Mill-right CARVE KING 2 User manual

Page 1 or 34

ASSEMBLY INSTRUCTIONS FOR THE MILLRIGHT CNC CARVE KING 2

Version 1.00

Note that these are instructions for the Carve King 2. For instructions on the original Carve King, see

www.millrightcnc.com/resources

Important safety rules for operating your MillRight CNC Carve King 2:

Never place your hands near a spinning end mill or bit.

Unplug the router before changing cutting tools.

Always wear eye and ear protection while operating your machine.

Always run a dust collector or wear a mask while performing a milling operation.

Do not leave the machine unattended while running a milling operation.

Do not operate your machine while under the influence of alcohol or drugs.

Secure long hair and loose clothing so it is not caught in spinning mechanisms.

Ensure work pieces are properly secured before running a milling operation.

Keep a fire extinguisher nearby.

Visually inspect wires prior to power up to prevent short circuits.

Note:

We recommend using a blue thread locker on any fastener not secured with a lock washer or lock nut.

Page 2 or 34

Building the Bed and Frame Section

Parts

(4) 593mm Extrusion

(1) Front Frame

(1) Rear Frame

(5) Black Aluminum T Track

(4) MDF Bed Section

Hardware

(16) #10x1 Self-tapping Screw

(20) M5x8 Button Cap Screw

(16) M5x16 Machine Screw

(16) M5 Split Lock Washer

(36) Drop-In T Nut

Tools

3mm Hex Key

Phillips Screwdriver

8mm or 5/16 Wrench or Socket

WD40 or Other Lubricant

Place (4) 593mm extrusions between the front and rear

frames. The slot on the 40mm side of the extrusion should

be facing up and oriented to the outside of the machine.

The two left should have the slot on the left, the two right

should have the slot on the right. You can put a T track over

these extrusions to get a better idea of the orientation

needed for the holes to align.

Page 3 or 34

Lubricate 2 #10x1 self-tapping screws.

Place the screws through the holes in the

bottom of the frame into the holes in the

end of the right most extrusion. Use the

8mm socket to drive in the screws. Leave

loose. Continue installing the #10x1

screws in the other 3 extrusions.

Spin the frame around to work from the

other side. Put one drop-in T nut in each

slot with the hole leading. Line up one T

track with the T nuts. Using the 3mm Hex

Key, drive in (4) M5x8 button cap screws.

Leave loose. Push the t track to the frame.

The hole of the T nut must be closer to

the frame when slid all the way down or

else the T track will not seat all the way to

the frame.

Put one T nut in each slot. Line up one

MDF bed section with the t nuts. Put (4)

split lock washers on (4) M5x16 machine

screws. Using the screwdriver, drive the

screws into the t nuts. Leave loose. Push

the bed section to the back, up against the

T track you previously installed.

Alternate between the remaining T track

and bed sections pushing each back.

On the fifth T track, place the T nuts into

the slot with the hole in the T Nut closest

to the outside. Finish installing the last T

track. Leave everything loose.

Page 4 or 34

Lubricate (2) #10x1 self-tapping screws.

Place screws through the holes in the

bottom of the remaining frame piece into

the holes in the end of the extrusion. Use

the 8mm socket to drive the screws. Leave

loose. Continue the process, installing the

remaining extrusions.

Y Rail Installation

Parts

(2) 593mm Extrusion

Hardware

(8) #10x1 Self-tapping Screw

Tools

8mm or 5/16” Wrench or Socket

WD40 or Other Lubricant

Working from the side of the assembly, place one 593mm

extrusion with the slot on the 40mm wide face pointing in

and oriented with the slot near the top of the extrusion as

shown in the picture. Remember, one of the frame pieces

should be slightly loose so you can set this extrusion in

place.

Page 5 or 34

Lubricate (2) self-tapping screws. Place the screws

through the two holes on the frame and into the holes in

the end of the extrusion. Finger tighten the screws to

hold the extrusion in place. Do the same to the other

end of the extrusion. Follow the same process with the

second extrusion on the other side of the bed. Be sure

that the slots on the side of the extrusion faces inboard

and are up.

