Ilsintech SWIFT F1 User manual

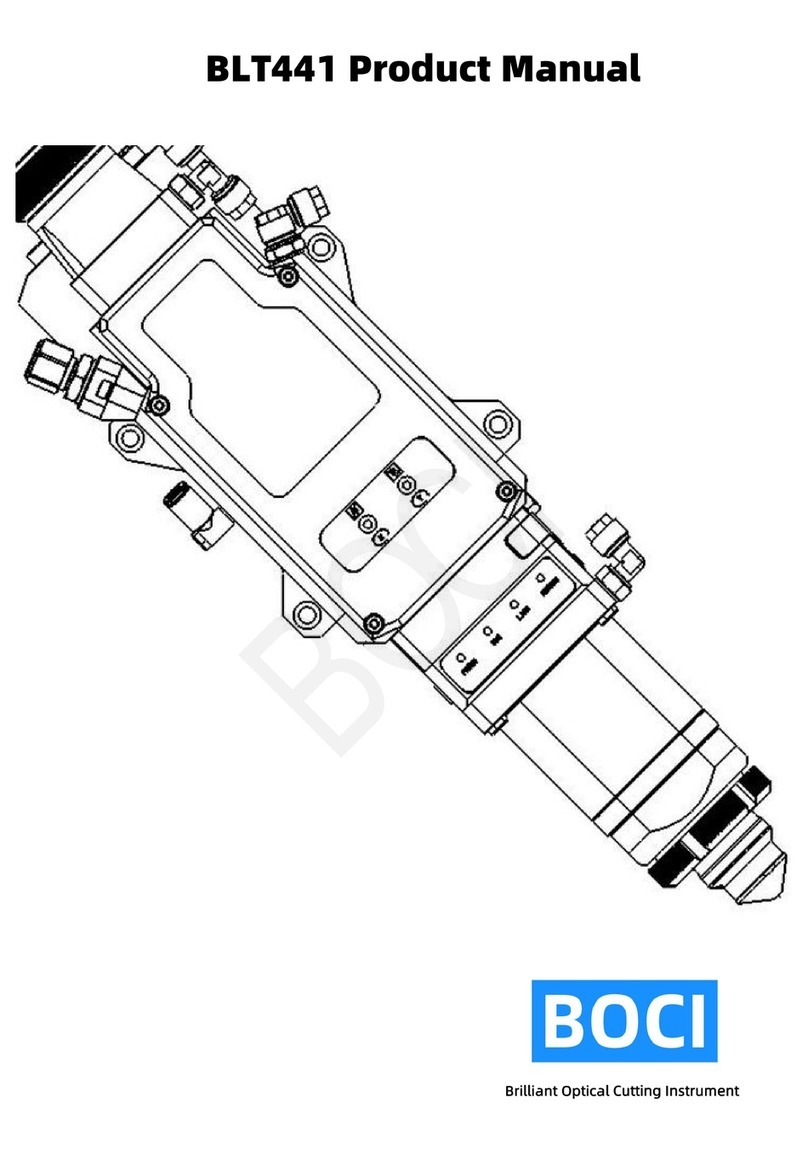

Body Appearance & How to use Keypad

Swift F1

Quick Reference Guide

Cleaner

Auto Stripper Sleeve Heater

Cleaver with Fiber Chip Collector

Splicer

Power Button

LCD Monitor

Reset / Return Button

Wind Protector

Cursor Buttons

Enter & Menu Button

Auto Stripper Button

(Start Heating)

Arc Button

(Start Splicing)

Sleeve Heater Button

(Start Heating)

Battery Pack

Battery Indicator Button

Remaining Battery Indicator LED

USB Port

Esc Button

Power Supply

Power Requirements

•A

C

po

w

e

r

supp

l

y

f

o

r

t

h

e

spec

ifi

ed

Charging the Battery

•When charging, LED light blinks Red→

Green→Yellow.

•Full charging the batteries take

approx. 2 hours.

