Miller-Leaman ULTRAPURE ML-VVF User manual

ML-VVF

VFD Pump Manual

1

INTRODUCTION:

The Miller-Leaman Variable Frequency Drive (Model ML-VVF) booster pump system is designed to

provide constant pressure even with fluctuating water volume demands. It provides this while

running with a “soft” start and stop feature providing added life to the pump. The ML-VVF is available

in 50gpm, 100gpm & 140gpm models in 230V and 460V 3 Phase and 230V 1 Phase. They are

“Turnkey” skid mounted systems available with brass or stainless-steel inlet and outlet manifolds.

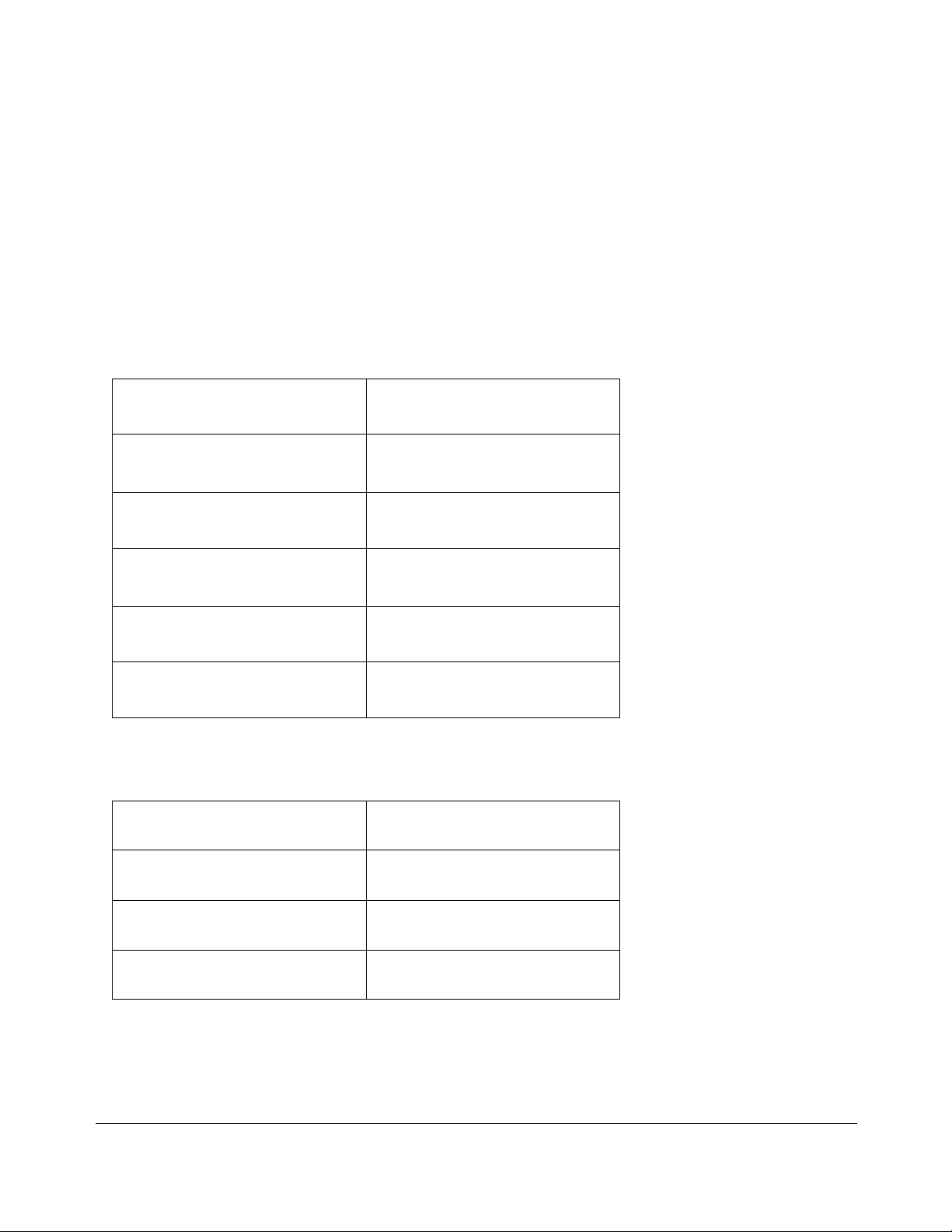

System Specifications

VFD Serial Number

VFD Model Number

Pump Serial Number

Pump Model Number

Drive Serial Number

Drive PO Number

Performance Test Results

PSI Setting

psi

Sleep Function

Flow Switch

Enclosure Fan

Miller-Leaman 800 Orange Ave, Daytona Beach, FL 32114

P: 386.248.0500 F: 386.248.3033 www.millerleaman.com

2

SETUP AND INSTALLATION:

1. Place skid mounted system in desired location and level skid using adjustable feet.

2. Connect plumbing to check valve on inlet (front) of pump and to Ball Valve on outlet on pump.

3. Connect wiring to fuse block on inside of control box, make sure to check that voltage that is

being installed matches voltage for VFD Drive.

4. Plug in Fan for control box to 120v outlet. NOTE: Fan is controlled by switch on cord only, it

does not run off VFD controller. Fan is for extra ventilation and should be used at all times

during warm months.

5. System comes programmed, you will not need to do any programming.

WARNING: DO NOT MODIFY SYSTEM IN ANY WAY. Modifying system will negate warranty.

START-UP:

Every ML-VVF system from Miller-Leaman comes fully programmed and tested and is ready to go

