milleteknik EN54 User manual

EN54

EN54 24V 15A 1U, EN54 24V 25A 2U, EN54 48V 7A 1U, EN54 48V 13A 2U

EN

350-240

Publication date 2023-11-09

Table of Contents

1. Revisions and the edition of this document .................................................................................. 4

1.1. Installation video ............................................................................................................. 4

2. Component overviews ................................................................................................................ 5

2.1. Component overview ....................................................................................................... 5

3. Enclosures ................................................................................................................................ 6

3.1. Installation in 19" rack ...................................................................................................... 6

3.2. Installation of battery shelf ............................................................................................... 7

3.3. Mounting ........................................................................................................................ 7

4. Connect mains ........................................................................................................................... 7

4.1. Connect mains 230 V AC ................................................................................................. 8

4.2. Temperature sensor ......................................................................................................... 8

4.3. Alarm ............................................................................................................................. 9

4.4. Alarm cable for battery fuse monitoring ............................................................................. 9

4.5. Communication - optional ................................................................................................ 9

4.6. Maximum wire resistance ................................................................................................. 9

4.6.1. Facts about ILAST ................................................................................................ 9

4.7. Connection of batteries in battery shelf ............................................................................. 9

5. Set battery capacity ................................................................................................................. 10

6. How to start the device ............................................................................................................. 10

7. Commissioning ........................................................................................................................ 11

8. Communication - optional ......................................................................................................... 11

9. List of settings via multi-selector wheel ...................................................................................... 11

10. Maintenance .......................................................................................................................... 12

11. Maintenance schedule batteries .............................................................................................. 13

12. Product sheet - technical data ................................................................................................. 14

12.1. Technical specifications: EN54-4 Certified / SBF110:8 Approved battery backup ............. 14

12.1.1. Name, article number, e-number and certificate number ...................................... 15

12.1.2. About EN54 1U and EN54 2U ........................................................................... 15

12.1.3. Area of use ...................................................................................................... 15

12.1.4. Fixed installation ............................................................................................... 15

12.2. Regulations and certifications ....................................................................................... 16

12.2.1. Standards that product (s) meet and are approved for ......................................... 16

12.2.2. Requirements that the product meets ................................................................. 16

12.3. Battery combinations 1U and 2U .................................................................................. 16

12.4. Reserve operating times, power outlet and load output current ....................................... 17

12.4.1. Cargo current ................................................................................................... 17

12.4.2. Reserve operating times for different alarm classes - overview ............................ 19

12.5. Internal resistance 1U and 2U ...................................................................................... 19

12.6. Circuit boards - Technical data ..................................................................................... 19

12.6.1. Technical data - 1HE (motherboard) ................................................................... 19

What is shown on the display - 1HE ...................................................................... 21

12.7. Power supply .............................................................................................................. 21

12.7.1. Power supply - Technical Data HRP-300-24 ....................................................... 21

12.7.2. Power supply - Technical Data HRP-600-24 ....................................................... 22

12.7.3. Power supply - Technical Data HRP-300-24 ....................................................... 22

12.7.4. Power supply - Technical Data HRP-600-24 ....................................................... 23

12.8. Technical data enclosures ............................................................................................ 24

12.8.1. Technical data 1U ............................................................................................. 24

12.8.2. Technical data 2U ............................................................................................. 24

12.9. Link to the latest information ......................................................................................... 24

12.10. Warranty, support, country of manufacture and country of origin ................................... 24

12.10.1. Warranty 5 years ............................................................................................ 24

12.10.2. Manufacturer support ...................................................................................... 25

3

12.10.3. Support .......................................................................................................... 25

Spare parts ......................................................................................................... 25

Support after the warranty period .......................................................................... 25

Questions about product performance? ................................................................. 25

12.10.4. Contact us ...................................................................................................... 25

12.10.5. Country of manufacture ................................................................................... 25

12.10.6. Designed and produced by: Milleteknik AB ....................................................... 25

12.11. Batteries - recommended, not included ....................................................................... 26

12.11.1. Batteries are not included they are sold separately ............................................ 26

12.11.2. Certified with battery type ................................................................................ 26

12.11.3. 20 Ah, 12 V AGM battery ................................................................................. 26

12.11.4. 28 Ah, 12 V AGM battery ................................................................................. 26

12.11.5. 45 Ah, 12 V AGM battery ................................................................................. 26

12.11.6. 75 Ah, 12 V AGM battery ................................................................................. 27

12.11.7. 100 Ah, 12 V AGM battery ............................................................................... 27

12.11.8. 55 Ah, 12 V AGM battery ................................................................................. 27

12.11.9. 100 Ah, 12 V AGM battery ............................................................................... 28

12.11.10. MT114-12V125-FT * ..................................................................................... 28

12.11.11. 150 Ah, 12 V AGM battery ............................................................................. 28

12.11.12. Reserve operating times for different alarm classes - overview ......................... 28

13. Appendix: Mount EN-54 Cover ................................................................................................ 30

1. REVISIONS AND THE EDITION OF THIS DOCUMENT

The current and most recently published edition of this document is available at www.milleteknik.com.

Audit log can be requested, see contact information for address or e-mail address.

The validity of this document can not be guaranteed, as new editions are published without prior notice.

User manual in original language: Swedish.

Instructions for use, technical data and translations thereof may contain errors. It is always the responsi-

bility of the installer to install the product in a safe manner.

1.1. Installation video

https://www.milleteknik.se/en54-1u-2u/

4

READ THIS FIRST!

If possible, leave 100 mm of free space.

The system is intended for use in a controlled indoor environment.

Only authorized persons should install and maintain the system.

It is the installer's responsibility to ensure that the system is suitable for its intended

use.

Documents accompanying the system must be kept in or in its immediate vicinity.

Ventilation should not be covered. Mains voltage should be disconnected during instal-

lation.

All information subject to change.

Upon installation of this product, the installer acknowledges and accepts the limitations

of this product as described in this manual.

Instructions original language: Swedish.

1. About translation of this document

User manual and other documents are in the original language in Swedish. Other

languages are machine translated and not reviewed, errors may occur.