•Power Indicator LED

LED light turns:

DC

-

DC Adaptor (Option)

Battery

Pack

F1-2

Charger

AC-DC

Adaptor

AC Code

Battery Capacity Check

•Remaining battery capacity is

displayed on both the top right

corner of the Monitor and the

AC

power

supply

for

the

specified

charger is AC 100-240V, 50-60Hz.

•Do not use AC power other than

the allowable power indicated.

•Do not use a battery charger other

than the specified charger provided

with product.

•The LED light turns Red→Green→

No Light (F1-2 Charger).

•Auto shutoff devices are built in the

batteries to prevent over arc, over

charge and overload.

When these protection functions

Red→Green→Yellow

DC

DC

Adaptor

(Option)

•Connect the DC cord of the charger to

Adaptor.

•DC adaptor charged while operating

and plugged.

•Only one Plug-in (Right Side Adapter)

DC-DC

Adaptor

battery indicator LED

Contact : Contact : [email protected][email protected] / +82/ +82--4242--671671--5609~115609~11

are performed, power is automatically

shutoff.

Cleaning & Inspection

Swift F1

Quick Reference Guide

•Brush the surface of the V-grooves & Stripper and clean

with a cotton swab moistened with alcohol.

•Remove the remaining alcohol in the V-grooves with a dry

clean cotton swab.

•Use the cleaved optical fiber to remove contaminants

from the V-grooves if any remain.

•

Clean the surface of the wind protector prisms with a lens

Clean the V-Groove Clean the Stripper

•

Turn OFF the F1 before Cleaning & Inspection.

•

Be careful handling the ELECTRODES.

•

Brush the V-Groove & Stripper frequently before / after using F1.

•

Be careful handling STRIPPER BLADE PART which is very sensitive.

Clean

the

surface

of

the

wind

protector

prisms

with

a

lens

cleaner or cotton swab.

•Remove the electrodes before cleaning the object lenses.

•Clean the surface of the lens(X axis & Y axis) softly with

a lens cleaner or cotton swab.

•Remove remaining alcohol with a dry clean cotton swab.

•Turn on the power and check the clarity of the lens into

the display LCD monitor.

Press the “▽” cursor button to change the screen and inspect

the surface of the lens.

Wind Protector Prism Clean the Object Lens

Routine Maintenance

Re

p

lacin

g

Electrode

s

•

Turn OFF the F1 before doing process.

•

Be careful handling the ELECTRODES.

•

Brush the V-Groove &Stripper frequently before / after using F1.

•

Cleaning Electrodes once every 500 times arc with a cotton swab

moistened with alcohol.

1

Fthi ltAUX

Battery Maintenance

•Discharge the battery completely

at least once every 3 months in

order to avoid memory effect.

•Storage temperature should be

between -20℃ and 30℃.

•

Recharge the battery every 6

pg

1

.

F

rom

th

e ma

i

n menu, se

l

ec

t

AUX

menu, press

ENTER, REPLACE ELECTRODES, and press ENTER.

2. Loosen the thumb-screws and remove the electrodes.

3. Clean the new electrodes and install.

4. From the main menu, perform the ARC Calibration.

Select AUX menu, perform the Stabilize Electrode

in order to stabilize electrodes.

5. From the main menu, select AUX menu, set the “O”

arc count through the Clear ARC Count

•

Recharge

the

battery

every

6

months when not in use.

Routine Diagnostics

The following tests are found in

the OTHER menu in the system

menu, and should be performed

once every 3 months.

•Dust Check

•Motor Drive

•

LED Check

Contact : Contact : [email protected][email protected] / +82/ +82--4242--671671--5609~115609~11

arc

count

through

the

Clear

ARC

Count

LED

Check

Change of Blade Channel (Cleaver)

Swift F1

Quick Reference Guide

1. Detach the automatic cleaver (Swift CI-03) from the F1

body using a hexagon wrench as shown the picture 1.

2. Open the cover and push the slider forward.

When the slider is fixed, loosen the set screw a little

bi ( 2 ) i h h h

1. Detaching 2. Loosing the set screw

•

Turn OFF the F1 before doing process.

