MILLART MACHINE TOOLS TB-12 User manual

V1.0

HEAVYDUTYBEADROLLER

OPERATIONMANUAL

V1.0

1

WARNING

Readandunderstandallinstructionsbeforeusingthistool.

Theoperatormustfollowbasicprecautionstoreducethe

riskofpersonalinjuryand/ordamagetotheequipment.

HAZARDDEFINITIONS

Pleasefamiliarizeyourselfwiththehazardnoticesfoundin

thismanual.Anoticeisanalertthatthereisapossibilityof

propertydamage,injuryorlossoflifeifcertaininstructions

arenotfollowed.

DANGER!

Thisnoticeindicatesanimmediateandspecific

hazardthatwillresultinseverepersonalinjuryor

lossoflifeiftheproperprecautionsarenottaken.

WARNING!Thisnoticeindicatesaspecifichazardorunsafe

practicethatcouldresultinseverepersonalinjuryor

lossoflifeiftheproperprecautionsarenottaken.

CAUTION!Thisnoticeindicatesapotentiallyhazardoussituation

thatmayresultinminorormoderateinjuryifproper

practicesarenottaken.

NOTICE!Thisnoticeindicatesthataspecifichazardorunsafe

practicewillresultinequipmentorpropertydamage,

butnotpersonalinjury.

V1.0

2

WORKAREA

1. Operateinasafeworkenvironment,Keepyourworkareaclean,

well‐litandfreeofdistractions.Placelightssoyouarenot

workinginashadow.

2. Keepanyonenotwearingtheappropriatesafetyequipment

awayfromtheworkarea.

3.Storeunusedtoolsproperlyinasafeanddrylocationtoprevent

rustordamage.Locktoolsawayandkeepoutofthereachof

children.

Usage

1. ThisHeavydutybeadrollermachineishandoperatedandwillform

sheetmetalupto18Gaugethicknessmildsteel(orequivalent).The

beadrollermachineisconstituteofcastironandsteel,andensuing

minimumdeflectionoftheworkpiecedungformingoperations.

V1.0

3

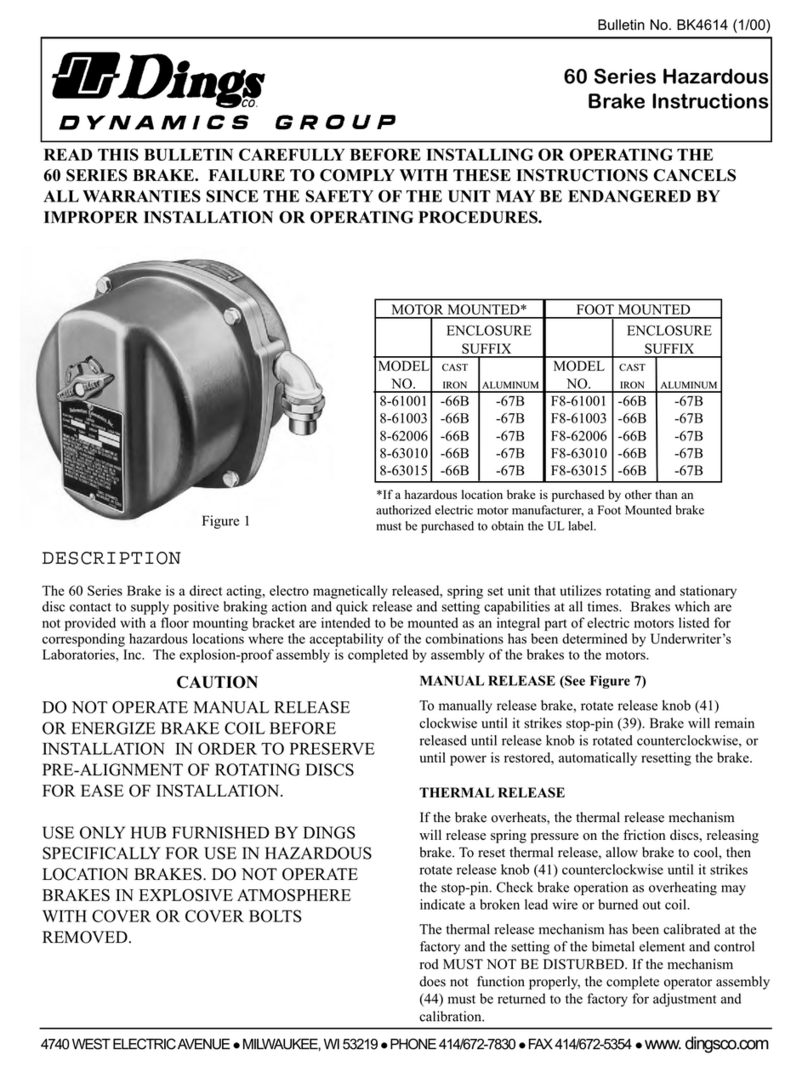

2. Maintechnicalspecification

Model TB-12

Capacity of Mild Steel 18 Gauge

1.2 mm

Cylinder length 5-1/2”

140 mm

Throat depth 8”

200 mm

Packing size (L x W x H ) 23-5/8” x 22-53/64” x12-13/64”

600mm x 580mm x 310mm

Net Weight 105.8 lbs

48 kg

Shipping Weight 127.9 lbs

58 kg

3.Installationandcaution

3.1Installation

3.1.1Pleasecheckwhetherthepartofthismachinearefullyequipped

andnotdamagedaccordingtothepartslistorpartfigure.

3.1.2Thismachineshouldbemountedonworkbenchorspecific

stand(notsupplied),Besuretoprovideclearanceforcrankam

rotationarea.

