Mill-right M3 KIT User manual

ASSEMBLY INSTRUCTIONS FOR THE MILLRIGHT CNC MODEL M3 KIT

Version 1.11

Important safety rules for operating your MillRight CNC M3:

Never place your hands near a spinning end mill or bit.

Unplug the router before changing cutting tools.

Always wear eye and hearing protection while operating your machine.

Always run dust collection or wear a mask while performing a milling operation.

Do not leave the machine unattended while running a milling operation.

Do not operate your machine while under the influence of alcohol or drugs.

Do not place your hands between the bed and frame while the machine is moving.

Visually inspect wires prior to power up to prevent short circuits.

Ensure work pieces are properly secured before running a milling operation.

Always wear the red tinted safety glasses when operating the laser (if equipped).

Research material considerations prior to machining or lasing (if equipped).

Page 1 of 35

Welcome to the assembly instructions for the MillRight CNC Model M3 kit. Assembly will

take between eight hours and a weekend depending on your experience, tools, and work pace.

Don’t get in a rush. Although you are probably eager to get your machine together, it will pay

off to take your time and have fun along the way. We encourage you to read the instructions all

the way through first. This will help you understand how the step you are working on ties into

the next. After that, follow these instructions step by step. If you get stuck or just have general

Tools Required:

Phillips Screwdrivers, #3, #2, and #1 sizes

Small Adjustable Wrench

Needle nose pliers

8mm socket with socket driver (preferred) or ratchet and extension (acceptable)

10mm open end wrench

Allen wrench (also known as hex keys), sizes M1.5, M2, M3 (set screws and other

hardware socket sizes can vary)

Basic voltage meter (needed to set stepper driver current)

Hammer (needed to nail one wire retaining clip and tee nuts)

Note that these are just the minimum tools recommended to assemble the kit.

Items included in basic kit: (Materials in upgrades not listed below)

(1) Set of laser cut aluminum plates including (1) X Axis Bearing Plate, (1) Z Axis Bearing Plate, (2)

Y Axis Bearing Plates, (1) Y Belt Anchor Plate, (1) Z Spring Stud Bracket

(1) Precision cut MDF frame set including front, rear, left, and right pieces

(12) V wheel kits with each including (2) 625-2RS bearings, (1) Polycarbonate V Wheel, (1) M5

Screw or M5 Bolt, (1) M5 washer, (1) M5 Nylock nut.

(6) Fixed aluminum spacers, ¼’’ (6.35mm) long (In bag with V Wheels)

(6) Eccentric spacers, ¼’’ (6.35mm) long (In bag with V Wheels)

(1)

24 Volt Power Supply, adapter to break out barrel plug to individual wires, small length of wire

for connection from power supply adapter to CNC shield

International buyers must supply their own plug

(3) NEMA 17 Stepper Motors

(2) NEMA 17 Steel L Bracket Mounts (you only need two, the Z motor mounts to the X plate)

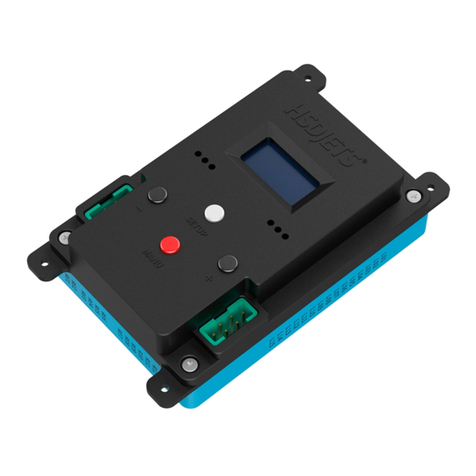

(1) Generic Uno (electronic controller board)

(1) Generic CNC Shield with (4) DRV8825 Stepper Motor Drivers (one extra)

(1) Fan for cooling the Stepper Motor Drivers (always point it close to the drivers!)