2. COMPONENT OVERVIEWS

2.1. Component overview

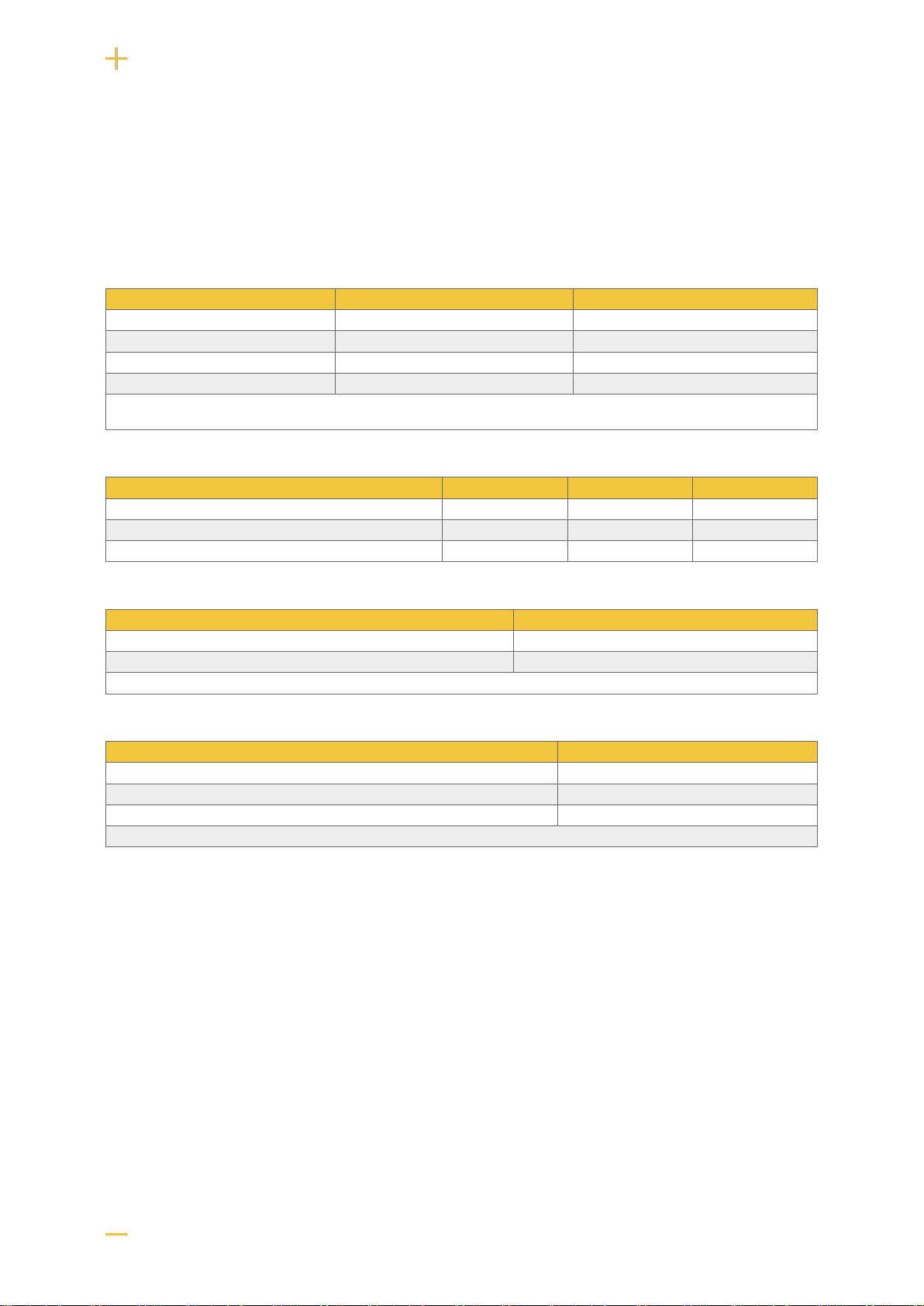

Table 1. Component overview

Letter Explanation

1 Motherboard.

2 Lockable door.

3 Battery fuse

4 Load fuses

5 LED

5

Table 2. Component overview, back

No . Explanation Comment

1 Connection of battery cables -

2 Load output 2 The fuse on the front is the one closest to the display.

3 Load output 1 Fuse on the front is the one closest to the corner.

4 Temperature sensor -

5 Mains connection 230 V.

6.1 Relay 1 Mains failure, NO/CO/NC.

6.1 Relay 2 PSU over/under voltage, aged battery, battery not connected, broken fuse, low battery

voltage in battery operation, NO/CO/NC.

