4

arsenic, barium, beryllium, lead, pesticides or other

health endangering materials.

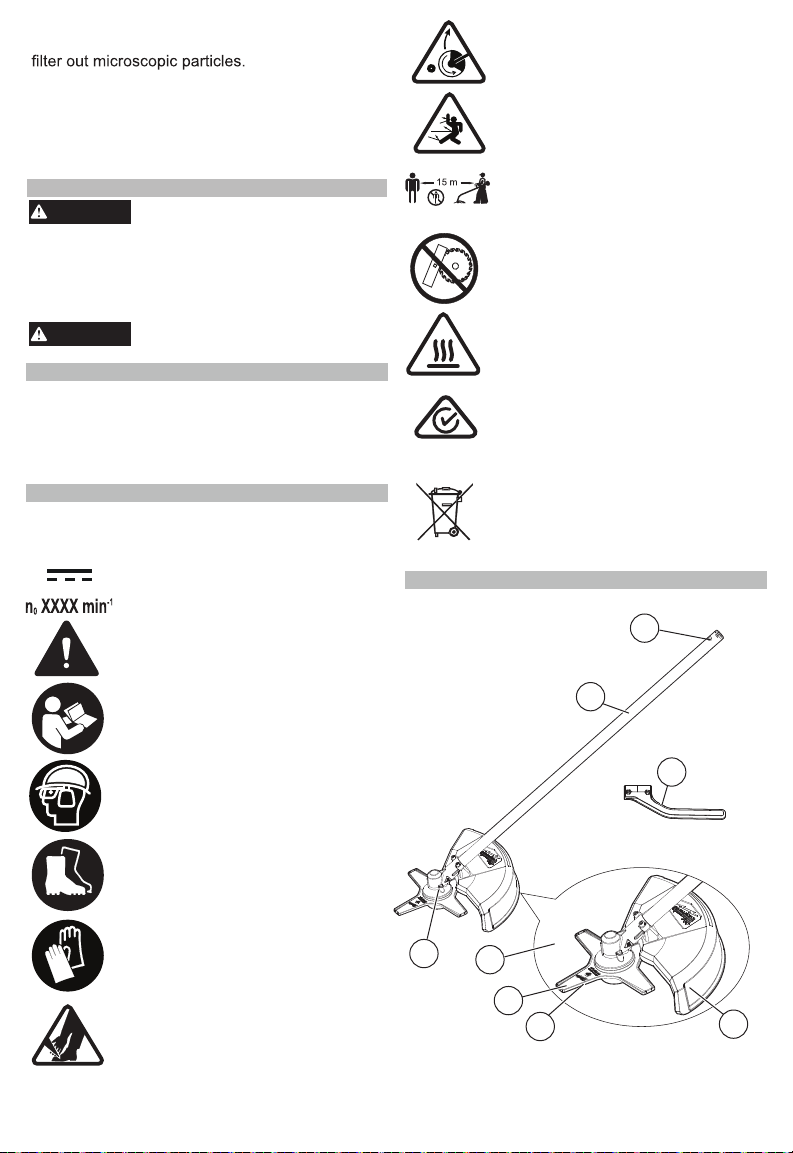

Blade thrust causes and related warnings:

•lead from lead-based paint

•crystalline silica from bricks and cement and other

masonry products, and

•arsenic and chromium from chemically-treated

lumber.

Your risk from these exposures varies, depending on

how often you do this type of work. To reduce your

exposure to these chemicals: work in a well ventilated

•Use care when using around decorative plants

and other obstacles. Accessories will cut/damage

many materials.

