-.)F-.G&1/->D&1-3433DEB5H&

The inching drive can be disassembled by following

the steps outlined below. Refer to Figure 18 for an

illustration of the components.

1. Drain oil from inching drive clutch housing

and V-Class reducer.

2. The inching motor may be removed to

facilitate disassembly of the Ultramite by

removing the mounting fasteners.

3. With Ultramite reducer properly supported,

remove the bolts that secure the Ultramite to

the clutch housing. To prevent damage to

the clutch do not allow the Ultramite

gearbox to hang at an angle while sliding the

Ultramite reducer off.

4. If necessary, remove the clutch outer

element by removing the mounting bolts.

5. If necessary, remove the clutch hub by first

removing the two (2) setscrews. The clutch

hub can then slide off.

6. Before removing the inner element of the

overrunning clutch, the snap ring must first

be removed from the V-Class shaft. The

inner element of the overrunning clutch may

require the use of a wheel puller to remove it

from the shaft. The tapped holes in the

clutch should be used for removal to prevent

damage to the sprag cage or sprags.

7. Only if necessary, remove the clutch

housing from the V-Class reducer by

removing the mounting bolts.

CAUTION: Since the clutch housing is

used to set the bearing float in the V-Class

reducer, removal is only recommended

when servicing the V-Class reducer. A

Rexnord factory service representative will

be required when reassembling the clutch

housing to verify the V-Class reducer has

the proper bearing float and bevel gear

contact.

8. Thoroughly clean all surfaces on the clutch

housing and the Ultramite flange to remove

any gasket eliminator before reassembling.

&

-.)F-.G&1/->D&433DEB5H&

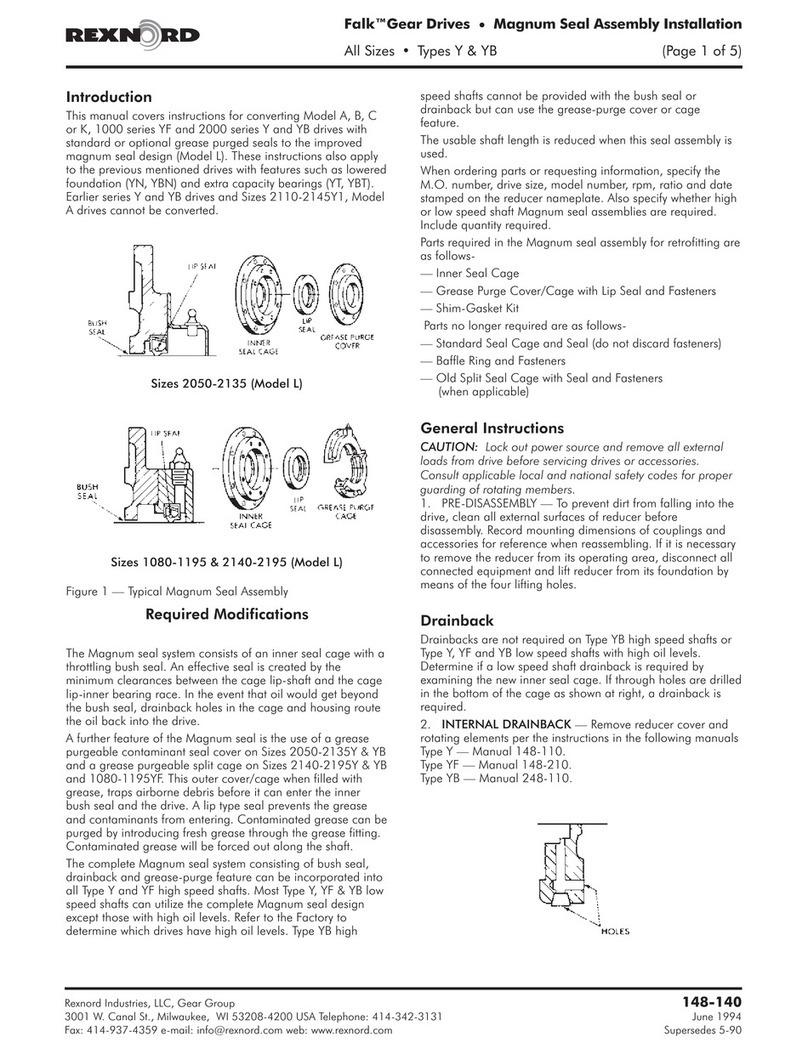

The inching drive assembly consists of an Ultramite

UB drive with output flange, Ultramite output shaft,

inching drive motor, clutch hub, overrunning clutch

and clutch housing. These components are shown

below in Figure 18.

