5

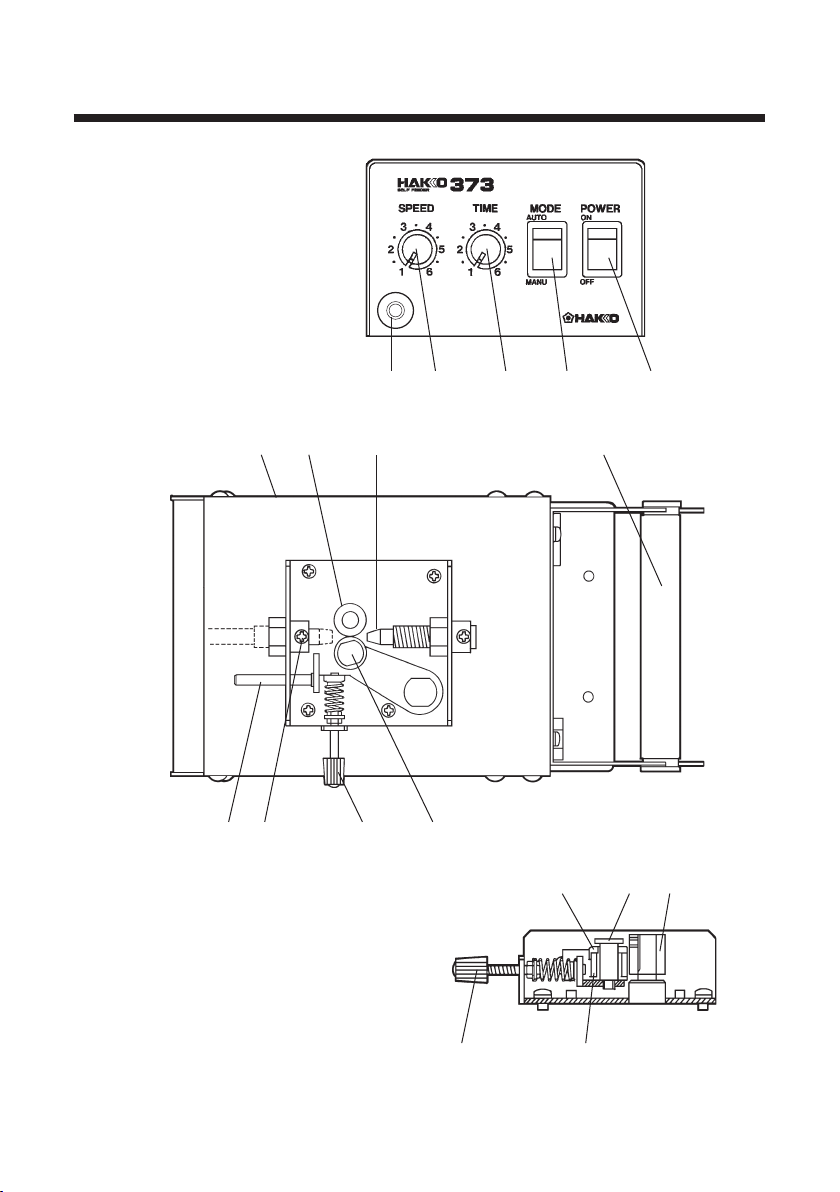

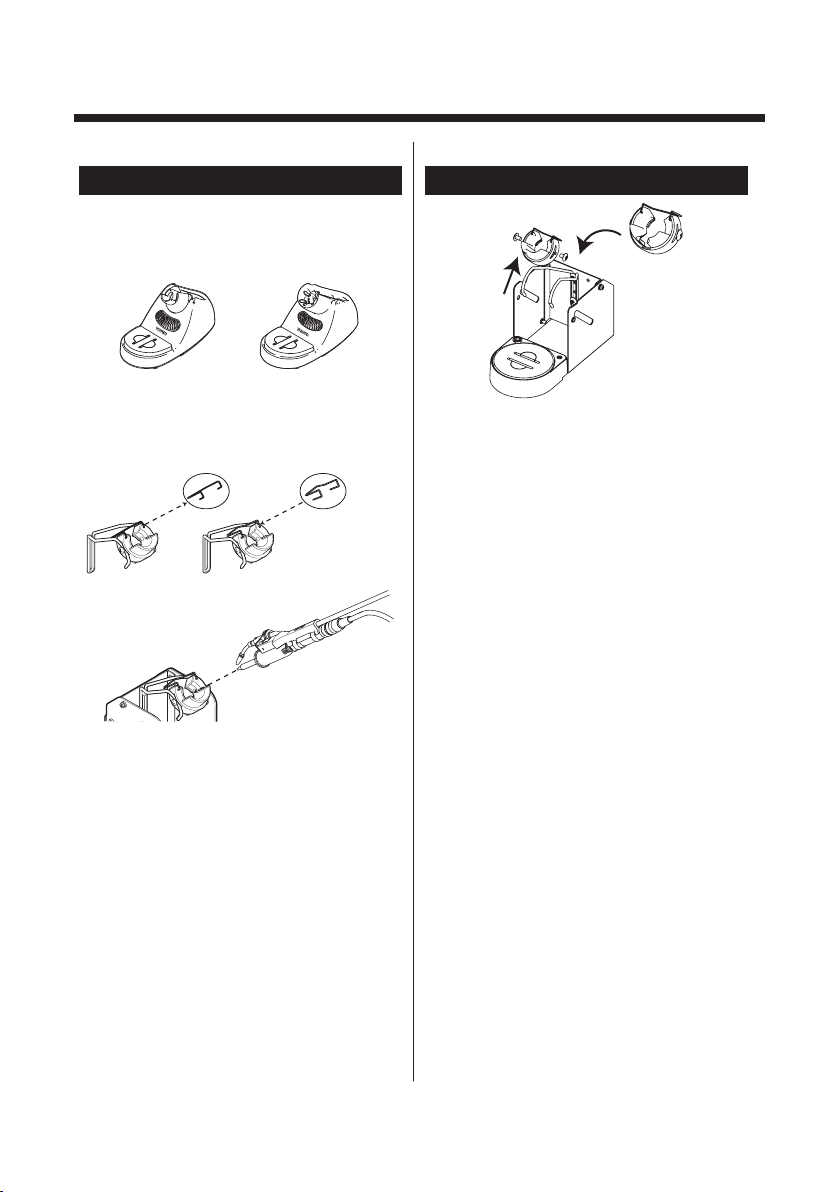

ASSEMBLY

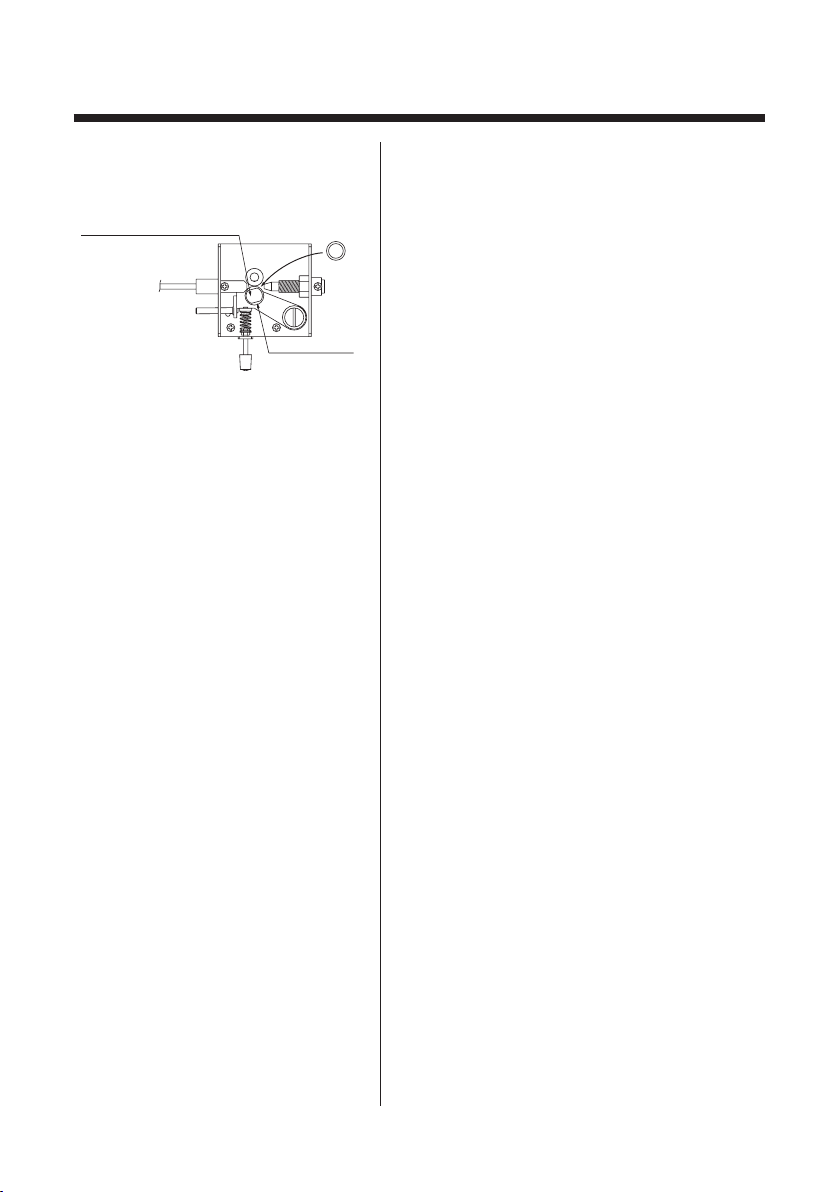