V1.0

4

3.1.3Pleaseleaveplentyroomaroundthemachineforyoureasy

operating,inordertoavoidinjury.

3.1.4Pleaseremovetheanti‐rustgreaseonprocessingsurfacesand

somepartsincludedkerosene.

3.2Caution

3.2.1Pleasereadthemanualbeforeoperationandmakeyourself

understanditsstructureandprinciplecompletely.

3.2.2Pleasedon'toperatethematerialwidthandthicknessthan

tablelistmax.range.

3.2.3Donotforcetherotarymachine.Itwilldothejobbetterandmore

safetyattherateforwhichitwasintended.

3.2.4Donotoverreach.Keepproperfootingandbalanceatalltimes.

3.2.5Pleasedon’ttouchthebeadrollerduringoperation.

3.2.6StayalertwatchwhatyouaredongDonotoperateanymachinery

whenyouaretired.

4.Operation

4.1Selectthediesetrequiredfortheoperationtobeperformed.

4.2Fistofallthenecessarytypeofrollsmustbemountedtothemachine.

Thetoprollhasrightthreadandbottomrollhasleftthread.Thesenuts

mustbetightenedsecurelywhensettinguptherolls.

V1.0

5

4.3Byusingtheleveronleftsidebottomrollshaftlengthisadjustedto

workparallelwiththetoproll.Whenyouaresatisfiedwithparallelism

youcantightentheboltofbottomrollonrighthandsideofthe

machineandfixthepositionofbottomroll.

4.4Byusingsmallleversonthetopofthemachineyoucanadjustthe

indexcoverpositionaccordingtothematerialposition.

4.5Youcannowinsertthematerialleadbetweentherollsandpinchthe

materialbetweentherollsbymovingthetoprolltopositionwiththe

handwheel.Alsotheindexcovershouldbeusedtoachieveaccuracy.

Thiscovercanbeusedasagaugeforthematerialleadandthroughout

theentireoperationthematerialshouldbetouchingtheindex.

4.6Nowyoucanbendthematerialbyusingthehandleandmovingthe

materialfrontandback.

5.Maintenance

5.1KeeptoolscleanforbetterandsaferperformanceKeephandledry,

clean.

5.2Checkfordamagedparts,beforeusinganytool,anypartthatappears

damagedshouldbecarefullycheckedtodeterminethatitwould

operateproperlyandperformitsintendedfunctionCheckfor

alignmentandbindingofmovingparts,anybrokenpansormounting

fixtures,andanyotherconditionthatmayaffectproperoperationAny

V1.0

6

partthatisdamagedshouldbeproperlyrepairedorreplacedbyan

authorizedservicecenterunlessotherwiseindicatedelsewhereinthe

instructionmanual.

5.3Allexposedironsurfacesshouldbecoatedwithlightoiltoprevent

rustingUseamulti‐purposeorbearinggreaseforlubrication.

5.4Themachineneedstobelubricatedperiodicallyforefficientworking

andlolife.Youcanseethepointsoflubricationchartforperiodic

maintenance.

Therollsofthemachinemustneverbegreasedorlubricated.

Because,thentherollswillslipthematerialandwillnotben.Always

keeptherollscleanandfreefromgreaseoranylubricant.Alsomake

surethatthematerialisfreefromgreaseanddirt.

③

②

①

V1.0

7

6.DiesDrawing

DescriptionS1S2S3S4

A0.11”(3mm)0.14”(3.5mm)0.16”(4mm)0.16”(4mm)

B0.25”(6.4mm)0.33”(8.4mm)0.37”(9.4mm)0.45”(11.4mm)

C0.5”(12.6mm)0.4”(10.1mm)0.34”(8.6mm)0.26”(6.6mm)

D0.16”(4mm)0.24”(6mm)0.28”(7mm)0.35”(9mm)

E0.7”(18mm)0.63”(16mm)0.59”(15mm)0.51”(13mm)

(Ø2.4”)

(Ø1.5”)

(Ø2”)

(Ø1.1”)

(Ø1.4”)

(Ø2.4”)

(Ø1.7”)

(Ø1”)

0.5”0.4”

0.5” 0.4”

V1.0

8

7.Partslist

Part#DescriptionPart#Description

1Body20Handle

2Backcover21Shafthandle

3Gearboxcover22Nut

4Protectioncover23Greaser

5Lovershaft24Socketheadcapbolt

6Rolls25Nut

7Key26Connectionbolt

8Roll27Nut

9Ring28Bolt

10Nut29Nut

11Innerbushing30Gear

12Innerbushingpart31Retainingring

13Protectioncoverconnection32Metalring

14Bolt33Mainshaftgear

15M16Bolt34Gear

16M16Bolt35Gear

17Sidefastener36Handle

18Sidefastenerwheel37Bolt

19Shaftofhandle38Nut

V1.0

9

8.Assemblydiagram

Table of contents

Popular Industrial Equipment manuals by other brands

GÜDE

GÜDE GBF 550 Translation of the original instructions

AFM

AFM LX-150 user guide

GF

GF Signet 2839 operating instructions

Adaptive Micro Systems

Adaptive Micro Systems Alpha 4000 RGB MNS B Series installation manual

NCMT

NCMT MAKINO A100-5XR-CD Operator's manual

Lagos

Lagos paintTROTTER REFINISH Mounting instruction and User manual

ABB

ABB HT570284 Operation manual

turck

turck RA-SAB-15-36 quick start guide

Siemens

Siemens UP 588/13 Technical specification

Regulus

Regulus HSK 350 K P-B Installation and operation manual

INOXPA

INOXPA KIBER KSF Ex Installation, service and maintenance instructions

schmersal

schmersal AZM201B-ST2-T-1P2PW-A Instructions for operation