6.3 Relay 3 Low system voltage, NO/CO/NC.

3. ENCLOSURES

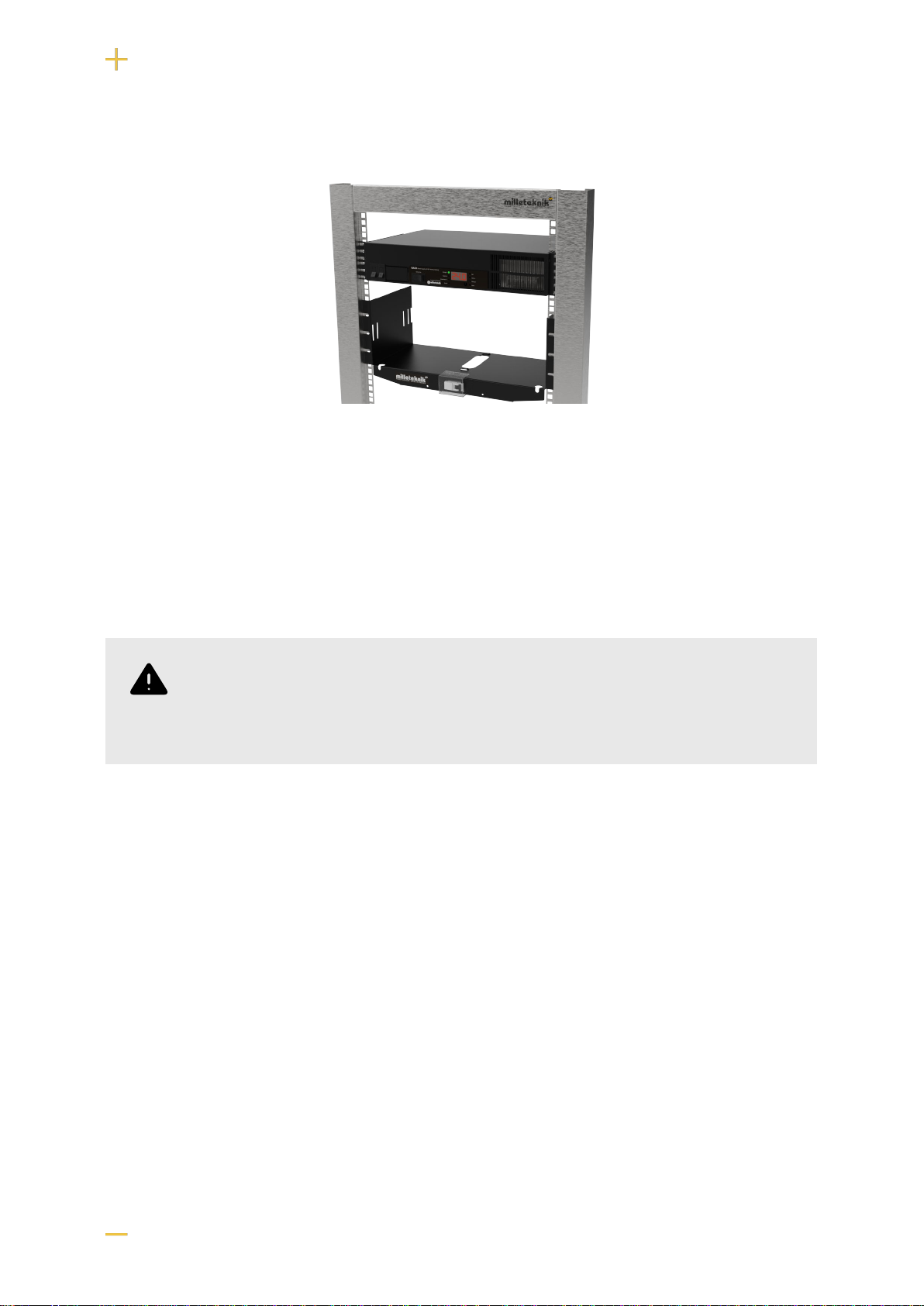

3.1. Installation in 19" rack

No . Explanation

1 The unit is mounted with screws into a 19" rack.

NOTE

Installation of the RACK EN54-COVER can be done before or after the unit is installed.

6

3.2. Installation of battery shelf

The battery shelf must be mounted in a 19" rack. Use the appropriate screw for the rack to attach the

shelf.

Attach the shelf in at least two places on each side. Use as many screws as you need to keep the

batteries and the shelf secure and stable.

In order for the device to function, batteries must be connected. These must be placed on a battery

shelf that comes with prepared cabling. The battery shelf must be mounted in the rack before batteries

are placed.

WARNING

The unit must be installed in a locked and protected indoor environment.

Risk of access to battery terminals. terminal protection must cover battery poles.

3.3. Mounting

4. CONNECT MAINS

Pull wiring through the cable entry on the cabinet.

7

Table 3. Back with shelter

No Explanation

1 Cable entries for alarm cables and load cables.

2 Strain relief for mains cable.

3 Shelter in powder-coated sheet metal.

4 Temperature sensor.

5 Connection for mains cable.

6.1-6.3 Relay 1-3, see component overview [6].

7.2 Load output 2.

7.1 Load output 1.

8 Forklift glove for connecting battery cables.

IMPORTANT

To protect the outputs on the back, a protective housing (1) in sheet metal is included.

If the facility is to be EN 54-4 or SBF 110:8 approved, the protective housing must be

mounted.

4.1. Connect mains 230 V AC

Connection of 230 V mains cabling to the unit takes place through the device connector on the back

of the unit. Connect the power supply to the mains via easily accessible isolation switch and suitable

ground fault protection (which is part of the building's existing wiring).

4.2. Temperature sensor

Temperature sensor for measuring battery temperature, place sensor between batteries.

The device has an internal temperature sensor and an external temperature sensor to measure internal

and ambient temperature.

8

4.3. Alarm

See table 6.1-6.3 [6]

4.4. Alarm cable for battery fuse monitoring

Alarm cable for battery fuse monitoring.

4.5. Communication - optional

Connection to communication (via RS-485) can take place during customer customization.

4.6. Maximum wire resistance

The voltage at the furthest load point must not be lower than the requirements of the connected load.

Lowest voltage is given when batteries are almost discharged (21 V / 42 V) together with voltage drop in

wiring. Ensure that the load can handle the lowest voltage with voltage drop in cabling.

4.6.1. Facts about ILAST

ILAST is the sum of the connected loads. The cable resistance (RKABEL) is the sum of the cable

resistance in both conductors x the cable length.

Minimum load voltage in battery operation taking into account voltage drop in cables = VUT(MIN) -

(ILAST x RKABEL). VUT(MIN) is the limit for deep discharge (21 V / 42 V) when the batteries are

empty.

The table takes into account to and from conductors, i.e. the actual distance in meters must be used.

