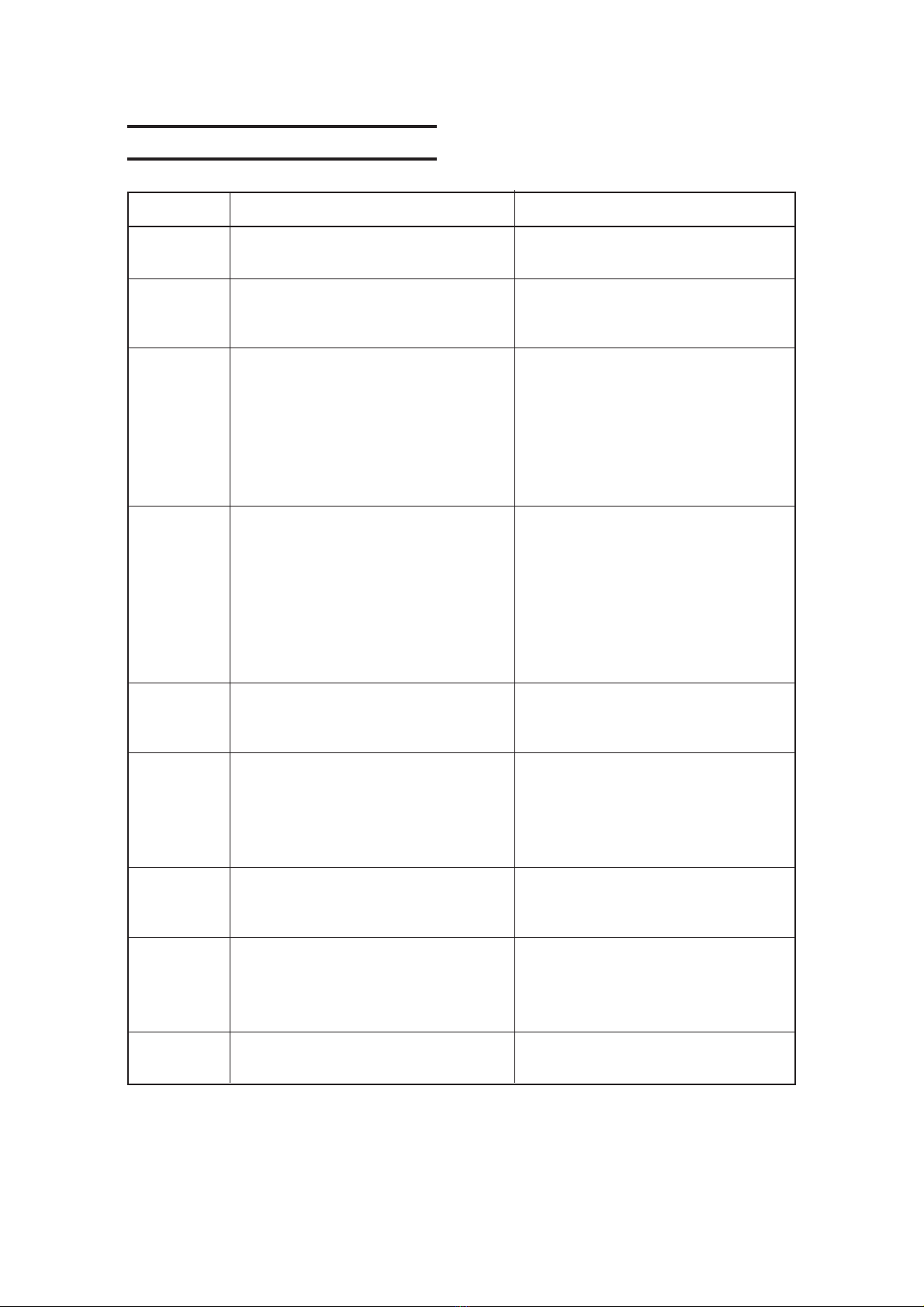

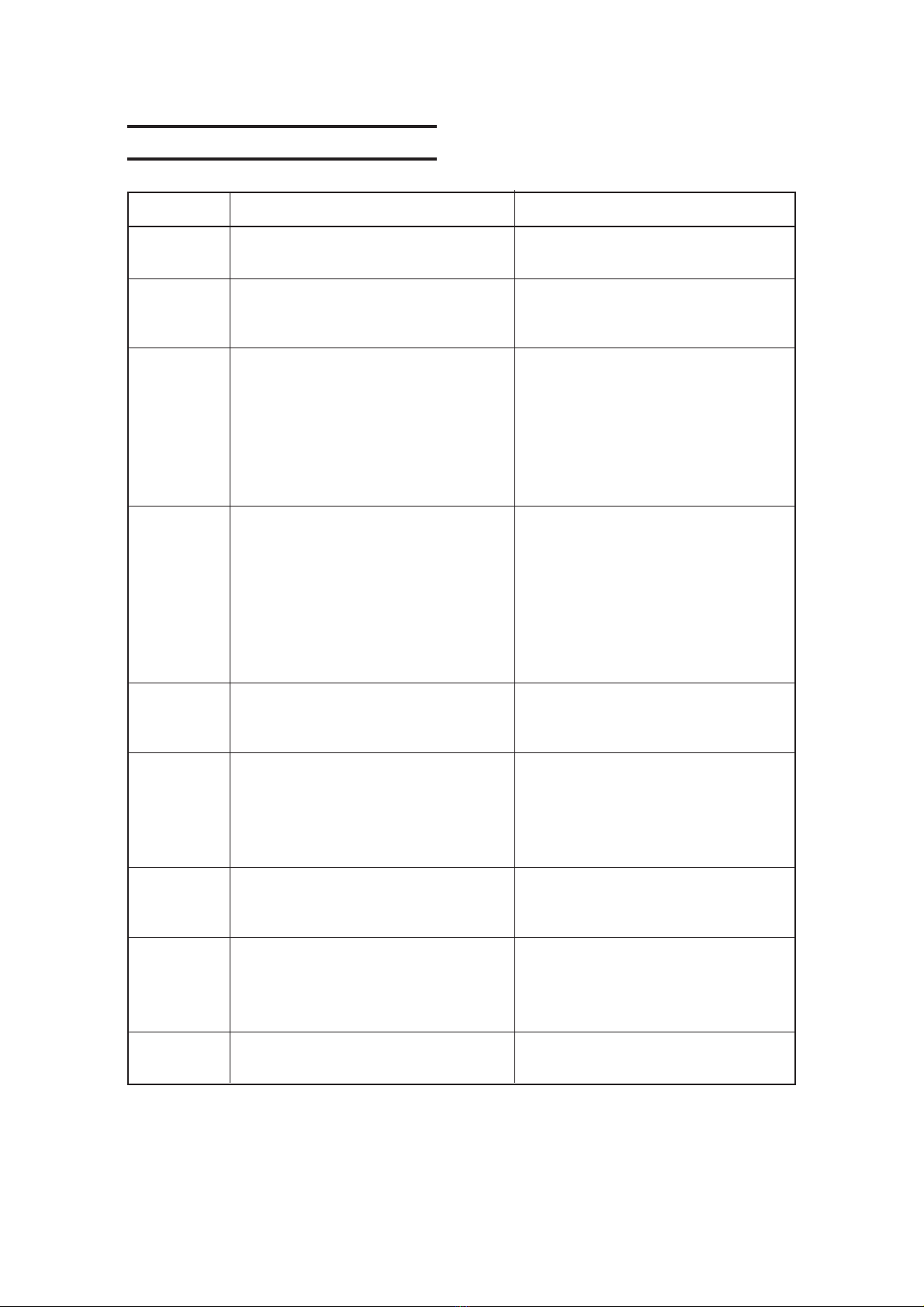

– 1.9 –

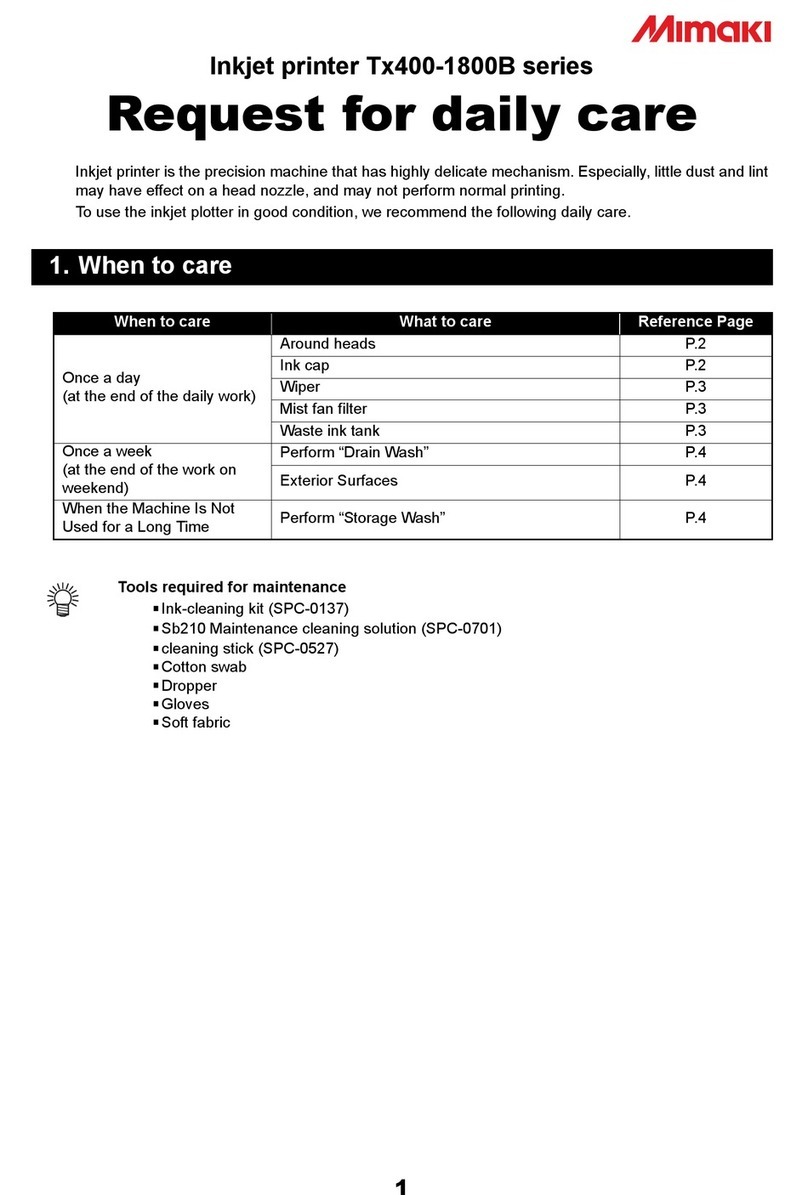

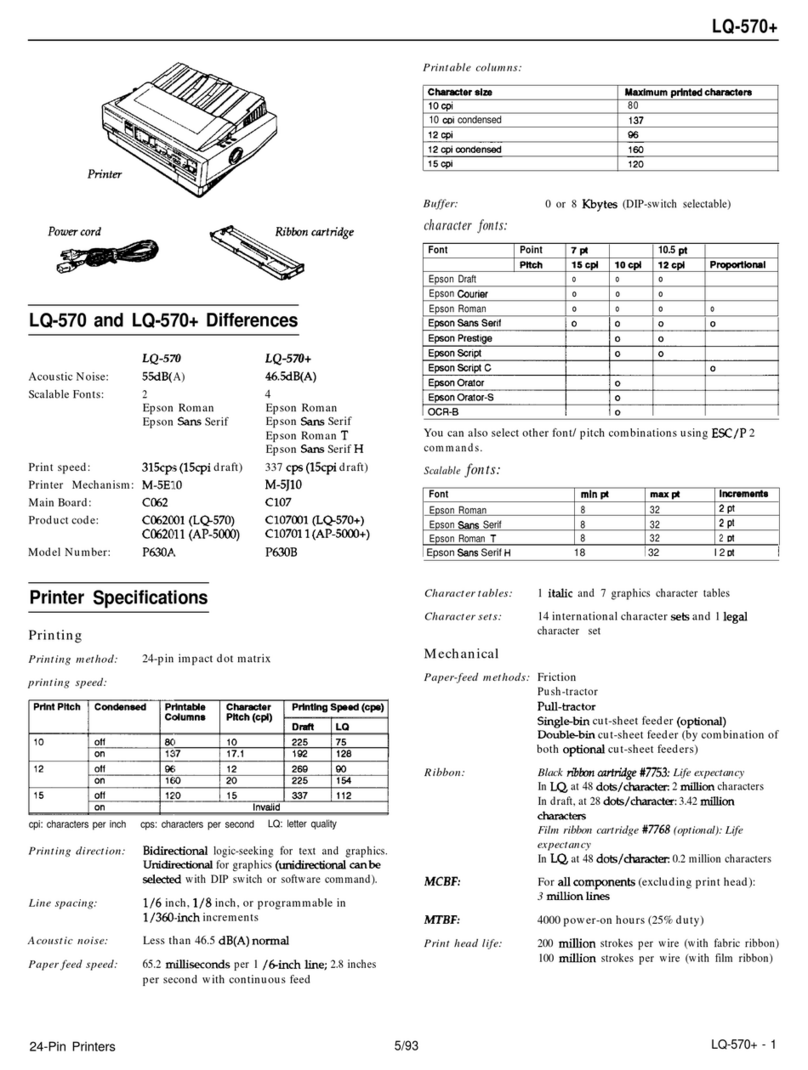

Handling Notes Effects and influences

Cloth setting 1

2

3

4

5

Winding 1

2

Plotting 1

2

1-6. Cloth Media Handling Notes

Pull out the cloth once to the front and then roll

by holding the roll holder or paper tube.

If the cloth is stretched on the right and left,

hardened by gumming, thick, or folded, release

the pinch roller at the faulty area.

Band stripe output in plotting differs when the

end of the cloth has exceeded the friction roller

and when it has reached the take-up device.

