milleteknik NOVA FLX M User manual

NOVA FLX M

NOVA 24V 15A FLX M, NOVA 24V 25A FLX M

EN

350-152

Publication date 2022-10-11

Table of Contents

1. Revisions and the edition of this document .......................................................................... 5

2. Variant overview NOVA ....................................................................................................... 5

3. Enclosures ........................................................................................................................ 6

3.1. Bracket ................................................................................................................... 6

3.2. Mounting on a wall or in a 19 "rack ........................................................................... 7

3.3. Mounting ................................................................................................................ 7

4. Component overviews ........................................................................................................ 7

4.1. Component overviewNOVA FLX M ........................................................................... 7

5. Batteries - placement and connection .................................................................................. 8

5.1. Placement of batteries ............................................................................................. 8

5.2. Connecting batteries in FLX M ................................................................................. 9

5.3. Connect battery fuse / blade fuse ........................................................................... 10

5.4. Connection of batteries in FLX S, FLX M and FLX L ................................................ 10

6. PCB description of PRO2v3 .............................................................................................. 11

6.1. Fuses ................................................................................................................... 12

6.2. Connect the mains to the motherboard (PCB) ......................................................... 12

6.2.1. Connect mains ........................................................................................... 12

6.3. Connect load ........................................................................................................ 13

6.4. Connection of load 15 A - 25 A units ....................................................................... 13

6.5. Load cards with blade fuses ................................................................................... 14

6.6. Alarm via communication ....................................................................................... 15

6.7. Communication to a parent system ......................................................................... 15

6.8. Configuration of communication via RS-485 ............................................................ 15

6.9. Dip switch 1-8 ....................................................................................................... 16

6.9.1. Address setting for external communication (Dip switch 1-4) .......................... 16

6.9.2. Mains failure delay (dip 5-6) ........................................................................ 16

6.9.3. Low battery level (dip 7) .............................................................................. 17

6.9.4. LED (dip 8) ................................................................................................ 17

6.9.5. Battery test (dip 8) ...................................................................................... 17

6.10. Reboot to confirm changes in address, battery and alarm settings to parent sys-

tem ............................................................................................................................. 18

6.11. Alarm card for PRO2 ........................................................................................... 18

7. Multiple units into one parent system ................................................................................. 19

8. Commissioning - how to start the unit ................................................................................ 20

8.1. 72 hours after commissioning / battery change ........................................................ 20

8.2. System test ........................................................................................................... 20

8.3. Recovery .............................................................................................................. 20

9. Alarm displayed on cabinet door ....................................................................................... 20

10. Adjustment of tamper switch ........................................................................................... 21

11. Maintenance .................................................................................................................. 22

11.1. About batteries .................................................................................................... 22

11.2. battery change .................................................................................................... 22

11.3. Battery recycling ................................................................................................. 23

12. NOVA product sheet ....................................................................................................... 24

12.1. SSF1014 certified battery backup with communication ........................................... 24

12.1.1. Name, article number, e-number and certificate number .............................. 24

12.1.2. About NOVA FLX ...................................................................................... 24

12.1.3. Area of use .............................................................................................. 25

12.1.4. Installation video ....................................................................................... 25

12.2. Regulations and certifications ............................................................................... 25

12.2.1. Standards that product (s) meet and are approved for ................................. 25

12.2.2. Requirements that the product meets ......................................................... 26

12.3. Spare operating times, power outlet and load output power .................................... 26

3

12.3.1. Charging current for batteries and battery capacity ..................................... 26

12.3.2. Power outlet NOVA FLX ............................................................................ 27

12.3.3. Power outlet ............................................................................................. 27

12.3.4. Permitted average load according to SSF1014 Alarm class 1-4: .................. 28

12.3.5. Reserve operating times for different alarm classes - overview .................... 28

12.4. Circuit boards - Technical data ............................................................................. 28

12.4.1. Technical data, motherboard: PRO 2 V3 ..................................................... 28

12.4.2. Technical data, alarm cards for PRO 2 and PRO2 V3 .................................. 29

12.5. Power supply ...................................................................................................... 30

12.5.1. Power supply - Technical Data RSP-320-24 ................................................ 30

12.5.2. Power supply - Technical Data HRP-600-24 ............................................... 31

12.6. Technical data enclosures .................................................................................... 31

12.6.1. Enclosures - Technical Data FLX M ........................................................... 31

12.7. Link to the latest information ................................................................................. 32

12.8. Warranty, support, country of manufacture and country of origin ............................. 32

12.8.1. Warranty 5 years ...................................................................................... 32

12.8.2. Manufacturer support ................................................................................ 32

12.8.3. Support .................................................................................................... 32

12.8.4. Contact us ................................................................................................ 33

12.8.5. Country of manufacture ............................................................................. 33

12.8.6. Designed and produced by: Milleteknik AB ................................................. 33

12.9. Product life cycle, environmental impact and recycling ........................................... 33

12.10. Batteries - recommended, not included ............................................................... 33

12.10.1. Batteries are not included they are sold separately .................................... 33

12.10.2. Battery combinations NOVA FLX M .......................................................... 33

12.10.3. Certified with battery type ........................................................................ 34

12.10.4. 20 Ah, 12 V AGM battery ......................................................................... 34

12.10.5. Reserve operating times for different alarm classes - overview ................... 34

13. Connection of battery box ............................................................................................... 36

13.1. Installation of battery box, what to do in battery backup .......................................... 36

13.2. Connection of batteries battery box ...................................................................... 37

13.3. Connection of battery box NOVA FLX with battery backup NOVA FLX ..................... 38

13.4. Wiring diagram and jumper .................................................................................. 39

13.5. Battery backup (NOVA FLX) with 4 battery boxes (NOVA FLX) ............................... 40

13.6. Tamper switch when using battery box(-es) ........................................................... 40

14. Address and contact details ............................................................................................ 40

4

1. REVISIONS AND THE EDITION OF THIS DOCUMENT

The current and most recently published edition of this document is available at www.milleteknik.se.

The validity of this document can not be guaranteed, as new editions are published without prior notice.

READ THIS FIRST!

Electronics, regardless of enclosure, are intended for use in a controlled indoor envi-

ronment.

Ventilation must not be covered.

Only authorized persons should install and maintain the system.

It is the installer's responsibility to ensure that the system is suitable for its intended

use.

Documents accompanying the system must be kept in or in its immediate vicinity.

Mains voltage should be disconnected during installation.

All information subject to change.

Upon installation of this product, the installer acknowledges and accepts the limitations

of this product as described in this manual.

ABOUT GLASS TUBE FUSES ON CERTIFIED

DEVICES

There are glass tube fuses on the circuit board's load outputs, these

have a tripping time of approx. 150 ms. In the event that a glass tube

fuse trips on ONE load output, the voltage on ALL load outputs drops

to 0 V for 150 ms.

The installer is responsible for ensuring that there is an energy buffer

of at least 150 ms in systems that the battery backup supplies power

to or accepts a power failure of 150 ms.