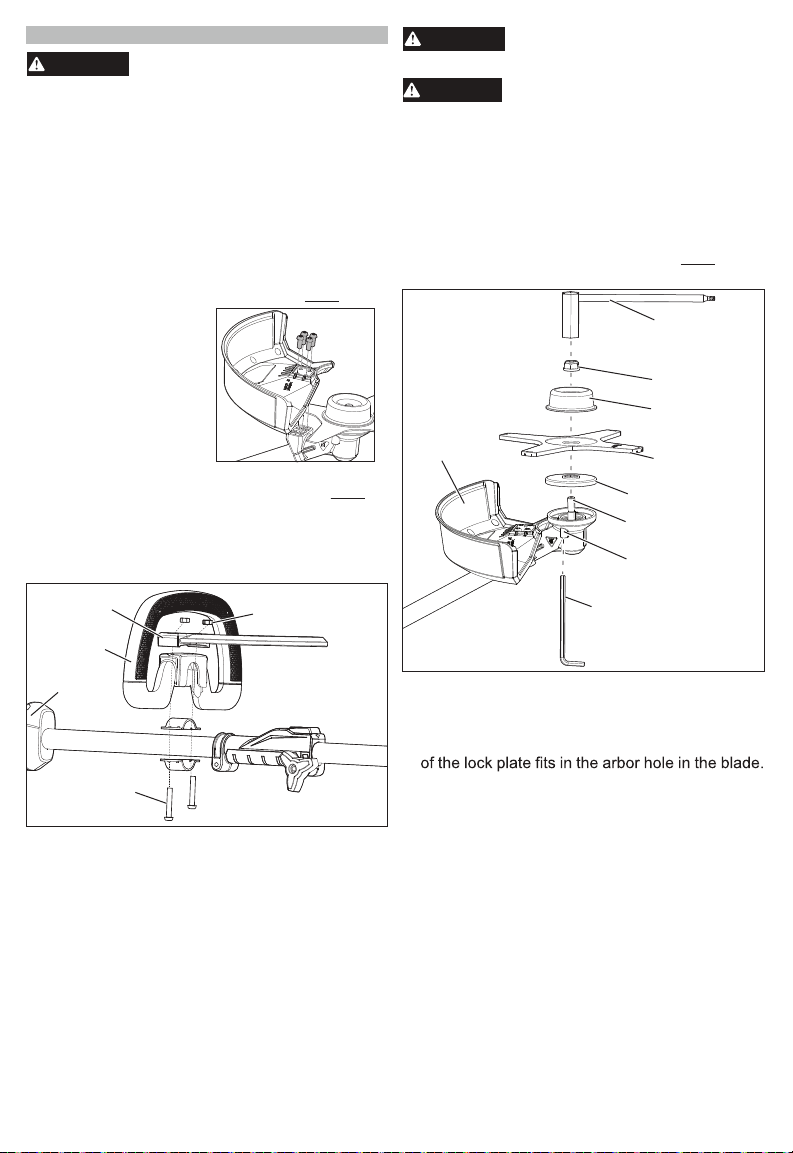

•Do not operate the tool without the guard in

place. The guard must be attached properly

during use. Operating the tool without the guard

will cause serious injury.

•Do not use tool with a damaged cutter head.

Cracked or broken pieces can be thrown.

