TABLE OF CONTENTS

5-3 OPERATING MODES...................................................................................................................... 30

Standby................................................................................................................................................... 30

Flush....................................................................................................................................................... 30

Filling Tank............................................................................................................................................ 31

Pre Operate............................................................................................................................................ 31

Dispensing.............................................................................................................................................. 32

Auto-Dispensing..................................................................................................................................... 32

5-4 HOW TO VIEW THE PRODUCT RESISTIVITY AND TEMPERATURE IN FILLING TANK MODE OR IN

PRE OPERATE MODE.................................................................................................................................... 33

5-5 HOW TO VIEW THE RO PERMEATE CONDUCTIVITY IN FILLING TANK MODE OR IN PRE

OPERATE MODE ........................................................................................................................................... 33

5-6 HOW TO RECIRCULATE WATER MANUALLY BEFORE DISPENSING ............................................... 34

5-7 HOW TO UNDERSTAND DIRECT-Q MESSAGES ............................................................................. 35

Pack Alarm............................................................................................................................................. 35

UV Lamp Alarm ..................................................................................................................................... 35

Flush: Open Tank Outlet Valve............................................................................................................. 36

CHAPTER 6MAINTENANCE......................................................... 37

6-1 MAINTENANCE SCHEDULE........................................................................................................... 37

6-2 HOW TO REPLACE THE SMARTPAK.............................................................................................. 38

Removing the SmartPak......................................................................................................................... 38

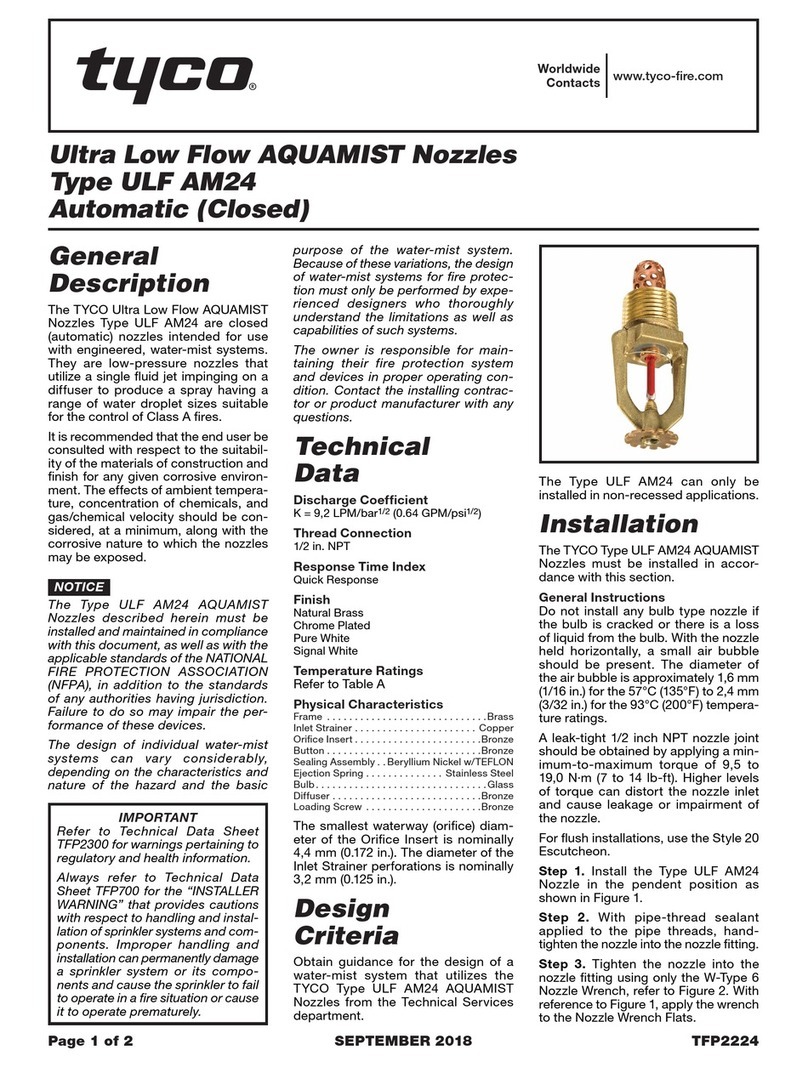

Installation ............................................................................................................................................. 39

Flush Mode............................................................................................................................................. 40

Rinsing the SmartPak............................................................................................................................. 40

Replacing the Vent Filter....................................................................................................................... 41

Installing the Tygon Tubing................................................................................................................... 41

Purging Air from the System.................................................................................................................. 41

Hydrating the System ............................................................................................................................. 41

Replacing the Final Filter...................................................................................................................... 41

6-3 HOW TO REPLACE THE FINAL FILTER.......................................................................................... 42

6-4 HOW TO CLEAN THE SCREEN FILTER........................................................................................... 43

6-5 HOW TO CALIBRATE THE TANK LEVEL (C04)............................................................................. 44

6-6 HOW TO EMPTY THE TANK (C03)................................................................................................ 46