(2) V Slot Rails 2020

(1) V Slot Rail 2040

(1) MDF bed with (16) pronged tee nuts with #10-32 threads (nuts in hardware kit)

(10) 90 degree cast aluminum corner brackets. NOTE:Beginning in January 2017, some kits started

shipping with slots in the frame to allow for clearance of the tabs on the corner brackets. If your

kit is like this, then (8) corner brackets will still have all tabs and (2) will have the tabs ground

down on one side. The two with tabs ground down are for mounting the idler bearings

(10) 625-2RS bearings (In bag with corner brackets; for X, Y, Z idlers, not related to V wheels)

(4) Linear rod mounts

Page 2 of 35

(2) Chromed, hardened linear rods, 8mm diameter

(4) Linear bearing blocks for 8mm rod

(3) Pulleys, GT2 profile, wide (In bag with hardware)

(3.14) Meters of GT2 belt, 9mm wide [ (1) 900mm, (1) 1200mm, (1) 1040mm section ]

(3) Aluminum spacers, 10 mm long, 8mm OD, 5.1mm ID (for spacing of Z pulleys) (In bag with

hardware)

(1) Extension spring (In bag with hardware)

(1) Hardware set (See the resources section of www.millrightcnc.com for a hardware matrix)

The contents of each order are independently checked by two people to confirm that everything is

Overview of build steps:

V Wheel Kit Assembly

Y Axis Stage Assembly

Z Axis Bearing Plate Assembly

X Axis Stage Assembly

X & Z Axis Assembly Connection to Y Axis Assembly

X & Y Axis Motor Mounting and Belt Routing

Homing Switch Installation (only if you ordered this upgrade)

Rigidity Kit Installation (only if you ordered this upgrade)

Controller Mounting and Software Configuration

Stepper Drivers, Stepper Connections, and Powering Up

V WHEEL KIT ASSEMBLY

Locate the (12) V Wheel Kits included with the basic kit. NOTE: Those that ordered the rigidity

kit upgrade should assembly the extra (2) V wheels that you have now. Take the wheel body and

snap (1) 625 bearing into one side. Run an M5 bolt through the inside hole of that same bearing,

then flip it over in your hand. Slide an M5 washer that comes in the V Wheel Kit down over the

threads of the M5 Bolt. This helps properly locate the washer on the race of the bearing. DO

NOT FORGET TO INSTALL THIS WASHER BETWEEN THE TWO BEARINGS, OR THE V WHEEL WILL NOT

SPIN WHEN TIGHTENED AND WILL BE VERY HARD TO GET BACK APART. While leaving the bolt in,

snap another 625 bearing into the wheel. It may take some effort as sometimes it’s a pretty tight

fit. Set the assembled V Wheel Kits to the side for use in the next steps.

Page 3 of 35

Y AXIS STAGE ASSEMBLY

Locate the Y Axis Bearing plates and (8) of the V wheels that you assembled in the last step.

Grab one of the V wheels and one of the Y Axis

Bearing Plates. Install an M5 bolt through one of

the holes indicated in the picture to the right.

Now install a non-adjustable 6.35mm (quarter inch) spacer on the opposite side of the plate,

sliding it over the threads of the bolt. Install an assembled V Wheel onto the threads of the bolt,

then tighten it down using an M5 nylock nut.

Using an Allen wrench or Phillips screwdriver

(depending on if your kit came with allen or phillips

head M5 screws) and 8mm socket, get these snug

now. Don’t torque too much, just a bit of tension is

fine. If you are straining as you tighten, it is FAR too

tight! The wheel should still turn fairly freely once

tightened. If it’s really hard to spin, back off the nut

a tad. Install another V wheel the same way in the

other hole indicated by the arrow.

Now, take an eccentric spacer and put it in one

of the holes opposite those installed that you just

installed. Spin the eccentric spacer in that hole

and observe how the bolt hole in the spacer gets

closer then farther away from the V wheel kits

that you already installed. This will allow you to

snug up the bearings to the V rail after installing

them. Leave the eccentric spacer in its loosest position (bolt hole farthest away from the other

bearings). Now run an M5 socket head bolt through the plate, then the spacer, then install a V

wheel and loosely install an M5 nylock nut. You should end up with the bolt head, then Y Axis

Bearing Plate, then eccentric spacer, the V wheel, then an M5 nylon nut. Do NOT tighten these

very much yet because you will need to be able to spin the spacer soon. Install another

eccentric spacer and V wheel in the other hole just like you did this one.

Repeat these steps to install the V wheels on the other Y Axis Bearing Plate. Keep the assembled

Y Axes Bearing Plates nearby.

Locate both 2020 V rails as well as the front frame piece (long rectangular piece with four holes in

the middle). Notice the small half circle notch at the bottom of this piece. If that notch is at the

bottom left, then you are looking at the front side of the piece. Check out the middle picture on

page 22 to see the correct orientation of this piece when installed.