Start plotting after the end of the cloth reaches

the take-up device or is set on the take-up paper

tube.

Use the platen board if the ink does not pen

etrates through the cloth.

The head gap becomes relatively large where

the cloth plotting area is drooping, and produces

a black line where it is not.

A narrow rolled cloth had better be rolled

inward and outward repeatedly for straightening

before setting.

For winding, use the interval method and avoid

the continuous (tension) method.

Since the interval method does not apply

tension, a cloth cannot be wound tight. Conse-

quently, a 46-meter cloth may not be wound.

A very elastic cloth (ex. Lycra or Spandex)

cannot be used. This should be explained to the

user in advance.

Wetting shrinks a cloth and the right and left

edges are stepped.

This corrects the cloth not fed straight or equally

tense at the left and right centers.

This prevents wrinkling behind the pinch roller.

Tension at the cloth plotting area is determined

by the friction roller tension and the self weight

of the drooping cloth. This tension should be

made almost constant.

If you take the drooping cloth during plotting,

you can check its influence at the plotting line.

(A line appears.)

The platen board prevents the cloth from

drooping from the plotting area by the self

weight (+ ink weight).

If “Media correction” is adjusted to where the

cloth is not drooping:

1)A black line appears at a dropping place.

2)A white line appears at a non-drooping

place.

A narrow rolled cloth may become askew

greatly because the cloth is projecting outward.

In the continuous method, if the winding

diameter becomes large, the winding torque is

lost due to its own load and the tension on the

cloth decreases.If constant tension is lost, a

band stripe appears.

Loose winding causes the cloth to interfere

with the nearby shaft early.

An elastic cloth is stretched at the friction

roller and starts slipping when stretched to

certain extent. This makes the feed rate not

constant.

A plotted band shrinks and its end does not

match that of the next band.