Tighten all the screws on the frame. Tighten the screws

for the MDF bed sections and the T tracks. You may need

a long screwdriver at a slight angle to the screw or a

stubby screwdriver to reach the screws under the Y rails.

Page 6 or 34

Gantry End Plate Assembly

Parts

Motor Side Gantry Plate

Idler Side Gantry Plate

X/Z Motor Spacer Plate

Short Wire Motor

Hardware

Pillow Block Bearing

Coupler

(2) Anti-backlash Nut

(2) M5 Grub Screw (in Anti-backlash nut bag)

(2) M5 Jam Nut (in Anti-backlash nut bag)

(4) M3x16 Machine Screw

(2) M5x10 Machine Screw

(4) M5x16 Machine Screw

V-Wheel Kit

Tools

8mm or 5/16 Wrench or Socket

Phillips Screwdriver

3mm Hex Key

2.5mm Hex Key

Place a v-wheel on a flat, hard surface. Place a

bearing on top of the v-wheel. Using something

else flat and hard, press the bearing into the v-

wheel using your body weight. A section of wood is pictured. Turn the v-wheel over. Place a M5

washer on the bearing in the wheel. It is especially important to remember the M5 Washer. It is

extremely hard to correct this if you forget. Press a second bearing into the wheel. Repeat this process

for the other wheels.

Page 7 or 34

Place (2) eccentric spacers in the

Idler Side Gantry Plate (top

picture on previous page). Place

eccentric spacers with the thin

wall portion pointing to the top of

the Idler Side Gantry Plate. Put a

M5x30 machine screw through

the v-wheel, then through the

eccentric spacer. Secure with a

M5 nylock nut. Leave Snug, not tight. Repeat the process with

another v-wheel. Take careful note of which side of the place the

spacers and wheels are installed on.

Place the pillow block bearing on the Idler

Side Gantry Plate as pictured. Secure the

pillow block bearings with (2) M5x10

machine screws. Flip the plate

over.Screw in a M5 grub screw in the top

of an anti-backlash nut using a 3mm Hex

Key. Stop tightening when the grub

screw touches the bottom. Cap the grub

screw with a M5 jam nut. Repeat the

process for the second anti-backlash nut.

Place an anti-backlash nut on the plate as

pictured. Secure it with (2) M5x16

machine screws.

Page 8 or 34

Place (2) eccentric spacers into the Motor Side Gantry

Plate with the thin wall of the eccentric spacer facing up.

Place a M5x30 machine screw through a v-wheel, then

the eccentric spacer, and secure with a M5 nylock nut.

Repeat the process with a second wheel. Flip the plate.

Place the coupler on the short wire motor using the X/Z

Motor Spacer Plate to set the coupler to the correct

position. See picture to right of spacer being used to set

the proper position. Tighten the coupler using the

2.5mm Hex Key.

With the Motor Spacer Plate still on the motor, insert

the coupler into the large hole on the Motor Side Y

Gantry Plate. The motor wire should be pointing left if

you are looking at the back of the motor. From the v-

wheel side of the place (4) M3x16 machine screw

through the Motor Side Y Gantry Plate, through the

Motor Spacer Plate, into the motor. Snug down.

Coupler should have free rotational motion.

Page 9 or 34

On the motor side of the Motor Side Y Gantry Plate,

place an anti-backlash nut. Using (2) M5x16 machine

screws, secure the anti-backlash nut to the plate.

Place both Y Gantry Plates to the side.

X Plate Assembly

Parts

X Plate

Z Bottom Plate

UHMW Screw Seat

Hardware

(2) M5 Nylock Nut

(1) Anti-backlash Nut

(1) M5 Grub Screw (in Anti-backlash nut bag)

(1) M5 Jam Nut (in Anti-backlash nut bag)

(2) M5x16 Machine Screw

Page 10 or 34

(2) M5x12 Button Cap

(2) #10x1 Self-tapping Screw

V-Wheel Kit

Tools

Phillips Screwdriver

8mm or 5/16” Wrench or Socket

3mm Hex Key

WD40 or Other Lubricant

The top of the X Plate Extrusion has a notch. The

bottom is flat. Take a M5x25 machine screw and put

it through a v wheel, then through a standard spacer

from the v-wheel kit, then screw it into the X Plate

Extrusion. Repeat the process with 3 other v-wheels.