•

Be careful handing the Blade.

bi

t

(

approx.

2

turns

)

w

i

t

h

a

h

exagon wrenc

h

.

3. Turn the marking on the blade counter-clockwise one

by one with a cotton swab.

Assemble the automatic cleaver in the reverse manner of

detaching.

3. Changing Channel

Blade Replacement & Adjustment of Blade Height (Cleaver)

Blade Replacement

•

Turn OFF the F1 before doing process.

•

Be careful handling the Blade.

•

Thoroughly & Accurately set the height using a gauge

because the height directly effect SPLICE LOSS.

1.

2. 3.

Adjustment of Blade Height

2.

1.

1. Loosen the set screw at the side of the cleaver detached

from the F1 a little bit (approx. 2 turns) with a wrench.

2. Insert a wrench into the hole at the bottom of the cleaver

and loosen the set screw of the slider a little bit

(approx. 2 turns). Slider has to be moved backward.

3. Insert the wrench bolt into the cam pin and pull it with

tweezers and detach the slider.

4. Not to damage the blade. Assemble the part in the

1. Insert a wrench into the hole at the bottom of the cleaver

and loosen the set screw of the slider a little bit

(approx. 2 turns). The slider has to be moved backward.

2. Adjust the blade height by turning Cam Pin.

Clockwise turning: HEADING to UPWARD

Counter-Clockwise turning: HEADING to DOWNWARD

3. When the blade reaches required position, tighten the set

screw of the slider.

Contact : Contact : [email protected][email protected] / +82/ +82--4242--671671--5609~115609~11

reverse manner.

