28a

28b

28

18a 18b

18c

18

7

1

2

3

4

5

6

15 14e 14d 14c 14b 14a

25 24 20 19b 19a

16

17a

17b

18a

18b

18c

17c

17d

17c

17e

17f

17g

17h

31d

31c

31a

31b

28b

28a

27

22b

36a

29a (4x)

30

26

17a 17b 17c 17d 17e

17f 17g 17h 18

17

19a

19b

19

33

34

35

19b

36b

36c

37

38

39

19b 36a

36b 36c

36

29b (2x)

31a 31b

31c 31d

31

29b

(2x)

29a

(4x)

DO NOT exceed

40 In/Lbs for #29b

There are slightly

smaller teeth

on one side of

drive sleeve

#34 that are to

face the spindle

bevel gear #33.

17h 20

Washer

#20 is to be

located here on

barrel #17h

17c

Position

tapered side

of rebound rings

#17c to face striker #19

and anvil #18 as shown

14a 14b 14c

14d 14e

14

9 8

12 11 10

13 14a 24

14a (Back side)

Be sure to orient front notches of bearing shield

#14a at the 12:00/6:00 position or at the 9:00/3:00

position prior to installing in gearcase #24. Doing

so will allow tabs in rear of bearing shield to

seat in corresponding notches in gear

case cavity. This must be done to

allow for proper seating of

retaining ring #13.

FIG. PART NO. DESCRIPTION OF PART NO. REQ.

19 45-56-5316 Striker Assembly (1)

19a 45-56-5320 Striker (1)

19b 34-40-5310 O-Ring (2)

20 45-88-5314 Washer (1)

22b 05-78-5316 M4 x 14mm Pan Hd. Taptite T-20 (2)

24 14-29-0028 Gearcase Assembly (1)

25 14-08-0055 Clutch Assembly (1)

26 45-06-5316 Rubber Gasket (1)

27 44-66-5313 Selector Bracket Clamp Plate (1)

28 14-46-5312 Fork Assembly (1)

28a --------------- Fork (1)

28b --------------- Fork Assembly Spring (1)

29a 05-78-5315 M5 x 33mm Pan Hd. Taptite T-25 (4)

29b 05-78-5315 M5 x 33mm Pan Hd. Taptite T-25 (2)

30 31-12-0013 Gearcase Cover (1)

31 23-66-5316 Selector Knob Assembly (1)

31a 44-62-0710 Rubber Plug (1)

31b 40-50-5320 Spring (1)

31c 34-40-5309 O-Ring (1)

31d 43-98-5321 Selector Knob (1)

33 32-75-5316 Spindle Bevel Gear (1)

34 45-22-5316 Drive Sleeve (1)

35 44-66-5312 Locking Plate (1)

36 14-09-5316 Piston and Connecting Rod Assembly (1)

FIG. PART NO. DESCRIPTION OF PART NO. REQ.

36a --------------- Wrist Pin (1)

36b --------------- Piston (1)

36c 44-94-0710 Connecting Rod (1)

37 32-30-0105 Crank Shaft (1)

38 02-50-5315 Needle Bearing (2)

39 45-88-5327 Washer (1)