RKABEL Ω/ m

1.5 mm20.024 Ω/ m

2.5 mm20.014 Ω/ m

4 mm20.009 Ω/ m

6 mm20.006 Ω/ m

10 mm20.0035 Ω/ m

16 mm20.0022 Ω/ m

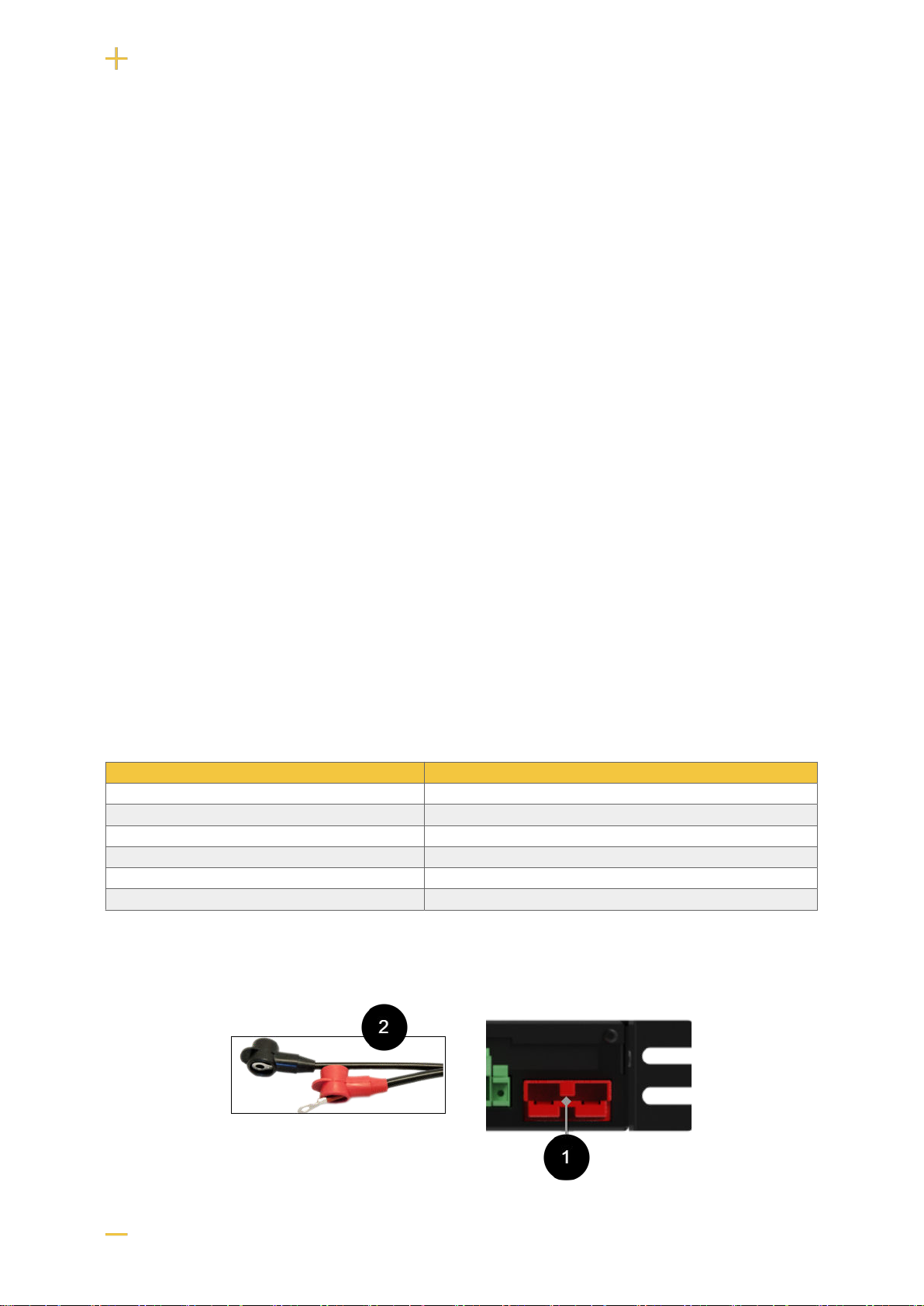

4.7. Connection of batteries in battery shelf

9

Use the included cabling to connect the batteries. Be careful not to short the terminals of the batteries.

First connect wiring in batteries, (2). Cabling must have rubber pole protection that covers the battery

pole. Then connect battery connector to the battery backup, (1).

5. SET BATTERY CAPACITY

Table 4. Set battery capacity

No Explanation

1 Set the steering wheel so that V lights up green.

2 Press and hold the multi selector for three seconds until C00 appears on the display.

Turn the multi-selection dial until C01 is displayed and press the multi-selection dial (a light push) to select the battery

capacity.

To accept the setting, press and hold the button for three seconds.

• Factory default setting is 2 x 20 Ah.

• Turn to C00 and press the button once to return to the regular menu.

NOTE

The device retains settings even if power is completely cut to the device. You therefore

do not need to set the battery capacity again when changing the battery.

6. HOW TO START THE DEVICE

After connection, start must take place in the following steps:

1. Connection/voltage setting of battery part.

10

2. Voltage setting to mains.

3. Apply voltage to the load by switching on the circuit breaker.

7. COMMISSIONING

When all connections have been made, the system has been configured and the three steps for how to

start the device have been completed - then the following should happen:

• Status indication is off in normal operation.

• The load will be powered. Check with a voltmeter that the load voltage is between 26 and 27.3 V DC

(48 V, 52-54.6 V DC).

• The batteries must be charged. Check this by measuring across the battery terminals. (Depending

on the condition of the batteries, the voltage may vary but should be above 24 V DC, (48 V DC) and

slowly increase by approximately 0.001 V/10 sec. When fully charged, the voltage of the batteries

should be 27.3 V DC (48 V, 54, 6 V DC).

• The ALARM indicator diode on the panel must be off.

• All fault alarm relays must be in the pulled state. Check that there is a connection between CO and

NC. Set the measuring instrument to continuity measurement and test termination. This should then

indicate a short circuit.

• All relay outputs are normally energized and thus give an alarm in de-energized mode. When con-

necting to communication, the parent system sends queries. The superior system must then give an

alarm if, for example, the unit is de-energized.

8. COMMUNICATION - OPTIONAL

Connection to communication (via RS-485) can take place during customer customization.

