2 3

click

BOARDS™

www.mikroe.com

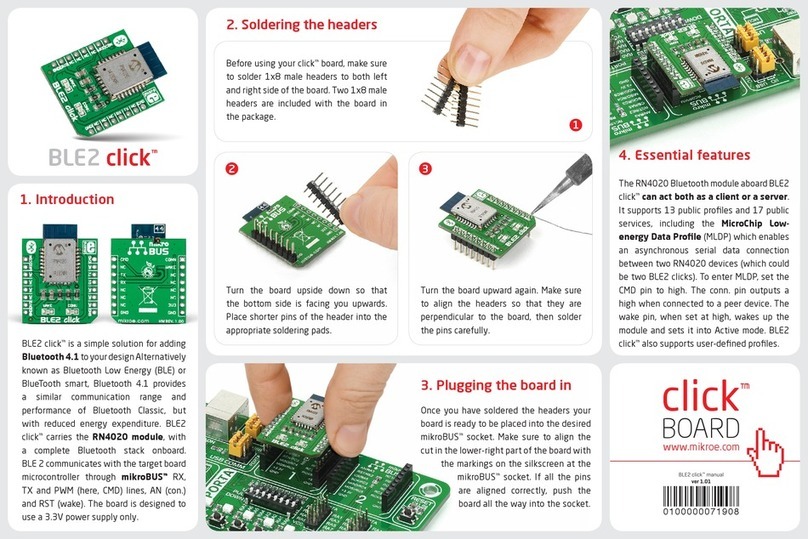

2. Soldering the headers

3. Plugging the board in

Once you have soldered the headers your

board is ready to be placed into the desired

mikroBUS™socket. Make sure to align the cut

in the lower-right part of the board with the

markings on the silkscreen at the mikroBUS™

socket. If all the pins are aligned

correctly, push the board all the

way into the socket.

Turn the board upward again. Make sure

to align the headers so that they are

perpendicular to the board, then solder the

pins carefully.

Turn the board upside down so that

the bottom side is facing you upwards.

Place shorter pins of the header into the

appropriate soldering pads.

Before using your click board™, make sure

to solder 1x8 male headers to both left and

right side of the board. Two 1x8 male headers

are included with the board in the package.

4. Essential features

DAC 3 click contains two analog output screw

terminals: Vout and GND. 16-bit data is sent

to the DAC through I2C. The digital value is

converted to the appropriate voltage level

in the range between GND and REFERENCE

(VCC or 4.096V), which is proportional to

the received 12-bit number. MCP4726 also

integrates EEPROM for storing DAC register

and conguration bit values.

1

DAC 3 click carries Microchip’s MCP4726, a

12-bit digital-to-analog converter, along with

voltage output screw terminals. The IC has

EEPROM, congurable reference voltage, and

communicates with the target board MCU

through the mikroBUS™I2C interface (SCL,

SDA pins). Standard (100 kHz), fast (400

kHz) and highspeed (3.4 MHz) I2C modes are

available. The board uses either a 3.3V or a 5V

power supply. The board is suitable for sensor

calibration, motor control, set point or oset

trimming and many other applications.

DAC 3 click

1. Introduction

DAC 3 click Manual v100

0100000093788