Page 4 of 35

Using a flat surface, flip the front MDF frame part

upside down and slide an M5 washer on a self-

drilling screw, then start threading the self-

drilling screw into the appropriate hole of the

MDF frame. Once the head of the screw starts to

poke through the other side, slide the center hole

of the 2020 V rail over the screw point.

Press the V rail against the MDF frame, while

holding it down against the flat surface and keep

driving the screw in. Get it snug, but not super

tight. The machine is designed for the top of the

Y Axis V Rails to flush up to the top of the front

frame piece, so flipping it upside down and

using a flat surface will help flush things up.

You should now have both 2020 V Rails screwed

into the front frame piece. Grab one of the Y

Axis Bearing Plates that you already installed the

V wheel bearings on, and slide it onto the right

V rail. Notice that the Y Axis Bearing Plate has

one side that is longer than the other. The

longer side (the one with four total holes, two of

which have eccentric spacers in them), will go

towards the outside. The bolts on the outside

wheels should be loose enough to allow you to

spin the eccentric spacer with a 10mm wrench,

but not “sloppy loose.” Now spin the eccentric

spacer on one of the v wheels so as to tighten

the V wheel into the V channel in the V rail. It’s

probably already almost tight enough.

Page 5 of 35

Tighten both eccentric spacers an equal amount. These wheels will need very little tightening with

the spacer. TAKE VERY CAREFUL NOTE OF THE FOLLOWING, OR YOU WILL CAUSE YOURSELF A

PROBLEM LATER. DO NOT OVERTIGTHEN THE V WHEELS INTO THE V RAIL. THE V WHEELS ARE

MADE OF A VERY TOUGH PLASTIC (ACETAL OR POLYCARBONTE), BUT THEY WILL DEFORM IF

TIGTHENED TOO MUCH, LEAVING YOU WITH

CLUNKY MOTION WHICH WILL RESULT IN POOR

CUTS. SET THE TENSION SUCH THAT YOU CAN

DRIVE THE ENTIRE Y AXIS BEARING PLATE BY

ROLLING A WHEEL WITH YOUR FINGER BUT LOOSE

ENOUGH THAT THE WHEEL WILL SLIP IN THE RAIL

IF YOU LIGHTLY HOLD THE Y AXIS BEARING PLATE

WHILE YOU SPIN A WHEEL. Slide the bearing plate

back and forth to make sure that it glides

smoothly along the rail. If the wheels are too

tight, loosen the spacer a bit and recheck. Note

that, if over time, you find the wheels develop a

flat spot over time from being too tight, you can

loosen the wheel and it will move back to its

circular shape in a few hours.

Now find the back frame piece (the other long

rectangular piece). Slide the Y Axis Bearing Plates

that you just installed onto the rails all the way to

the Front Frame Piece. Hold the Back Frame Piece

upside down and cantilever the Front Frame Piece

and Y Axis Bearing Plates over the edge of your

table so the other side of the rail flushes up to the

Back Frame Piece. Slide an M5 washer onto a

self-drilling screw and place it in the appropriate hole. If it’s snug in that hole, continue to turn it

through the Back Frame Piece until the drill point of the screw is sticking out. Slide the tip of that

screw into the center tap how of the V Rail. Do the same with the other rail. Grab the rail firmly

with your hand as you tighten. The torque of threading the screw tends to cause the rail to spin,

which you want to prevent. As you start to get good bite into the V rail with both screws, you can

set this assembly in its natural position (as it will be on the completed machine) in order to make

Page 6 of 35

tightening and alignment easier. Remember that the top frame piece should flush up to the top

of the V rail. Make sure it ends up that way when you finish tightening the screws. Now confirm

that the rails are close to parallel. This shouldn’t be a problem, but the holes sometimes allow

for a bit of a free fit for the screws, so you will want to check this and adjust accordingly. If you

have a square, you can check that the rail and the frame pieces are perpendicular, but this

usually just arises naturally from how it all goes together. Flip them back over and sit it down on

a known flat surface. If there is a bit of rock back and forth, you need to slightly loosen one or

more of the self-drilling screws

Keep this close and find the MDF bed. Lay the bed top down so you can see all of the pockets

that look like this:

Page 7 of 35

Flip the bed back over so the Y Axis Assembly is upside

down. Using your hammer, tap the T-nuts into the 16

holes labelled “A” in the above diagram.