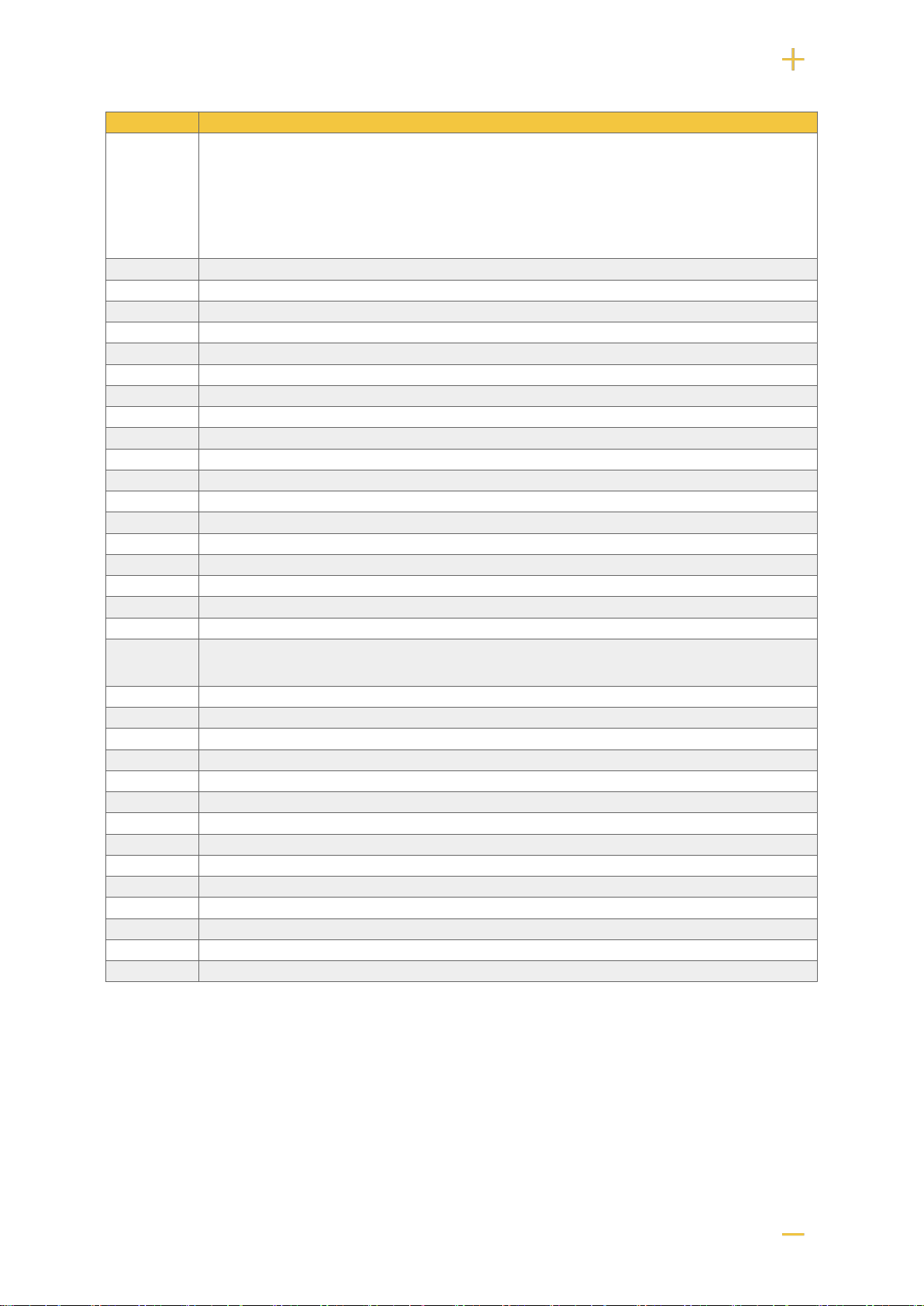

9. LIST OF SETTINGS VIA MULTI-SELECTOR WHEEL

Configuration mode on the display, accessed by a long button press on the multi-selector wheel.

