54-24-0575

54-24-0576

1-1/8" ROTARY HAMMER 893B

Feb. 2006

5303-20 58-01-1130

FIG. PART NO. DESCRIPTION OF PART NO. REQ.

3 12-20-0407 Nameplate (1)

6 10-07-6215 Product Label (2)

8 45-88-1245 Washer (1)

9 44-90-0340 Snap Ring (Ext.) (1)

10 43-87-0080 Isolation Block (1)

102 31-15-0255 Brush Cover (2)

106 05-74-0685 Screw (4)

107 05-74-0715 Screw (2)

108 05-78-0715 Screw (3)

109 05-74-0695 Screw (2)

110 05-74-0700 Screw (2)

113 05-78-0745 Screw (4)

132 34-40-0145 O-Ring (1)

200 31-40-0040 Gearcase (1)

204 44-86-0625 Splined Retainer (1)

206 31-15-0305 Crankcase (1)

207 43-44-0375 Gasket (1)

208 45-88-8825 Washer (1)

209 34-40-4440 O-Ring (1)

210 02-80-6025 Thrust Bearing Set (1)

211 14-73-0246 Wobble Shaft Assembly (1)

212 36-66-3160 Reduction Gear Shaft (1)

214 45-88-1250 Washer (1)

215 40-50-8895 Spring (1)

216 45-22-0300 Coupling Sleeve (1)

217 45-88-1240 Washer (1)

218 36-92-0745 Wobble Plate (1)

219 32-60-2621 Reduction Gear (1)

220 32-60-2155 Offset Gear (1)

221 32-60-2165 Internal Gear (1)

222 44-82-0190 Ram (1)

223 --------------- Piston (1)

224 44-60-1405 Wrist Pin (1)

225 45-88-1180 Washer (2)

226 44-90-4500 Shift Ring (1)

227 34-40-4454 O-Ring (1)

228 44-60-1485 Pin (1)

229 44-66-6055 Retaining Plate (1)

232 --------------- Spindle (1)

233 40-50-7975 Belleville Spring (6)

234 45-88-7765 Stop Washer (1)

235 32-75-1205 Spindle Gear (1)

236 44-90-4510 Retaining Ring (Ext.) (1)

237 45-88-1255 Washer (1)

FIG. PART NO. DESCRIPTION OF PART NO. REQ.

238 02-80-0150 Thrust Washer (1)

239 45-88-0775 Locking Washer (1)

240 45-60-0495 Striker Support (1)

241 44-82-0085 Ram Catcher (1)

242 34-40-4451 O-Ring (1)

243 42-76-0725 Thrust Collar (1)

244 44-90-4415 Retaining Ring (1)

245 45-56-2535 Striker (1)

246 45-88-1260 Washer (1)

247 34-40-4452 O-Ring (1)

248 45-88-1265 Washer (1)

249 34-40-4453 O-Ring (1)

251 34-40-4459 O-Ring (1)

252 42-76-0265 Quik Change Collar (1)

253 44-90-0105 Ring (1)

254 02-02-0100 Ball (6)

255 40-50-8900 Spring (1)

256 44-90-0350 Snap Ring (Int.) (1)

257 44-90-0110 Ring (1)

258 40-50-8905 Spring (1)

259 45-88-1270 Washer (2)

260 45-88-1275 Washer (1)

267 05-77-0030 Bolt (1)

269 45-60-0511 Spindle Bearing Support (1)

270 44-90-0115 Ring (1)

274 34-40-4465 O-Ring (1)

420 36-66-4266 Intermediate Gear Set (1)

426 45-88-1170 Washer (1)

427 45-88-1175 Washer (2)

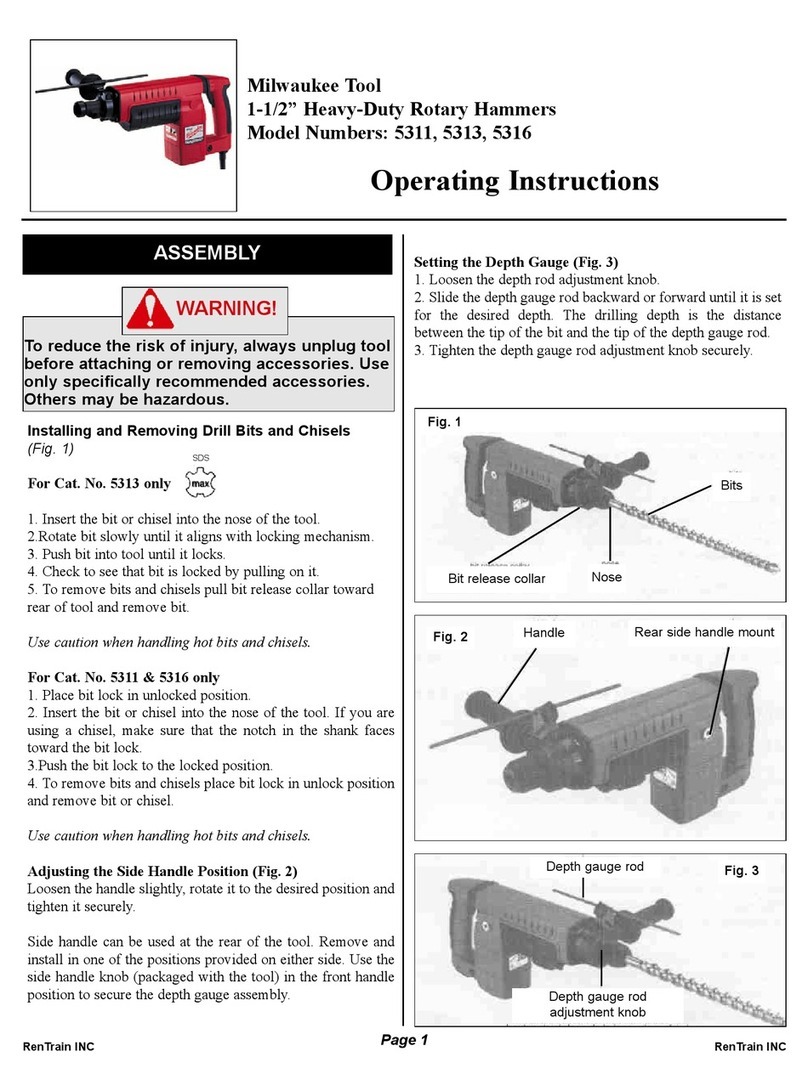

605 43-46-0170 Depth Gauge (1)

610 48-03-3040 Quik Change SDS-Plus Chuck (1)

700 48-55-5303 Carrying Case (1)

703 49-15-0305 Side Handle w/Depth Rod (1)

1202 44-10-0075 Shift Lever (1)

10-15-0270 Warning Tag (1)

14-46-5303 Lubrication Service Kit (1)

PAGE 1 OF 2

SEE BACK PAGE OF THIS BULLETIN

FOR ADDITIONAL LUBRICATION

AND SERVICE NOTES

REVISED BULLETIN

SERVICE PARTS LIST BULLETIN NO.

EXAMPLE:

Component Parts (Small #) Are Included

When Ordering The Assembly (Large #).

WIRING INSTRUCTION

DATE

0

00

CATALOG NO.

SPECIFY CATALOG NO. AND SERIAL NO. WHEN ORDERING PARTS

SERIAL

NUMBER

MILWAUKEE ELECTRIC TOOL CORPORATION

13135 W. LISBON RD., BROOKFIELD, WI 53005

Drwg. 4

«

«

«

«

«

«

«

«