Now find the Y Axis Belt Anchor Plate. Slide an M6 washer onto an M6x25 screw then put the

bolt through the plate in the orientation shown below. If you were looking down at the plate

in this orientation, you should see the bolt heads. In this orientation, the M6 screw needs to

go through an M6 flat washer, through the plate, then through a split-lock washer, then

secured with an M6 nut. Get a final tighten on the nuts now. These don’t screw to anything

else, they just serve as studs to anchor the belt.

Put the Y Belt Anchor Plate against the bed so the heads of

the M6 bolts are laying inside the holes marked “D” in the

center of the above picture. Line up the holes on the

corners of the Y Belt Anchor Plate with the holes marked

“B” that form a square around the holes marked “D.” Slide

an M5 washer onto a 5/8” wood screw, then screw it into

the bed in order to secure the Anchor Plate to the bed. DO

NOT OVER-TORQUE THESE OR THE SCREW WILL RIP THE

HOLE OUT. Pick one corner to start, and leave the screw

alittle loose. Line up the hole on the opposite corner,

then screw it in. Put a final torque on the four wood

screws once you have them all in. A contributor to this

kit’s development has suggested inserting the screw

fully, pulling it out, putting a couple drops of

superglue (not included) in the hole, and

immediately rethreading the screw in the

hole. This is intended to prevent the screws

from vibrating loose over time.

You will now install the Bed onto the Y Axis

Assembly. Orient the bed so that it holes are

facing up, like in the diagram above. The holes

designated as “C” above are recesses for the

bolt heads of the V Wheel Kit bolts that are

on the Y Axis Bearing plate. Flip the Y Axis

Page 8 of 35

Assembly upside down and

lay it onto the bed so that

these bolt heads lay in

those recesses. Looking at

the bed in the orientation

above, the Front Frame

Piece should be towards the

top. Notice that each Y Axis

Bearing Plate has three

small holes left. Line these

holes in the plate up with

the small pilot holes. Slide

an M5 washer onto the

wood screws, then begin to

thread it into the holes. Do

not tighten the wood

screws down until you get

all the screws in both

bearing plates (six total,

three in each plate). Check

as you tighten the screws

down that the bed flushes up

to the front of back Frame

Piece. It should not be

canted or twisted. After you

finish mounting the bed, flip

the Y axis assembly back

over and slide it back and

forth to ensure that the

motion is smooth. If not,

either the eccentric spacers

are too tight or the bearing

plates were a bit cocked

relative to one another

when you torqued them down tight.

Z AXIS BEARING PLATE ASSEMBLY

We will now assemble the Z Axis plate. This is the plate that will carry your router or spindle

up and down. The diagram to the below shows the FRONT of the Z Axis plate. Notice that the

Page 9 of 35

position of the holes marked (A) being

slightly left of center will help you orient

the plate properly. The Z Axis plate was

designed to accommodate some of the

most popular choices in hobby CNC.

Hopefully, you’ve already selected the

router/spindle and mount combination

that you wish to use. See

www.millrightcnc.com/FAQ for more info

on the compatible spindles and mounts if

you don’t already have one. We have also

included some dimensional information

about the mounting holes for those

interested in making their own mount or

confirming fitment of available mounts.

The hardware used in each hole is as

follows:

Each one of these will be installed such that the head of the

screw or bolt is visible as you view the Z Axis Bearing Plate in

this orientation.

A: M5x30 - Belt Idler

B: M4x10 –Bearing Block

C: M4x14 –Bearing Block / Spring Stud Bracket

We will first assemble the idler bearings on your Z Axis plate.

Each idler is made of two 625 bearings, so go ahead and grab

four 625 bearings, two M5x30 bolts, 4 M5 flat washers, two

10mm long aluminum spacers, and two M5 Nylock nuts.

TAKE NOTE THAT THE ALUMINUM SPACERS USED HERE ARE

LONGER THAN THE ALUMINUM SPACERS USED WITH THE

NON-ADJUSTABLE V WHEELS. Slide an M5 washer onto the

M5x30 bolt and put the bolt through one of the holes

labelled with (A) in the above diagram. You should insert the

bolt through the hole when looking at the Z Axis Plate as

shown in the diagram.