(J) value is adjustable

(N) value is resettable

(U) Can perform a test/function

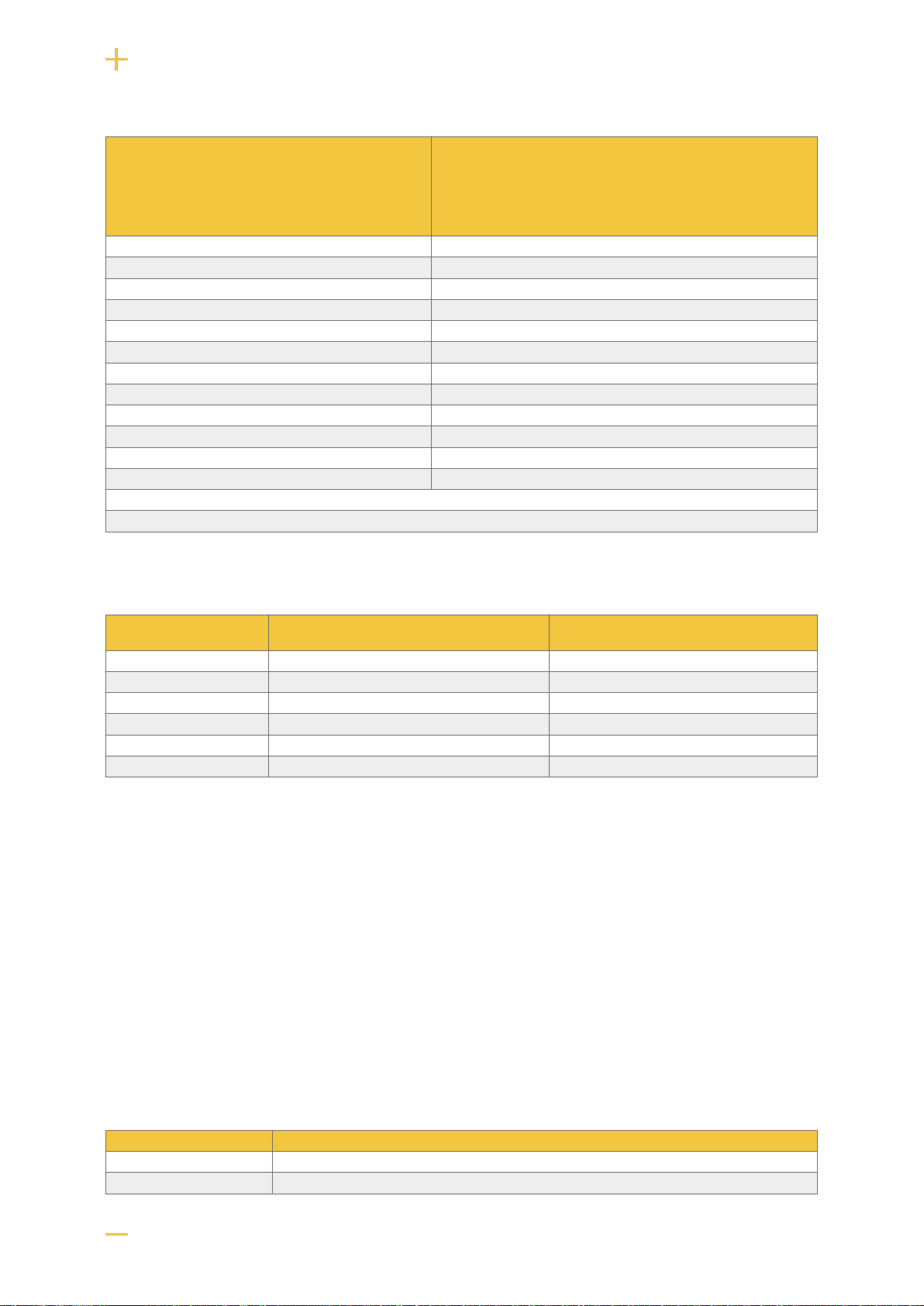

Table 5. Complete list of settings via the multi selector

On display Explanation

C00 Return to normal viewing mode.

C01 Setting of battery capacity in Ah (J).

C02 Setting the minimum allowed battery operating time (J).

C03 Alarm limit for low battery voltage in battery operation (J).

C04 Delay alarm mains failure (J).

C05 Low system voltage alarm (J).

11

On display Explanation

C06 Show relay status, 100s = Power supply, 10s = Batteries 1s = Mains interruption.

Tripped relay shows for power supply = 011.

Tripped relay for battery shows = 101.

Tripped relay for mains failure = 110.

Example if all relays are set = 000. Alarm=0, energized relay=1.

C07 Charge Cycle (J). Duration of the charging phase, 72 hours. Full rest phase cycle is 20 days.

C08 Highest measured tension (N).

C09 Lowest measured tension (N).

C10 Highest measured temperature (N) - external temperature sensor.

C11 Lowest measured temperature (N) - external temperature sensor.

C12 Number of minutes with overtemperature (N).

C13 Number of minutes with sub-temperature (N).

C14 Stopwatch load current above 170% of nominal load (N). Risk of load bills triggering.

C15 Minute counter load current above 100% of nominal load (N). Risk that dimensioning requirements are not met.

C16 Day counter load current above 80% of nominal load (N). Risk that the warranty period is not reached.

C17 Perform battery connection test (U).

C18 Perform Cell Test (U).

C19 Perform Weekly Test (U).

C20 Calibrate battery voltage (J). Factory setting - May not be changed.

C21 Calibrate voltage from mains plug (J). Factory setting - May not be changed

C22 Calibrate zero current (N). Factory setting - May not be changed

C23 Calibrate load current (J). Factory setting - May not be changed

C24 Setting of nominal load (J).

C25 Limit value for deep discharge protection (J).

ATTENTION! 1HE has hardware-controlled deep discharge.

C26 Limit value for weekly test (J).

C27 Original value for Cell test (J).

C28 Allowed additional voltage drop during cell test (J).

C29 Raw data from the A/D converter.

C30 Raw data from the A/D converter.

C31 Raw data from the A/D converter.

C32 Raw data from the A/D converter.

C33 Raw data from the A/D converter.

C34 Raw data from the A/D converter.

C35 Raw data from the A/D converter.

C36 Internal flags.

C37 Internal flags.

C58 Measured value from internal temperature sensor.

C59 Highest measured value from internal temperature sensor.

10. MAINTENANCE

The system with the exception of batteries is maintenance-free when installed in an indoor environment.

12

11. MAINTENANCE SCHEDULE BATTERIES

The maintenance schedule applies to batteries made by UPLUS and with the following serial names:

US, USL, USF, and for batteries made by XLENT POWER with serial names XLT and XLL. For

maintenance instructions see separate document "care instructions valve-regulated lead-acid battery”.

Table 6. Battery replacement

Series designation Battery type Replace battery after

XLT 3-5 years 2-3 years

US 6-9 years 3-5 years

USL 10-12 years 5-7 years

USF 12 years 8-10 years

* battery life depends mainly on ambient temperature and charging current. An AGM battery should never be charged with more

than 30% of its rated capacity. The battery will be fully charges, but the charning current must not excced 30% of its rated capacity.

Table 7. Charging voltages

Charging voltage from power supply 12 V units 24 V units 48 V units

Minimum charging voltage 13.6 V 27.2 V 54.4 V

Maximum charging voltage 13.7 V 27.4 V 54.8 V

Tolerance +/- 0.5% +/- 0.5% +/- 0.5%

Table 8. terminal voltage

terminal voltage After 15 minutes of rest / charging.

Minimum terminal voltage 12.9 V

Maximum allowable difference between battery pairs 0.5 V

New battery with terminal voltage below 12.0 V is defective and should be reported to the supplier.

Table 9. Ambient temperature for batteries

Temperature in battery backup Temperature

Lowest 15 ° C

Recommended 20 ° C - 25 ° C

Highest 32 ° C

Warranty is valid only if the temperature is within these levels.

Installation control batteries

1. Check that the battery is completely clean and that the terminals are free from corrosion.

2. Check and note the temperature in the battery compartment.

3. Check the terminal voltage of each battery before installation. If the difference between the batter-

ies exceeds 0.5 V, the battery loop should be equalized in connection with installation. If any

battery has a terminal voltage of less than 12V, this battery must be replaced with a new battery

and reported to the supplier.

4. Connect the battery and check the charging voltage. The charging voltage should be between 2.25

V - 2.27 V per cell = between 13.5 V - 13.62 V for a 12 V system and between 27.0 V - 27.24 V for

a 24 V system.

Year-round inspection

1. Check that the battery is completely clean and that the terminals are free from corrosion. If there is

corrosion on the terminals: Check that the battery does not leak acid. Then clean the terminals and

reconnect the battery. Then lubricate with battery terminal grease over the connected terminal.