right out of the crate. Simply follow thesesteps before pushing start.

1. Flood suction side of pump with water from city water supply, well water supply or storage tank.

2. Turn power on to ML-VVF system from disconnect near system or master breaker panel.

System should read Xpsi, 0 Amps, 0 Hz.

3. Keep ball valve on outlet manifold shut during initial start-up. (You may need to open valve to

flood pump)

4. Confirm keypad is in “REM” (displayed in top left corner of display screen). If keypad is in “LOC”

change to “REM” using LOC/REM button on keypad.

5. Push Start on keypad

6. Confirm Pump is rotating in the correct direction.

7. System should ramp up to 60psi and Hz will start to decrease. System will go into

ALARM 2018 –PID SLEEP “sleep” after 30 seconds of pump running with less than 57.5 Hz.

a. NOTE: ALARM 2018 - PID SLEEP is normal and means that the system has reached

maximum pressure and has sustained that pressure for 30 seconds without any water

demand.

8. After system goes into ALARM 2018 - PID SLEEP open ball valve on outlet manifold. System is

now operational.

Miller-Leaman 800 Orange Ave, Daytona Beach, FL 32114

P: 386.248.0500 F: 386.248.3033 www.millerleaman.com

3

MANUAL OPERATION:

There may be times you need to run the ML-VVF system slower or faster at a constant

Hz for troubleshooting purposes. This can be accomplished by following thesesteps.

1. Using LOC/REM button on keypad change operation to “LOC”. This will appear in upper left

corner of display.

2. Press Start.

3. Using arrow keys, you can increase and decrease the Hz thus speeding up or slowing down the

pump speed.

4. After troubleshooting is finished press the LOC/REM button to change back to “REM”, push start

to go back to normal operation.