Be careful not to build things on the wrong side. Now, slide

the 10mm aluminum spacer on the bolt threads and butt it

up against the back side of the Z Axis Plate. Put on a 625

Page 10 of 35

bearing, followed by an M5 washer, and then

another 625 bearing. DON’T FORGET THE

WASHER BETWEEN THE TWO BEARINGS OR THEY

WON’T SPIN. Secure all of this with an M5 Nylock

nut. You want to get this good and snug, but

don’t go crazy. Looking down at the Z Axis plate in

the orientation shown in the diagram above, you

should have the head of the M5 bolt, an M5

washer, the Z Axis Plate, a 10mm aluminum

spacer, a 625 bearing, an M5 washer, another

625 bearing, and a Nylock nut. Install the other

idler this same exact was in the other hole

labelled with letter (A).

Now locate your linear bearing blocks. Notice in

the diagram that the top left of the Z Axis Bearing

Plate has two holes marked (B) and two marked

(C). The other three bearing blocks have all

(B) holes and use M4x10 screws with split-

lock

washers. Install these bearing blocks on the Z Axis Bearing plate with M4x10 screws and M4

split-lock washers in the holes marked (B). You should see the heads of the screws when

looking at the Z Axis Bearing Plate in the orientation shown in the diagram above. The bearing

blocks should be on the back side of the plate.

The top left two holes are labelled (C) and will be used to mount the spring stud bracket. Use

M4x14 screws with a split-lock washer to mount the Spring Stud Bracket to the plate. You’ll

screw into the bearing block to secure this. Looking at the Z Axis Bearing Plate in the orientation

shown in the diagram, you should have the screw head, an M4 split-lock washer, the Spring

Stud Bracket, the Z Axis Bearing Plate, then the linear bearing block. Make sure you get the

orientation of this spring stud bracket correct. Slide an M6 flat washer onto the M6x50 screw

then put it in the slot in the Spring Stud Bracket with the screw threads pointing towards the

back of the Z Plate. Secure it with an M6 split-lock washer and an M6 nut. Slide one loop of the

extension spring onto the threads of the

M6x50 screw you just installed.

Sandwich the loop of the spring between

the M6 nut you already have installed

and another M6 nut so that the spring

naturally points to about the 10 o’clock

position. Looking at the Z axis plate in

the orientation shown above, you should

have the head of the M6 screw, a flat

washer, the Spring Stud Bracket, an M6

Page 11 of 35

split-lock washer, an M6 nut, the loop of the spring, and finally another M6 nut. This screw will

also engage the Z axis homing switch, so if you have homing switches you will tweak this position

in the slot later. This spring orientation is very important to make sure the spring folds out of the

way when your machine lifts Z all the way to the top. Keep it at 10 o’clock.

Install the router or spindle mount that you have selected now. THE MOUNT SHOULD BE ON THE

FRONT SIDE OF THE PLATE. We recommend mounting into the bottom row of mount holes if

your mount gives you the option of mounting in the top or bottom row. Some mounts, such as

the 52mm spindle mount, use both the top and bottom rows to mount. Install only the mount

right now. Wait to install the router or spindle

until later. These assembly instructions do not

show a mount being installed.

Set aside the assembled Z Axis Bearing Plate

for now.

X AXIS STAGE ASSEMBLY

Let’s get started on the X Axis Assembly. You are

making some real progress here!

Locate the X Axis Bearing Plate. Use the

following diagram of the FRONT SIDE of the X

Axis Bearing Plate, to help you place the parts

and fasteners on the plate:

TAKE NOTE THAT THE LETTER LABELS HERE

HAVE NOTHING TO DO WITH THE LETTER LABELS

OF THE BED DIAGRAM. If there is an (H) below, it

means that you will see the head of the bolt or

screw when looking at the X Axis Bearing plate in

this orientation. If there is a (T), it means that

the threaded side of the bolt will be pointing

towards you when looking at the X Axis Bearing

plate in this orientation. Be careful here, it’s easy

to install things on the wrong side if you aren’t

paying close attention.

Page 12 of 35

A: M5x25 - V Wheel (H)

B: M6x25 - Belt Anchor (T)

C: M5x30 - Belt Idler (T)

D: M3x8 - Motor Bolt (H)

E: M6x40 - X Homing Switch Stud (H)

F: M3x20 –Z Homing Switch (H)

G: M5x16 - Rod Support (H)

Let’s go in letter order to get the X Axis Bearing

plate built.