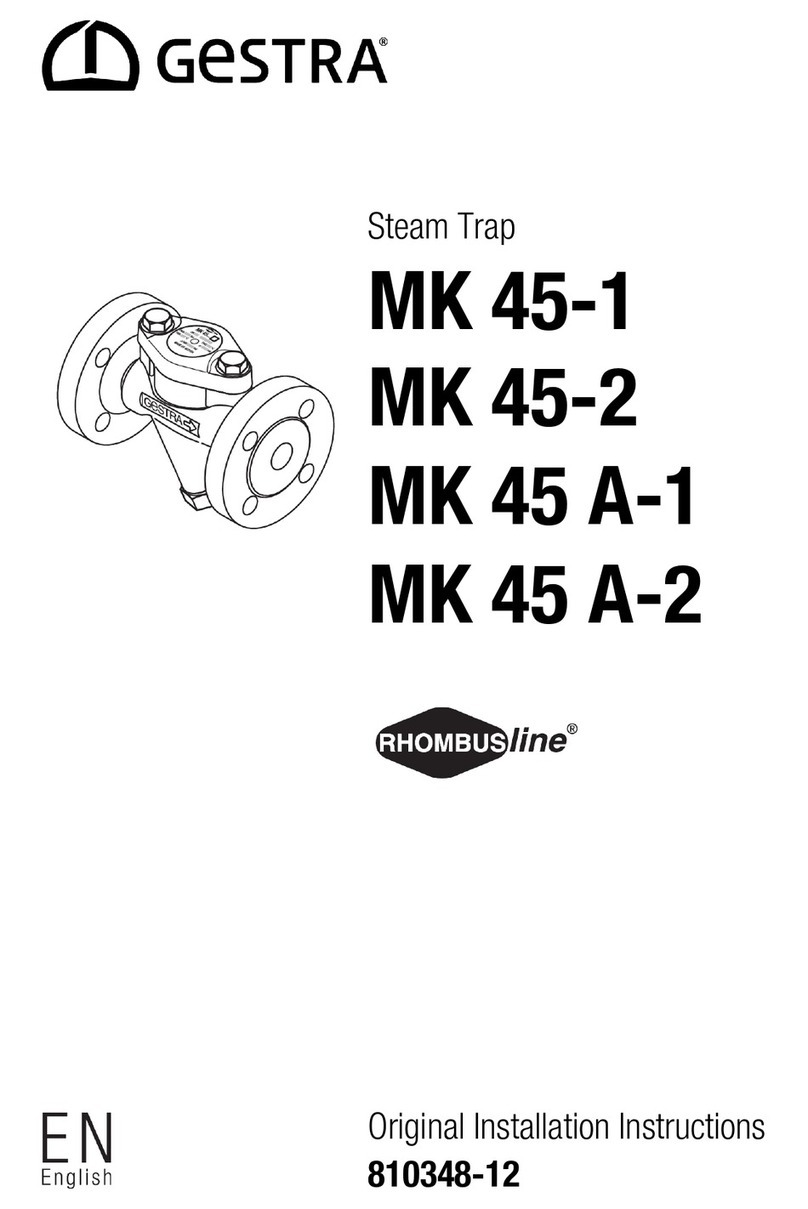

Splicing Operation

Swift F1

Quick Reference Guide

Step Description Procedure

1Turn the F1 on

Press and The POWER button 1 time.

Home screen will be displayed when all motors

are reset to their initial positions.

Select a proper splice mode for exact splicing.

The current splice mode is displayed in the

2Select Splice

Mode

and Heater Mode

The

current

splice

mode

is

displayed

in

the

home screen.

Select heater mode.

The current heater mode is displayed on the

home screen.

3

Inserting Sleeve

Tube &

Connector Boot

Installing Holder

Insert the sleeve tube and boot part (when

splice fiber to connector) into the fiber.

FOR FERRULE, TAKE OFF THE ORIGINAL CAP,

THAN INSERT THE FERRULE CAP.

Install the fiber or ferrule into the proper fiber

holder.

(250㎛, 900㎛, 2.5㎛, and Ferrule t

yp

e holders)

Sleeve Tube Fiber

Ferrule Ferrule Cap

yp

4Stripping

Operation

Warm up stripper heater. First close holder

part cover after mounting the fiber holder

onto the Auto stripper. SECOND, SLAM THE

HEATER PART COVER IN ORDER TO FIRMLY

STRIP COATING WITH BLADES. The fiber is

heated up and the coating is automatically

stripped by moving the slide. When process is

completed, FIRST SOFTLY OPEN HOLDER PART

COVER, AND DETACH FIBER HOLDER. Open

heater part cover, remove remaining coating

and brush for next operation. CAREFULLY

HANDLING BLADE PARTS FOR STRIPPING

HANDLING

BLADE

PARTS

.

FOR

STRIPPING

TEMPERATURE BETTER SET BETWEEN 75℃ to

80℃.

5Cleaning

Operation

Discharge alcohol by pressing 2 or 3 times with

a cleaning wipe by hand. BE CAREFUL NOT TO

WET THE EQUIPMENT.

Contact : Contact : [email protected][email protected] / +82/ +82--4242--671671--5609~115609~11

Splicing Operation

Swift F1

Quick Reference Guide

Step Description Procedure

6Cleaving

Operation

Automatic clever(CI-03) cleaves SM & MM

fibers at right angle. Open cleaver cover and

mount stripped and cleaned fiber holder into

the cleaving position. CHECK THE FIBER IS

PROPERLY LYING IN PLACE. Open chip-box

located at the right side of the F1. WHEN

CLEAVE FIBER, FIRMLY PUSH CLEAVE COVER.

After cleaving BE CAREFUL THE FIBER FROM

ANY DUST OR CONTAMINANT

ANY

DUST

OR

CONTAMINANT

.

7Splicing

Operation

Mount cleaved fiber holders into both sides of

the splicer between the V-grooves and

electrodes. CHECK THE FIBERS ARE PROPERLY

PLACED ON THE V-GROOVES. Gently close the

wind protector. Press the ARC button to begin

splicing. REDUCING SPLICE LOSS FIBERS MUST

BE PLACED ON CORRECT POSITIONS AND BE

CAREFUL THE FIBER FROM ANY DUST OR

CONTAMINANT. Dispatch fibers from the

holders, and gently move the sleeve tube to

the spliced part of fiber. For ferrule, softly hold

the

spliced

part

of

fiber.