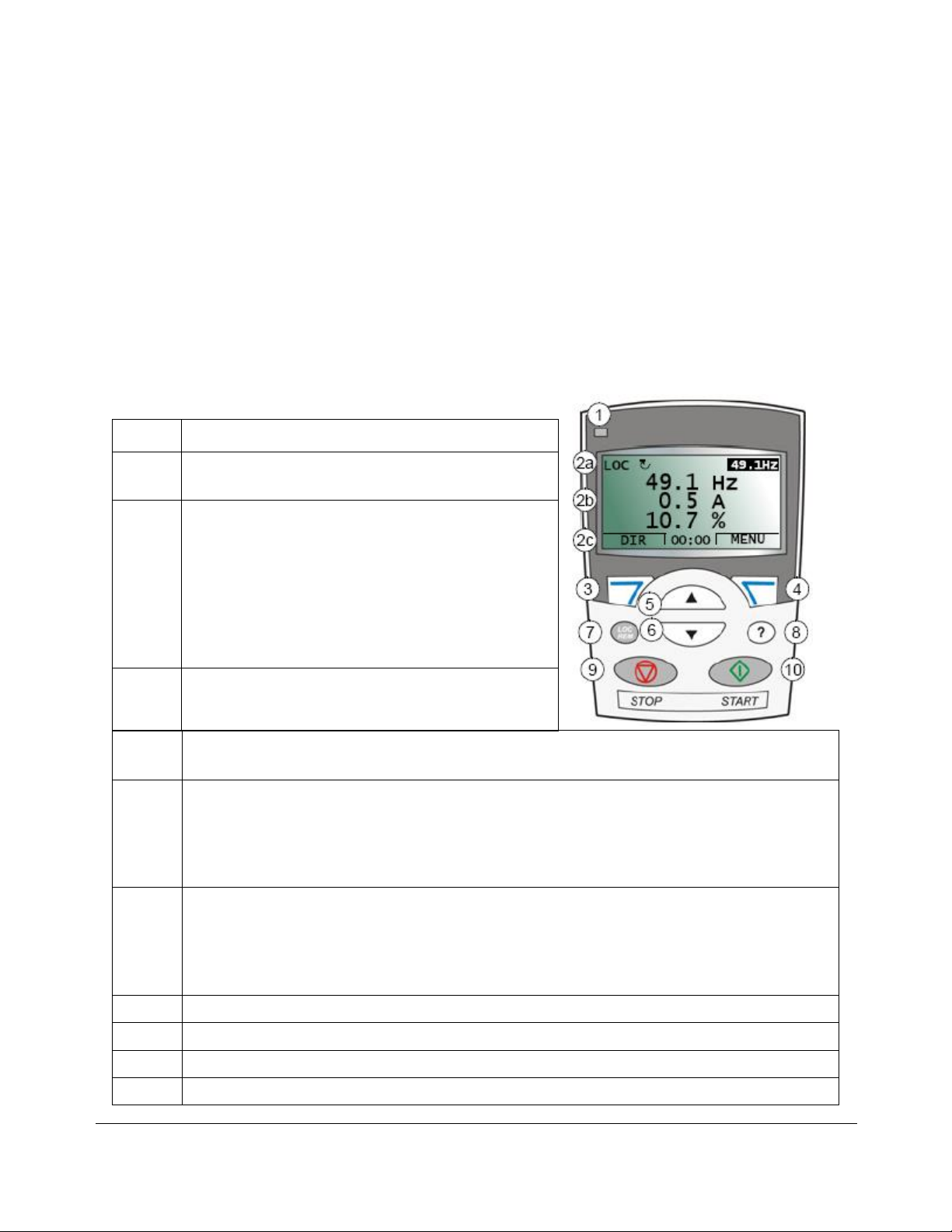

No.

Use

1

Status LED –Green for normal operation. If LED is

flashing or RED check faults.

2

LCD display –Divided into three main areas:

2a: Status line –Shows Remote or Local Mode,

rotation of pump, MAX % setting

2b: Center line –shows parameter values, line 1

psi, line 2 Amps, line 3 Hz

2c: Bottom Line –shows current function of the

two soft keys and if enabled, the clock display

3

Soft key 1 –Function depends on the context. The

text in the lower left corner of the LCD display

indicates the function

4

Soft key 2 –Function depends on the context. The text in the lower right corner of the LCD

display indicates the function

5

Up –

•Scrolls up through a menu or list displayed in the center of the LCD display.

•Increments a value up if a parameter is selected.

•Increments the reference value up if the upper right corner is highlighted.

Holding the key down changes the value faster.

6

Down –

•Scrolls down through a menu or list displayed in the center of the LCD display.

•Increments a value down if a parameter is selected.