Grab (4) assembled V Wheels and (2) eccentric

spacers, or (6) assembled V Wheels and (3) eccentric

spacers if you ordered the rigidity upgrade. If you did

not order the extra two wheels, make sure you install

them in the outer four holes and leave the two inner

holes empty. Start with the bottom row of holes

marked (A). Install V wheels there, such that the

wheels are on the back side of the plate as you are

looking at it in the diagram. Looking at the X Axis

Bearing plate in the orientation shown in the above

diagram, you will have the M5 fastener head, then the

X Axis Bearing plate, then a 6.35mm (1/4”) aluminum

spacer, then an assembled V Wheel, then secured with

an M5 nylock nut. The top (A) holes are going to be

the same, except that you’ll have eccentric spacers

instead of the fixed aluminum spacers. Remember that

the eccentric spacers are used to tighten the V Wheels

to the rail, so install them now in their loosest position

and leave the bolts loose enough that you can adjust

them once you have the bearings riding on the V Rail

extrusion (you’ll install it on the rail later). DON’T

FORGET TO TIGTHEN THEM THEN.

Now you’ll install the M6x25 screws that are used as

belt anchors in the holes labeled letter (B). Take special

note of the orientation called for in the table above.

The threaded side of the bolt will be pointing

TOWARDS you when looking down at the front of the X

Axis Bearing Plate. There is one (B) hole at the top left

and one (B) hole at the bottom center. Slide an M6

washer onto an M6x25 bolt, insert it in the top (B) hole

Page 13 of 35

FROM THE BACKSIDE. Slide an M6 split-lock washer onto the bolt, then thread on an M6 nut.

Looking down at the X Axis Bearing Plate in the orientation shown in the above diagram, you

should see the threads pointing at you, an M6 nut, an M6 split-lock washer, the X Axis Bearing

Plate, an M6 flat washer, then the M6 bolt head. Do the same with the hole labelled (B) at the

bottom of the plate. Remember, these bolts should be pointing TOWARDS you.

There is only one hole labeled (C). This bolt will also point towards you when looking at the front of

the X Axis Bearing Plate. You’ll need an M5x30 screw, two M5 washers, two 625 bearings, one M5

Nylock nut, and one 10mm aluminum spacer. BE CAREFUL WHICH SPACER YOU PICK UP HERE. THE V

WHEELS USE A DIFFERENT SPACER (6.35MM). THIS SPACER IS LONGER THAN THOSE. Slide an M5

washer onto the bolt and insert the bolt through hole (C) from the backside. Now slide the 10mm

aluminum spacer onto the threads, followed by a 625 bearing, an M5 washer, another 625 bearing,

and top it off with an M5 Nylock nut. Get this nice and snug, but don’t go crazy. Bolts can bend if

overtightened. As you look down at the plate in the same orientation shown in the diagram, you

should have the Nylock nut, a 625 bearing, an M5 washer, another 625 bearing, the 10mm spacer,

the X Axis Bearing Plate, an M5 washer, then the head of the M5 bolt.

Now grab a NEMA 17 stepper motor so you can install it at the top of the X Axis Bearing Plate. You

will mount it with M3x8 bolts in the four holes labeled (D). Take special note that wires coming out

of the motor should be pointing towards the bottom left when you install the motor. Look at the top

of the diagram. There is a top (D) hole, a right (D) hole, bottom (D) hole, and left

(D) hole. You want the wires on the motor to be sticking out between the left (D) hole and the

bottom (D) hole. Slide an M3 split-lock washer onto an M3x8 button head bolt and install the

motor. Looking down at the X Axis Bearing plate in the orientation shown in the above

diagram, you should see the M3 bolt head, M3 split-lock washer, X Axis Bearing Plate, then the

stepper motor body. The shaft of the stepper motor will be pointing up at you in this

orientation if you are looking down at the X Axis Bearing Plate as shown in the diagram above.

If you purchased the homing switch kit, you will install an M6x40 bolt in the hole labelled (E).

There is only one such hole.

Slide an M6 flat washer onto

the M6x40 bolt, insert the bolt

into hole (E). Secure the bolt

using an M6 split-lock washer

and M6 nut. Looking down at

the X Axis Bearing Plate in the

orientation shown in the above

diagram, you should see the

head of the M6 bolt, then a flat

washer, then the X Axis Bearing

Plate, then an M6 split-lock

washer, then an M6 nut.

Page 14 of 35

If you purchased the homing switch kit, you will install the Z axis

homing switch with M3x20 bolts in the two holes labelled

(F). You’ll need one limit switch, two M3x20 screws, two M3

split-lock washers, two M3 flat washers, and two M3 nuts.

