TM-268 819 Page 2 Belt Drive Generator

STEAM AND HOT COOLANT can burn.

DIf possible, check coolant level when engine is

cold to avoid scalding.

DAlways check coolant level at overflow tank, if

present on unit, instead of radiator.

DIf the engine is warm, checking is needed, and there is no overflow

tank, follow the next two statements.

DWear safety glasses and gloves and put a rag over radiator cap.

DTurn cap slightly and let pressure escape slowly before completely

removingcap.

ELECTRIC AND MAGNETIC FIELDS (EMF)

can affect Implanted Medical Devices.

DWearers of Pacemakers and other Implanted

MedicalDevices should keep away from serv-

icing areas until consulting their doctor and the

device manufacturer.

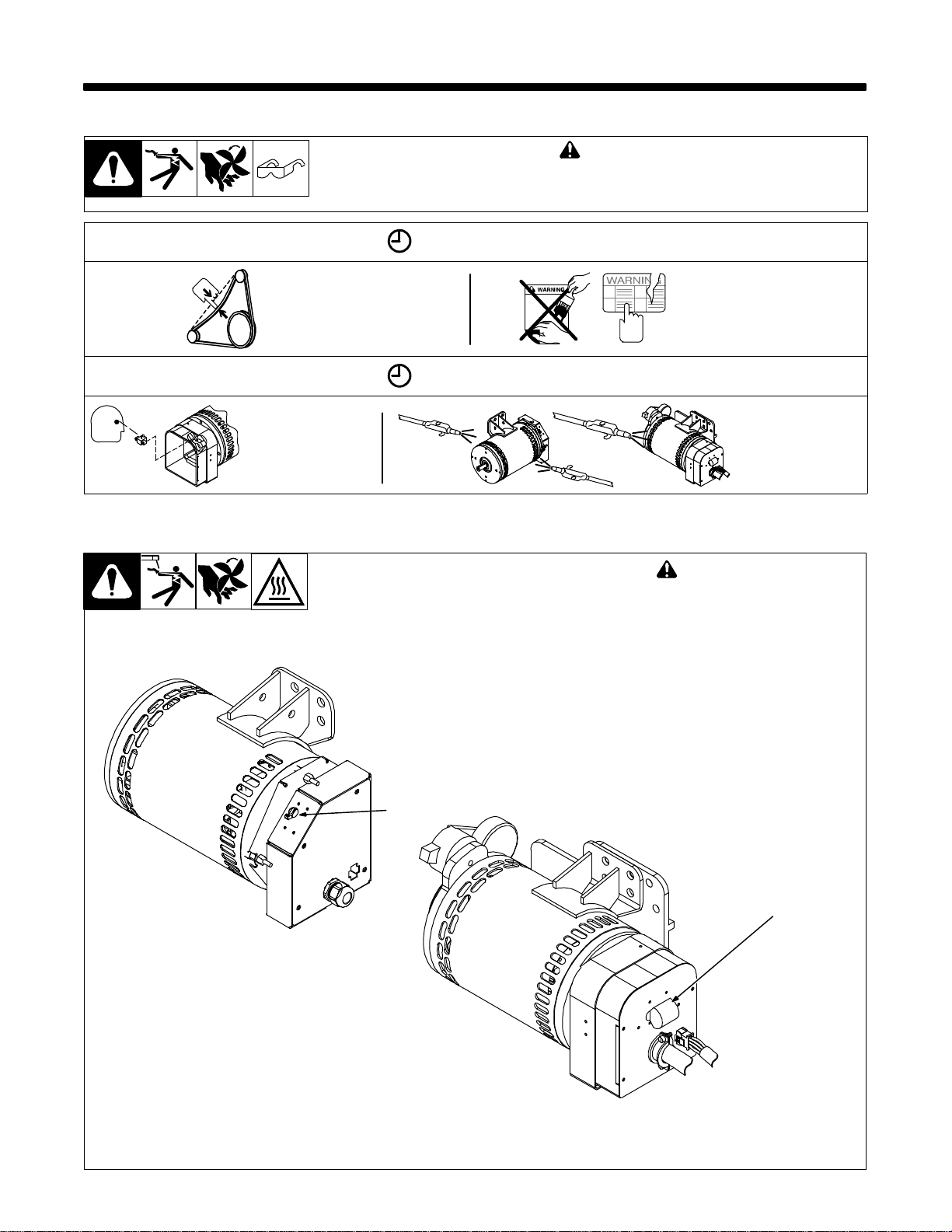

FALLING EQUIPMENT can injure.