Screw an M5 grub screw into the top of an anti-

backlash nut using the 3mm Hex key. Cap the grub

screw with a M5 Jam Nut. Using M5x16 machine

screws, attach the anti-backlash nut to the X Plate

Extrusion.

Page 11 or 34

Place a M5x30 machine screw through the hole in the

front of the X Plate Extrusion. Place an eccentric

spacer on the screw. The thin part of the spacer

should face the top if near the top, the bottom if near

the bottom.

Then place a V-wheel on the screw and secure with a

M5 nylock nut. Repeat the process with three other

v-wheels. Leave Snug. See the picture to the right of

the screw being inserted through the hole in the front

of the X plate with the other components slid onto it.

Of the 8 V wheels on the X plate, 4 use eccentric

spacers and 4 use standard spacers. The top and

bottom holes use eccentric spacers. The four in the

middle use standard spacers.

Attach the UHMW Screw Seat to the Z Bottom Plate

using (2) M5x12 button cap screws and (2) M5 nylock

nuts.

Page 12 or 34

Place the Z Bottom Plate on the bottom of the

X Plate Extrusion. Lubricate (2) #10x1 self-

tapping screws and place them through the Z

Bottom Plate into the holes at the end of the X

Plate Extrusion. Tighten with the 8mm wrench.

Place the X Plate Extrusion to the side.

Page 13 or 34

Z Motor Mount

Parts

Z Motor Mount

X/Z Motor Spacer Plate

Long Wire Motor

X Drag Chain Post

Hardware

(4) M3x16

(1) M4x12

(1) M4 Split-Lock Washer

Tools

Phillips Screwdriver

Put the motor on the table with the cord pointing

away from you. Place the Motor Spacer Plate on the

motor. Place the Z Motor Mount on the Motor

Spacer Plate. Screw in (4) M3x16 machine screws into

the motor.

Make sure the motor is centered with the Motor

Spacer Plate and the Z Motor Mount. Tighten screws.

Lay the motor on its side. Attach the X Drag Chain

Post using a M4x12 Machine Screw with an M4 Split-

Lock Washer. Tighten. Place to the side. Note that

the X Drag Chain Post is just a cylinder with holes

tapped on each side. Do not confuse this with the Y

Drag Chain Post, which has additional features

machined into it.

Page 14 or 34

Z Plate

Parts

Z Plate

Router Mount

2 Hole Spacer

178mm Lead Screw

Hardware

(1) Anti-backlash Nut

(2) Nylock Nuts

(1) Grub Screw (in Anti-backlash nut bag)

(1) M5 Jam Nut (in Anti-backlash nut bag)

(1) Coupler

(2) M5x25 Machine Screw

(2) #10x1 Self-tapping Screw

V-Wheel Kit

Tools

Phillips Screwdriver

2.5mm Hex Key

3mm Hex Key

8mm or 5/16 Wrench or Socket

10mm Wrench

WD40 or Other Lubricant

Page 15 or 34

Place eccentric spacers in the (6) large holes on the Z Plate.

The thin part of the eccentric spacers should face the middle

of the plate. Place a M5x30 machine screw through the Z

Plate, then through the eccentric spacer. Place a v-wheel on

the screw and secure with a M5 nylock nut. Tighten firmly.

Repeat the process with (5) other v wheels.

Press (2) M5 nylock nuts into the hexagonal holes on the face

of an anti-backlash nut. The nylon portion of the nut should

be facing up. Drive a grub screw into the top of the anti-

backlash nut using the 3mm Hex key. Stop when the screw

touches. Cap the grub screw with a M5 jam nut.

Place the 2-hole spacer on the Z Plate. Place the anti-backlash

nut on the 2-hole spacer. From the opposite side attach the

anti-backlash nut using (2) M5x25 machine screws. You may

have to hold the nylock nuts in place to prevent them being

pushed out of the antibacklash nut as you insert the screws.

The router mount will already have its hardware installed.