For

ferrule,

softly

hold

its cap and take out from fiber holders.

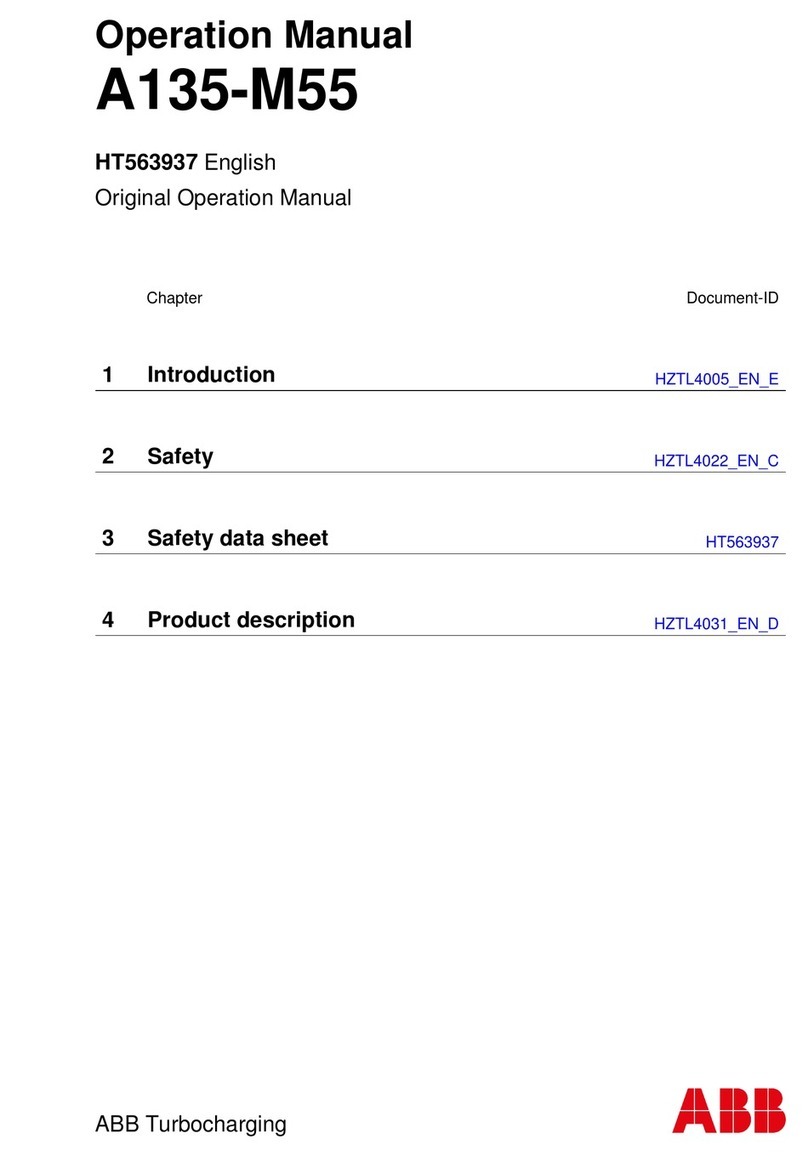

8Sleeve Heater

Operation

Open heater cover and set the fiber into the

inside of heater. FOR FERRULE, RED MAKE

MUST BE HEADING TO USER’S CHEST AND

MUST BE SET TO THE RIGHT-MOST POSITION

OF HEATER. Press sleeve heater button in order

to active. Cooling fan is run to cool the sleeve

tube after 20 sec when completed the heating

process. Open the heater cover when cooling is

completed and take out the reinforced fiber.

9Assembling

Connector

Operation

Take off ferrule cap and assemble it with boot

part. Assemble ferrule , jointed with boot part,

with grip part.