DUse lifting eye to lift unit and properly installed

accessories only, NOT gas cylinders. Do not

exceed maximum lift eye weight rating (see

Specifications).

DUse equipment of adequate capacity to lift and support unit.

DIf using lift forks to move unit, be sure forks are long enough to

extend beyond opposite side of unit.

DFollowthe guidelines in the Applications Manual for the Revised

NIOSH Lifting Equation (Publication No. 94−110) when manu-

ally lifting heavy parts or equipment.

HOT PARTS can burn.

DDo not touch hot engine parts bare-handed.

DAllow cooling period before working on

equipment.

DTo handle hot parts, use proper tools and/or

wear heavy, insulated welding gloves and

clothingto prevent burns.

TILTING OR TIPPING can injure.

DDo not put any body part under unit while lifting.

DAlways use proper equipment (hoists, slings,

chains, blocks, etc.) of adequate capacity to lift

and support components (stator, rotor, engine,

etc.) as needed during job.

PINCH POINTS can injure.

DBe careful when working on stator and rotor assemblies.

EXPLODING PARTS can injure.

DFailedparts can explode or cause other parts to

explodewhen power is applied to inverters.

DAlways wear a face shield and long sleeves

when servicing inverters.

H.F. RADIATION can cause interference.

DHigh-frequency (H.F.) can interfere with radio

navigation, safety services, computers, and

communicationsequipment.

DHave only qualified persons familiar with elec-

tronic equipment perform this installation.

DThe user is responsible for having a qualified electrician promptly

correct any interference problem resulting from the installation.

DIf notified by the FCC about interference, stop using the equipment

at once.

DHave the installation regularly checked and maintained.

DKeep high-frequency source doors and panels tightly shut, keep

spark gaps at correct setting, and use grounding and shielding to

minimize the possibility of interference.

OVERUSE can cause OVERHEATING.

DAllow cooling period; follow rated duty cycle.

DReduce current or reduce duty cycle before

startingto weld again.

DDo not block or filter airflow to unit.

SHOCK HAZARD from testing.

DStopengine or turn Off welding power source (if

applicable)before making or changing meter

lead connections.

DUse at least one meter lead that has a self-

retainingspring clip such as an alligator clip.

DRead instructions for test equipment.

READ INSTRUCTIONS.

DUse Testing Booklet (Part No. 150 853) when

servicing this unit.

DConsultthe Owner’s Manual for welding safety

precautions.

DUse only genuine replacement parts from the manufacturer.

DReadand follow all labels and the TechnicalManual carefully be-

fore installing, operating, or servicing unit. Read the safety in-

formationat the beginning of the manual and in each section.

DPerform maintenance and service according to the Technical

Manual,industry standards, and national, state, and local codes.

DReinstallinjectors and bleed air from fuel system according to

enginemanual.

HYDRAULIC EQUIPMENT can injur

or kill.

DBefore working on hydraulic system, turn of

and lockout/tagout unit, release pressure, and

be sure hydraulic pressure cannot be accident-

ally applied.

DDo not work on hydraulic system with unit running unless you are a

qualifiedperson and following the manufacturer’s instructions.

DDo not modify or alter hydraulic pump or manufacturer-supplied

equipment. Do not disconnect, disable, or override any safety

equipmentin the hydraulic system.

DKeepaway from potential pinch points or crush points created by

equipment connected to the hydraulic system.

DDo not work under or around any equipment that is supported only

by hydraulic pressure. Properly support equipment by mechanical

means.

HYDRAULIC FLUID can injure or kill

DBeforeworking on hydraulic system, turn off a

lockout/tagoutunit, release pressure, and be su

hydraulicpressure cannot be accidentally applie

DRelieve pressure before disconnecting or co

nectinghydraulic lines.

DCheck hydraulic system components and all co

nections and hoses for damage, leaks, and we

before operating unit.

DWear protective equipment such as safe

glasses, leather gloves, heavy shirt and trouse

high shoes, and a cap when working on hydrau

system.

DUse a piece of paper or cardboard to search f

leaks−−never use bare hands. Do not use equ

mentif leaks are found.