Remove the (2) screws and (2) lock washers from the back of

the mount. Put the screws through the lock washers, through

the Z Plate using the last two holes, and into the mount using

the 3mm Hex Key. Be careful to install the router mount

straight on the Z plate.

Slide the Z Plate, mount end first, into the X Plate Extrusion

from the top. If the Z Plate will not fit, use the 10mm wrench

to turn the eccentric spacers until the Z Plate will slide

completely in. Turn the eccentrics until the wheels are snug

against the X Plate Extrusion. Do the same with the next pairs

of wheels as you continue to slide the Z plate into the X plate.

The wheels should each make firm contact, but the Z plate

should still slide when given some hand pressure.

Page 16 or 34

From the top of the X Plate Extrusion, thread the

178mm lead screw through the anti-backlash nut

connected to the Z Plate. Continue until the lead

screw is sitting in the pocket on the UHMW Screw

seat.

Place the coupler on the top of the lead screw. Leave

loose.

Grab the Z Motor Mount. Place the shaft of the

motor into the top of the coupler. Leave loose.

Lubricate (2) #10x1 self-tapping screws. Place them

through the Z motor mount into the holes at the end

of the X Plate Extrusion. Tighten with the 8mm

wrench.

Using the 2.5mm Hex Key, tighten the coupler to

the motor shaft and the lead screw. The lead

screw MUST be firmly against the UHMW piece

at the bottom of the assembly or the coupler

will separate, causing the Z axis to lose height

during operation. Make sure the coupler does

not separate when the Z axis plate is pulled

downward.

Page 17 or 34

Attaching XZ Assembly to Gantry Plates

Parts

613mm Extrusion w/ MillRight Sticker

613mm Extrusion

(1) 600mm Lead Screw

Hardware

(8) #10x1 Self-tapping Screws

Tools

Phillips Screwdriver

1.5mm Hex Key

2.5mm Hex Key

8mm or 5/16”Wrench or Socket

WD40 or Other Lubricant

Run the 613mm extrusions through the v-wheels on

the X Plate Extrusion. The extrusion with the

MillRight sticker will go up top. Make sure the

extrusions are oriented as pictured. If the wheels are

too tight, use the 10mm wrench to turn the eccentric

spacers until the extrusions fit. Once the extrusion is

in, turn the eccentric spacers until the wheels are

making good contact with the extrusion.

Tighten the v-wheels making sure not to turn the

eccentric spacers. Turn the XZ Assembly over and

move it to the end of the extrusions with the sticker.

Page 18 or 34

Lubricate (4) #10x1 self-tapping screws and place

them through the Idler Side Y Gantry Plate into the

holes on the end of the 613mm extrusion. Use the

8mm socket to tighten the screws.

Using the 1.5mm Hex Key, loosen the set screws on

the pillow block bearing. Thread the 600mm lead

screw through the anti-backlash nut on the XZ

Assembly until a portion of it sticks through the pillow

block bearing as pictured on the top right of this

page.

Lubricate (4) #10x1 self-tapping screws. Place them

through the Motor Side Y Gantry Plate and into the

holes in the end of the 613mm extrusion. Use the

8mm socket to tighten the screws.

Turn the 600mm lead screw until the screw fits into

the coupler attached to the Motor Side Gantry Plate.

Make sure the screw is still engaging the pillow block

bearing. Use the 2.5mm Hex Key to tighten the

coupler to the lead screw.

Use a Philips screwdriver to tighten the machine screws on the pillow block bearing. Use the 1.5mm

Hex Key to tighten the set screw on the pillow block bearing. The coupler should NOT separate if you

push the X/Z assembly to the right. If it separates, the set screws on the pillow block bearing are not set

properly.

Page 19 or 34

Gantry to Y Rails

Parts

(2) 600mm Lead Screw

(2) Motors (one long wire, one short wire)

(2) 3 Hole Motor Spacers

Hardware

(2) Drop-in T Nut

(2) M5x10 Machine Screw

(2) M5x16 Machine Screw

(4) M5x16 Button Cap Screw

(6) M3x20 Machine Screws

(2) M5 Washer

(2) M5 Split Washer

(6) M5 Nylock Nut

(2) Pillow Block Bearing

(2) Corner Bracket

(2) Coupler

V-Wheel Kit

Tools

Phillips Screwdriver

3mm Hex Key

2.5mm Hex Key

1.5mm Hex Key

8mm or 5/16” Wrench or Socket

10mm Wrench

Page 20 or 34

Place the Gantry onto the Y Rails as pictured.