4-4. Setting the Solder If there is any solder in the tube, remove it

before installing the new solder.

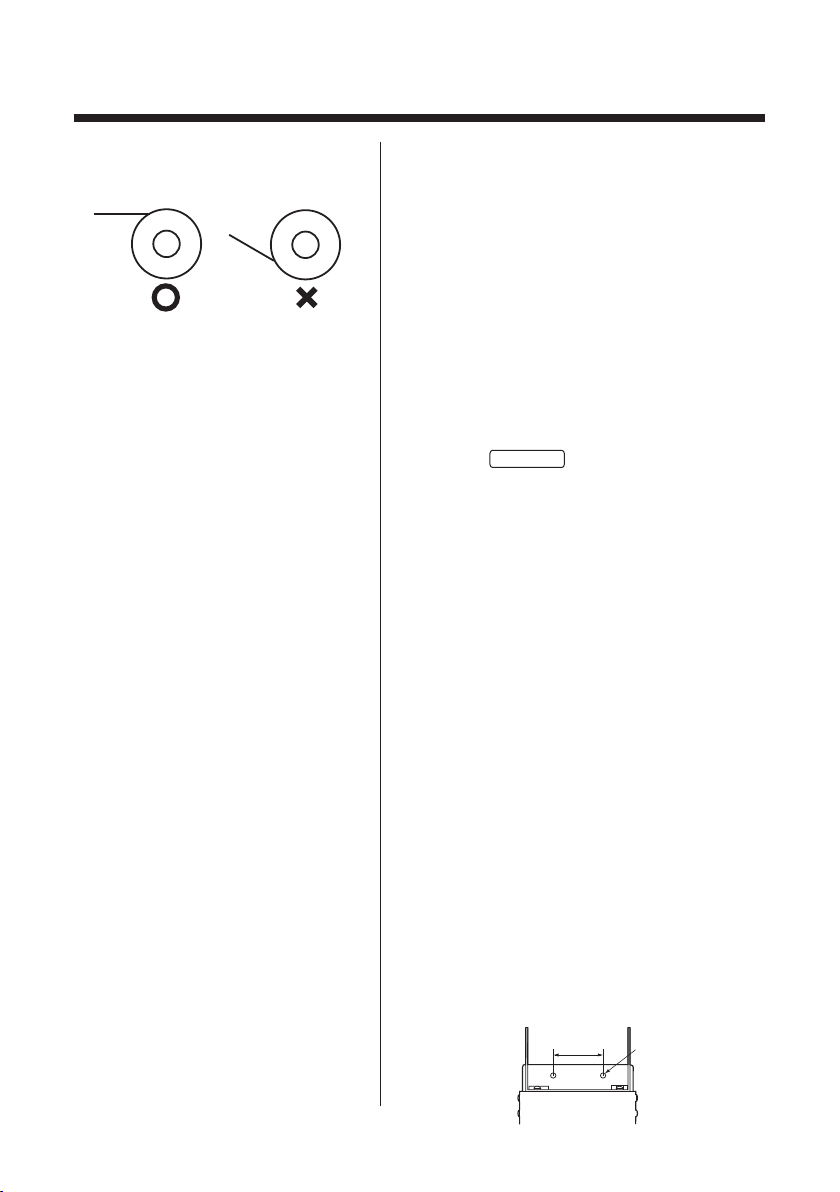

(a) Pass the solder bobbin shaft through the

solder bobbin and attach the shaft to the

rear of the station. As shown left, attach the

shaft so that the solder is fed from the top

of the bobbin.