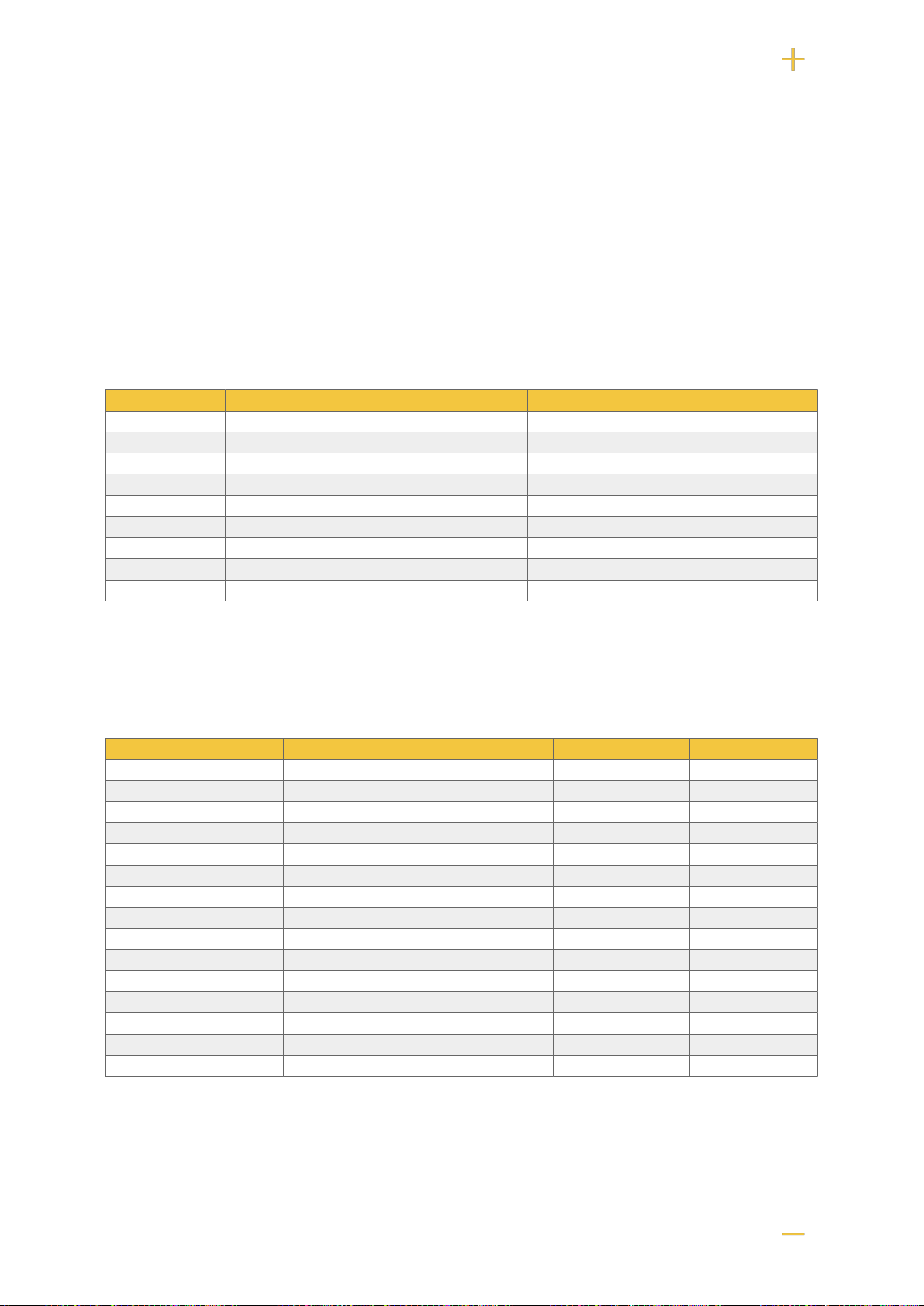

2. VARIANT OVERVIEW NOVA

Table 1. Variant overview

Product name Certified name Mother-

board:

PRO1

Mother-

board

PRO2:

Mother-

board

PRO2 v3

Mother-

board:

PRO3

NOVA 12V 10A FLX S 12 V meets the requirements but

is not certified. - - - x

5

Product name Certified name Mother-

board:

PRO1

Mother-

board

PRO2:

Mother-

board

PRO2 v3

Mother-

board:

PRO3

NOVA 12V 10A FLX M - - - x

NOVA 12V 10A FLX L - - - x

NOVA 24V 5A FLX S NOVA 25 50-FLX-S X X - X

NOVA 24V 10A FLX S NOVA 25 100-FLX-S X X - X

NOVA 24V 5A FLX M NOVA 25 50-FLX-M X X - X

NOVA 24V 10A FLX M NOVA 25 100-FLX-M X X - X

NOVA 24V 15A FLX M NOVA 25 150-FLX-M X X X -

NOVA 24V 25A FLX M NOVA 25 250-FLX-M X X X -

NOVA 24V 5A FLX L NOVA 25 50-FLX-L X X - X

NOVA 24V 10A FLX L NOVA 25 100-FLX-L X X - X

NOVA 24V 15A FLX L NOVA 25 150-FLX-L X X X -

NOVA 24V 25A FLX L NOVA 27 250-FLX-L X X X -

3. ENCLOSURES

3.1. Bracket

Brackets are used so that the unit can be mounted on a wall or in a 19 "rack.

Nr Explanation

1 Clip in bracket that secures the bracket to the housing.

2 Holes for screws - can be used to secure the bracket in the housing.

3 The brackets is screwed to a wall or 19 "rack.

6

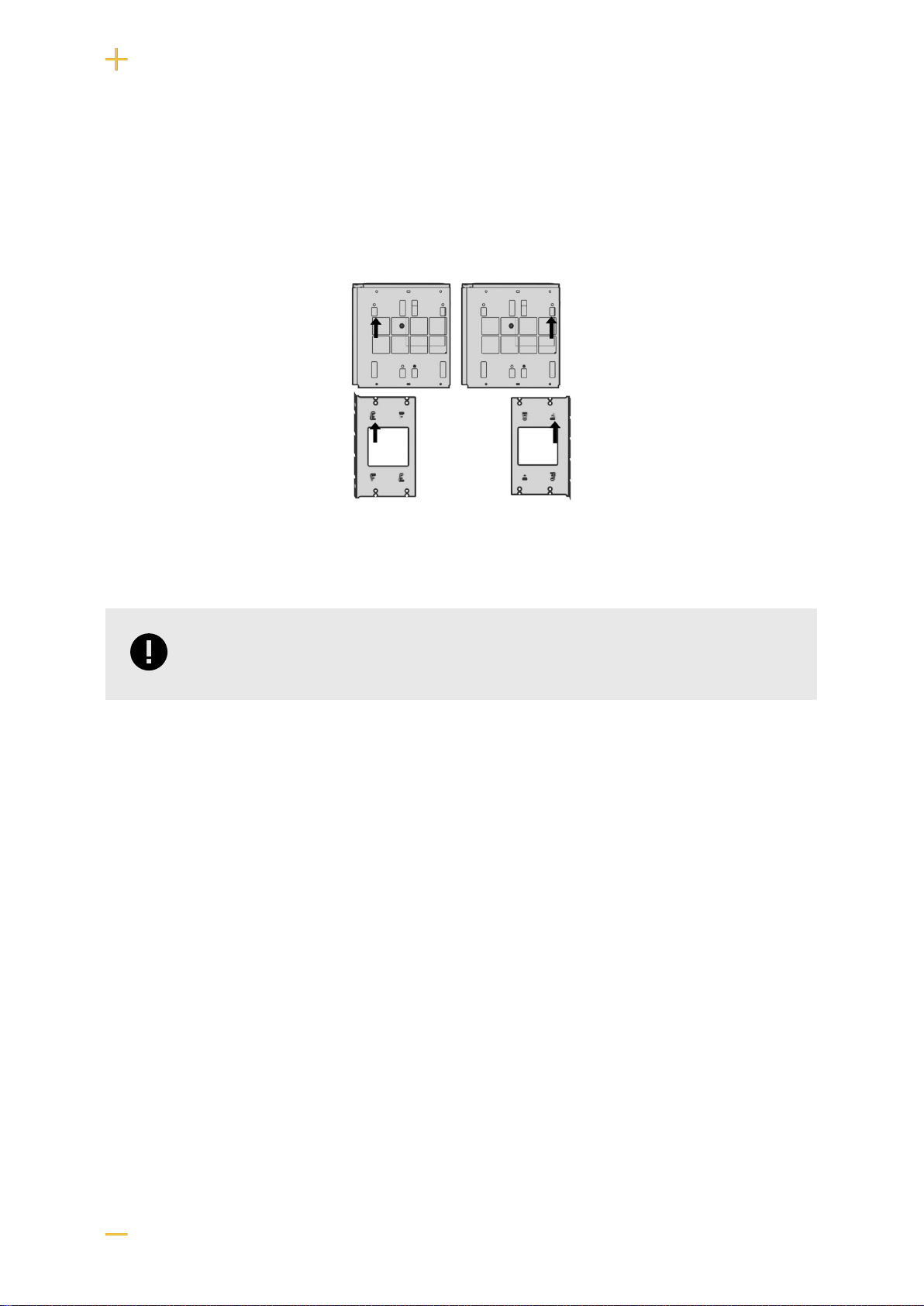

3.2. Mounting on a wall or in a 19 "rack

The unit can be mounted in a 19 ”rack or on a wall. The included brackets can be attached in two

ways: When mounting on a wall, the brackets must sit backwards, against the wall. When mounting in a

19 ”rack, the console must be at the front edge of the unit.

