Clements SUC84602 User manual

HiFlo2

High Vacuum High Flow

Mobile Sucon Pump

SUC84602

220-240 V 50 60 Hz

User Manual

CLEMENTS

Manual No. SUC84602008

Issue 3

User Manual

HiFlo2 High Suction Pump

Manual Number SUC84602008 MD evision 0

Issue 3 2022-07-12

Copyright © 2022 ICU Medical Australia Pty Ltd

The information in this manual was originated by, and is the exclusive

property of ICU Medical Australia Pty Ltd. It is furnished for customer

information only, and is not an authorisation or licence to make this

product or to furnish this information to others.

Safety

Thank you for purchasing this Clements HiFlo2 High

Suction Pump.

For your safety it is imperative that this unit only be

operated by authorised personnel in accordance with the

instructions as described in this manual. Operated in this

way, the HiFlo2 High Suction Pump will provide the

standard of service specified.

Due to continual improvements in product design, the

HiFlo2 High Suction Pump may vary in detail from the

descriptions in this manual. In the event of further

questions please contact your local distributor or ICU

Medical Australia direct.

Familiarise yourself with these Directions for Use

before operating this device.

Sponsor:

ICU Medical Australia Pty Ltd

Unit U, 10 - 16 South St

ydalmere NSW 2116 Australia

Phone: +61 2 9466 5300

Website: www.clements.net.au

CA-MI srl

Via Ugo La Malfa 13

Frazione Pilastro

43013 Langhirano (P )

Italy

0123

CLEMENTS

CLEMENTSCLEMENTS

CLEMENTS

3

Contents

Description......................................................................... 4

Specifications .................................................................... 5

Environmental Conditions .................................................. 6

Symbols. ...... ..... ...... ...... ..... ...... ...... ...... ..... ...... ...... ..... ...... .. 7

Cautions ........ ...... ..... ...... ...... ..... ...... ...... ..... ...... ...... ...... ..... 9

Important Safety Rules ..... ...... ..... ...... ...... ..... ...... ...... ..... .... 1

Controls and Operation..... ...... ..... ...... ...... ..... ...... ...... ..... .... 13

Using FLOVAC Liners... ..... ...... ...... ..... ...... ...... ...... ..... ...... .. 15

Cleaning .......... ...... ..... ...... ...... ...... ..... ...... ...... ..... ...... ...... ... 16

Spare Parts........................................................................ 19

Troubleshooting ......... ...... ...... ..... ...... ...... ..... ...... ...... ..... ..... 21

Wiring Diagram....... ...... ...... ..... ...... ...... ..... ...... ...... ..... ...... .. 22

Diagnostic Setup...... ...... ...... ..... ...... ...... ...... ..... ...... ...... ..... . 23

Periodic Safety Check... ...... ..... ...... ...... ..... ...... ...... ..... ...... .. 25

Emissions Guidance Table ................................................ 26

Immunity Guidance Table .................................................. 27

Immunity Guidance Table ................................................. 28

Separation Guidance Table .............................................. 29

Warranty...... ..... ...... ...... ..... ...... ...... ..... ...... ...... ...... ..... ...... .. 3

CLEMENTS

CLEMENTSCLEMENTS

CLEMENTS

4 Description

Description

The Clements HiFlo2 High Suction Pump is a mobile unit designed

to suit the needs of hospitals, doctors’ surgeries and paramedics in

providing a strong source of suction for use in indoor environments

where mains power is available.

Identification

SUC84602 HiFlo2 High Vacuum / High Flow Mobile Suction Pump

Intended Use

To provide a continuous vacuum source, within the stated operating

vacuum range, for the aspiration of fluids and particulate matter in

medical procedures carried out by clinically trained and authorized

personnel.

Contraindications

Before using the HiFlo2, consult the instructions for use.

Failure to follow the instructions in this manual could cause harm.

Do not use the HiFlo2 for thoracic or low vacuum drainage.

Do not use the HiFlo2 for suctioning of explosive, corrosive or easily

flammable fluids.

HiFlo2 is not suitable for M I. Do not place in M I environments.