(b) Pass the solder through the supply nozzle.

(c) With pressing release lever, put the

inserted solder of approx. 10 mm (0.4

in.) into the feed nozzle through between

tension gears.

(d) Turn the power switch ON and set the

mode to

MANUAL

.

(e) Pressing the feed switch (or footswitch),

and feed the solder.

4-5. Changing the Solder

Diameter

The following parts may need to be

changed in order to accommodate a

change in the solder diameter or type of

soldering iron used.

Solder dia. adjustment ring

Nozzle

Guide pipe assembly Tube unit

Change these parts as necessary

according to the procedure below.

(a) Power switch off. Open therelease lever

androll back the left solder to the bobbin.

(b) Remove the tension gear guide shaft, and

replace the solder dia. adjustment ring

according to desired solder dia. Remove

the tension gear guide shaft turning with a

spanner or pliers.

(c) Replace the guide pipe assembly if it is

necessary.

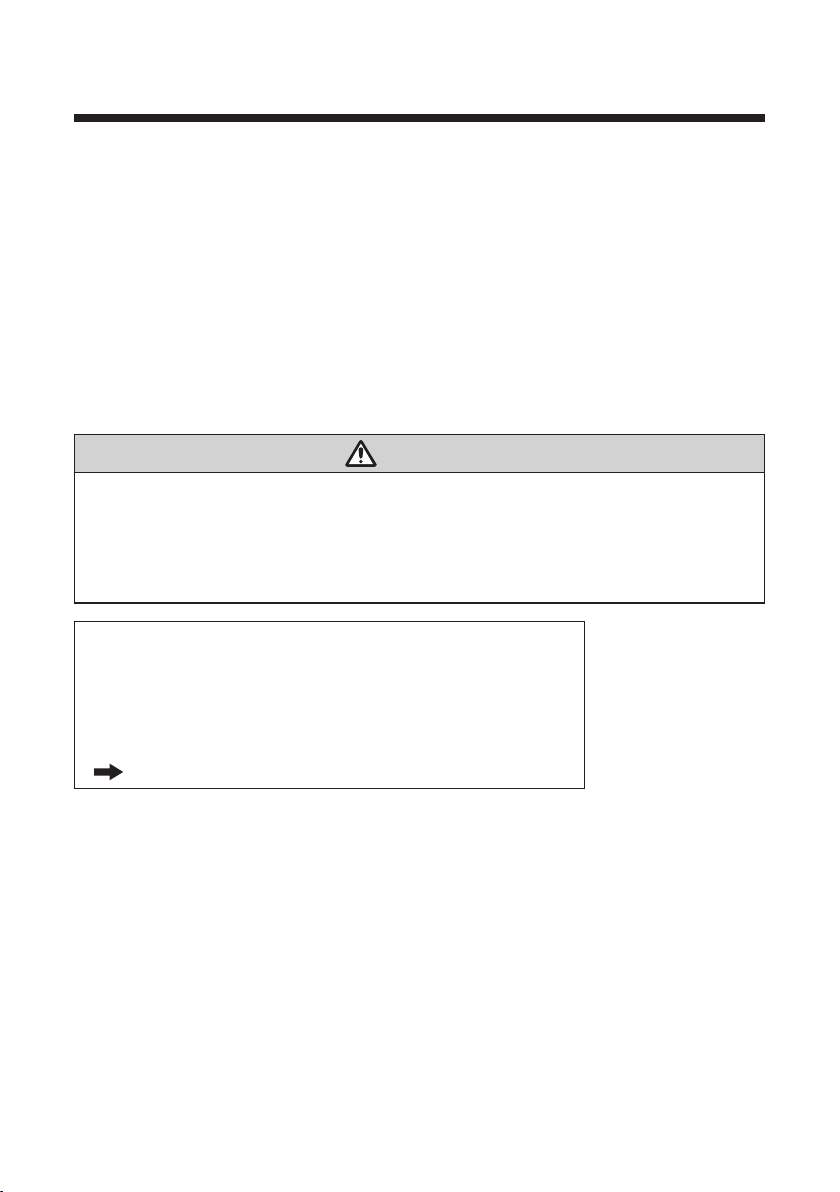

4-6. Vertical Mounting

The HAKKO 373 can be mounted vertically.

Mount as shown in the figure.

←

46mm 2-φ4.2

6

OPERATION

Solder will be fed by pressing the feed switch (or foot switch).

