P a g e | 1

Table of Contents

Introduction............................................................................................................................................3

Purpose of machine.............................................................................................................................4

Safety.....................................................................................................................................................7

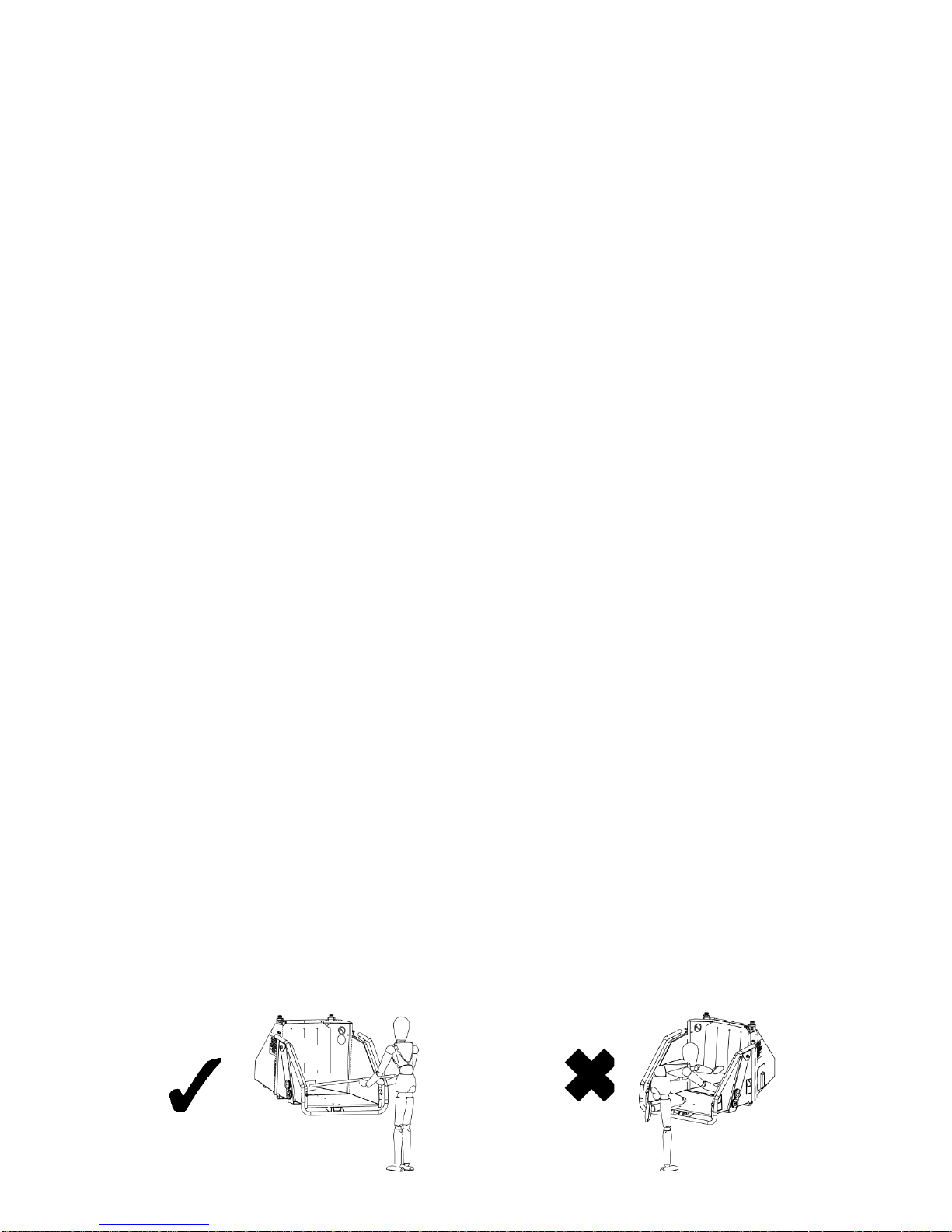

Safe working .....................................................................................................................................7

Machine lifting...................................................................................................................................8

DOs and DON’Ts .............................................................................................................................9

Noise test information........................................................................................................................10

Machine operation..............................................................................................................................11

Machine control panel, start/stop & operating settings ............................................................12

Ignition switch .................................................................................................................................12

Emergency Stopping –Standard Program ....................................................................................15