Figure 1. FLX M - mount brackets

Left bracket facing the front for mounting in a 19 "rack.

Right bracket facing the back for wall mounting.

IMPORTANT

Leave 100 mm free around the air vents.

3.3. Mounting

Use the appropriate screw for mounting on a wall or in a 19" rack. Screws for mounting on a wall or in a

rack are not included.

4. COMPONENT OVERVIEWS

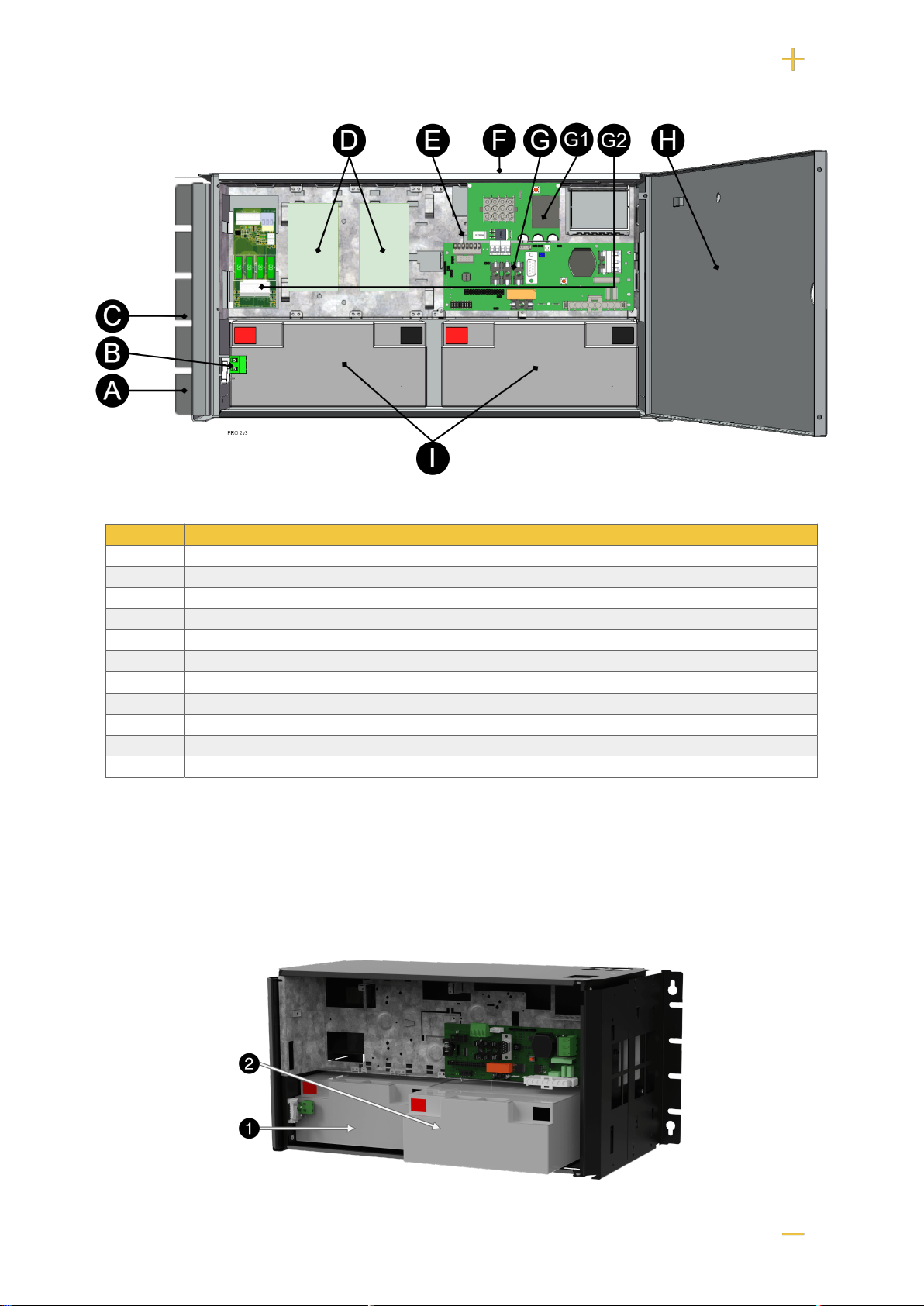

4.1. Component overviewNOVA FLX M

7

Table 2. Component overview

Letter Explanation

A Bracket, reversible for wall mounting or 19 "rack.

B Sabotage contact. If alarm class 3 (SSF) is to be met, the tamper switch must be on the wall.

C Cabinet in powder-coated sheet metal.

D Load card - load is connected here.

E Power supply.

F Cable entries.

G Motherboard.

G1 Effect card.

G2 Load card.

H Lockable door.

I Space for batteries.

5. BATTERIES - PLACEMENT AND CONNECTION

5.1. Placement of batteries

8

5.2. Connecting batteries in FLX M

Figure 2. Connection of batteries in FLX M. Motherboards may differ depending on the configuration, but connection of batteries takes

place in the same way.

Note that cards (4) differ from different configurations.