■MODE □AUTO MODE

If you press the feed switch, solder will be

fed with set time and speed independently

of length of pressing time.

□MANUAL MODE

Solder will be fed with set speed during

pressing the feed switch.

■Setting for Feed Time

and Feed Speed

Set the speed before the time. For the

setting speed, both

&

are

effective, but only

is effective for

setting time.

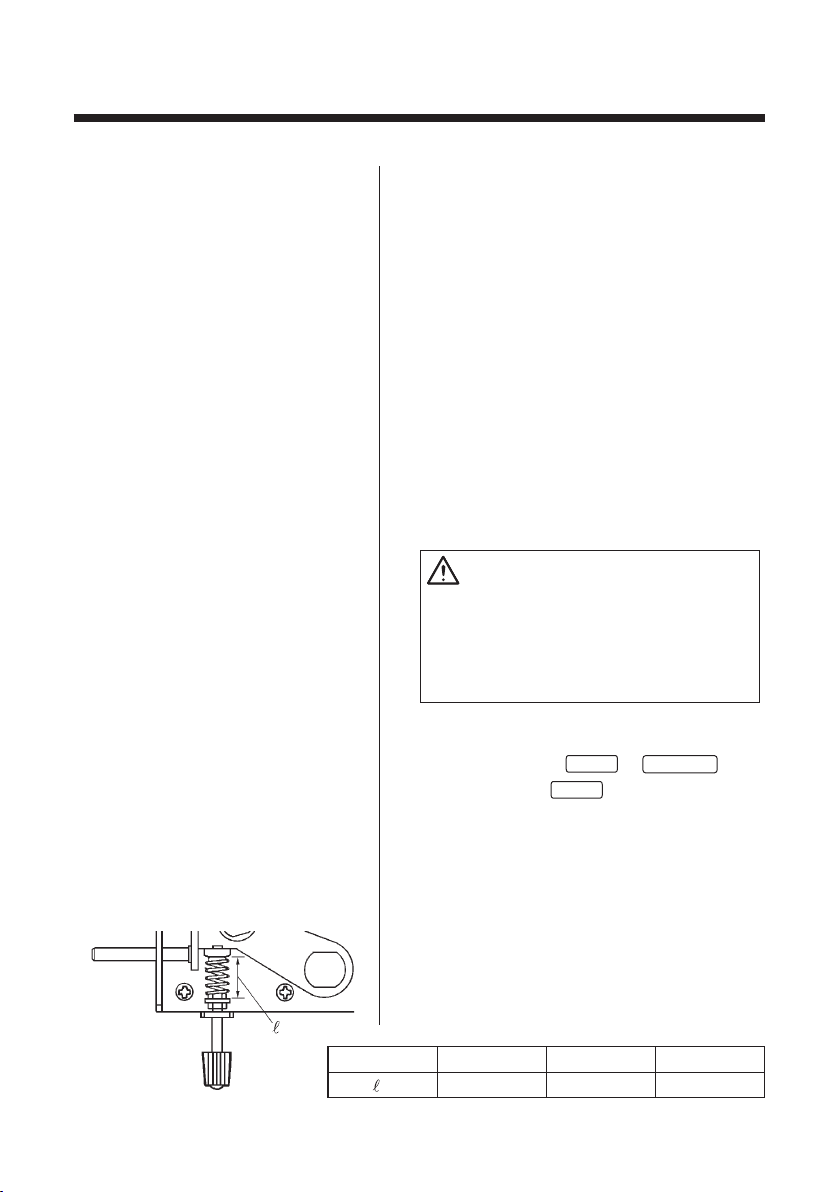

■Adjustment of Tension When adjust the tension, be sure that not

the gear to be slipped during feed solder,

or do not force to feed solder slipping gear

when solder clog.

Set the tension gear loosely for fine solder

(ø0.6mm, 0.8mm/0.024 in., 0.031 in.).

Refer to the following chart.

■Adjustment of the

Nozzle Position

If there is a solder in the guide pipe, pull it

out of the pipe and then adjust the nozzle

position.

(a) Loosen the pipe securing nut, turn the

guide pipe to adjust the nozzle position,

and then tighten the loosened pipe

securing nut.

Solder Dia. ø0.6mm

maximum

ø1.0mm

14mm

ø1.6mm

10mm

CAUTION

Do not over tighten the pipe securing nut.

Otherwise, the guide pipe can break.

This adjustment must be done during the

iron tip is cold. Otherwise, you may suffer

burns.