General Safety

Operating this chipper safely is necessary to prevent or minimize the risk of death or serious injury. Unsafe operation can

create a number of hazards for you. Always take the following precautions when operating this chipper:

•

This machine is designed to operate at 540 rpm only! Never operate the machine at a faster speed; doing so can cause

serious injury to the operator or bystanders and could cause damage to the machine that is not covered under

warranty.

•

The Mighty Mac 3-Point Hitch Chipper must be operated with the weight of the machine on the ground. Operating the

machine while it is off the ground can result in injury to yourself or others, or can cause damage to the machine

which is not covered under warranty.

•

Keep in mind that the operator or user is responsible for accidents or hazards occurring to other people, their property,

and

themselves.

•

Your 3-Point Hitch MIGHTY MAC GRAVITY SELF-FEEDING Chipper is a powerful tool, not a plaything. Exercise extreme

caution at all times. The

design of this machine is to chip wood. Do not use it for any other purpose.

•

Know how to stop the chipper quickly by disengaging the PTO and shutting down the tractor.

•

Operate this machine on a level surface only. Never operate your unit on a slippery, wet, muddy, or icy surface.

Exercise caution to avoid slipping or falling.

•

Keep your face and body back from the chipper hopper to avoid accidental bounce back of any material.

•

When feeding material into the chipper hopper, be extremely careful that pieces of metal, rocks, or other foreign

objects are not included. Personal injury or damage to the machine could result.

•

Whenever you leave the operating position or if you have to remove processed material, leaves, or debris from the

machine,

always disengage the PTO, shut down the tractor engine, remove the key, wait for all moving parts to come to a

complete stop, disconnect the PTO shaft from the tractor, then wait 5 minutes before removing processed material,

leaves, or debris from the machine.

•

If the cutting mechanism strikes a foreign object or if your machine should start making an unusual noise or vibration,

immediately disengage the PTO, shut down the tractor engine, remove the key, wait for all moving parts to come to a

complete stop, disconnect the PTO shaft from the tractor, then wait 5 minutes before inspecting for clogging or

damage. Vibration is generally a warning of trouble. Clean and repair and/or replace damaged parts.

•

Never tamper with safety devices. Check their proper operation regularly.

•

Stay alert for hidden hazards or traffic. Never carry passengers on your machine.

•

Never overload or attempt to chip material beyond the manufacturer’s recommendation; see chapter 4. Personal

injury or damage to the machine could result.

•

While using the 3-Point Hitch MIGHTY MAC GRAVITY SELF-FEEDING Chipper, don't hurry or take things for granted.

When in doubt about the

equipment or your surroundings, stop the machine and take the time to look things over.

•

Never operate the machine when under the influence of alcohol, drugs, or medication.

•

Use the machine only in daylight.

•

Keep all nuts and bolts tight and keep the equipment in good operating condition.