Nr Explanation

1 Minus coil for battery cable from 4.

2 Fuse.

3 Plus terminal for battery cable from 4.

4 Motherboard, varies with configuration.

5 Battery cables are located on the system board.

6 Yellow cable, which must be cut when connecting the battery box.

7 Connection for connection of battery box.

8 Alarm cable for battery box.

9 Cable for tampering in battery box.

9

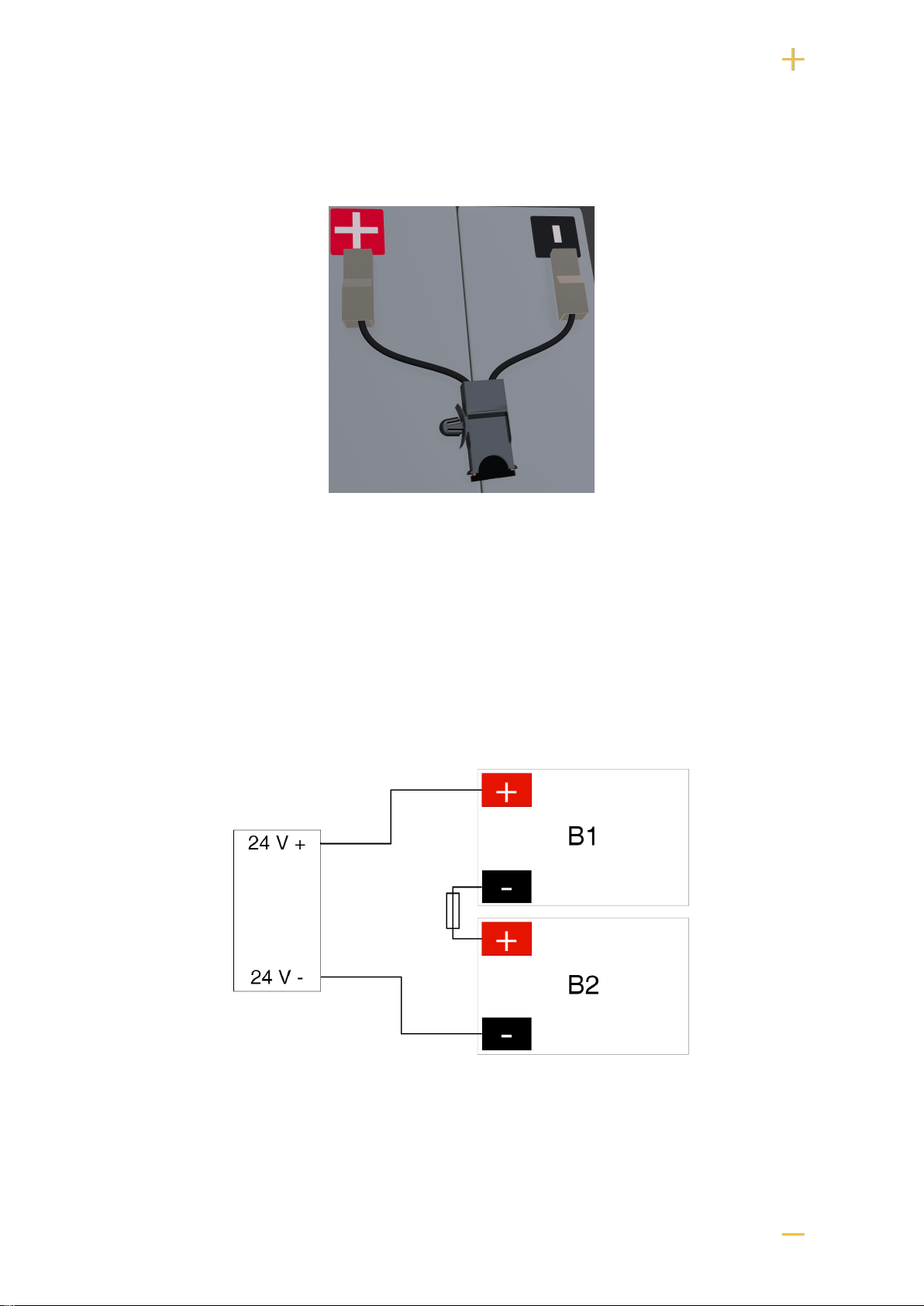

5.3. Connect battery fuse / blade fuse

Figure 3. Fuse holders with blade fuses are connected to + and minus on batteries

5.4. Connection of batteries in FLX S, FLX M and FLX L

Battery wiring is mounted on the circuit board upon delivery. Pictures below only show how to connect

wiring.

1. Place the batteries in the cabinet with the battery terminals facing outwards.

2. Connect the battery cable. Red cable on + and black cable on -.

• If possible, disconnect mains voltage when replacing the battery.

Figure 4. Wiring diagram for batteries in battery backup

Connect the terminals correctly so that you do not damage the equipment.