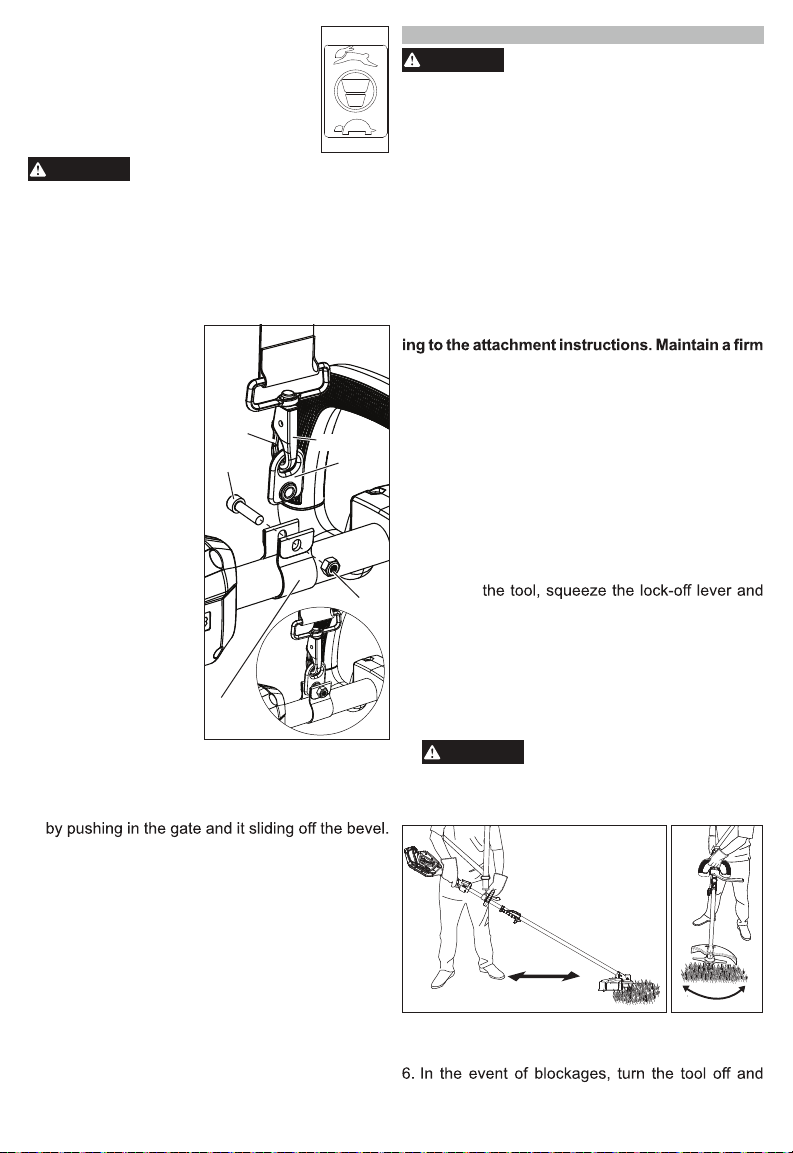

•Do not operate the tool without the front handle

and hip barrier in place. The front handle must

be attached properly during use. Use both

hands when operating the tool, according to the

Using one hand could cause loss of control and

result in serious injury.

•

•Keep face, hands and feet clear of moving parts at

all times. Moving parts can cause severe lacerations.

•Brace for unexpected movement when contact

is made with a hard object. Loss of control could

result in serious injury.

such as walls, trees, and rocks and cause injury.

When possible, do cutting by hand in closed in areas.

•Carry the tool by the front handle to avoid ac-

cidental starting. Proper handling of the tool will

prevent injury.

•

one location to another.

on the trigger. Accidental starting can cause serious

personal injury.

•Do not immerse in water or spray with a hose. Do

not clean with a pressure washer. Water entering

a power tool will increase the risk of electric shock.

Store tool indoors.

•Do not store the power tool on or near to fertilisers

or chemicals.

•

pack before changing or removing accessories.

WARNING

Do not operate near electric

•

power lines. The unit has not been

designed to provide protection from electric

shock in the event of contact with electric

power lines. Consult local regulations for safe

distances from electric power lines and ensure

that the operating position is safe and secure

before use.

•

Do not use an attachment extension with this

tool attachment. The additional length will make

cause injury.

Use the shoulder strap to reduce user fatigue

and help in maintaining control of the tool dur-

ing use.

•Do not wear multiple shoulder straps simultane-

ously. When wearing a shoulder strap, ensure

that no other wearable interferes with the release

and removal of the strap.

•Do not use the tool near anything that is burning or

smoking such as cigarettes, matches, or hot ashes.

•

To reduce the risk of health hazards from vapours

or dust, do not use tool near toxic, carcinogenic

or other hazardous materials such as asbestos,

machine and position your arms to resist blade

thrust. Position your body to the left side of the

machine. Blade thrust can increase the risk of injury

due to the machine moving unexpectedly. Blade

thrust can be controlled by the operator if proper

precautions are taken.

•If the blade binds, or when interrupting a cut

the machine motionless in the material until the

blade comes to a complete stop. While the blade

is binding, never attempt to remove the machine

from the material or pull the machine backward

while the blade is in motion, otherwise blade

thrust may occur. Investigate and take corrective

actions to eliminate the cause of blade binding.

•Do not use blunt or damaged blades. Blunt or

damaged blades increase the risk of jamming or

catching on an object, resulting in blade thrust.

•Always maintain good visibility of the material

being cut. Blade thrust is more likely to occur in

cut.

•If you are approached by another person while

There is an increased risk of injury to other persons

being struck by the moving blade in the event of

blade thrust.

Other brushcutter safety rules:

•

Before use, read this manual, and all manuals

and labels of this tool and its power head.

Failure to follow the warnings and instructions

may result in serious injury. Use tool only as

described in this manual. Use only attachments

recommended by MILWAUKEE®.

Do not use the tool as an edger. Do not tilt tool

to create a right angle to the ground. Keep

brushcutter head parallel to the ground. Guard

cannot protect against flying debris in this

orientation.

WARNING

Some dust

sawing, grinding,

creat

drilli

ed by power sanding,

ng, and other

construction activities contains chemicals known to

cause cancer, birth defects or other reproductive

harm. Some examples of these chemicals are:

•

Maintain labels and nameplates. These carry

important information. If unreadable or missing,

contact a MILWAUKEE®service facility for a

replacement.

•Always use common sense and be cautious

when using tools. It is not possible to anticipate

every situation that could result in a dangerous

outcome. Do not use this tool if you do not

understand these operating instructions or you feel

the work is beyond your capability; contact

MILWAUKEE®Tool or a trained professional for

additional information or training.

Blade thrust is a sudden sideways, forward or

backward motion of the machine, which may occur

when the blade jams or catches on an object such

as a sapling or a tree stump. It can be violent

enough to cause the machine and/or operator to be

propelled in any direction, and possibly lose control

of the machine.

Blade thrust and its related hazards can be avoided

by taking proper precautions as given below.