13

2. Check and note the temperature in the battery compartment.

3. Check and note the average current.

4. Check that all connections are securely fastened and that there is no gap in the connection.

5. Check that the fan (if units have a fan) is working properly. Clean the fan if necessary.

6. Check the charging voltage by measuring with a multimeter between the connection points + &

amp; -. The charging voltage should be between 2.25-2.27 volts per cell = between 13.5-13.62V for

a 12V system and between 27-27.24V for a 24V system.

7. Turn off the rectifier and let the batteries rest for 10 - 15 minutes. Then measure the terminal

voltage of each battery. After resting, the terminal voltage must be between 12.9 V - 13.5 V.

12. PRODUCT SHEET - TECHNICAL DATA

12.1. Technical specifications: EN54-4 Certified / SBF110:8 Ap-

proved battery backup

Figure 1. EN54 1U and EN 54 2U

The battery backup is mounted in a 19" rack.

14

12.1.1. Name, article number, e-number and certificate number

Name Item number Email

num-

ber

Product

name on

certificate

Certified

according

to

SBSC

Certifi-

cate

number

Certification scheme:

EN54

24V

15A 1U

1U01R10024P150-

EN54 52 135

55 RACK 27

150-1HE, SBF 110:8

The prod-

uct also

meets SBF

110:7

No.

18-244 Scheme 1a (ISO/IEC

17067:2013)2017-12-18

EN54

24V

25A 2U

2U01R10024P250-

EN54 52 135

56 RACK 27

250-2HE SBF 110:8

The prod-

uct also

meets SBF

110:7

No.

18-244 Scheme 1a (ISO/IEC

17067:2013)2017-12-18

EN54

48V 7A

1U

1U01R10048P070-

EN54 52 135

57 RACK 54

70-1HE SBF 110:8

The prod-

uct also

meets SBF

110:7

No.

18-244 Scheme 1a (ISO/IEC

17067:2013)2017-12-18

EN54

48V

13A 2U

2U01R10048P130-

EN54 52 135

58 RACK 54

130-2HE SBF 110:8

The prod-

uct also

meets SBF

110:7

No.

18-244 Scheme 1a (ISO/IEC

17067:2013)2017-12-18

12.1.2. About EN54 1U and EN54 2U

EN54 powers fire alarms with 24 V DC – 48 V DC. The rectifier in the power supply converts 230 V

DC down to 48 V or 24 V and supplies power to all important parts of the fire alarm system. Batteries

continue to power the fire alarm system when the power goes down. EN54 power supply is certified to

be used in security facilities that must meet EN54-4 or be approved for SBF 110:8.

Long life, energy efficient and support is available if something goes wrong, now or in 10 years.

12.1.3. Area of use

EN54 is used for fire alarm systems in public environments such as schools, offices and commercial

properties.

12.1.4. Fixed installation

The product is intended for fixed installation. The battery backup must be installed by a qualified

installer.

15

12.2. Regulations and certifications

12.2.1. Standards that product (s) meet and are approved for

Table 10. EN54

EN50131-6:2017.

EN 54-4:1997, EN 54-4:1997/AC:1999, EN 54-4:1997/A1:2002 and EN 54-4:1997/A2:2006.

Table 11. SBF

SBF 110:8

Table 12. SSF

SSF1014 Alarm class 1-4 (burglar alarm).

SSF1014, Issue 5.

Table 13. Certificate and certificate number

Certificate number, SBSC

No. 18-244

12.2.2. Requirements that the product meets

EMC: EMC Directive 2014 / 30EU

Electricity: Low voltage directive: 2014/35 / EU

CE: CE directive according to: 765/2008

Emission: EN61000-6-: 2001 EN55022: 1998: -A1: 2000, A2: 2003 Klass B, EN61000-3-2: 2001

Immunity: SS-EN 50 130-4:2011 Edition 2, EN50131-6

12.3. Battery combinations 1U and 2U

Table 14. EN54 24V 15A 1U, EN54 24V 25A 2U

Ah Number of battery used in combination with EN54 24V

15A 1U combination with EN54 24V

25A 2U

28 Ah 2 pcs. 28 Ah Yes No

45 Ah 2 pcs. 45 Ah Yes Yes

55 Ah 2 pcs. 55 Ah F (front fed) Yes Yes

75 Ah 2 pcs. 75 Ah Yes Yes

90 Ah 4 pcs. 45 Ah Yes Yes

100 Ah 2 pcs. 100 Ah / 2 pcs 100 Ah F (front fed) Yes Yes

110 Ah 2 pcs. 55 Ah F (front fed) Yes Yes

125 Ah 2 pcs. 125 F (front fed) Yes Yes

16

Ah Number of battery used in combination with EN54 24V

15A 1U combination with EN54 24V

25A 2U

135 Ah 6 pcs. 45 Ah Yes Yes

150 Ah 2 pcs. 150 F (front fed) or

4 pcs. 75 Ah

Yes Yes

180 Ah 8 pcs. 45 Ah Yes Yes

200 Ah 2 pcs. 100 Ah or

2 pcs. 100 Ah F (front fed)

Yes Yes

240 Ah 4 pcs. 120 Ah No Yes

250 Ah 4 pcs. 125 F (front fed) No Yes

300Ah 4 pcs. 150 F (front fed) or

6 pcs. 100 F (front fed)

No Yes

Table 15. EN54 48V 7A 1U, EN54 48V 13A 2U

Ah Number of battery used in combination with EN54 48V 7A 1U combination with EN54 48V 13A 2U

20 Ah 4 pcs. 20 Ah Yes Yes

28 Ah 4 pcs. 28 Ah Yes Yes

45 Ah 4 pcs. 45 Ah Yes Yes

55 Ah 4 pcs. 55 Ah F (front fed) Yes Yes

75 Ah 4 pcs. 75 Ah Yes Yes

90 Ah 4 pcs. 45 Ah Yes Yes

100 Ah 4 pcs. 100 Ah F (front fed) Yes Yes

110 Ah 8 pcs. 55 Ah F (front fed) No Yes

120 Ah 4 pcs. 120 Ah No Yes

125 Ah 4 pcs. 125 Ah F (front fed) No Yes

150 Ah 4 pcs. 150 Ah F (front fed) No Yes

200 Ah 8 pcs. 100 Ah F (front fed) No Yes

12.4. Reserve operating times, power outlet and load output current

12.4.1. Cargo current

Table 16. EN54 24V 15A 1U

Battery size Maximum

Power outlet i

network operation

(Imax. A)