PART NO. DESCRIPTION OF FIXTURE

61-10-1027 Armature Press Gauge

61-10-1030 Seal Driver

61-10-1032 Seal Expander

61-10-1035 Anvil Insertion Guide

61-10-1037 Seal Driver

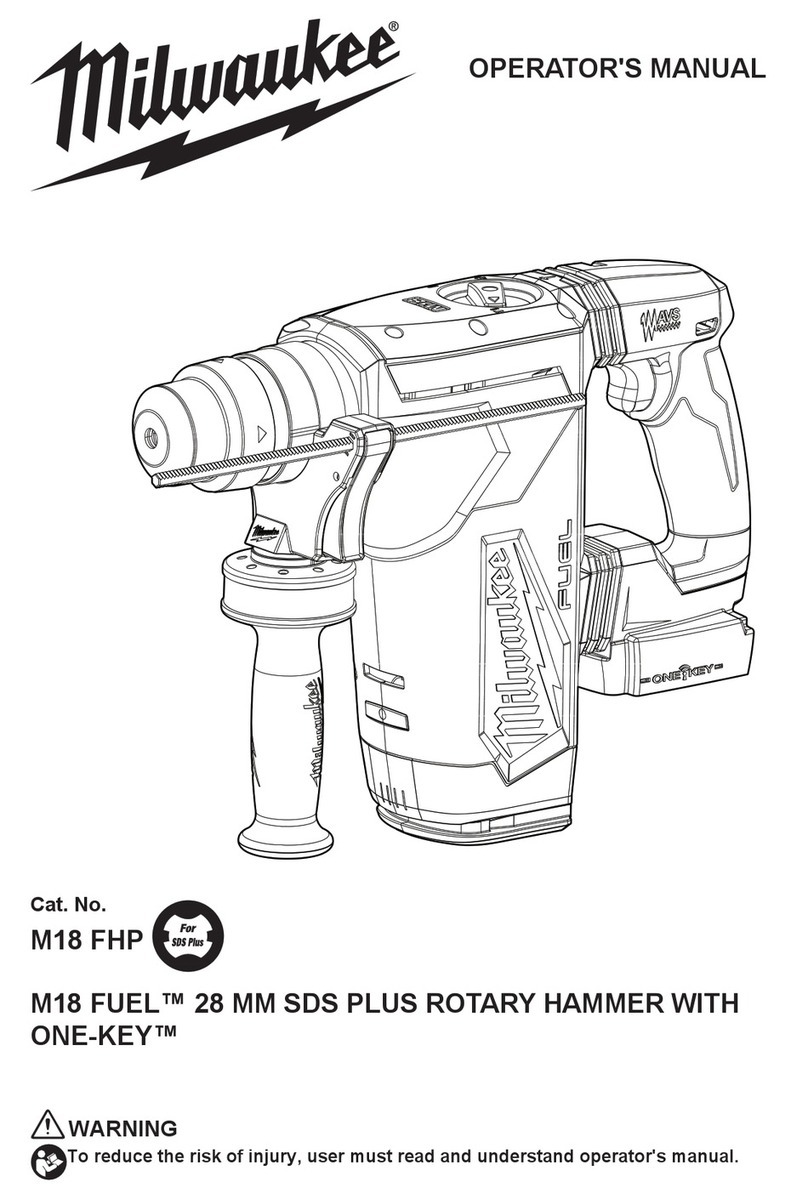

SERVICE FIXTURES FOR THE

2717-20 and 5317-20 SDS ROTARY HAMMER

FIG. PART NO. DESCRIPTION OF PART NO. REQ.

1 45-12-5316 Rubber Dust Shield (1)

2 45-22-5317 Front Latch Sleeve (1)

3 34-60-5316 Retaining Ring (1)

4 45-88-5316 Washer (1)

5 34-40-5316 Spindle O-Ring (2)

6 45-88-5321 Washer (1)

7 45-22-5319 Sliding Collar (1)

8 45-22-5321 Locking Sleeve (1)

9 45-88-5371 Washer (1)

10 44-66-5316 Front Spring Retainer (1)

11 40-50-5318 Spring (1)

12 44-66-5314 Rear Spring Retainer (1)

13 34-40-5315 Retaining Ring (1)

14 14-46-5316 Bearing Shield Assembly (1)

14a --------------- Bearing Shield (1)

14b 34-40-5321 O-Ring (2)

14c 45-06-5170 Felt Seal (1)

14d 45-06-5180 Rotary Seal (1)

14e 02-50-5316 Bearing Ring (1)

15 45-88-5323 O-Ring (1)

16 44-20-5316 Key (2)

17 38-50-5316 SDS-Max Spindle Assembly (1)

17a 44-82-5317 SDS-Max Spindle (1)

17b 43-06-5317 Brake Ring (1)

17c 45-88-5325 Rebound Ring (2)

17d 34-60-5321 Back Press Ring (1)

17e 44-60-5316 Spindle Sleeve Pin (6)

17f 44-90-5317 Steel Ring (1)

17g 44-90-5319 Spring Ring (1)

17h 38-50-5323 Barrel (1)

18 42-06-5316 Anvil Assembly (1)

18a --------------- Anvil (1)

18b 34-60-5319 O-Ring (2)

18c 45-06-5317 Turcon Seal (2)

=Component of the 14-46-0064

Service Maintenance Kit