•

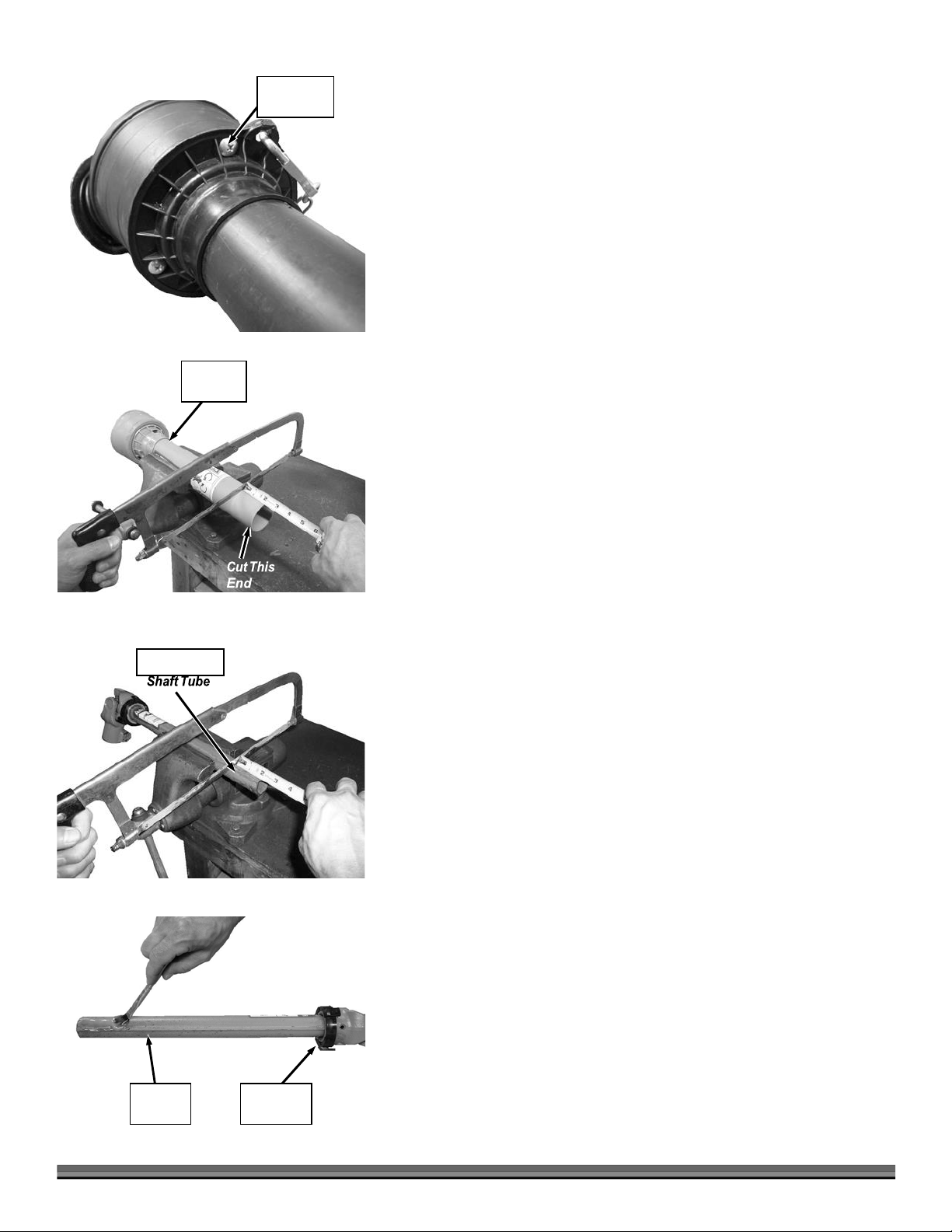

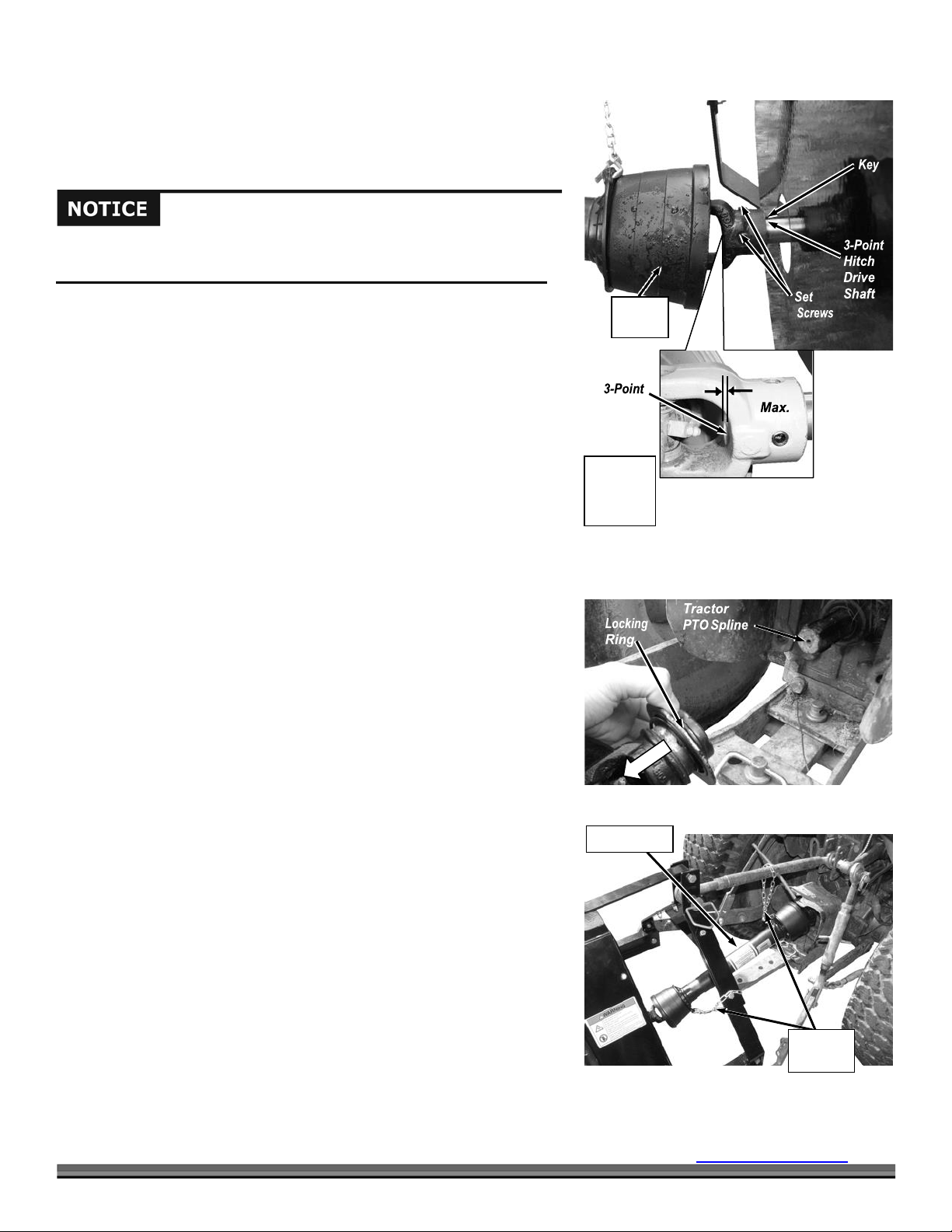

Your 3-Point Hitch MIGHTY MAC GRAVITY SELF-FEEDING Chipper is driven by a PTO shaft that transfers power

from your tractor. A PTO shaft is

extremely dangerous and can cause serious injury or death. Read and understand all of

the safety and operating instructions

manual that came with your PTO shaft.