28 Ah 12 A

45 Ah 11 A

55 Ah 10.3 A

75 Ah 9.1 A

90 Ah 8.2 A

100 Ah 7.5 A

110 Ah 6.9 A

120 Ah 6.3 A

125 Ah 6 A

135 Ah 5.3 A

17

Battery size Maximum

Power outlet i

network operation

(Imax. A)

150 Ah 4.3 A

180 Ah 2.5 A

200 Ah 1.3 A

Maximum power consumption battery operation: 14 A

Maximum current consumption battery operation, (same as Imax.b): 15 A

Table 17. EN54 24V 25A 2U

Battery size Maximum

Power outlet i

network operation

(Imax. A)

45 Ah 24 A

55 Ah 23.3 A

75 Ah 22.1 A

90 Ah 21.2 A

100 Ah 20.5 A

110 Ah 19.9 A

120 Ah 19.3 A

125 Ah 19 a

135 Ah 18.3 A

150 Ah 17.4 A

180 Ah 15.5 A

200 Ah 14.3 A

240 Ah 11.8 A

250 Ah 11.2 A

300 Ah 8 A

Maximum power consumption battery operation: 14 A

Maximum current consumption battery operation, (same as Imax.b): 15 A

Table 18. EN54 48V 7A 1U

Battery size Maximum

Power outlet i

network operation

(Imax. A)

14 Ah 6 A

20 Ah 5.6 A

90 Ah 5.1 A

100 Ah 4.1 A

120/125 Ah 3.4 A

135 Ah 2.2 A

150 Ah 1.3 A

180 Ah 0.65 A

Maximum current consumption battery operation: 14 A

Maximum current consumption battery operation, (same as Imax.b): 15 A

18

Table 19. EN54 48V 13A 2U

Battery size Maximum

Power outlet i

network operation

(Imax. A)

20 Ah 11.6 A

28 Ah 11.1 A

45 Ah 10.1 A

55 Ah 9.4 A

75 Ah 8.2 A

90 Ah 7.3 A

100 Ah 6.6 A

110 Ah 6 A

120 Ah 5.4 A

125 Ah 5.1 A

150 Ah 3.5 A

200 Ah 0.4 A

Maximum power consumption battery operation: 14 A

Maximum current consumption battery operation, (same as Imax.b): 15 A

12.4.2. Reserve operating times for different alarm classes - overview

Alarm class Spare operating time in the event of a power

failure Maximum number of hours of battery re-

charging (80%)

EN54-4 - 24 h

SBF110: 8 30 h + 10 min 24 h

EN50131-6 grades 1-2 12 h 72 h

EN50131-6 grade 3 24 h 24 h

SSF1014 Alarm class 1/2 12 h 72 h

SSF1014 Alarm class 3/4 30 h 24 h

The table shows the requirements for backup operating time and recharging of batteries for different

alarm classes.

12.5. Internal resistance 1U and 2U

24 V two pairs of power resistors each parallel 3.3 Ω

48 V two pairs of power resistors each parallel 15 Ω

12.6. Circuit boards - Technical data

12.6.1. Technical data - 1HE (motherboard)

Info Explanation

Article title 1HE

Description Circuit board for control, distribution, status and alarm from the device.

19

Info Explanation

Status indication LED, display and communication output (RS-485).

Communication protocol RS-485 Milleprotokollet - Optional

Error output Potential-free relay switches rated 1 A @ 30 V DC (all fault outputs).

Self consumption, (in bat-

tery operation) 24 V units: 270 mA. 48 V units: 200 mA

Switching time Batteries rest for 20-day cycles, after which a charging cycle picks up and charges the batteries

for 72 hours. If there is a power failure when the batteries are in the charging cycle, there is no

switching time.

Deep discharge Deep discharge protection is activated: 1U / 24 V and 2U / 24 V systems when the power supply

voltage is below 19 V DC. (1 U / 48 V and 2 U / 48 V systems when the power supply voltage is

below 38 V DC.)

Tension, ripple less than 210 mVp-p in normal operation. (Max 2 V in ripple voltage when recharging batteries,

when the power supply goes within the current limit).

Table 20. Alarm from alternating relay

Name Alarm

Power Outage / Mains Alarm NO / CO / NC

Fault in power supply and Fuse Error / PSU and Fuse Error NO / CO / NC

Battery Error, Aged Battery NO / CO / NC

Table 21. Alarm displayed on Alarm (LED)

LED status

(1) Explanation Comment

Off Normal operation -

1 blink Network outages -

2 flashes Delayed network

failure 10 second delay.

3 flashes Charger error If the batteries have not reached the desired voltage (26.7V) after completing the charg-

ing cycle. If the power supply drops below the limit value (26.5V) during the current

dormant phase for the batteries. If the voltage from the power supply drops during the

connection test for the batteries that occurs every 10 seconds. At low voltage in the

power supply (26.7V), the batteries are disconnected every 10 minutes, if low voltage in

the power supply remains an alarm is given. If the mains voltage is below system voltage

(24V) during mains operation, an alarm is given.

4 flashes Surge power sup-

ply Voltage above 27.9 V DC (24 V), / 55.8 V DC (48 V).

5 blink Battery fault Aged batteries, failed weekly test. Cell test, the internal resistance of the battery has

risen above the limit value. Failed connection test. Batteries are not connected or battery

voltage below 16 V.

6 flashes Low battery volt-

age Low battery voltage in battery operation.

7 flashes Summarmarm Temperature alarm, the temperature is below or above the limit value. Fuse failure, load

or battery fuse has blown. Fuse fault from external card with load outputs. Ground fault

(D-Sub). Signal error (D-Sub). The temperature sensor is incorrect or missing. Fan fault.

8 blink System error The system is not calibrated.

20

Other manuals for EN54

1

This manual suits for next models

4

Table of contents

Other milleteknik Power Supply manuals