Milltronics Sigma2 VM16 User manual

Electrical Manual

VM16,17,24,25,30

Sigma2 Axis Drives

With M5 Spindle

Rev 12

7-08-02

Electrical Manual

VM16,17,24,25,30 Sigma2 W/M5

SERVING YOUR METAL CUTTING NEEDS FOR MORE THAN 25 YEARS

Table Of Contents

Transformer Connection Alert.......................................................................................................................v

Electrical Safety Rules................................................................................................................................. vi

Machine Schematic.......................................................................................................................................1

Electrical Panel Layout (2-speed 22/15 shown)..........................................................................................23

Yaskawa M5 1-Speed Spindle Drive Parameters.......................................................................................27

Yaskawa M5 2-Speed Spindle Drive Parameters.......................................................................................28

C7 parameter group setting for 22/15 HP models using VS-626M5-11KW Inverter and VS-656MR5-

15KW Converter......................................................................................................................................29

Sigma 2 Axis Drive Parameters For VM Series..........................................................................................30

Card Cage Gain Setting Procedure.........................................................................................................31

Drive Setting Procedure ..........................................................................................................................32

Centurion 6 CNC Connector Signal Listing.................................................................................................33

Connector X-Input ...................................................................................................................................33

Connector Y-Input ...................................................................................................................................33

Connector Z-input....................................................................................................................................33

Connector A-Input ...................................................................................................................................33

Connector X-Output.................................................................................................................................33

Connector Y-Output.................................................................................................................................33

Connector Z-Output.................................................................................................................................34

Connector A-Output.................................................................................................................................34

Connectors X, Y, Z, A and B Axis (DC Brush Drives).............................................................................34

Connectors X, Y, Z, A and B Axis (Yaskawa Brushless Drives).........................................................34

Axis Home Connector..............................................................................................................................34

Spindle Drive Connector..........................................................................................................................35

Spindle Encoder Connector.....................................................................................................................35

Miscellaneous Connector (Misc) .............................................................................................................35

Front Panel Connector (FPP) and J2 on keyboard encoder card...........................................................35

Power Connector.....................................................................................................................................35

Connector Handwheel for remote handwheel option .........................................................................35

Connector Tool Changer.........................................................................................................................35

Connector COM1 (Card Cage)................................................................................................................36

Connector COM2 For rigid tapping option...............................................................................................36

Connector Floppy Disk............................................................................................................................36

Connector CRT (Video)...........................................................................................................................36

Connectors in the CNC control box ............................................................................................................36

Connector CRT (Monitor Power).............................................................................................................36

Connector FPACC...................................................................................................................................36

Connector P2...........................................................................................................................................36

Keyboard DIN Connector (J1).................................................................................................................37

Connectors in the Mag Box.........................................................................................................................37

Connectors ATC1 and 1-1E ....................................................................................................................37

Connector ATC2......................................................................................................................................37

Connector on +24 VDC Regulated Power Supply ..................................................................................37

Connector COM1 (on Mag Panel)...........................................................................................................37

Card Cage Assembly..................................................................................................................................38

LCD Front Panel Assembly.........................................................................................................................44

LCD Chassis Assembly...............................................................................................................................46

Electrical Manual

VM16,17,24,25,30 Sigma2 W/M5

SERVING YOUR METAL CUTTING NEEDS FOR MORE THAN 25 YEARS

History

4-21-99 Original Version

6-3-99 Update electrical drawings to rev D (reactors added).

7-12-99 Rev2 Added front panel drawings and SGDB15 drive parameters

7-28-99 Rev3 Added Auger / Flush circuit and updated mag panel drawing

10-29-99 Added remote hand controller

12-17-99 Rev 4 Updated chip flush / auger schematic to rev G.