Pump Classifications

GMDN 63642

GMDN Term Surgical sucon pump

GMDN Synonym Aspirator

Device Class

Typology (Regula ion EU 2017/745)

Medical Device Class IIa

Electrical Protecon Class

Protecon Type B Applied Part

Sterilisaon Not supplied in sterile state

Anaesthec Rang NOT Category AP

NOT Category APG

Operaon Mode Connuous operaon

SO 10079-1 Designaon High Vacuum / High Flow

CLEMENTS

CLEMENTSCLEMENTS

CLEMENTS

5

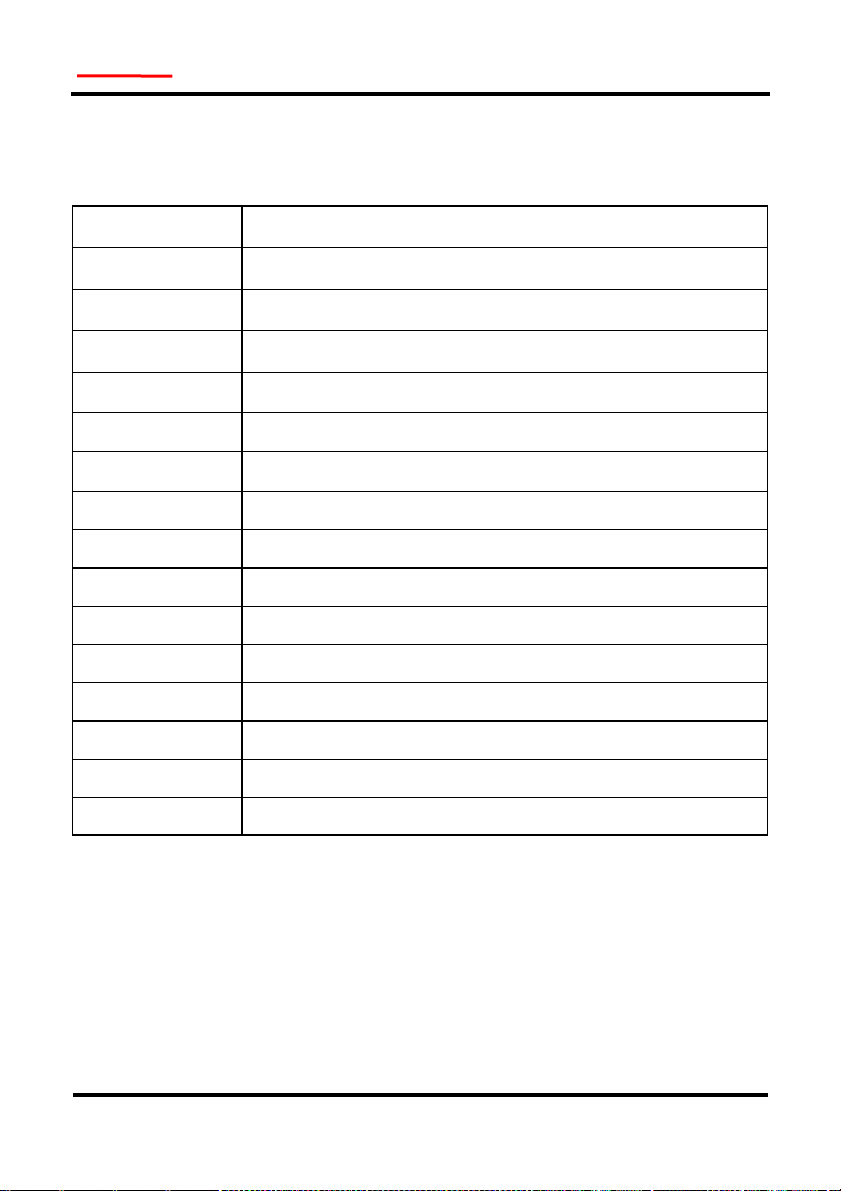

Specifications

Specifications

Maximum Vacuum -90 kPa [-675 mmHg]

Maximum Flow 80 L/min ( hrough jar) 90 L/min (free air)

