4

1. INDICATIONS AND GENERAL SAFETY REGULATIONS

To ensure the best working conditions and safety, please read the following

paragraphs:

One of the basic factors of security is respect for the maintenance intervals (see

maintenance chart). Also, never attempt repairs or maintenance if you have no experience and

/ or tools required.

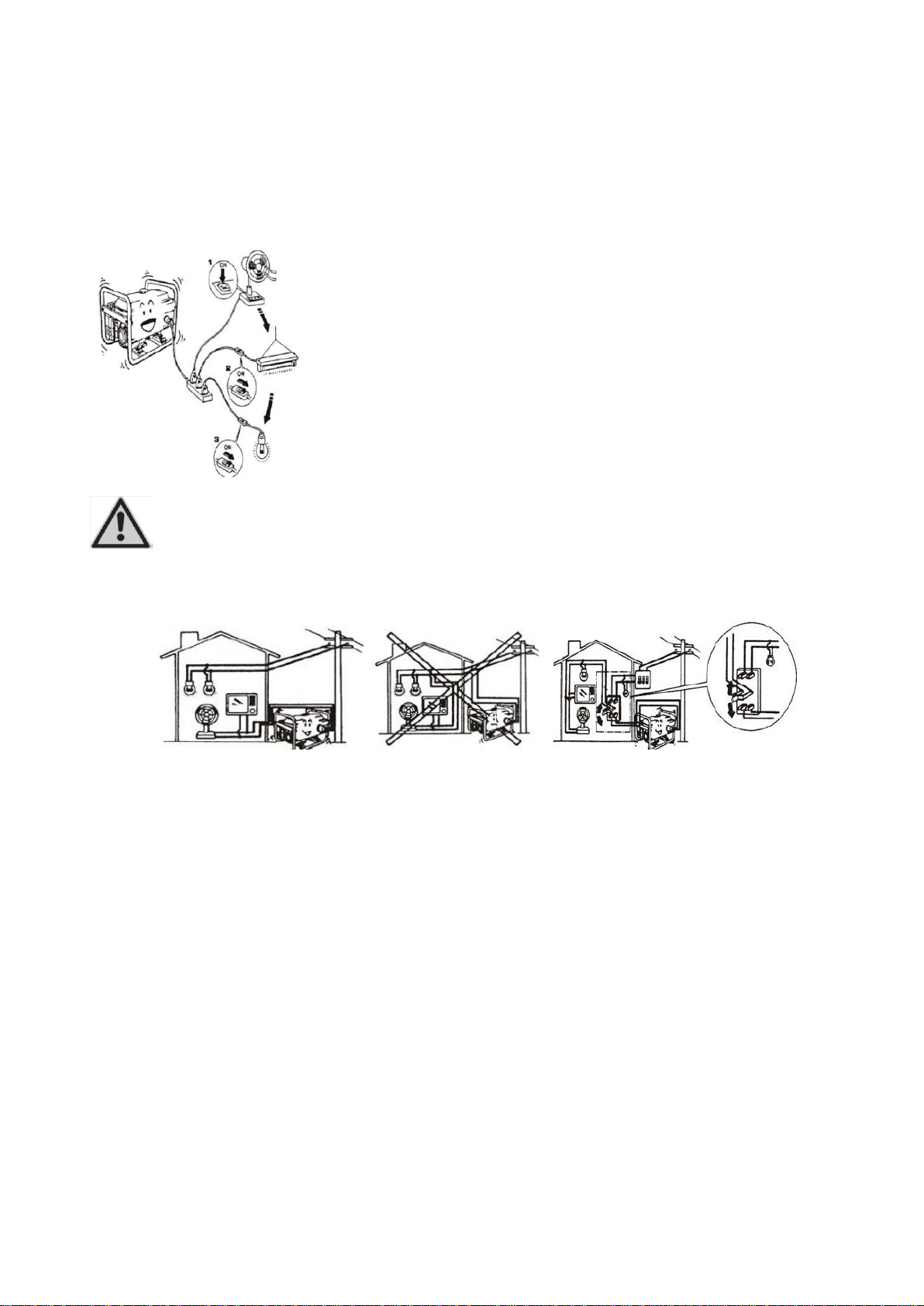

ELECTROCUTION

- The generators supply electrical current during use.

- Never touch damaged or disconnected cable connections.

- Never operate a generator with wet hands feet.

- Never expose the equipment to liquid splashes or outdoors, or place it on a

wet floor.

- Keep electrical cables and connections in good condition.

- The use of material in poor condition can cause electrical shock or equipment damage.

- Provide a differential protection device between the generator and the apparatus if

the length or the cables used is greater than 1 meter.

- Use flexible and resilient rubber sheathed cables in accordance with current regulations.

- The generator must not be connected to other energy sources, such as public distribution

network. In the particular case a backup connection is foreseen to networks

electrical existing, should only perform this operation a qualified electrician.

To do this you must take into account the differences in operating the equipment, according to

the public grid or generator is used.

- The lightning protection breakers depends on a specifically provided in the generator. If the

latter should be replaced, it should be done by others with identical nominal values and

characteristics.

FIRE Never refuel the fuel tank while the generator is running or the engine is hot.

- Clean any traces of fuel with a clean cloth.

- Fuel is extremely flammable and explosive vapors. Do not smoke, approaching

a flame or cause sparks when refueling the fuel tank.

- Keep any flammable or explosive product (fuel, oil, rags, etc.) when the

group is underway.

- Place the generator always on level ground, flat and level in order to prevent the

fuel tank spills on the engine.

- The storage of chemical / oil products and handling is carried out according to the

laws.

EXHAUST GASES

- Exhaust gases contain highly toxic component: carbon dioxide. This component

can cause death if present in very high concentrations in the air we breathe.

- For this reason, always use your generator in a well ventilated place where the

gases can not accumulate.

- In addition, good ventilation is required for the proper operation of your generator. Without

this ventilation, the engine quickly increase the temperature to values that produce accidents

or damage to the equipment or surrounding property.

- However, if an operation must be performed within a building, provide for the

appropriate ventilation so that persons or animals are not present

affected.