1-31-00 Rev 5 Update to SBC card cage, add electrical safety caution

2-4-00 Rev6 Update to revE electrical schematics, ECO No. 4387

12-15-00 Rev 7 Update machine wiring and mag panel. Remove RHC

3-2-01 Rev 8 Update prints, electronic orient, single and dual speed

Updated spindle and axis drive parameters

4-10-01 Rev 9 Updated MC5 parameters for two-speed spindle systems

9-5-01 Rev 10 Updated prints to show Sigma2 axis drives but not M5 spindle. Remove Sig1 axis

parameters add Sigma2 parameters for VM16&17

1-23-02 Rev11 Change prints and spindle parameters to reflect M5 spindle change, updated Sigma2

parameter table

7-08-02 Rev12 Remove MC5 spindle parameters and add 2-speed M5 parameters

Electrical Manual

VM16,17,24,25,30 Sigma2 W/M5

SERVING YOUR METAL CUTTING NEEDS FOR MORE THAN 25 YEARS

Transformer Connection Alert

***** CAUTION *****

DRIVES WILL BE DAMAGED BY INCORRECT POWER CONNECTION

Disconnect transformer entirely from power supply.

Check resistance between transformer ground wire and each secondary leg.

If resistance is more than 1 or 2 ohms, then the transformer ground wire is not

connected to a neutral point within the secondary windings.

or

Disconnect transformer entirely from power supply.

Remove transformer cover and follow transformer ground wire to determine if it is

merely a case ground or if it actually goes to a neutral point within the secondary

windings.

or

Check voltages between each secondary leg and ground.

If they are not equal, the secondary windings are “floating” with respect to ground.

THE GROUND WIRE GOING INTO THE MACHINE MUST BE CONNECTED

TO A NEUTRAL POINT WITHIN THE SECONDARY WINDINGS

AND TO EARTH GROUND.

The secondary windings must be grounded.

Voltages between each secondary leg and ground should be equal, half the voltage

between secondary legs.

Electrical Manual

VM16,17,24,25,30 Sigma2 W/M5

SERVING YOUR METAL CUTTING NEEDS FOR MORE THAN 25 YEARS

Electrical Safety Rules

Read and understand the following list of cautions before attempting to perform service on this

equipment. Failure to observe these rules can result in death or serious injury.

Caution

· Beware of High Voltage present within the machine’s electrical cabinet

· Do not attempt to service electrical components unless you are qualified to work on them

safely

· Only qualified personnel should attempt to make current and voltage readings

· Always turn the main power off before servicing components within the electrical cabinet

· Always keep hands and fingers away from live electrical terminals

· Remove jewelry while servicing the machine to avoid shorting any electrical circuits

· Allow all components to discharge before servicing them, wait at least 15 seconds after

