Remove ink on the wiper and bracket with a cleaning stick dampened with cleaning liquid.

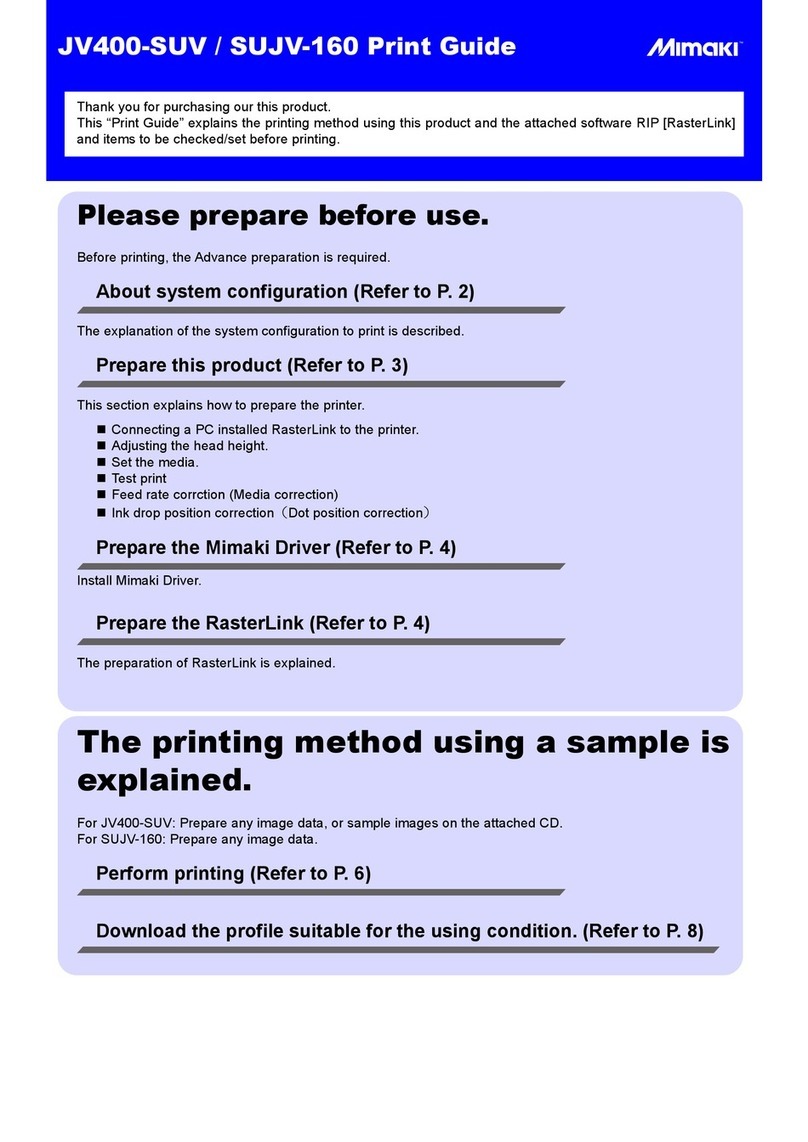

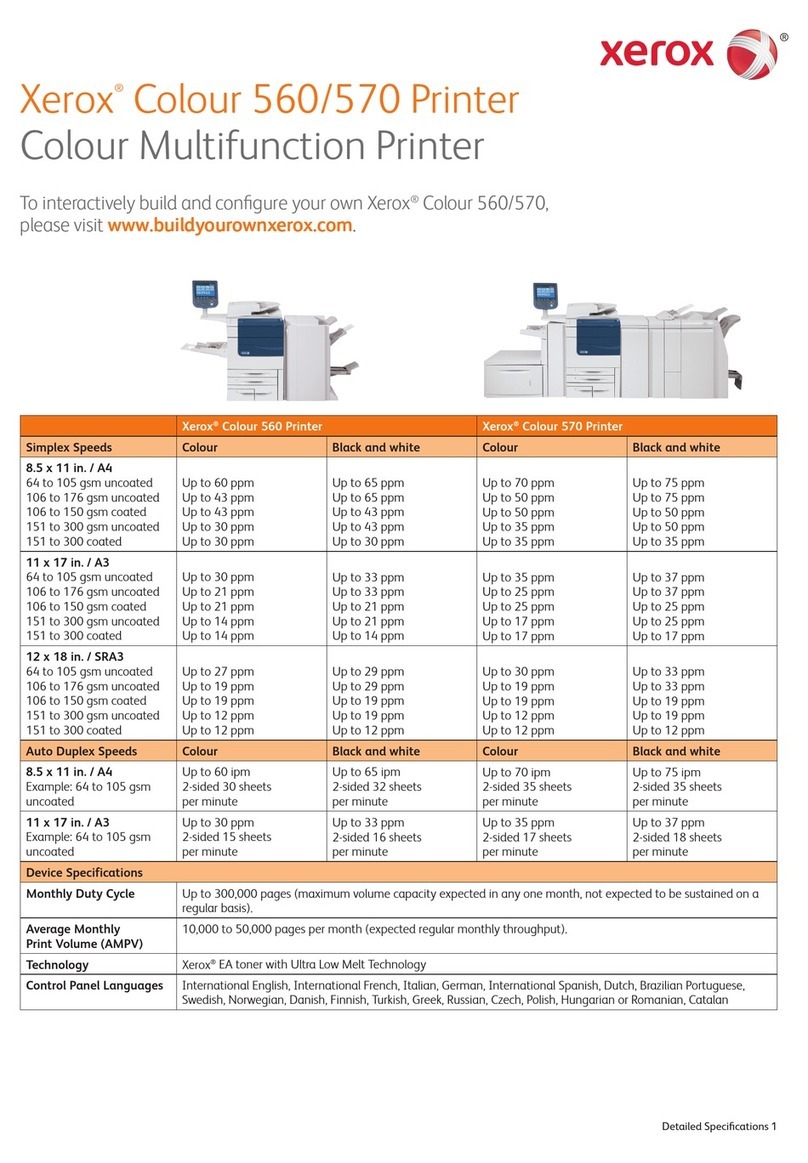

To keep your printer running at its best, make sure to work on the daily maintenance along with the instructions described below.

See [Operation Manual Chap.4 Maintenance] and [Request for Care and Maintenance] for details.

・Maintenance cleaning liquid 200 kit for solvent ink (for use of solvent inks) [part number: SPC-0369]