Figure 18 – Inching drive assembly

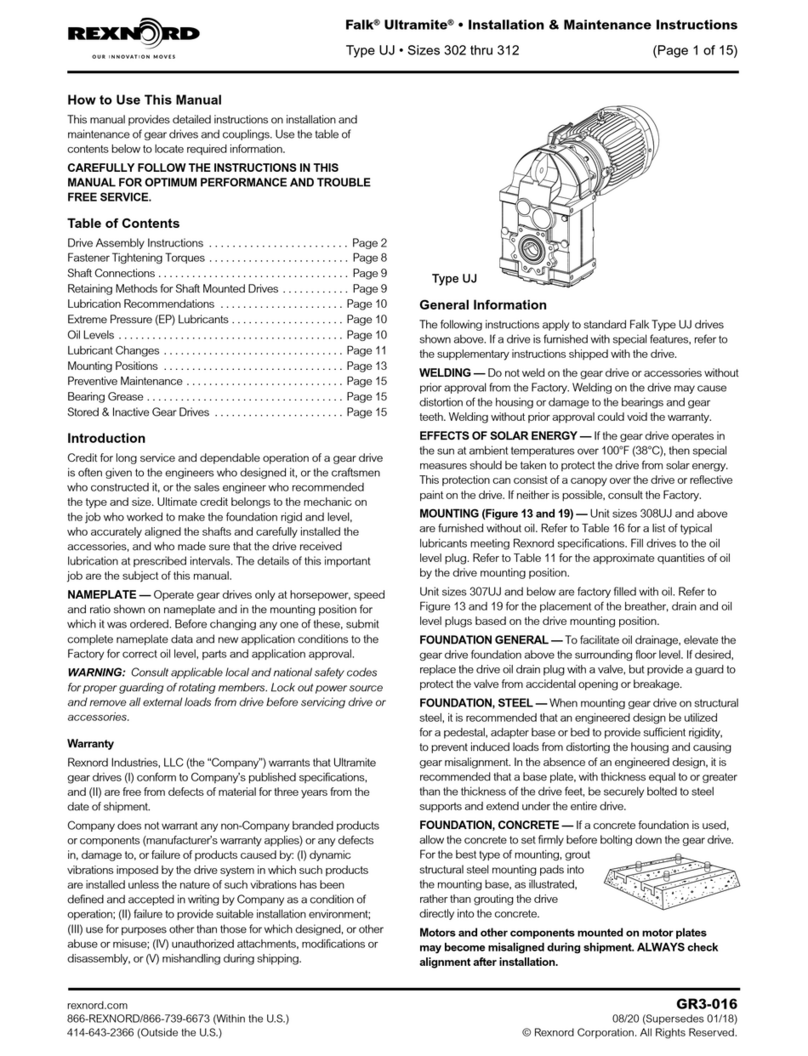

2$+@"A9+%&2B&4,,%A#$I&

The Ultramite UB is supplied from the factory with

flange sealant applied to the output flange when it is

mounted to the Ultramite. If the output flange is ever

removed from the Ultramite, flange sealant will need

to be applied to a clean surface before remounting it

to the Ultramite.

Insert the snap ring into the Ultramite hollow shaft on

the side opposite the output flange. Install the keys in

the keyways of the Ultramite output shaft. Apply a

continuous bead of flange sealant (Loctite 515 or

equivalent) to the Ultramite drive side of the flange

on the output shaft as shown in Figure 19. Slide the

output shaft into the Ultramite drive hollow shaft.

Apply Loctite 242 or equivalent to the cap screw and

using the keeper plate, secure the output shaft.

Tighten cap screw to torque value specified in Table

2. Apply Permatex sealant to the bore plug and

install into the Ultramite housing to cover the output

shaft.

Figure 19 – Ultramite UB components