ABOUT THE TRANSDUCER

The ST-100 series of transducers operates in

association with Milltronics ultrasonic level

monitoring products.

The transducer converts the electrical energy of

the transmit pulse from the transceiver into

acoustical energy. It then converts the acoustical

energy of the echo back into electrical energy for

the transceiver receive period.

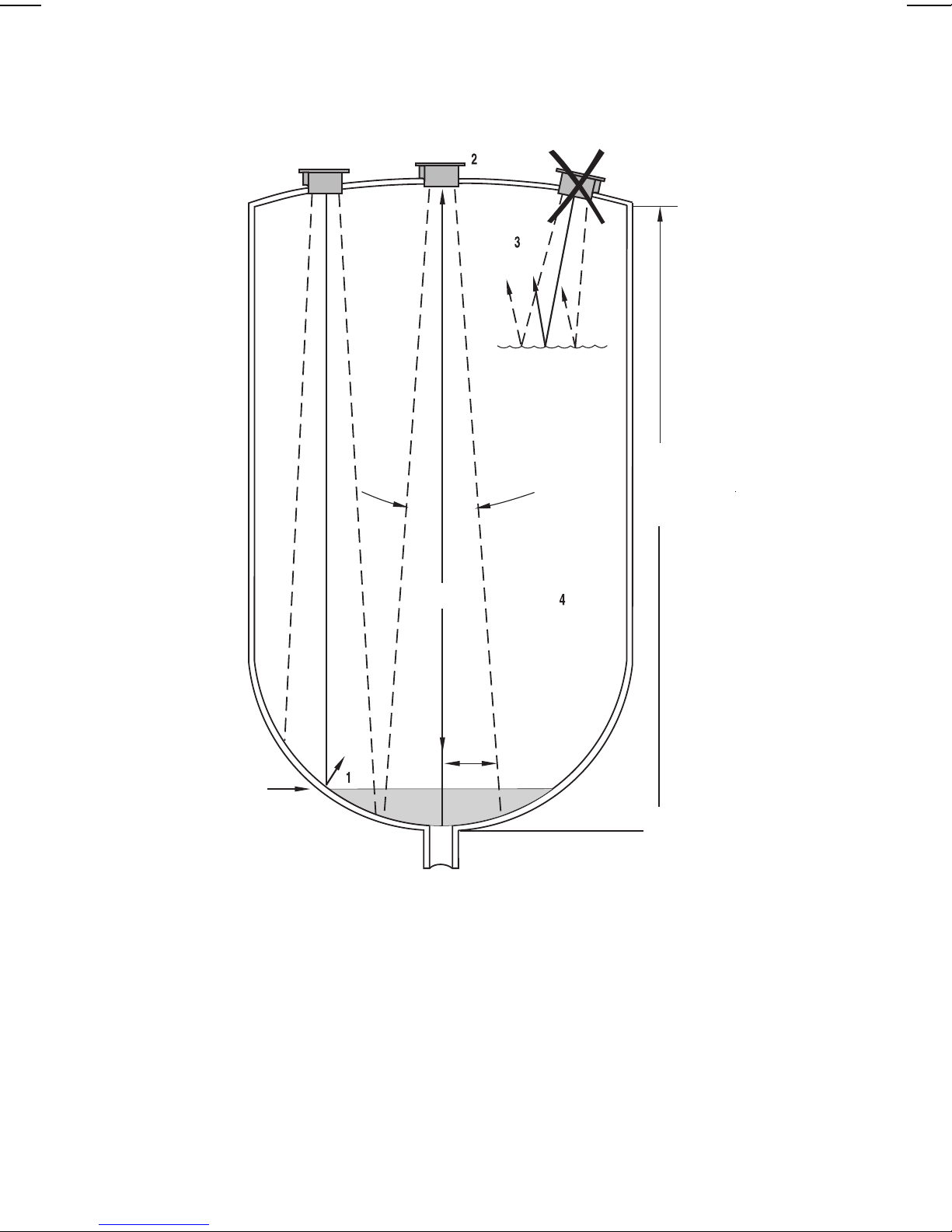

The effective acoustical energy is generated from

the transducer face and is radiated outward,

decreasing in amplitude at a rate inversely

proportional to the square of the distance.

Maximum power is radiated axially (perpendicular)

from the transducer face in a line referred to as the

axis of transmission. Where power is reduced by half

(– 3 dB), a conical boundary defining the sound beam,

centered about the axis of transmission is established.

The diametric measurement of the cone in degrees

defines the beam angle. Impedance matching

techniques are used to optimize the transfer of

power from the transducer into air and from the air

back into the transducer.

SPECIFICATIONS

Model : » ST-100

Measurement range : » typically 30 m (100 ft.) restricted to transceiver maximum▲

Temperature range : » – 40 to 93 °C (– 40 to 200 °F)✧

Frequency : » typically 44 KHz, transceiver dependent

Beam angle : » 7°

Weight* : » 15.9 Kg (35 lb)

Construction : » aluminum housing with polyurethane face

» 1/2" NPT female conduit connection

» options: » flanging: the transducer can be factory flanged,

consult Milltronics

» facing: » CPVC for corrosive applications.

» Teflonfor corrosive applications.

» polyethylene foam for dry-dust applications.

Separation : » typically 365 m (1200 ft) from associated transceiver▲

Approvals : » CSA, FM and BASEEFA / CENELEC

*approximate shipping weight of transducer with standard cable length and unflanged

▲refer to associated transceiver manual.

✧ maximum temperature for polyethylene foam facing is 77 °C (170 °F).

Teflonis a registered trade mark of Dupont.

–3 db

boundary

transducer

face

axis of

transmission,

perpendicular

to transmission

face

12 °

beam

angle

transducer

PL-419 1