powering off, before servicing

FAILURE TO FOLLOW THESE RULES CAN RESULT IN SERIOUS INJURY OR DEATH

Electrical Manual

VM16,17,24,25,30 Sigma2 W/M5

SERVING YOUR METAL CUTTING NEEDS FOR MORE THAN 25 YEARS

1 Rev.12

Machine Schematic

Electrical Manual

VM16,17,24,25,30 Sigma2 W/M5

SERVING YOUR METAL CUTTING NEEDS FOR MORE THAN 25 YEARS

2 Rev.12

Electrical Manual

VM16,17,24,25,30 Sigma2 W/M5

SERVING YOUR METAL CUTTING NEEDS FOR MORE THAN 25 YEARS

3 Rev.12

Electrical Manual

VM16,17,24,25,30 Sigma2 W/M5

SERVING YOUR METAL CUTTING NEEDS FOR MORE THAN 25 YEARS

4 Rev.12

Electrical Manual

VM16,17,24,25,30 Sigma2 W/M5

SERVING YOUR METAL CUTTING NEEDS FOR MORE THAN 25 YEARS

5 Rev.12

Electrical Manual

VM16,17,24,25,30 Sigma2 W/M5

SERVING YOUR METAL CUTTING NEEDS FOR MORE THAN 25 YEARS

6 Rev.12

Electrical Manual

VM16,17,24,25,30 Sigma2 W/M5

SERVING YOUR METAL CUTTING NEEDS FOR MORE THAN 25 YEARS

7 Rev.12

Electrical Manual

VM16,17,24,25,30 Sigma2 W/M5

SERVING YOUR METAL CUTTING NEEDS FOR MORE THAN 25 YEARS

8 Rev.12

Electrical Manual

VM16,17,24,25,30 Sigma2 W/M5

SERVING YOUR METAL CUTTING NEEDS FOR MORE THAN 25 YEARS

9 Rev.12

Electrical Manual

VM16,17,24,25,30 Sigma2 W/M5

SERVING YOUR METAL CUTTING NEEDS FOR MORE THAN 25 YEARS

10 Rev.12

Electrical Manual

VM16,17,24,25,30 Sigma2 W/M5

SERVING YOUR METAL CUTTING NEEDS FOR MORE THAN 25 YEARS

11 Rev.12

Electrical Manual

VM16,17,24,25,30 Sigma2 W/M5

SERVING YOUR METAL CUTTING NEEDS FOR MORE THAN 25 YEARS

12 Rev.12

Electrical Manual

VM16,17,24,25,30 Sigma2 W/M5

SERVING YOUR METAL CUTTING NEEDS FOR MORE THAN 25 YEARS

13 Rev.12

Electrical Manual

VM16,17,24,25,30 Sigma2 W/M5

SERVING YOUR METAL CUTTING NEEDS FOR MORE THAN 25 YEARS

14 Rev.12

This manual suits for next models

4

Table of contents

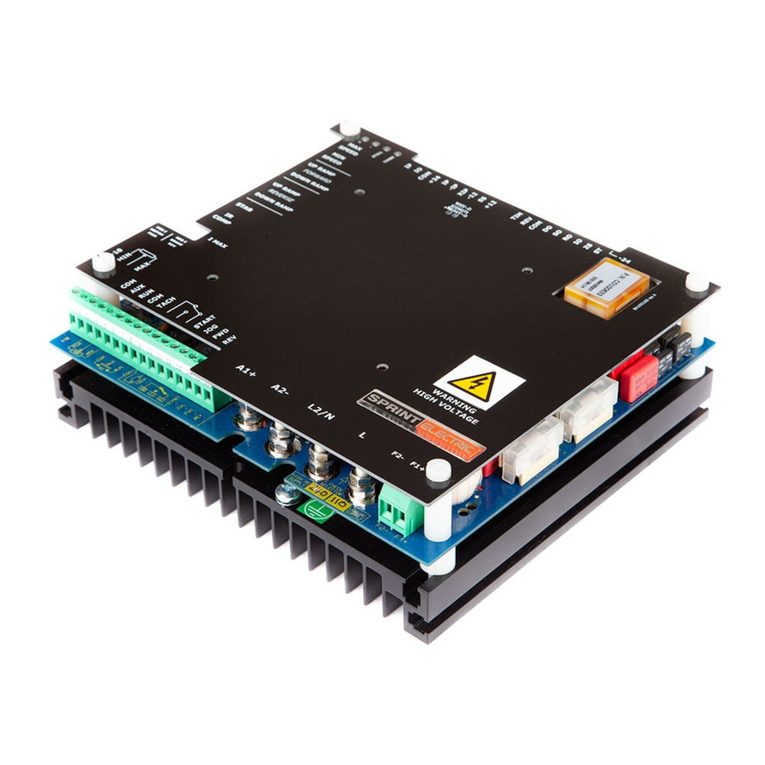

Popular DC Drive manuals by other brands

ABB

ABB ACS 300 user manual

Allen-Bradley

Allen-Bradley PowerFlex 4M installation instructions

Rockwell Automation

Rockwell Automation MD60 user manual

OWC

OWC ThunderBlade user guide

HardWay

HardWay RangeMaster V Series owner's manual

Rexnord

Rexnord Falk V-Class VR Installation, operation & maintenance manual