10

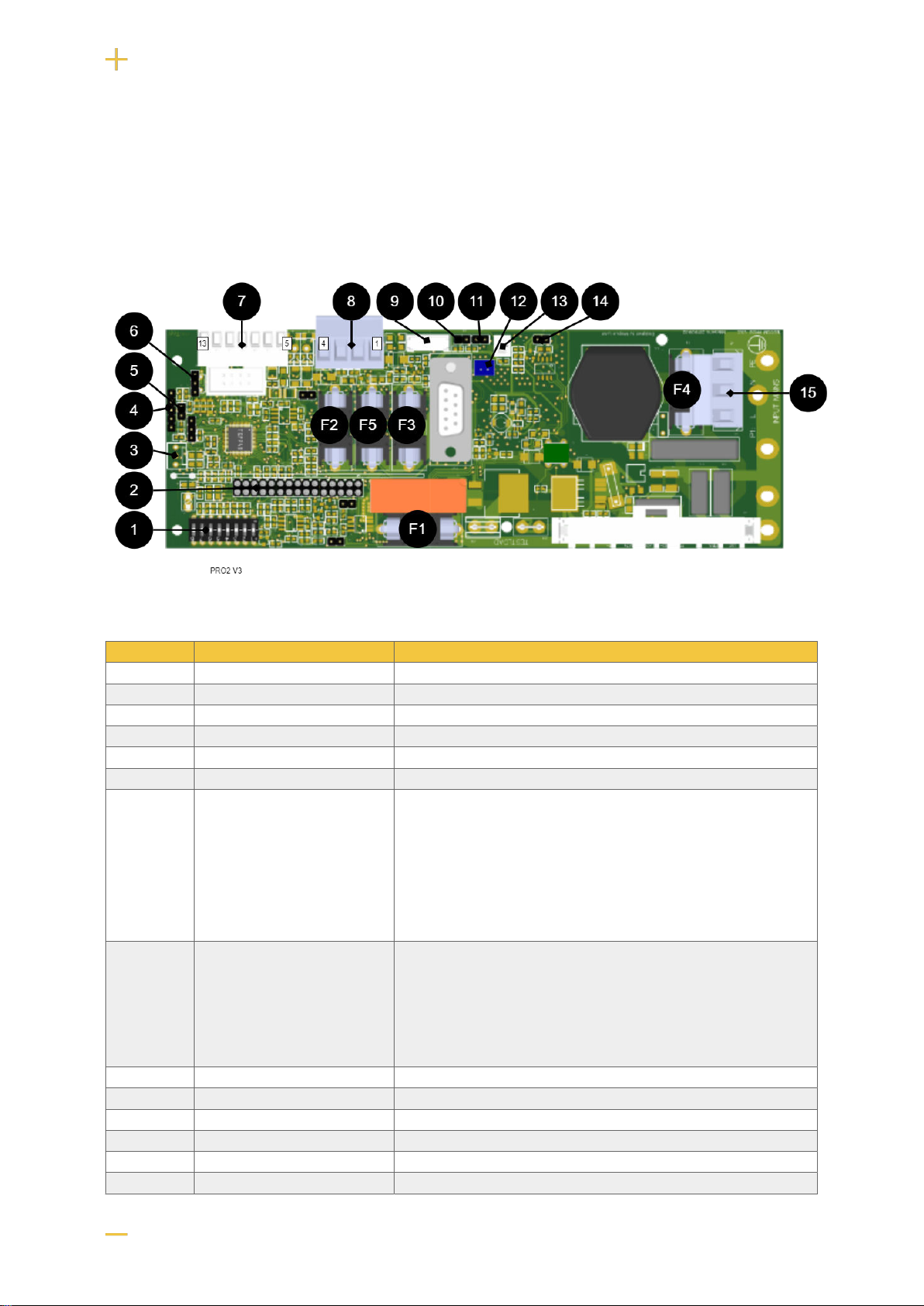

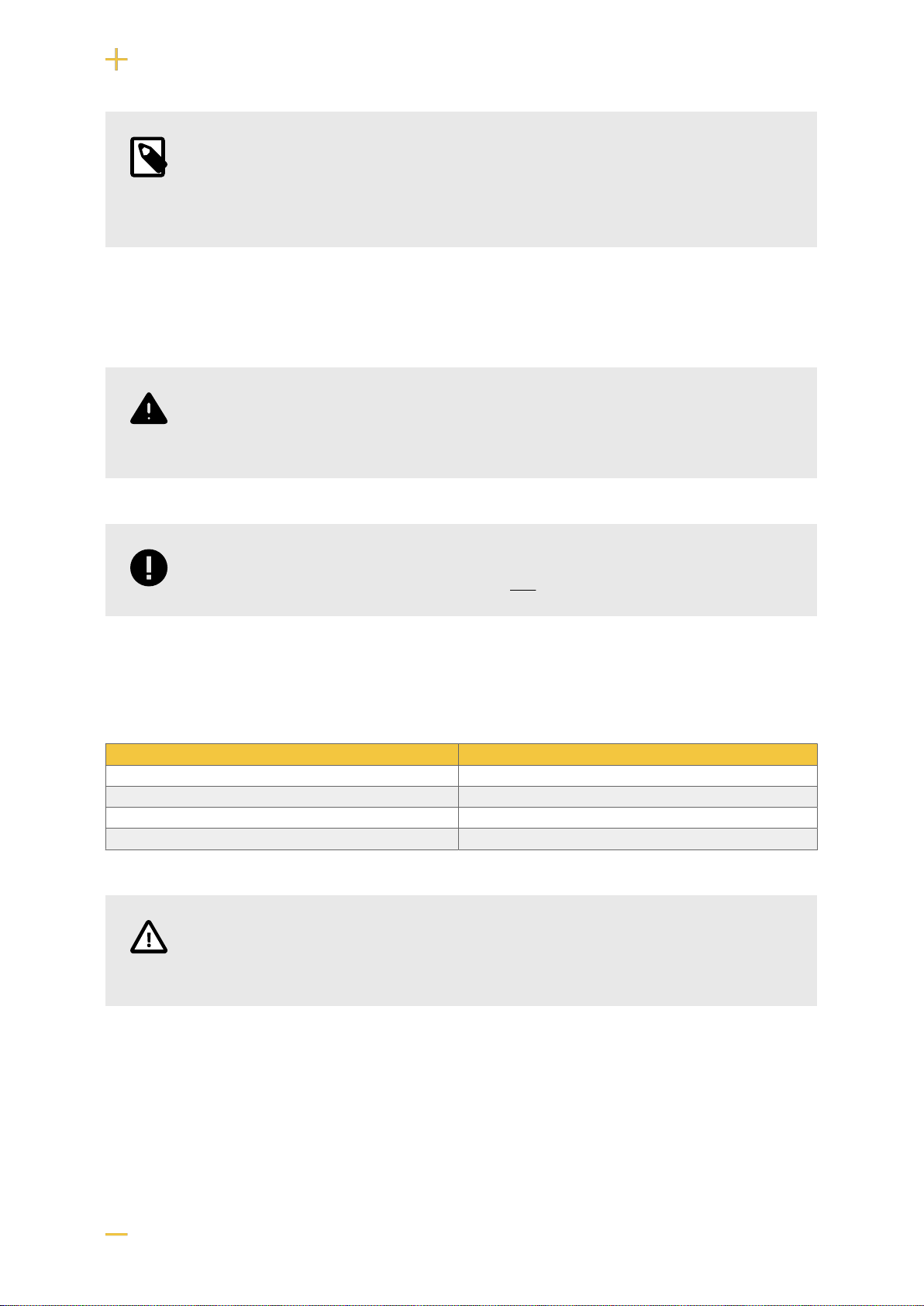

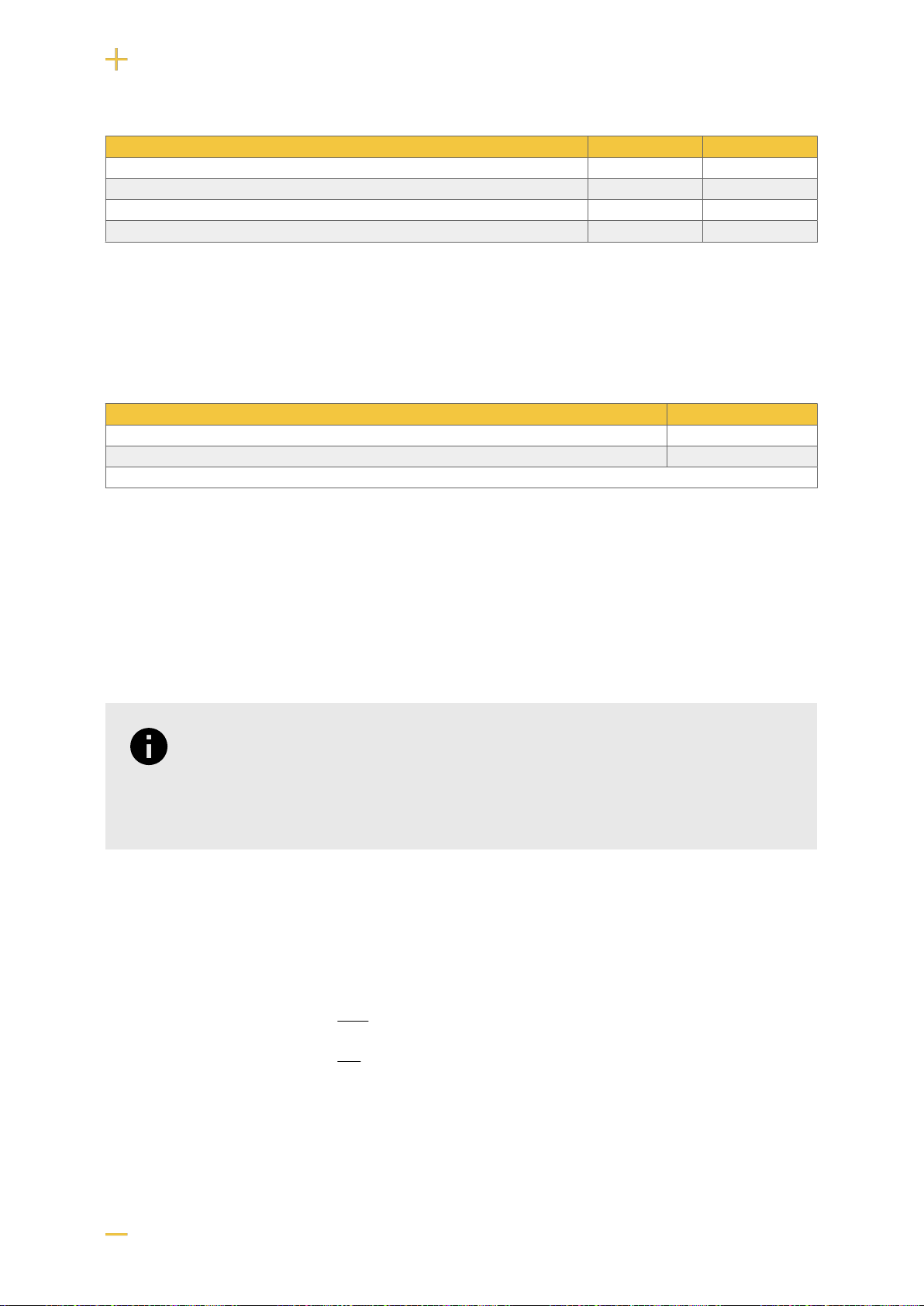

6. PCB DESCRIPTION OF PRO2V3

The motherboard controls the device, distributes power and communicates with other systems. See

technical data for more information.

Figure 5. PRO2 v3

Table 3. Circuit board overview, explanation

No . On circuit board Explanation

1 Dip SW Dip switch 1-8

2 J20 Connection relay board.

3 JU17 Connection external indicator diode.

4 - Programming contact.

5 J13 Reset of data after battery replacement.

6 J6 Temperature sensor.

7 P2:7-13

7-8

9-10

11

12

13

Connection communication.

RS-485

GND, Protective earth

RX

TX

+5V

8 P2:1-4

1

2

3

4

Load outputs.

+

-

+

-

9 J29 Connection to fan.

10 J14 Tamper switch connection.

11 J3 Connection tamper switch from battery box.

12 J1 Connection option card.

13 J4 Connection external fuse (NO).

14 J7/21 Connection to external fuse (NC).

11

No . On circuit board Explanation

15 P1:1-3 Incoming mains, (230 V). L, N, PE.

6.1. Fuses

Table 4. Fuses on PRO2 / PRO2 V3

Fuse Type Explanation

F1 T16A Mains fuse

F2 T2A Load fuse 2 + (for P2: 4)

F3 T2A Reading protection 1 + (for P2: 1)

F4 T2.5A / T4A Mains fuse, the lower valute for units 5 A - 15 A and the higher value for 25 A units.

F5 T16A Load fuse 1+ (for P2: 2)

FUSE REPLACEMENT WARNING (A)

There is a risk of damage if the fuse is changed to a larger one than what the unit

is delivered with. The function of the fuse is to protect the connected load and cables

against damage and fire. It is not possible to change the fuse to a larger one to

increase the power output.

6.2. Connect the mains to the motherboard (PCB)

6.2.1. Connect mains

Pull wiring through the cable entry on the cabinet.

If possible, secure the mains cable with cable ties where possible.

Electrical network cabling shall be kept separate from other cabling to avoid EMC interference.

Figure 6. Connect the mains to the motherboard

Connect the mains cable to the terminal before it is put back on the motherboard. Secure F and N with

cable ties for electrical safety.