Install the switch in the orientation shown in the picture. Slide

an M3 flat washer onto the M3x20 screw, then slide the bolt

through hole (F) and through the homing switch bolt hole.

Secure it with an M3 split-lock washer and M3 nut. Do this

with both holes. Snug it up enough to flatten the split-lock

washers, but DO NOT OVERTIGHTEN OR YOU WILL DESTROY

THE SWITCH.

Locate (4) linear rod supports. Look at the rod supports and

notice that there is an Allen head screw that tensions the rod

support to the linear rod. Make sure that the heads of these

adjustment screws are oriented to the outside when you install

them. Place the first rod support over the bottom left two (G)

holes. Install it with an M5x16 machine screw and secure it

with an M5 flat washer, and M5 Nylock nut on the backside of

the X Axis Bearing Plate. Leave these just slightly loose. Looking

down at the plate in the orientation shown in the diagram

above, you should have an M5 Machine screw going through

the rod support, then going through the X Axis

Bearing Plate hole (G), secured on the back side by an M5 washer and M5 Nylock nut. Install the

bottom right rod support now. Also leave these a bit loose. We will come back to the X Axis

Bearing Plate in a minute to install the top two rod supports in the remaining (G) holes.

Page 15 of 35

Grab your Z Axis Bearing Plate and your

two 8mm diameter chromed linear rods.

CAREFULLY slide the rods through the

openings in the linear bearing blocks. If

the rods seem hard to push through the

second bearing, you need to loosen the

screws fastening the linear bearing blocks

to the Z Axis Bearing Plate. Put tension

back on the screws that mount the linear

bearing blocks once you get the rods in. If

try to force these in or if you are not careful

sliding the rods through the bearing blocks,

you could push some of the ball bearings

out of the bearing blocks. If you accidently

push a couple out it’s not the end of the

world, however.

Now, lay the Z Axis Bearing Plate (with

the linear rods still in it, careful not to let

them slide out!) next to the X Axis Bearing

Plate. Study the orientations of these

plates shown in the above diagrams. We

should end up with the Z Plate in front of

the X Plate with these same orientations

shown. Let’s do that now.

Work with the X Axis Bearing Plate laying

on the table, face up. Keeping in mind the

required orientation of the plates, slide in

the bottom of the rods that are in the Z

axis linear bearings into the bottom rod

supports that you’ve already installed on

the X Axis Bearing Plate. As soon as you slide the bottom of the linear rods into the bottom rod

supports, slide the top two rod supports onto the top of the rod. On just the bottom rod

supports, tension the Allen head bolt that clamps the rod support to the rod. Now install M5x16

machine screws into the mounting holes for the top rod supports, through the top (G) holes on

the X Axis Bearing Plate, and begin to snug them up using an M5 flat washer and M5 Nylock nut.

Now run the left most M5 screw through the free loop of the spring, and snug it down. Make

sure the rods are parallel and the two rod supports are even in terms of their position on the X

Axis Bearing Plate before you put a final torque on these mounting and tension screws.

Page 16 of 35

You should now have your assembled Z Axis

Bearing Plate mounted to your X Axis Bearing

Plate. This is the X & Z Axis Bearing Plate

Assembly. Before you go any further, check

the diagrams again. Did you get the

orientation right?

Congrats on the progress!

We will now route the Z Axis Belt. Fair warning:

Belt installation is one of the trickier parts of the

build for some people, so take your time, read

carefully, and relax.

See the diagram to the right which shows the Z

Plate in front of the X Plate with most of the

unrelated holes removed for clarity. The red

circles are the idler pulleys mounted on the Z

Axis Bearing plate. The blue circles are on the X

Axis Bearing Plate. The top left blue circle is the

top belt anchor point. The blue circle with the

“M” in the middle is the motor pulley. The

smaller blue circle at the bottom is the bottom

belt anchor. The blue circle marked with an “I”

in the middle is an idler pulley.

Install the pulley on the motor shaft. Look

down this assembly from the top so you can

position the motor pulley’s teeth in line with

the idler pulleys. One of the set screws must be

set against the flat of the motor.