Mains Power

Requiremen

220 - 240 V 50/60 Hz 385 VA

Pump Pis on ype

Mo or PSC AC mo or

Fil er Disposable hydrophobic and bac erial fil er

BFE 99.9999%, VFE 0.027 micron

Collec ion Con ainer 2x 2 li re au oclavable, reusable jar

Op ional 5 li re au oclavable, reusable jar

Op ional 2 li re disposable liner jar

Op ional 3 li re disposable liner jar

Overfill Pro ec ion Floa valve mechanism in ex ernal rap jar

Vacuum Con rol Needle valve

Gauge Bourdon ube ype. Dual scale. CL 2.5

Gauge Range 0 o -100 kPa gradua ed a 5 kPa

0 o -760 mmHg gradua ed a 50 mmHg

Weigh 16.5 kg

Dimensions 460W x 850H x 420D mm

S andard

Condi ions

25 °C, Sea level, 100 kPa

Packed Dimensions 500W x 910H x 500D mm

Packed Weigh 22 kg

Fuse F4A L 250V

CLEMENTS

CLEMENTSCLEMENTS

CLEMENTS

6 Environmental Conditions

Package Contents

The Clements HiFlo2 package contains:

• HiFlo2 mobile suction pump

• 2 x 2 litre reusable collection jar with lid assembly

• External trap jar

• Silicone 8 x 14 mm medical suction tubing

1.5m x1, 0.34m x2

• 2-Pin AU plug to IEC 320 power lead

• Disposable antibacterial/hydrophobic filter

• Stepped conical tubing connector

Environmental Conditions

Environmental conditions for operation, transportation and

storage are shown in the following table. In addition, for

vehicular transportation, the unit should be kept upright.

State Parameter Minimum Maximum

Opera ing Tempera ure 5 ºC 35 ºC

Humidi y 30% RH 75% RH

Barome ric Pressure 800 hPa 1060 hPa

Tempera ure -40 ºC 70 ºC

Humidi y 10% RH 100% RH

Barome ric Pressure 500 hPa 1060 hPa

Transpor and S orage

Al i ude 0 m 2000 m

CLEMENTS

CLEMENTSCLEMENTS

CLEMENTS

Symbols

General warning

Consul user manual

Type B Applied Par (suc ion cannula)

Insula ion Class II (double insula ion)

Hz Mains power frequency

~Al erna ing curren

On / Off

CE Mark in conformi y wi h Regula ion EU 2017/745

Manufac urer

REF Model / Reference Number

LOT Lo / Ba ch Number

Consul user manual before use

Medical Device

Symbols

0123

CLEMENTS

CLEMENTSCLEMENTS

CLEMENTS

8 Symbols

SN Serial Number

Fragile

Rela ive Humidi y Range

Keep Cool / Keep ou of direc sunligh

Tempera ure Range

A mospheric Pressure Range

Fuse

C-Tick Mark

Dispose of elec rical produc according o requiremen s

of WEEE direc ive

Symbols

CLEMENTS

CLEMENTSCLEMENTS

CLEMENTS

9

Cautions

Usage

1. Use only for the specified Intended Use.

2. Only suitably trained and authorised personnel may operate.

3. Keep out of reach of children or non-competent persons.

4. Do not use near flammable substances such as oxygen or

anaesthetic gases.

Fluids

1. Keep device clear of water and other fluids. Do not handle pump

with wet hands.

2. Handle full containers very carefully when transferring to

disposal area, observing local protocols.

Electrical

1. Use only the supplied power cord.

2. Confirm that electrical rating of rating label matches that of the

mains power.

3. Avoid the use of power boards and extensions.

4. Maintain clear access to the mains power outlet to facilitate

disconnection.

5. Place pump clear of patient and other electronic equipment.

6. When not in use, disconnect pump from power supply.

7. Do not pull cable to remove plug from mains power outlet.

General

1. Check the pump and fittings for damage before each use.

2. Do not use without the bacteria/hydrophobic filter correctly

fitted.

3. Switch off pump immediately if overflow float valve is actuated.

4. After use, clean and store away from heat, dust and sunlight.

Repair

1. efer all service to suitably trained technicians.

2. Use only original spare parts and accessories.

3. No modifications are permitted.

Cautions

CLEMENTS

CLEMENTSCLEMENTS

CLEMENTS

10

Important Safety Rules

1. Check the condition of the unit before each use. The surface of

the unit should carefully inspected for visual damage. Check the

mains cable and do not connect to power if damage is apparent.

2. Before connecting the appliance always check that the electric

data indicated on the data label and the type of plug used,

correspond to those of the mains electricity to which it’s to be

connected.

3. espect the safety regulations indicated for electrical appliances

and particularly:

• Use original components and accessories provided by the

manufacturer to guarantee the highest efficiency and safety

of the device.

