network or signals;

- for the sensors which failed due to incorrect software update.

5. Package contents

Name

Quantity

FLS Mielta KATANA

1

Mounting cable

1

Mounting kit:

- Gasket

- Pipe bottom cap

- self-tapping screw

- self-tapping screw for sealing

- seal

- wire for sealing

1

1

2

2

1

1

Passport

1

Package

1

MIELTATECH.COM

info@mielta.ru

16

Table of contents

Other Mielta Accessories manuals