Contact : Contact : [email protected][email protected] / +82/ +82--4242--671671--5609~115609~11

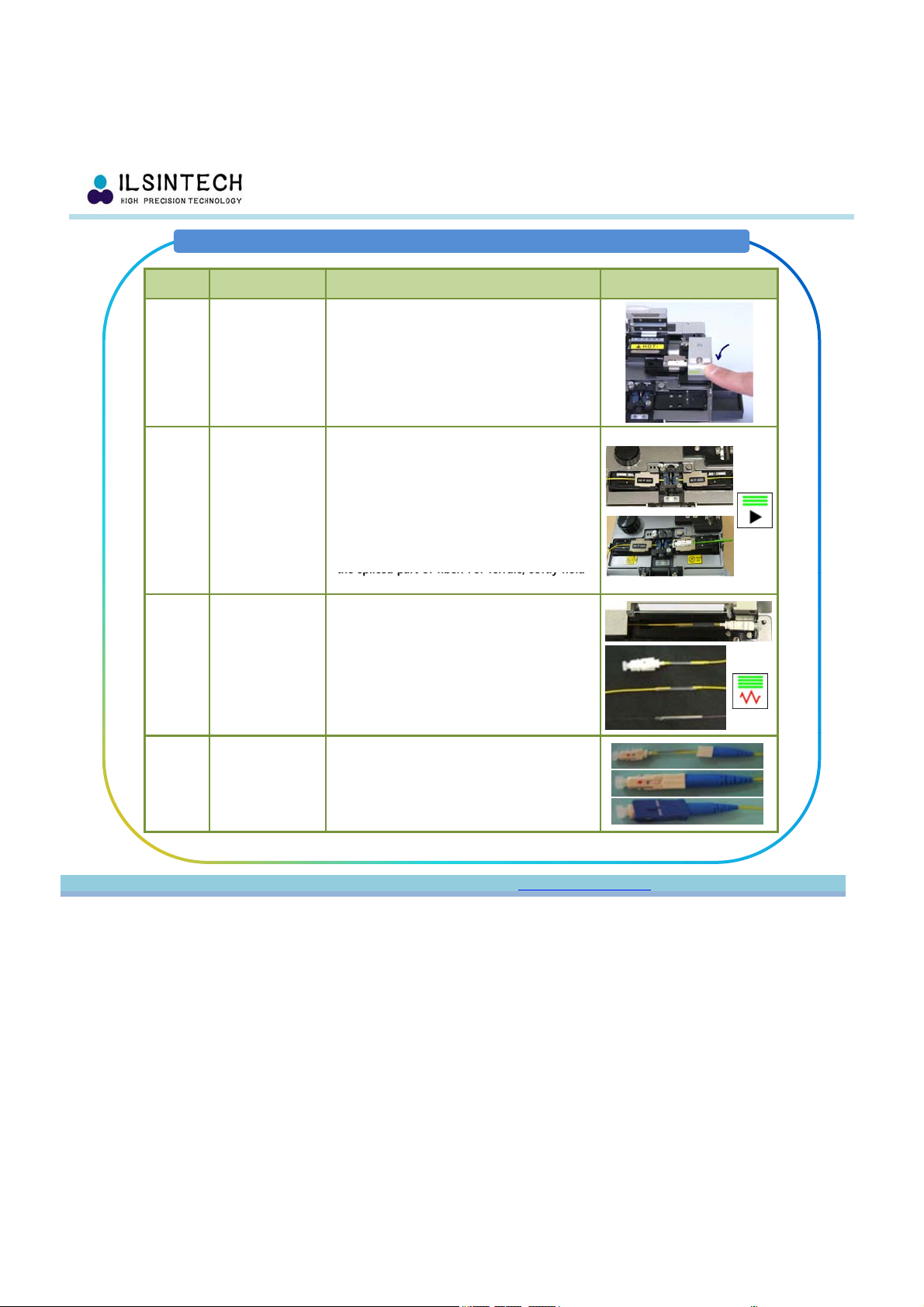

THE Choice of a Lever Block by Cable & Connector Type

Swift F1

Quick Reference Guide

Heater Block R

Type Description Type Description

•SC / FC Connector

•LC Connector

•0.25 / 0.9mm Fiber

•2.0 / 2.4mm Cable

•

2.0mm Cable

Set Screw

2.0mm

Cable

•Indoor Cable

Lever Block

Heater Block L Heater Block R

Type Description Type Description

•0.25 / 0.9mm Fiber •0.25 / 0.9mm Fiber

•2.0 / 2.4mm Cable

•LC Connector

•2.0 / 2.4mm Cable

•

30mm

Cable

•

30mmCable

•

3

.

0mm

Cable

•

3

.

0mm

Cable

•Indoor Cable •Indoor Cable

Standard Package: Heater Block R (2EA), Lever Block (1PAIR)

O

p

tional Packa

g

e: Lever Block

(

3PAIR

)

Contact : Contact : [email protected][email protected] / +82/ +82--4242--671671--5609~115609~11

pg ()

THE Choice of a Lever Block by Cable & Connector Type

Swift F1

Quick Reference Guide

Sleeving 0.9mm Fiber with SC Connector

Step Description Procedure

1•Loosen the Set Screw on Heater Block L

2•Mount “1” Lever Block

•Tighten the Set Screw

3•Loosen the Screw on Bottom of Heater Block R

4•Replace the Heater Block R for SC/FC Connector

•Tighten the Screw

5•Placed on the 0.9mm Fiber & SC Connector on the

Sleeve Heater

6•Complete

Contact : Contact : [email protected][email protected] / +82/ +82--4242--671671--5609~115609~11

THE Choice of a Lever Block by Cable & Connector Type

Swift F1

Quick Reference Guide

Sleeving 3.0mm Cable with SC Connector

Step Description Procedure