• The device can be used only with the bacteriological filter.

• Never immerge the appliance into water.

• Position the device on stable and flat surfaces in a way that

the air inlets on the back aren’t obstructed.

• To avoid incidents, do not place the aspirator on unstable

surfaces, which may cause it to accidentally fall and lead to a

malfunction and/or breakage. Should there be signs of

damage to the plastic parts, which may expose inner parts of

the energised device, do not connect the plug to the electrical

socket. Do not attempt to make the device work before it has

been thoroughly checked by qualified personnel.

• Don’t use in the presence of inflammable substances such as

anaesthetic, oxygen or nitrous oxide.

• Don’t touch the device with wet hands and always prevent

the appliance coming into contact with liquids.

• Don’t leave the appliance connected to the power supply

socket when not in use.

• Don’t pull the power supply cable to disconnect the plug

remove the plug from the mains socket correctly.

• Store and use the device in places protected against the

weather and far from any sources of heat. After each use, it is

recommended to store the device in its own box away from

dust and sunlight.

• In general, it is inadvisable to use single or multiple adapters

and/or extensions. Should their use be necessary, you must

use ones that are in compliance with safety regulations,

however, taking care not to exceed the maximum power

CLEMENTS

CLEMENTSCLEMENTS

CLEMENTS

11

supply tolerated, which is indicated on the adapters and

extensions.

4. For repairs, exclusively contact technical service and request the

use of original spare parts. Failure to comply with the above can

jeopardise the safety of the device.

5. Use only for the purpose intended. Don’t use for anything other

than the use defined by the manufacturer.

The manufacturer will not be responsible for damage due to

improper use or connection to an electrical system not complying

with current regulation.

6. Instrument and accessory disposal must be done according to

current regulations in the country of use.

7. WA NING: Do not change this equipment without the permission

of the manufacturer. None of electric or mechanical parts have

been designed to be repaired by customers or end-users. Don’t

open the device, do not mishandle the electric / mechanical parts.

Always contact technical assistance

8. Using the device in environmental conditions different than those

indicated in this manual may harm seriously the safety and the

technical characteristics of the same.

9. The medical device is in contact with the patient by means of a

disposable probe (not supplied with the device). If this device must

be used with a specific suction probe, the end user is responsible

for making sure it complies with the ISO 10993-1 rule.

10. The product and its parts are biocompatible in accordance with

the requirements of regulation EN 60601-1.

11. Operation of the device is very simple and therefore no further

explanations are required other than those indicated in the

following user manual.

12. The medical device requires special precautions regarding

electromagnetic compatibility and must be installed and used

in accordance with the information provided with the

accompanying documents. The HiFlo2 Max device must be

installed and used away from mobile and portable F

communication devices (mobile phones, transceivers, etc.) that

may interference with the said device.

CLEMENTS

CLEMENTSCLEMENTS

CLEMENTS

12

13. Any serious incident occurrence in relation to the device

should be reported to the manufacturer and the competent

authority in your country/area. If you have no contact

information of such authority, please contact the

manufacturer or distributor whose contact information is

indicated in this instruction manual.

Under certain failure conditions, the temperature of the

casing (HiFlo2) may become hot and there may be a risk

of burns if you touch those parts.

In any case, the temperatures do not exceed the limit of

105°C (ref. Interpretation Sheet IEC 60601-1 / ISH May

2013)

The manufacturer cannot be held liable for accidental or

indirect damages should the device be modified, repaired

without authorization or should any of its components be

damaged due to accident or misuse.