・Cleaning liquid bottle kit for sublimation ink (for use of sublimation inks) [part number: SPC-0137]

・Cleaning stick to clean head-surrounding area (part number: SPC-0527)

・Goggles (accessory of the printer)

・Gloves (included in the maintenance cleaning liquid kit)

・Dry cloth (lint-free, clean cotton cloth)

・Cotton swab (included in the maintenance cleaning liquid kit)

② Remove ink on the wiper slider with a cleaning stick dampened with cleaning liquid.

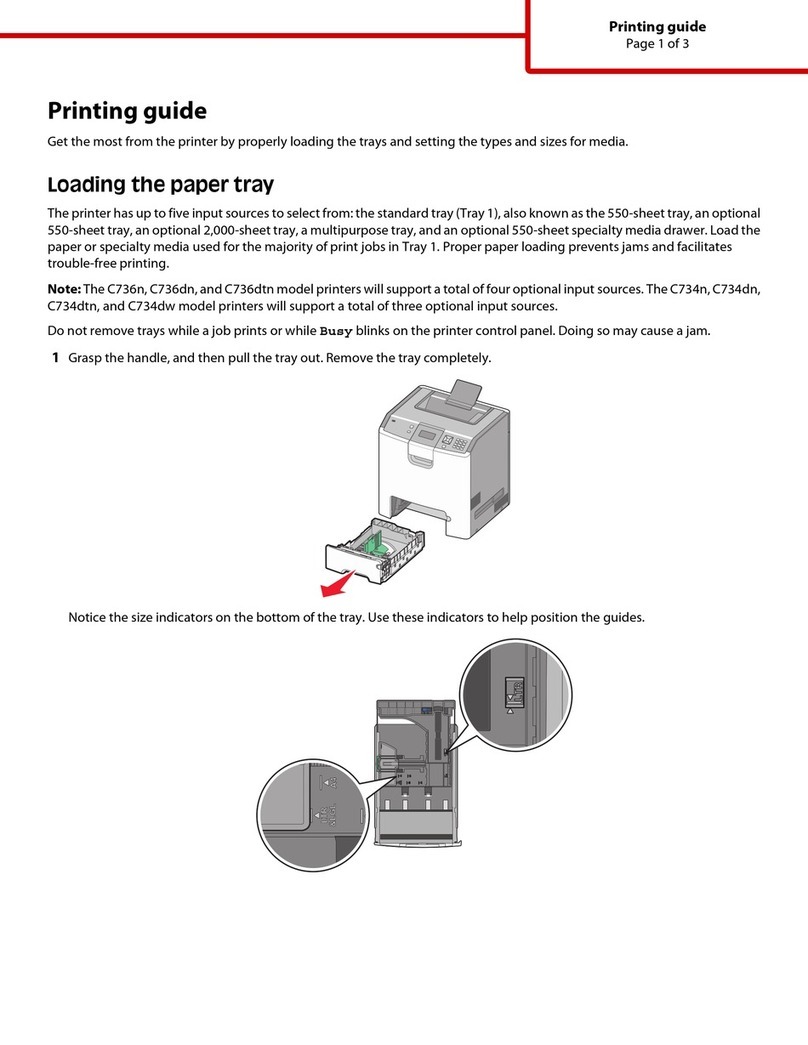

Perform [head maintenance] to clean up the carriage and station surrounding area.