1•Loosen the Set Screw on Heater Block L

2•Mount “3” Lever Block

•Tighten the Set Screw

3•Loosen the Screw on Bottom of Heater Block R

4•Replace the Heater Block R for SC/FC Connector

•Tighten the Screw

5•Placed on the 3.0mm Cables on the Sleeve Heater

6•Complete

Contact : Contact : [email protected][email protected] / +82/ +82--4242--671671--5609~115609~11

Swift LC Connector Assembly Procedure (2.0mm)

Swift F1

Quick Reference Guide

Step Description Procedure

1•Place Ferrule Part on HF-LC Holder

2•Ferrule Part Stripping

3

Fl

PtCl i

3

•

F

erru

l

e

P

ar

t

Cl

eav

i

ng

4•Stripe 2.0mm Cable PVC Outer Sheath.

•Cut Kevlar.

5•Insert Boot, Heat Shrinkable Tube, Stopper,

Spring and Sleeve into the 2.0mm Cable.

•Place 2.0mm Cable on HF-2.5 Holder

Sleeve use environmental condition

-Tem

p

.: 160℃

Boot

Heat Shrinkable Tube

Stopper

Spring

Sleeve

Contact : Contact : [email protected][email protected] / +82/ +82--4242--671671--5609~115609~11

p

- Operating Time: 20sec

※ The most recommended Operating Time: 30sec ※

Swift LC Connector Assembly Procedure (2.0mm)

Swift F1

Quick Reference Guide

Step Description Procedure

6•2.0mm Cable Stripping & Cleaving

7•Splicing

8

•Sleeve 1 – Heating Sleeve

8

(Placed on Sleeve on Heater as PIC)

9

Splicing & Stopper Assembly

(APC Connector – Red Mark in the APC Ferrule

must head to the upward, then assembly to the

Plug Frame)

10 •Sleeve 2 – Heating Heat Shrinkable Tube

(Placed on Tube on Heater as PIC)

11

•

Complete

Contact : Contact : [email protected][email protected] / +82/ +82--4242--671671--5609~115609~11