Any minimal modification / repair on the device voids the

warranty and does not guarantee the compliance with the

technical requirements provided by the egulation

2017/745 and its normatives

Connection Diagram

PATIENTVACUUMOUT IN

IN

Pump

Por

Bac eria /

Hydrophobic

Fil er

Trap Jar

Shu off

Valve

Collec ion

Jar

CLEMENTS

CLEMENTSCLEMENTS

CLEMENTS

13

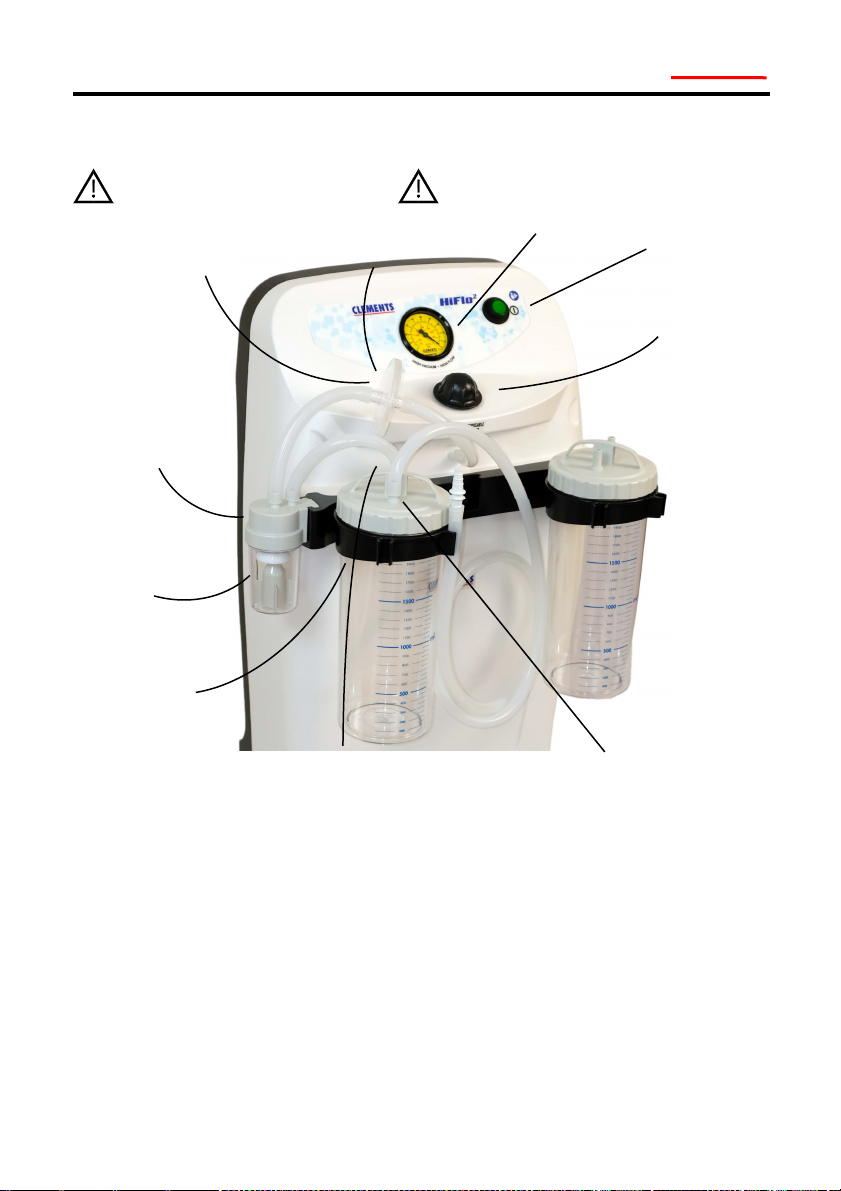

Operation

1. Place the pump on a flat stable horizontal surface.

2. Connect a short length of silicone tubing from the trap jar centre

port to the “IN” (or directional arrow symbol) side of the bacterial/

hydrophobic filter. Connect a short length of silicone tubing from

the other side of the filter to the pump port.

Connect a short length of silicone tubing from the trap jar

peripheral port to the “VACUUM” port of the collection jar.

3. Connect the long silicone tubing to the collection jar “PATIENT” port.

4. Connect supplied power cord to power socket at rear of pump.

Connect power cord to compatible mains outlet.

5. Press switch button to turn on pump. (Press again to turn off.)

Controls and Operation

Pump Controls

Trap Jar

Vacuum

Gauge

“VACUUM” por

(above floa valve)

“PATIENT” Por

Connec Pa ien

Tubing

Vacuum

Con rol

ON / OFF

Swi ch

Bac erial / Hydrophobic Fil er

» Mus ALWAYS be fi ed «

“IN” or Δ Side

of Fil er

Overflow floa

valve fi ed

inside jar

Overflow floa

valve fi ed

inside rap jar

CLEMENTS

CLEMENTSCLEMENTS

CLEMENTS

14 Suction Accessories

6. Occlude tubing and adjust vacuum control to the required

vacuum level. (Clockwise = increase)

Always reduce the vacuum level for paediatric and neonatal

patients.