Table 5. Electrical network connections

Letter Explanation

F Phase

N Neutral

PE Protective earth

12

ELECTRICAL MAINS CONNECTION 230 V AC ON CIRCUIT

BOARD

Check that the marking on the circuit board matches the cable arrangement on the

terminal block.

6.3. Connect load

MAX CURRENT

Maximum current must not be exceeded. Maximum current is indicated on the CE-

marking on the unit.

LOAD OUTPUTS WHEN SSF CERTIFIED

In order for certificates to be maintained, only one load output must be used.

If there are one or more connection cards (to increase the number of load outputs), load must be

connected there and not on the main board.

Table 6. Load connections

Circuit board number Explanation

P2: 1 Connection for load 1 +

P2: 2 Connection for load 1 -

P2: 3 Connection for load 2 -

P2: 4 Connection for load 2 +

CAUTION

Load may only be connected to the motherboard in 5 A and 10 A units. For other units,

load must be connected via power board or option board.

6.4. Connection of load 15 A - 25 A units

For units with a effect card, which is available to handle the higher currents (15 ampere and above), the

load must be connected on an optional board.

See documentation for option board for how to connect load.

13

WARNING

Load must not be connected to the motherboard if the device is a 15 A or 25 A, as it

will be destroyed during commissioning. Motherboards that are faulty due to incorrect

connections are not covered by warranty.

Figure 7. Effect card

The effect card increases the current for 15 A and 25 A units.

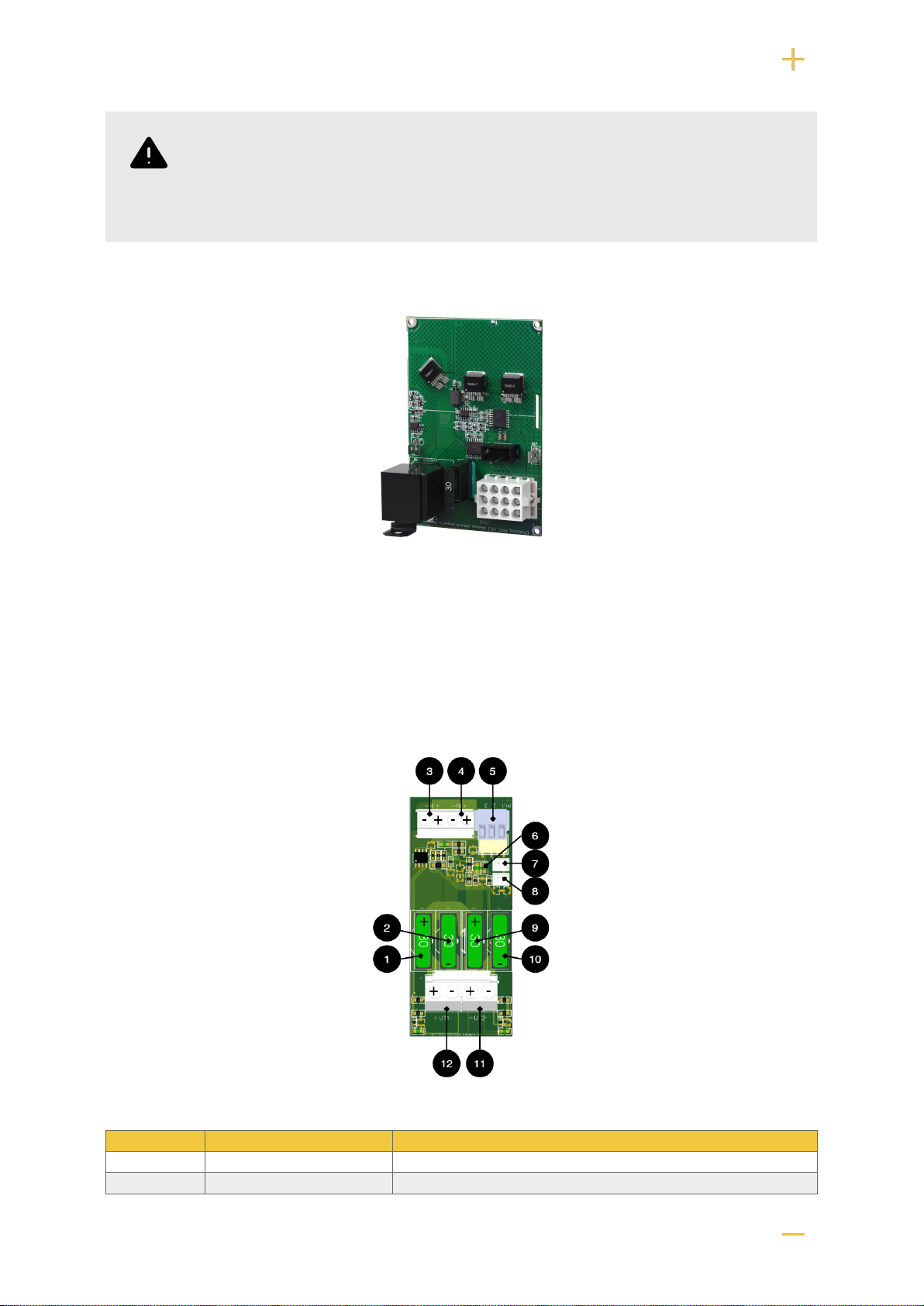

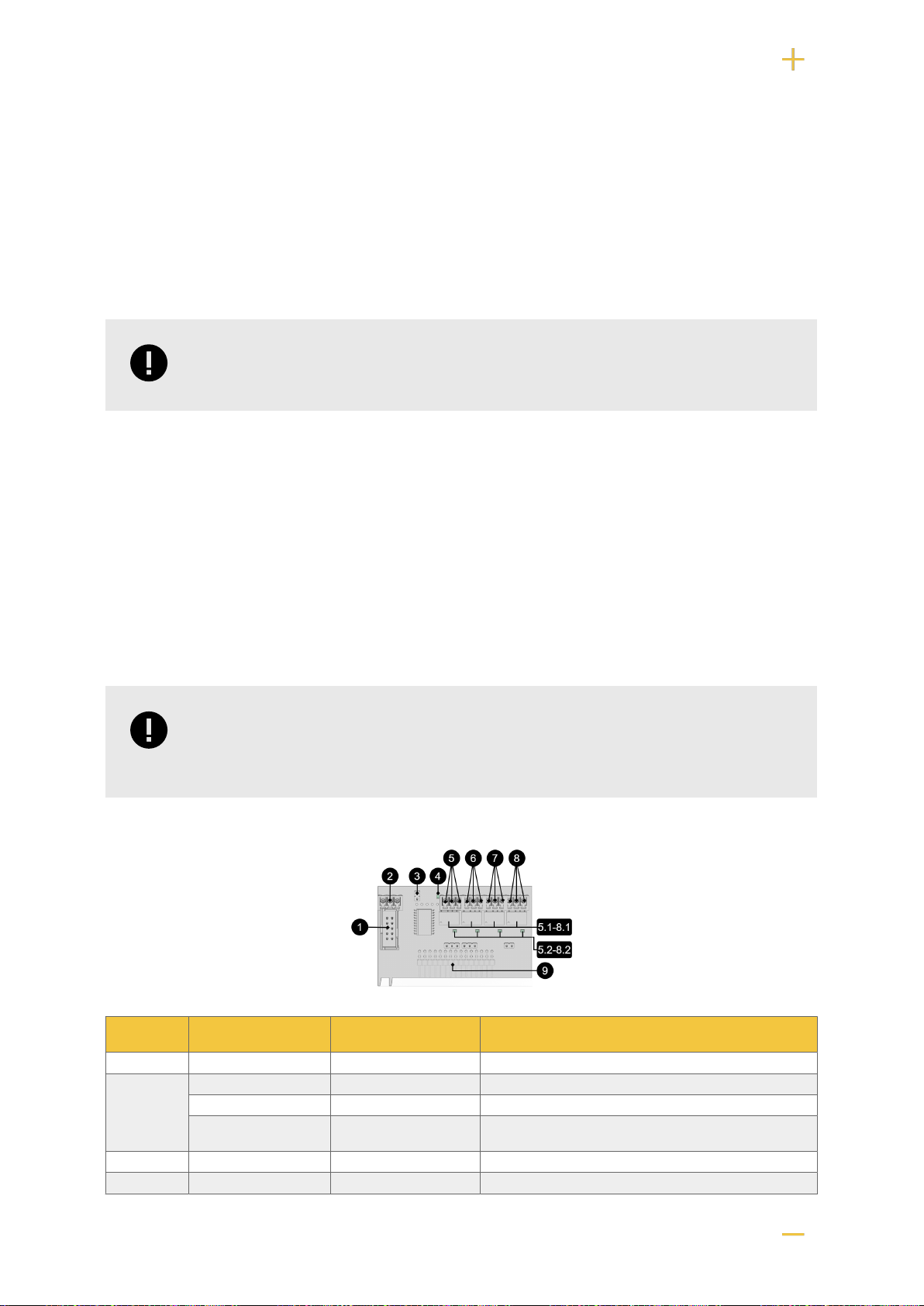

6.5. Load cards with blade fuses

The card replaces the load output on the motherboard.