Place a V-wheel on an M5x25 machine screw,

followed by a standard spacer from the V-

wheel kit. Put the v-wheel into the V groove

of the extrusion before tightening the screw.

Screw the v-wheel into the bottom of the

Gantry Y Plate. It the fit is tight, use the

10mm wrench to adjust the eccentric spacers.

You may have to loosen the screws on the top

wheels to get the bottom wheel screws to line

up with the threaded hole.

Repeat the process for the other 3 V-wheels.

Use the 10mm wrench to turn the eccentric

spacers to give the v-wheels a good grip on

the extrusion. Tighten the v-wheels, being

careful not to turn the eccentric spacers when

you do.

This will secure the gantry assembly to the Y

rails. The gantry should smoothly roll forward

and back.

Table of contents

Other Mill-right Control System manuals

Popular Control System manuals by other brands

Neets

Neets SieRRa II 310-0102 user manual

Ormazabal

Ormazabal cgmcosmos-l General instructions

Motorline professional

Motorline professional CHAINLIFT User& installer's manual

Varifan

Varifan VPM-1 user manual

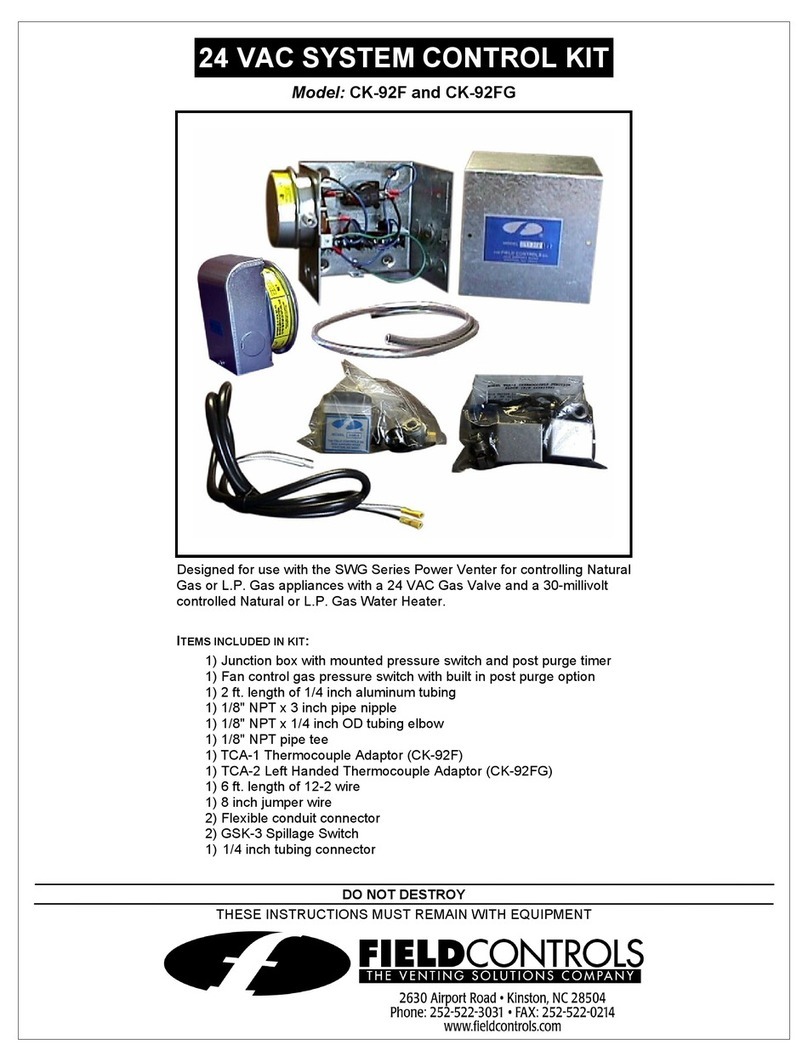

Field Controls

Field Controls 46285400 manual

Honeywell

Honeywell Experion LX 8 series Installation instruction

Compool

Compool Cp3800 Installation & operating instructions

Daisy

Daisy 9016 X-Purge user manual

Precision Engineering

Precision Engineering Bimba PCS user manual

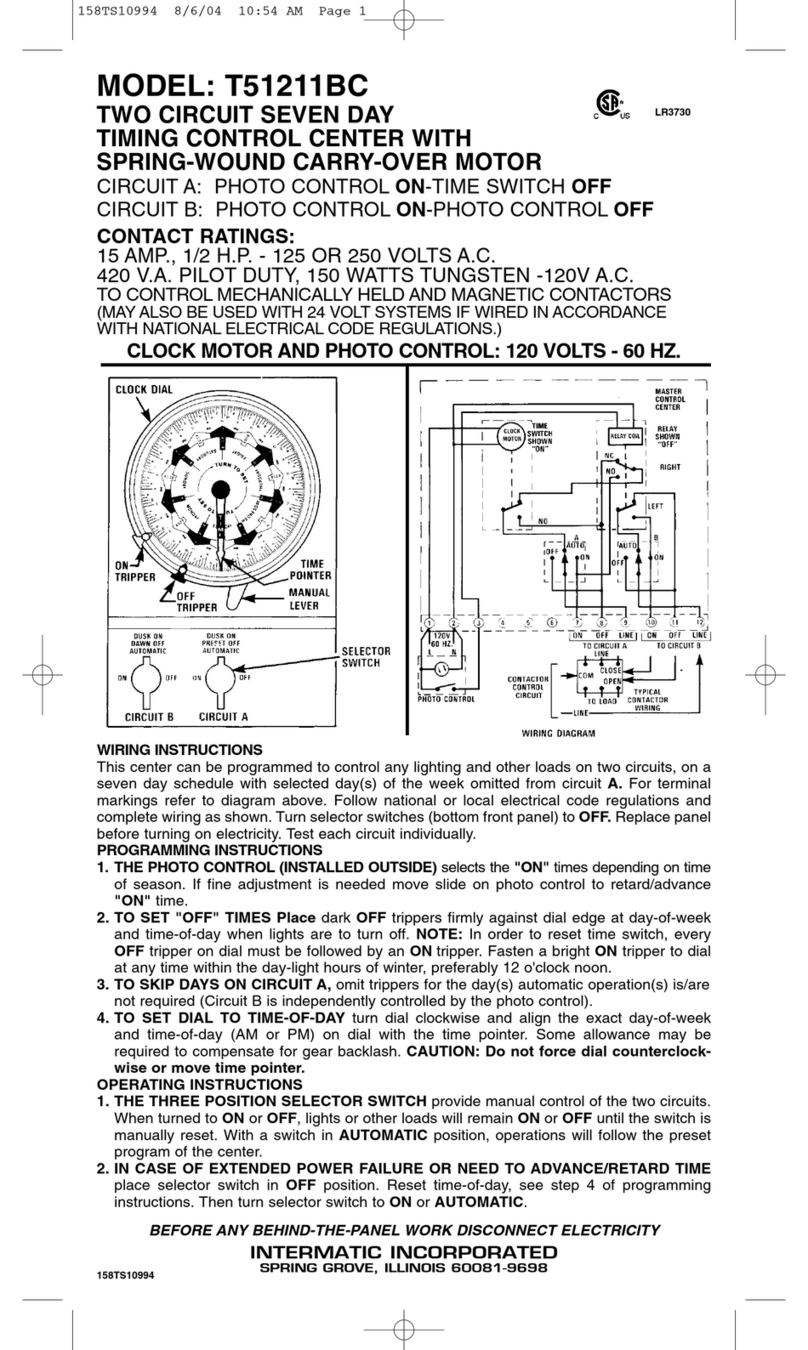

Intermatic

Intermatic T51211BC supplementary guide

GATE ARMS+

GATE ARMS+ LIFTMASTER MEGA ARM Series installation manual

Beninca

Beninca VE.650 Operating instructions and spare parts catalogue