7. Apply suction to patient with a compatible suction cannula

fitted to the patient tubing.

8. When finished, switch off pump by pressing switch.

Ensure that the mains power plug is accessible at all times when

pump is in use, in case a positive disconnection from the mains

power supply is required.

Suction Accessories

The device and its accessories are biocompatible in accordance with

EN 60601-1.

Suction Cannulae

Suction cannulae or suction probes for contact with the human body

should comply with ISO 10993-1 requirements for biocompatibility.

Collection Jar (Canister)

The mechanical strength of the reusable collection jar (canister) is

guaranteed for 30 cycles of cleaning and sterilization. Beyond this,

there may be signs of decay and replacement is recommended.

Silicone Tubing

The number of cleaning and sterilization cycles of the silicone tubing

is dependent on the actual usage. Tubing should be checked for

cracking and other visible signs of wear before re-use.

CLEMENTS

CLEMENTSCLEMENTS

CLEMENTS

15

Using FLOVAC Liners

1. Fit FLOVAC ring bracket to multipurpose rail.

2. Insert liner bag [1] into the matching size

support jar [2].

Press edge of lid firmly all around edge to

ensure seal.

3. Close the TANDEM inlet [3] with the attached

cap [4].

4. Fit jar assembly into FLOVAC ring bracket.

5. Press short side of yellow connector firmly into

matching yellow port [5] on the lid.

6. Using a short length of tubing connect the

yellow connector to centre port of the trap jar.

7. Connect patient tubing to white inlet elbow[7].

Connect patient tubing to suitable suction

cannula.

8. Follow steps in Operation section.

Using FLOVAC Disposable Liners

9

1

2

7

4

3

5

If fluid reaches the maximum level the hydrophobic filter in the

lid will operate to prevent further fluid flow. When this

happens switch off pump and replace liner.

Disposal

1. Switch off pump.

2. Disconnect tubing from jar.

3. emove the white elbow [7] and close the inlet port with

the cap [9] attached to lid.

4. Using the lid handle remove the liner [1] from the support

jar and dispose of liner according to hospital protocol.

5. etain support jar [2] for reuse.

Support Jar Cleaning

The reusable support jar may be cleaned either with water and

neutral detergents or autoclaved at 121°C for 15 minutes.

Do not use solvents or alcohol for cleaning and disinfection.

These may damage the support jar.

The mechanical integrity of the support jar is guaranteed for

30 cleaning cycles under the specified conditions.

After this, the jar may show signs of wear and replacement is

recommended.

CLEMENTS

CLEMENTSCLEMENTS

CLEMENTS

16 Cleaning

Cleaning

After Each Operation

Empty Collection Jar

The contents of the collection jars, trap jars, suction tubing and

bacteria filter, may contain biohazard wastes. Handle using safe

handling procedures, which may include the use of rubber gloves,

clothing and eye protection, and dispose of according to local

protocols for biohazardous materials.

To empty collection jar disconnect tubing and remove jar from

pump. emove lid from jar and dispose of aspirated fluid

according to local protocols for potentially biohazardous waste.

Dispose of single use suction cannula according to local

protocols for potentially biohazardous waste.

Clean

Housing

Wipe clean with a damp soapy cloth. Do not immerse or allow

liquid to enter the housing. Do not use abrasive cleaning agents.

Accessories

Before using the device, the manufacturer advises you to clean or

sterilize the accessories.

The filter must not be cleaned or autoclaved.

ear rubber gloves, apron and eye or face protection

to avoid contact with contaminated substances.

Collection Jars

Separate all parts of the lid. Unlock bayonet on float cage by

rotating cage clockwise. Disconnect float cage and float from lid

(bung) and separate seal from lid (bung).

Wash each part of the jar under cold running water and then

clean every part in hot water (temperature not exceeding 60°C).

Once again, carefully wash each part using, if necessary, a non-

abrasive brush to remove any deposits.

CLEMENTS

CLEMENTSCLEMENTS

CLEMENTS

1

inse with hot running water and dry all parts with a soft non-

abrasive cloth. It is possible to wash with commercial disinfectants by

carefully following the instructions and dilution values supplied by

the manufacturer. Do not use phenolic solutions as disinfecting

agents in polycarbonate jars.