The load card has a different type of fuse that is easier to change and at the same time the card

provides a easier connection of the load.

Table 7. Circuit board overview, explanation

No . On circuit board Explanation

1, 9 FUS2, FUS4 + fuse, 10 A- 25 A depending on the product.

2, 10 FUS1, FUS3 - fuse, 30A.

14

No . On circuit board Explanation

3, 4 IN1, IN2 Incoming connection 24 V, (from motherboard).

5 P1:1-3 Alarm relay: NC, Com, NO

6 D29, D30 LED.

7 J1 Fuse alarm.

8 J2 Fuse alarm for forwarding to several cards.

11, 12 +UT1-, +UT2- Load connection, outgoing, 24 V

Load is connected to 11 or 12 on fuse card, see component overview.

6.6. Alarm via communication

Connection of communication to the parent system takes place via JU6. See the parent system docu-

mentation for more information.

6.7. Communication to a parent system

It is possible to connect communication to a parent system via connections on P2: 5-13. See also

parent system documentation for compatible protocol. For more information on alarms; see ???.

Table 8. Connections over communication

Terminal block Explanation

P2: 7 RS-485 -

P2: 8 RS-485 +

P2: 9 System minus -

P2: 10 System-minus -

P2: 11 RXD

P2: 12 TXD

P2: 13 +5 V

6.8. Configuration of communication via RS-485

Communication via RS-485 is connected to P2: 7- & P2: 8+.

The address is set binary on the switch.

ADDRESS configuration:

Table 9. S1 Dip switch

Dip switch Value

Dip switch 1= 1

Dip switch 2= 2

Dip switch 3= 4

Dip switch 4= 8

If all dip switches are set to OFF, the address is 0+0+0+0=0.

If dip-switch 1 and 3 are ON, the address is 1+0+4+0= 5.

If dip-switch 2 and 4 are ON, the address is 0+2+0+8=10.

15

For Sentrion only: addresses in Sentrion add +1. This means that 1 must always be added to the

configuration.

If all dip switches are set to OFF, the address is 0+0+0+0(+1*)=0 (1*).

If dip-switch 1 and 3 are ON, the address is 1+0+4+0(+1*)= 5(6*).

If dip-switch 2 and 4 are ON, the address is 0+2+0+8(+1*)=10(11*).

6.9. Dip switch 1-8

Dip-Switch has several different configuration modes:

Table 10. Dip switch 1-8

Dip switch In mains operation or in battery operation Comment

1-4 Address for external communication. -

2 Address for external communication -

3 Address for external communication -

4 Address for external communication -

5 Sets alarm for mains failure delay Available from software v1.5

6 Sets alarm for mains failure delay Available from software v 1.5

7 Sets alarm for low battery level. Available from software v 1.5

8 Turns LED off or on. Upcoming feature through software update

8 in sequence Performs battery test Not available in NEO.

6.9.1. Address setting for external communication (Dip switch 1-4)

Dip-Switch S1: 1-4 sets addressing.

Table 11. Addressing Dip-Switch 1-4

Dip: 1 Dip: 2 Dip: 3 Dip:4

Adress 1 ON OFF OFF OFF

Adress 2 OFF ON OFF OFF

Adress 3 ON ON OFF OFF

Adress 4 OFF OFF ON OFF

Adress 5 ON OFF ON OFF

Adress 6 OFF ON ON OFF

Adress 7 ON ON ON OFF

Adress 8 OFF OFF OFF ON

Adress 9 ON OFF OFF ON

Adress 10 OFF ON OFF ON

Adress 11 ON ON OFF ON

Adress 12 OFF OFF ON ON

Adress 13 ON OFF ON ON

Adress 14 OFF ON ON ON

Adress 15 ON ON ON ON

6.9.2. Mains failure delay (dip 5-6)

It is possible to change the time for when the alarm for a power outage should be given. Use the matrix

to set the alarm.

16

Table 12. Mains failure delay

Alarms for mains failure are given after: Dip 5 Dip 6

10 seconds OFF OFF

30 minutes OFF ON

60 minutes ON OFF

240 minutes (4 hours) ON ON

6.9.3. Low battery level (dip 7)

Dip: 7 has the same function regardless of whether the unit is in mains or battery operation or whether

the tamper switch is held down.

Table 13. Low battery level

Alarm for low battery level is given Dip 7

22,8 V* ON

24 V OFF

*25% of battery capacity remains.

6.9.4. LED (dip 8)

LED/battery-test always lights up when the door is open.

Dip-switch 8=ON turns off the LED.

Dip-switch 8=OFF turns on the LED.

NOTICE

For certified units:

To comply with SSF-1014 up to alarm class 4, the LED on the door must be off

(Dip-switch 8 to ON).

6.9.5. Battery test (dip 8)

To do a battery test, dip 8 needs to change position and five seconds need to pass before the test is

initiated.

• If dip 8 in original position is on OFF then switch dip 8 to: ON (wait 5 seconds) and then switch back

to OFF.

• If dip 8 in original position is on ON then switch dip 8 to: OFF (wait 5 seconds) and then switch back

to ON.

This activates the battery test after 3-8 seconds. The battery test lasts for about 6 seconds and then

the LED flashes yellow quickly. Aged battery alarms may be indicated while the battery test is being

performed.

Only reset dip 8 when the test is complete.

17

6.10. Reboot to confirm changes in address, battery and alarm set-

tings to parent system

After the dip-switch has been set for various parameters, the device's software needs to be restarted.

This is for the new settings to be stored and take effect.

Restarting the device software is done by jumpering J13 (PRO2)

IMPORTANT

Reboot must be done every time a change is made to the device.

6.11. Alarm card for PRO2

Relay card - description, connections and alarm outputs.

• All fault arm relays must be in the drawn state. Check that there is a gap between CO and NC. Put

the measuring instrument on continuity measurement and test closure. This should then indicate a

short circuit.

• All relay outputs are normally live and give an alarm in the event of no voltage.

IMPORTANT

There is normally a 10 second delay in alarm reset. The software on the main board

must be configured for a different time period.

No . Relay (Terminal no.) The relay is normally

energized. Alarm type / explanation

1 J7 - Connection for RS-232 cable.

2 P4:1 - RS-232: TxD, data OUT from motherboard.

P4:2 - RS-232: RxD, data IN to motherboard.

P4:3 - RS-232: Ground, do not connect ground to another termi-

nal.

3 J6 - Reset jumper.

4 D7 - Indicator diode, flashes green during normal operation.

18

No . Relay (Terminal no.) The relay is normally

energized. Alarm type / explanation

5,5.1, 5.2 P5:1-3 NO, COM, NC Tamper alarm, (optional for EN54). 5.1 Relay. 5.2 LED,

lights up green when relay is energized.

6, 6.1, 6.2 P5:4-6 NO, COM, NC Alarm for: Low system voltage. 6.1 Relay. 6.2 LED, lights

up green when relay is energized.