•Increments the reference value down if the upper right corner is highlighted.

Holding the key down changes the value faster.

7

LOC/REM –Changes between Local and Remote control of the drive

8

Help –Displays context sensitive information when the key is pressed.

9

STOP –Stops the drive in Local or Remote mode.

10

START –Starts the drive in Local or Remote mode.

Miller-Leaman 800 Orange Ave, Daytona Beach, FL 32114

P: 386.248.0500 F: 386.248.3033 www.millerleaman.com

4

ALARM CODES:

ALARM 2001 – Overcurrent

•Drive detected an overcurrent situation

oCheck Motor load

oCheck acceleration time

oCheck motor and motor cable (including phasing)

ALARM 2002 – Overvoltage

•Drive detected an overvoltage situation

oCheck input power line for static or transient overvoltage

ALARM 2003 – Undervoltage

•Drive detected an undervoltage situation

oCheck input power supply

ALARM 2006 – AI1 Loss

•Analog input AI1 signal (Pressure transducer) has fallen below limit defined by parameter

oCheck pressure transducer connections

oCheck pressure transducer output reading vs inline pressure gauge

ALARM 2008 – Panel Loss

•Control panel has ceased communicating

oCheck Panel connection

oCheck control panel connector (ethernet cable)

oCheck group 10 START/STOP/DIR Settings

ALARM 2010 – Motor Temp

•Motor temp is too high (or appears to be too high) due to excessive load, insufficient motor

power or inadequate cooling.

oCheck motor ratings, load and cooling

ALARM 2018 – PID SLEEP

•Sleep function has entered sleeping mode

oALARM 2018 - PID SLEEP is normal and means that the system has reached maximum

pressure and has sustained that pressure for 30 seconds without any water demand.

Miller-Leaman 800 Orange Ave, Daytona Beach, FL 32114

P: 386.248.0500 F: 386.248.3033 www.millerleaman.com

5

FAULT CODES:

FAULT 0001 – Overcurrent

•Output current has exceeded trip level

oCheck motor load

oCheck motor and motor cable (including phasing)

FAULT 0002 – DC Overvolt

•Excessive intermediate circuit DC voltage. DC overvoltage trip limit is 420v for 200v drives and

840v for 400v drives.

oCheck input power line for static or transient overvoltage.

FAULT 0006 – DC Undervolt

•Intermediate circuit DC voltage is not sufficient.

oCheck input power voltage.

oCheck for missing input power phase.

oCheck fuses.

FAULT 0007 – AI1 Loss

•Analog input AI1 signal (Pressure transducer) has fallen below limit defined by parameter.

oCheck pressure transducer connections.

oCheck pressure transducer output reading vs inline pressure gauge.

FAULT 0009 – Motor Overtemp

•VFD Motor temp is too high (or appears to be too high) due to excessive load, insufficient motor

power or inadequate cooling.

oCheck motor ratings, load and cooling

FAULT 0010 – Panel Loss

•Control panel has ceased communicating

oCheck Panel connection

oCheck control panel connector (ethernet cable)

oCheck group 10 START/STOP/DIR Settings

FAULT 0014 – EXT FAULT 1

•Safety flow switch has triggered ext fault 1. The flow switch is an optional safety feature

available on the ML-VVF systems, it sends the drive into a fault when the pump continues to

run with no water flow for 90 seconds. This is to prevent the pump from overheating.

oCheck flow switch micro switch for damage.

oCheck pump inlet check valve for obstruction (if water can flow back to storage tank

pump will not hold pressure and continue to run with no flow on outlet side)

•*NOTE: The Safety Flow Switch has a built-in auto-restart and will try to reset itself 3 times

before going into a “Hard Fault” and shutting down the system.

FAULT 0016 – Earth Fault

•Drive has Detected earth (ground) fault in motor or motor cable.

oCheck motor.

oCheck Motor cable.

oCheck ground.

Miller-Leaman 800 Orange Ave, Daytona Beach, FL 32114

P: 386.248.0500 F: 386.248.3033 www.millerleaman.com

Table of contents