After cleaning, leave the parts to dry in an open, clean environment.

Suction Tubing

The silicone aspiration tubes and the conical fitting may be carefully

washed in hot water (temperature must not exceed 60°C). After clean-

ing, leave the parts to dry in an open, clean environment.

Suction Tubing may be sterilised with sterilants determined by local

protocols and compatible with silicone tubing. Suction tubing may be

autoclaved to a maximum of 121°C for 15 minutes. At higher temper-

atures the suction tubing will discolour and lose shape.

Autoclaving

Separate the jar and lid items as detailed in the cleaning section

above.

The following items may be autoclaved in a single steam sterilisation

cycle at 121°C and 1 bar for 15 minutes:

• Jar - position jar upside down in autoclave

• Lid - position lid upside down in autoclave

• Silicone tubing

• Conical connector

• Trap jar - position jar upside down in autoclave

Re-Assembly

Place float valve into overflow cage with the seal facing up. Connect

overflow cage to lid and lock bayonet on float cage by rotating cage

anticlockwise. Place lid seal carefully into groove in lid. Fit lid to jar

and lock securely into place by engaging bayonet and rotating lid

firmly clockwise.

CLEMENTS

CLEMENTSCLEMENTS

CLEMENTS

18 Waste Disposal

Check Bacteria Filter

The bacterial/hydrophobic filter is an important device to help protect the pump

and environment from moisture and bacteria from the patient. It is

recommended that the filter be changed every month or when damp or

discoloured. Do not clean, sterilise or disassemble filter.

Change filter after every use when used on infectious patients

or patients whose infection status is unknown.

After Every 100 Hours or 2 Months of Operation

• Check all suction tubing and replace if it is perished, soft or

discoloured.

• Check the seal ring on the lid and replace if hard, cracked or

perished. Check the fit of the lid in the collection jar (canister).

• Check the overflow cut off valve seal and replace if perished or

damaged.

Waste Materials

The contents of the collection jars, trap jars, suction tubing and

bacteria filter may contain biohazard wastes. Handle using safe

handling procedures, which may include the use of rubber gloves and

eye protection, and dispose of according to local protocols for

biohazard materials.

Recycling

At the end of their service life, the pump and accessories should be

dismantled if necessary, and disposed of according to the WEEE

directive.

CLEMENTS

CLEMENTSCLEMENTS

CLEMENTS

19

Spare Parts

Spare Parts

SUC81030009 Kit, Seal, Lid, 1L/2L Reusable Jar (Pack 2)

SUC81030010 Kit, Lid Assembly for 1L/2L Reusable Jar (Pack 2)

SUC81030034 Kit, Float and Cage for 1L Reusable Jar (Pack 2)

SUC81030042 Kit, 2L Reusable Collecon Jar (Pack 1)

SUC84500013 Jar, Support for FLOVAC 3L Disposable Liner

SUC84500112 Kit, Liner Connect Nipple (Pack 5)

SUC84500123 Kit, Disposable 3L Liner (Pack 50)

SUC84600120 Jar, Trap, 220mL for Mulpurpose Rail

SUC84600122 Jar, Sucon, Reusable, 2L, Complete

SUC84600125 Jar, Sucon, Reusable, 5L, Complete

SUC84600135 Jar, Sucon, Reusable, 5L, Jar Only

SUC84600145 Lid, Assembly with Shutoff Valve and Seal for 5L Reusable

Jar

SUC84600155 Seal, Lid for 5L Reusable Jar.

SUC84600171 Silicone Tubing Set for HiFlo2 (1.5m x1, 0.34m x2, Conical

Joiner)