The kit came with three sections of belt. Grab the

SHORTEST SECTION OF BELT (900mm) and anchor

it to the threads of the M6 bolt with a zip tie. Loop

it EXACTLY as shown in the diagram and make sure

the teeth of the belt are meshed together. If you

don’t loop it as shown here and zip it together

with the toothed side of the belt, the belt will get

routed backwards. You must zip tie it at a point

that is in line with the pulleys, or the belt will run

off the pulleys. Run the belt around the bottom Z

Axis Bearing Plate Idler Pulley (indicated

Page 17 of 35

by the bottom red circle in the belt route diagram). It is easiest to do this if the Z plate is all the

way at the bottom. Then guide the belt onto the pulley using your index finger. The teeth

should be against the pulley bearings on this one. Loop it down around the bottom idler pulley,

indicated by the blue circle with an “I” in the center.

Page 18 of 35

Now run it up the middle to loop around the motor pulley, then around the top Z Axis Bearing

Plate Idler Pulley, indicated by the top red circle. The toothed side of the belt should mesh with

the teeth on the motor pulley and the backside of the belt will run on the top Z Axis Idler Pulley.

Keep some tension on this belt to make sure it doesn’t slip off a pulley. Run the belt around the

top anchor point and secure it with a zip tie. The teeth should mesh together. You’ll want at

least 6 or 7 pounds of tension on the belt. Floppy belts are no good. Get some tension.

Now that you have the belt fully anchored, move the Z Axis Bearing Plate up and down to make

sure that the belt isn’t slipping off any of the pulleys. If it is, one or both of the anchor points is

misaligned, the motor pulley is misaligned, a screw is looser, or you have too much tension. If

you used the proper spacers when you assembled the bearing plates (10 mm aluminum spacers),

the bearings on the pulleys will be aligned on both plates.

Now locate the left frame piece as well as the 2040 V Rail Extrusion. Slide an M5 washer onto a

self-drilling screw and put the

screw through the top hole.

Slide the screw point into the

top tap hole of the 2040 V Rail

Extrusion and begin threading it

in. It’s best to tilt the frame

piece back with the opposite

end of the V Rail Extrusion on

the table or floor as you thread

it in. Get a few threads turned

into the top hole then get the

second hole started with

another M5 washer and self-

drilling screw. You’ll want to

end up with the top of the

frame flushed up to the top of

the V Rail Extrusion. Take

special care that the rail isn’t

cocked in any way, or your

router (or spindle) will never be

plum. Keeping this in mind, get

a final torque on the top and

bottom self-drilling screws.

Page 19 of 35

Now slide the X & Z Axis Bearing Plate Assembly onto the

other side of the V Rail extrusion. Continue to support the

V Rail Extrusion and place the right frame piece in position.

Slide an M5 washer onto a self-drilling screw then place

the screw into the top hole. Get a few threads turned into

the top center tap hole of the 2040 V Rail Extrusion then

get the bottom hole started with another M5 washer and

self-drilling screw. Just like with the other side, make sure

that the top of the V Rail Extrusion flushes up to the top of

the right frame piece. Once you are confident that the rail

isn’t canted and everything is flush, put a final torque on

the self-drilling screws on both sides of the frame.

X&Z AXIS ASSEMBLY CONNECTION TO Y AXIS

ASSEMBLY

Take your Y Axis Assembly and set it down so that the

moving bed is facing upward. We will now put the frame

pieces together. Take special care to get the orientation

correct. The front frame piece has four holes below the

cutout for the belt for the motor mount, while the back

frame piece only has one hole in this area. The right frame

piece has four holes for a motor mount under the cutout

for the belt, while the left frame piece only has one hole in

this area. Grab your completed X&Z Axis Assembly which

has the left and right frame pieces attached and place it

into position within the Y axis assembly which has the front

and back frame pieces. Sometimes this fit is a little snug,

so you may have to slightly pry at the sides of the front

and rear frame pieces to get the left and right frame pieces

to slide in. Move things around a bit in order to flush up

the edges and square everything up. Don’t worry if every

corner isn’t perfectly flush yet where the left and right

frame pieces meet the front and back frame pieces. You’ll

get it locked down right in a minute.

Page 20 of 35

Table of contents

Other Mill-right Control System manuals

Popular Control System manuals by other brands

CYBELEC

CYBELEC CybTouch 12 user manual

Julabo

Julabo PRESTO A80 operating manual

Pentair

Pentair IntelliSync 523404 quick start guide

UTC Fire and Security

UTC Fire and Security Kidde Fire Systems Gemini II Multi-Hazard manual

HSDJets

HSDJets MFC-2085 quick start guide

Carbide 3D

Carbide 3D Shapeoko 5 Pro Assembly guide