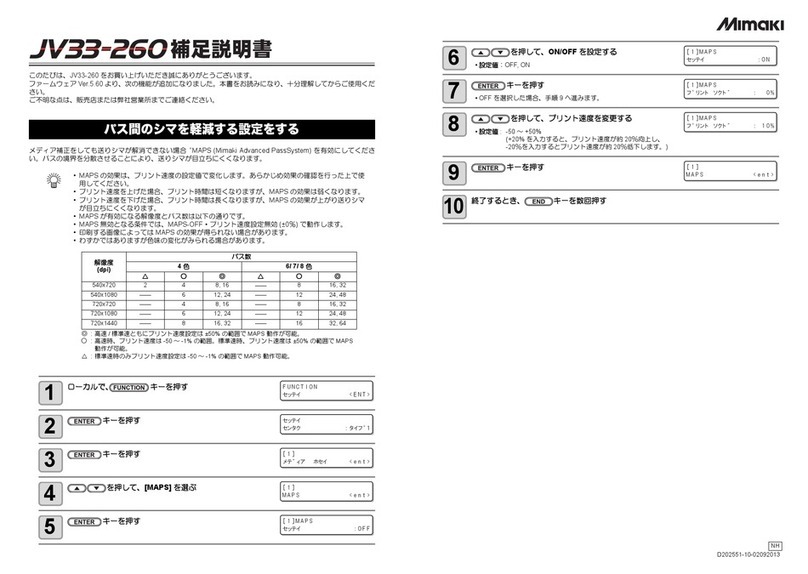

(1) Press the [FUNC1](MENU) key in local.

(2) Select [MAINTENANCE] and press the [ENTER] key.

(3) Select [STATION MAINT.] and press the [ENTER] key.

(4) Select [CARRIAGE OUT] and press the [ENTER] key.

(5) Select [HEAD MAINTENANCE] and press the [ENTER] key.

(6) Open the head maintenance cover and maintenance cover.

Remove ink on the head surrounding area or the carriage bottom with a cleaning stick dampened with cleaning liquid. Use a cotton swab to clean up the media sensors on the platen on the rear of the unit and on the carriage bottom and wipe of

the dust or contaminants.When the contaminants don't come off easily,

then dilute neutral detergent with water and wet a cotton swab with the solution and wipe off the contaminants.

DO NOT touch the nozzles during the cleaning.

Wipe off debris from cutting or dust on the media press with a dry cloth or a cotton swab.

Remove ink on the rubber on the cap with a cleaning stick dampened with cleaning liquid.

Once all the cleaning is finished, close the head maintenance cover and the maintenance cover,

・Dried ink or contaminants on the cap prevent the cap from sealing the nozzle surface firmly, and then press the [ENTER] key.

causing dried-out nozzle surface or nozzle drop-out that may not get unclogged with the cleaning function.

・If you keep using filthy wiper with dried ink on it, dried ink porlicles can sneak into the nozzles,

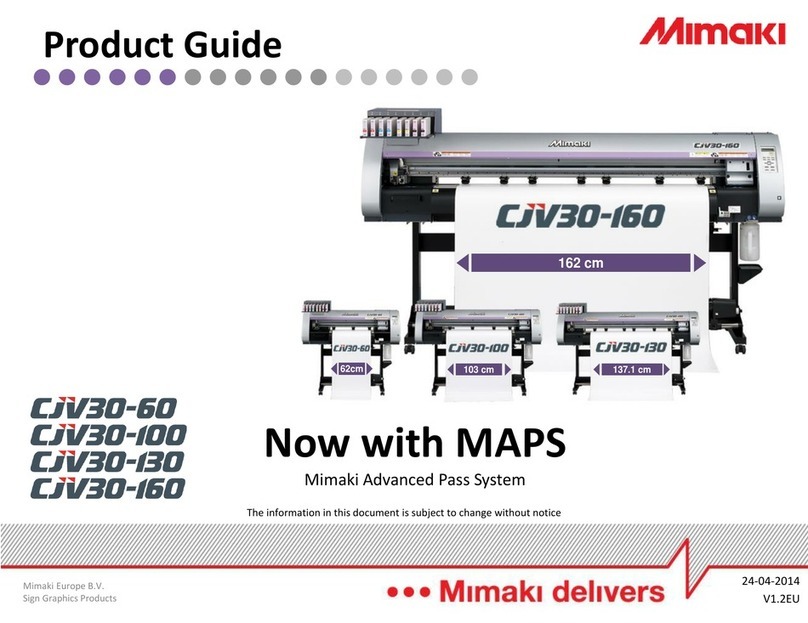

© 2014 MIMAKI ENGINEERING CO.,LTD.

The nozzle part

(Never touch it.)

Daily

For your safety, Wear the goggles and gloves that came

with the product when performing the maintenance.

1. Performing head maintenance

2. Cleaning head surrounding area

Clean the carriage bottom with a cleaning stick.

Clean the side of the head with a cleaning stick.

3. Cleaning cap

Before cleaning *Picture of JV300

After cleaning *Picture of JV300

Before cleaning After cleaning

Pinch the nubs on both

edges and slide out the wiper.

Before After cleaning

4. Cleaning wiper

Rear view of the unit View of the carriage bottom

DO NOT use organic solvents to clean the sensor.

6. Cleaning media press

7. Finishing maintenance

Maintenance

cover

Wiper slider

Media press

Cap rubber

Media sensor

Media sensor

Bracket

Wiper