SUC84600176 Filter, Hydrophobic/Anbacterial for HiFlo2

SUC84600100 Rail, Mulpurpose, 5-Posion

CLEMENTS

CLEMENTSCLEMENTS

CLEMENTS

20 Spare Parts

Spare Parts

SUC84600101 Hook, RH for Mulpurpose Rail

SUC84600102 Hook, LH for Mulpurpose Rail

SUC84600103 Cap, for Mulpurpose Rail

SUC84600110 Bracket, Ring for 2L Reusable Jar

SUC84600111 Bracket, Ring for 5L Reusable Jar

SUC84600112 Bracket, Ring for 2L/3L FLOVAC Jar

SUC84600113 Bracket, Ring for Catheter Holder

SUC84600114 Catheter Holder

SUC84600160 Rail, Stainless Steel Standard Medical, 30 x 10

SUC84600201 Motor/Pump for HiFlo2, 200-240V 50/60Hz

SUC84600202 Kit, Piston, Rings for HiFlo2 Pump

SUC84600203 Vacuum Controller + Black Knob for HiFlo2 Pump

SUC84600205 Fuse, F4A L 250V for HiFlo2 Pump

SUC84600206 Gauge, -100 kPa, for HiFlo2 Pump

SUC84602008 User Manual for HiFlo2 Mobile Sucon Pump

SUC84602214 Switch, lluminated, Main for HiFlo2 Pump

Table of contents

Other Clements Water Pump manuals

Popular Water Pump manuals by other brands

Jebao

Jebao GS WP950 owner's manual

Marco

Marco 164 624 13 - UP6/E-DX 24V Instructions for use

hawa

hawa 2612-7500-00-00 operating instructions

Pentair

Pentair MYERS B12-3036 Installation and service manual

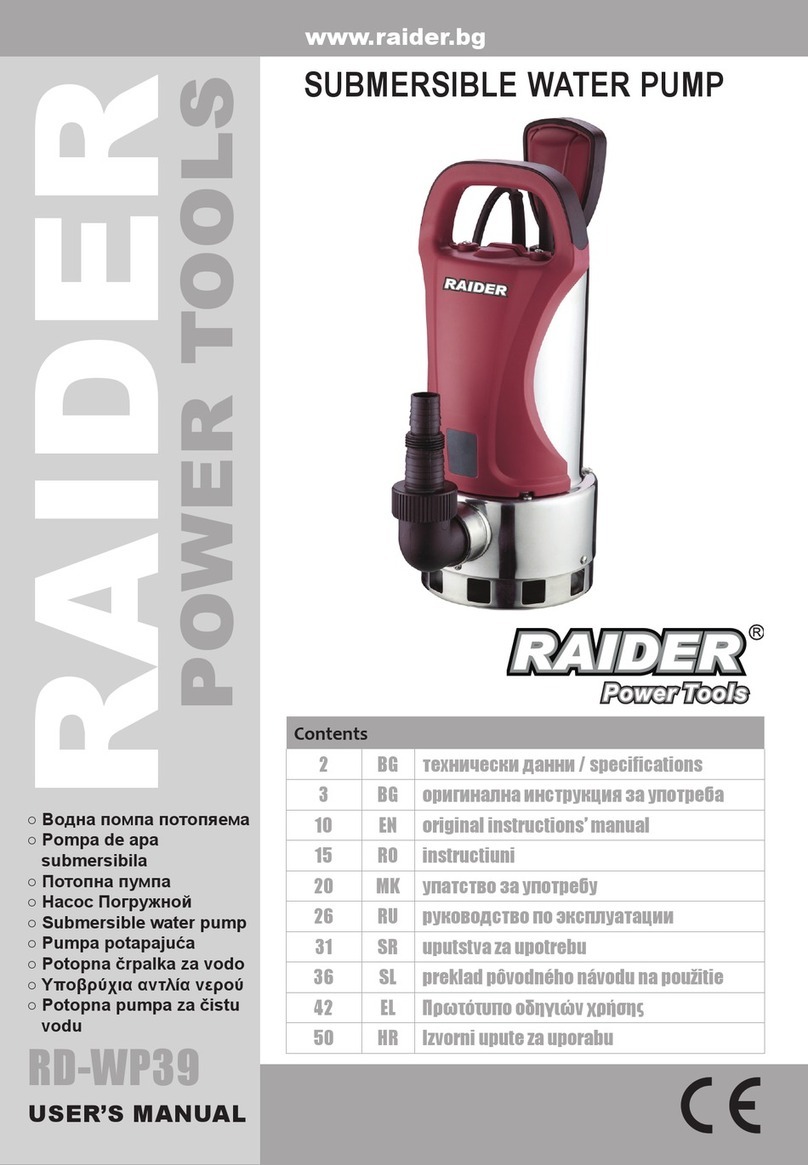

Raider

Raider RD-WP39 Original instruction manual

Profi-pumpe

Profi-pumpe INVERT-TECH 6 10 Series operating instructions