7, 7.1, 7.2 P5:7-9 NO, COM, NC Alarm for: Fuse failure, charger failure overvoltage, charger

failure undervoltage, cell failure/not connected battery, low

battery voltage in case of mains failure and aged battery.

7.1 Relay. 7.2 LED, lights up green when relay is energized.

8, 8.1, 8.2 P5:10-12 NO, COM, NC Power failure alarm. 8.1 Relay. 8.2 LED, lights up green

when relay is energized.

9 J11 - Connection to motherboard.

Via communication on PRO1 card: All alarms and alarms for: Fan fault, overtemperature, subtemperature, short battery life left,

overcurrent 100% of minute average, overcurrent 80% daily average and overcurrent 175% second average.

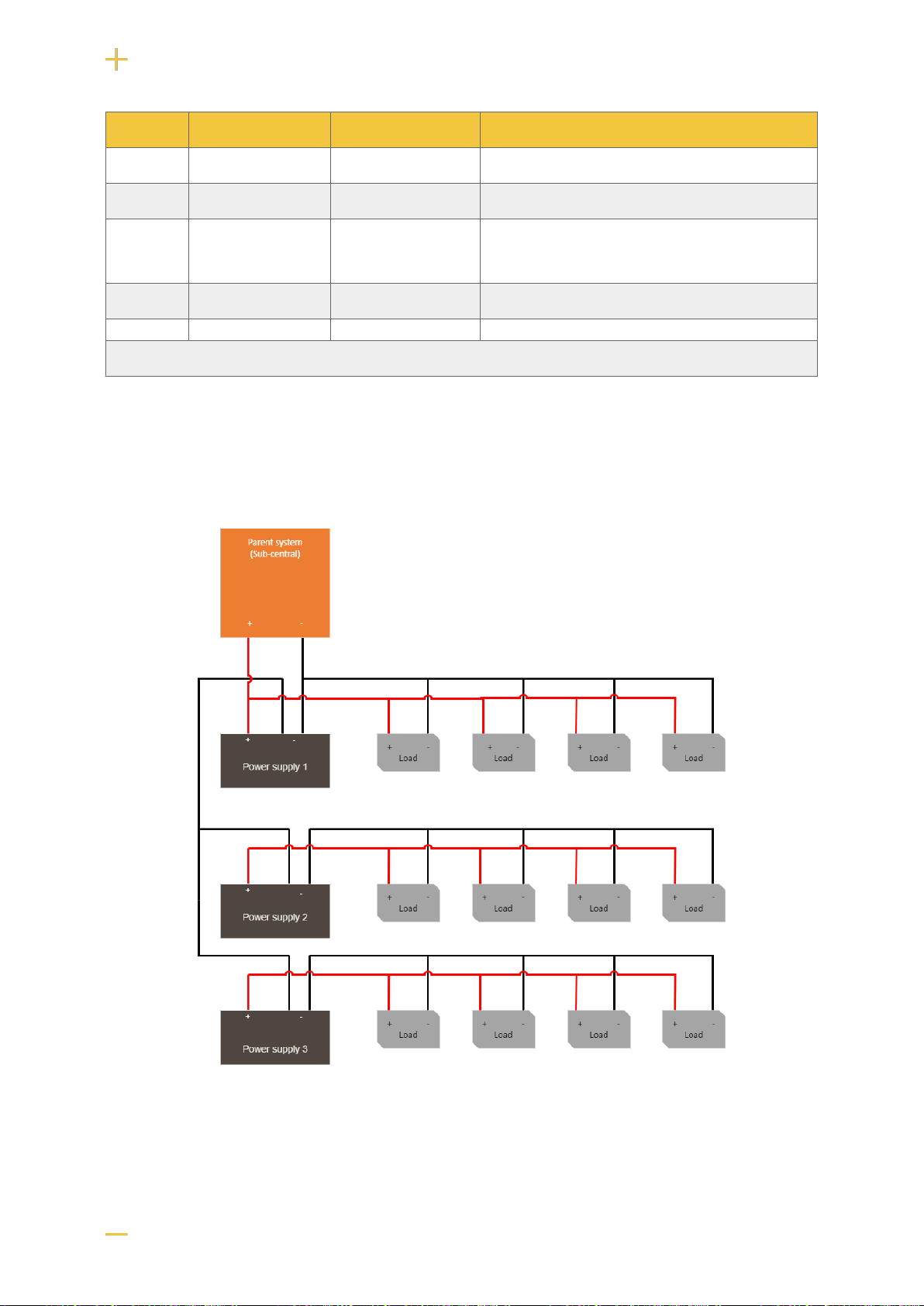

7. MULTIPLE UNITS INTO ONE PARENT SYSTEM

To connect several units to a parent system, load-minus (P2: 2, P2: 4) must be connected.

19

8. COMMISSIONING - HOW TO START THE UNIT

1. Connect batteries

2. Connect / switch on fuses

3. connect load, alarm and possibly. other connections.

4. Screw the mains cable into the terminal block and attach the terminal block to the motherboard.

5. Switch on mains voltage.

The unit works normally when the indicator LED on the outside of the cabinet door lights up with a solid

green light. See front panel for other status indications.

It may take up to 72 hours before the batteries are fully charged.

8.1. 72 hours after commissioning / battery change

For the first 72 hours after commissioning, the device does not perform a battery capacity test. The test

is postponed so that the device does not falsely alarm before the batteries are charged. The unit must

always be started with new batteries when commissioning or changing batteries and it is unlikely that

new batteries are faulty.

8.2. System test

Test the connected device by performing a system test afterwards commissioning [20].

• Switch on incoming mains voltage.

• Indicator LED on the outside of the cabinet door lights up with a solid green light. Disconnect the

mains voltage to check that the unit is operating in battery mode and alarms.

• Indicator LED on the cabinet door flashes, see alarm type panel.

• Switch on incoming mains voltage. Indicator LED, on the outside of the cabinet door, lights up with a

solid green light. Normal operation.

8.3. Recovery

Reset the unit by completely de-energizing the unit.

Disconnect battery wiring and mains voltage and reconnect after 5 seconds.

9. ALARM DISPLAYED ON CABINET DOOR

In normal mode, the indicator LED shows a solid green light.

20

Other manuals for NOVA FLX M

1

This manual suits for next models

24

Table of contents

Other milleteknik Power Supply manuals

Popular Power Supply manuals by other brands

Helios Power Solutions

Helios Power Solutions TDK-Lambda PFE700SA Series instruction manual

Gallagher

Gallagher M550 instructions

BCP

BCP PUOOUBZ How to install

Spellman

Spellman uX50P50 instruction manual

Elmdene

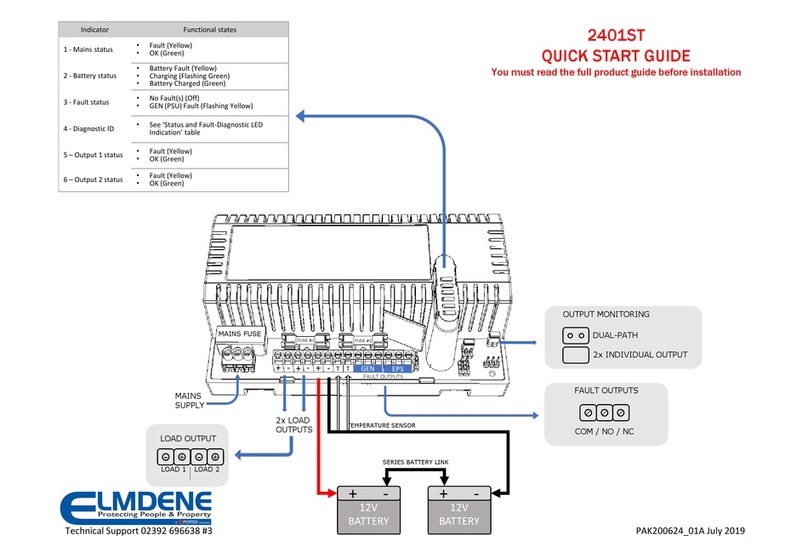

Elmdene 2401ST quick start guide

Cross Technologies

Cross Technologies 2000-2 LNB Series instruction manual