Emergency Stopping –Orange Button Program...........................................................................16

Feed jam & blockages.......................................................................................................................17

Transportation.....................................................................................................................................18

Attaching to the vehicle tow hitch ................................................................................................19

Unhitching the machine.................................................................................................................19

Routine maintenance.........................................................................................................................20

Engine maintenance......................................................................................................................21

Fastener tightening torques..........................................................................................................21

Service schedule............................................................................................................................22

Covers: engine, chipping chamber, side panels.................................................................24

Engine bay ......................................................................................................................................25

Blade changing……………………………………………………………….…………………...27

Blade sharpening ...........................................................................................................................28

Hydraulic oil filter............................................................................................................................29

Battery..................................................................................................................................................32

Battery safety information.............................................................................................................32

Storage and transport....................................................................................................................32

Initial operation ...............................................................................................................................32

Battery removal & maintenance...................................................................................................32

Charging..........................................................................................................................................33

Jump starting...................................................................................................................................33

Taking battery out of service ........................................................................................................34

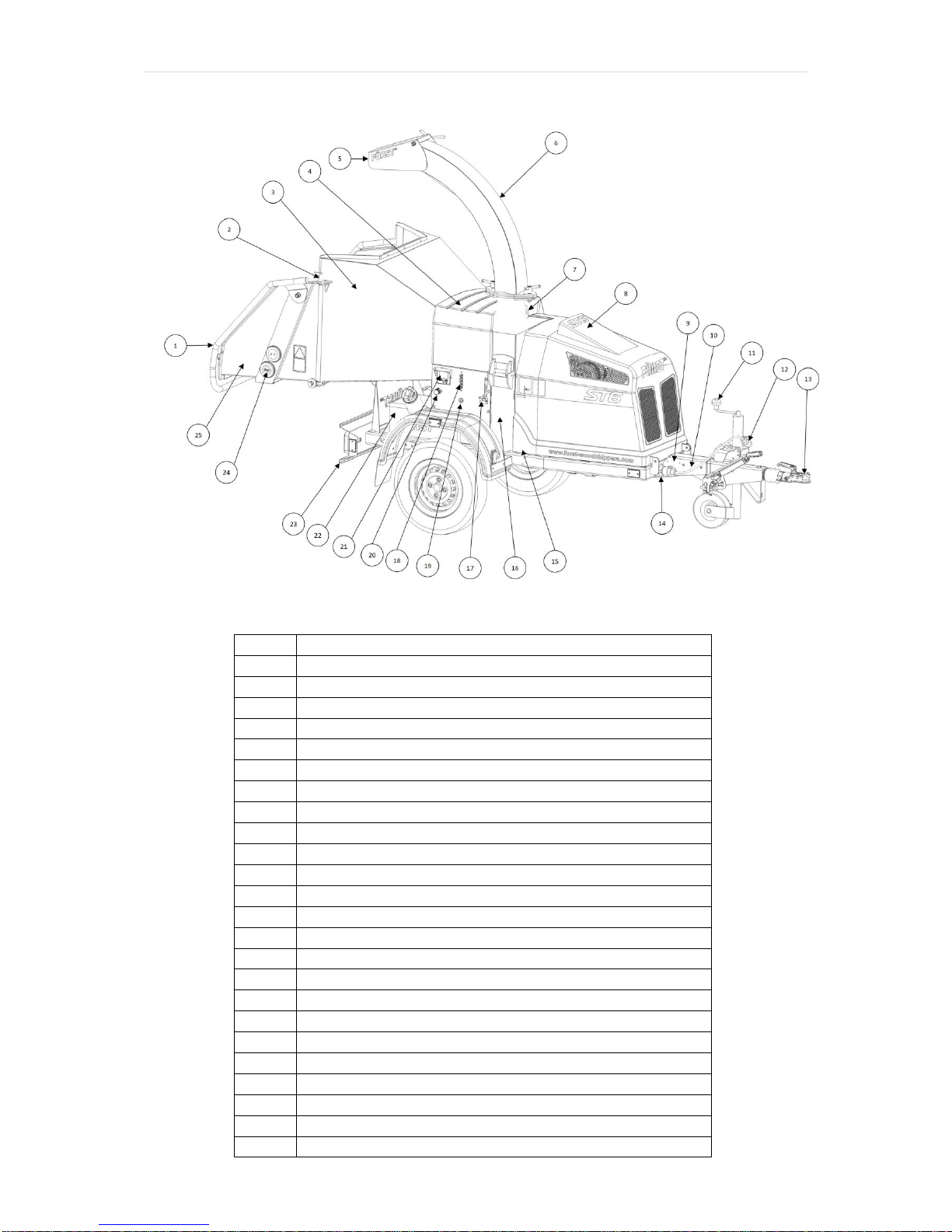

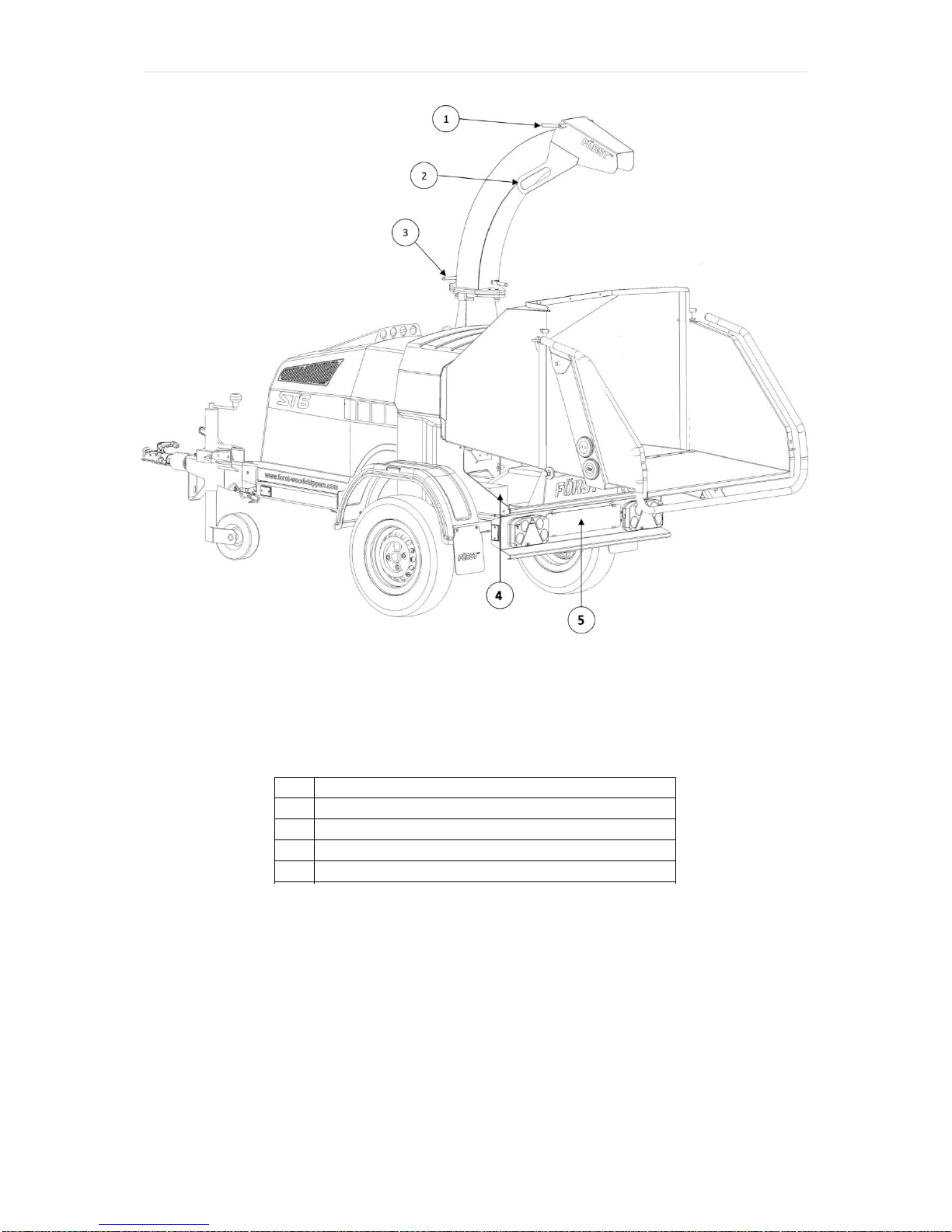

Parts lists.............................................................................................................................................35

Hopper tray touch sensor..........................................................................................................35