11

Complete

2.0~3.0mm Indoor Cable Connector Assembly Process

Swift F1

Quick Reference Guide

Step Description Procedure

1Place 2.0~3.0mm Cable on Holder

Cutting Kevlar point

2Cut Kevlar

Approx. 20mm

3Heat Shrink the Sleeve

Sleeve

Kevlar inside of Sleeve

Contact : Contact : [email protected][email protected] / +82/ +82--4242--671671--5609~115609~11

2.0~3.0mm Indoor Cable Connector Assembly Process

Swift F1

Quick Reference Guide

Step Description Procedure

4Assemble Boot

5Assemble Housing & Clamp Cap

Boot

Clamp Cap

6Complete

Housing

Contact : Contact : [email protected][email protected] / +82/ +82--4242--671671--5609~115609~11

Error Messages

Swift F1

Quick Reference Guide

Symptom Cause Solution

Clad

Deviation Dust in V-Groove or

the chip of core wire

guide.

Cleaning V-Groove

or the chip of core

wire guide.

Clad An

g

le

Dust in V-Groove or

the chip of core wire

g

uide.

Cleaning V-Groove

or the chip of core

wire

g

uide.

Symptom Cause Solution

Bubble

Bad condition of the

cross section of

fiber.

Checking whether

fiber cleaver is

working properly.

Too low amount or

short time of initial

arc discharge.

Increase the amount

and/or time of initial

are discharge.

g

g

g

Bad condition of the

cross section of fiber.

Checking whether

fiber cleaver is

working properly.

Clad

Deformation

Bad condition of the

cross section of fiber.

Checking whether

fiber cleaver is

working properly.

Too low amount or

short time of initial

arc discharge

Increasing the

amount and time of

initial arc discharge.

Ch ki

hth

Separation Too high amount or

long time of initial

arc discharge.

Increase overlapping.

Decreasing the

amount and/or time

of initial arc

discharge.

Thick Too long fiber

length.

Reducing the length

of duplicated area.

Clad Flexion

Bad condition of the

cross section of fiber.

Ch

ec

ki

ng w

h

e

th

er

fiber cleaver is

working properly.

Too low amount or

short time of initial

arc discharge.

Increase the amount

and time of initial

arc discharge.

Burning

Bad condition of the

cross section of

fiber.

Checking whether

fiber cleaver is

working properly.

Dust still remaining

after

cleaning the

Cleaning carefully

the fiber or

Thin

Improper discharge

amount.

Conducting

discharge amount

calibration

A few improper

discharge factors.

Adjusting initial

discharge amount,

initial discharge time

and overlapped area.

Line Several number of

im

p

ro

p

er dischar

g

e

Adjusting initial

discharge amount,

initial discharge time

after

cleaning

the

fiber or conducting

cleaning discharge.

the

fiber

or

increasing the arc

discharge time.

pp g

factors.

initial

discharge

time

and overlapped area.

Contact ILSINTECH

Add:

#703 Gwanpyeong-dong Yusung-gu

Daejeon

305

-

509 Korea

Contact : Contact : [email protected][email protected] / +82/ +82--4242--671671--5609~115609~11

Daejeon

305

509

,

Korea

Tel:

+82-42-671-5609~11

Fax:

+82-42-671-5612

E-mail:

www.ilsintech.com

Other manuals for SWIFT F1

1

Table of contents

Popular Industrial Equipment manuals by other brands

Kooltronic

Kooltronic KNHX32 Series Operator's manual

ABB

ABB HT611730 Operation manual

Rockwell Automation

Rockwell Automation Allen-Bradley LDAT Series installation instructions

ABB

ABB HT581629 Operation manual

DALIN

DALIN DLVC Installation, operation and maintenance

schmersal

schmersal AZM201B-I2-SK-T-1P2PW-A instructions

GREEN INSTRUMENTS

GREEN INSTRUMENTS G3610 instruction manual

matev

matev CLS-SE operating manual

Donaldson Torit

Donaldson Torit RWB-2000 Installation and operation manual

Premier

Premier 370PK Service guidelines

Rath

Rath RGD Series Installation & operating manual

Martin

Martin Tornado installation instructions