Minarik DIGI-LOK DLC300 User manual

USER’S MANUAL

Model DLC300/DLC400

DIGI-LOK®Programmable Digital Control

250-0112-rev3.qxd 7/18/00 10:46 AM Page a

Copyright 2000 by

Minarik Corporation

All rights reserved. No part of this manual may be reproduced or transmitted in any

form without written permission from Minarik Corporation. The information and

technical data in this manual are subject to change without notice. Minarik

Corporation and its Divisions make no warranty of any kind with respect to this

material, including, but not limited to, the implied warranties of its merchantability

and fitness for a given purpose. Minarik Corporation and its Divisions assume no

responsibility for any errors that may appear in this manual and make no

commitment to update or to keep current the information in this manual.

Printed in the United States of America.

250-0112-rev3.qxd 7/18/00 10:46 AM Page b

Safety Warnings

•This symbol denotes an important safety tip or warning.

Please read these instructions carefully before performing

any of the procedures contained in this manual.

•DO NOT INSTALL, REMOVE, OR REWIRE THIS

EQUIPMENT WITH POWER APPLIED. Have a qualified

electrical technician install, adjust and service this equipment.

Follow the National Electrical Code and all other applicable

electrical and safety codes, including the provisions of the

Occupational Safety and Health Act (OSHA), when installing

equipment.

•Reduce the chance of an electrical fire, shock, or explosion by

proper grounding, over-current protection, thermal protection,

and enclosure. Follow sound maintenance procedures.

It is possible for a drive to run at full speed as a result of

a component failure. Minarik strongly recommends the

installation of a master switch in the main power input of the

drive controllng the motor to stop the drive in an emergency.

Circuit potentials are at 115 VAC or 230 VAC above earth

ground. Avoid direct contact with the printed circuit board or

with circuit elements to prevent the risk of serious injury or

fatality. Use a non-metallic screwdriver for adjusting the

calibration trimpots. Use approved personal protective

equipment and insulated tools if working on this drive with

power applied.

250-0112-rev3.qxd 7/18/00 10:46 AM Page i

250-0112-rev3.qxd 7/18/00 10:46 AM Page ii

iii

Specifications 1

Dimensions 3

Installation 5

Mounting ....................................................5

Wiring .......................................................6

Shielding guidelines . . . . . . . . . . . . . . . . . . . . . .....................7

Panel installation ..............................................8

DIP Switch Settings . . . . . ......................................12

Connections . ................................................13

Calibrating the speed control . . ...................................17

Programming Instructions 17

Programming Mode . . . . . ......................................18

DLC programming parameters ...................................18

Speed Scaling Factor ........................................19

Load Response Number . . ...................................21

Display Scaling Factor . ......................................23

Decimal point location . ......................................26

Exit the Programming Mode ...................................27

Troubleshooting 29

Before troubleshooting . . . . . . . . . . . . . . . . . . .......................29

Unconditional Warranty 33

Contents

250-0112-rev3.qxd 7/18/00 10:46 AM Page iii

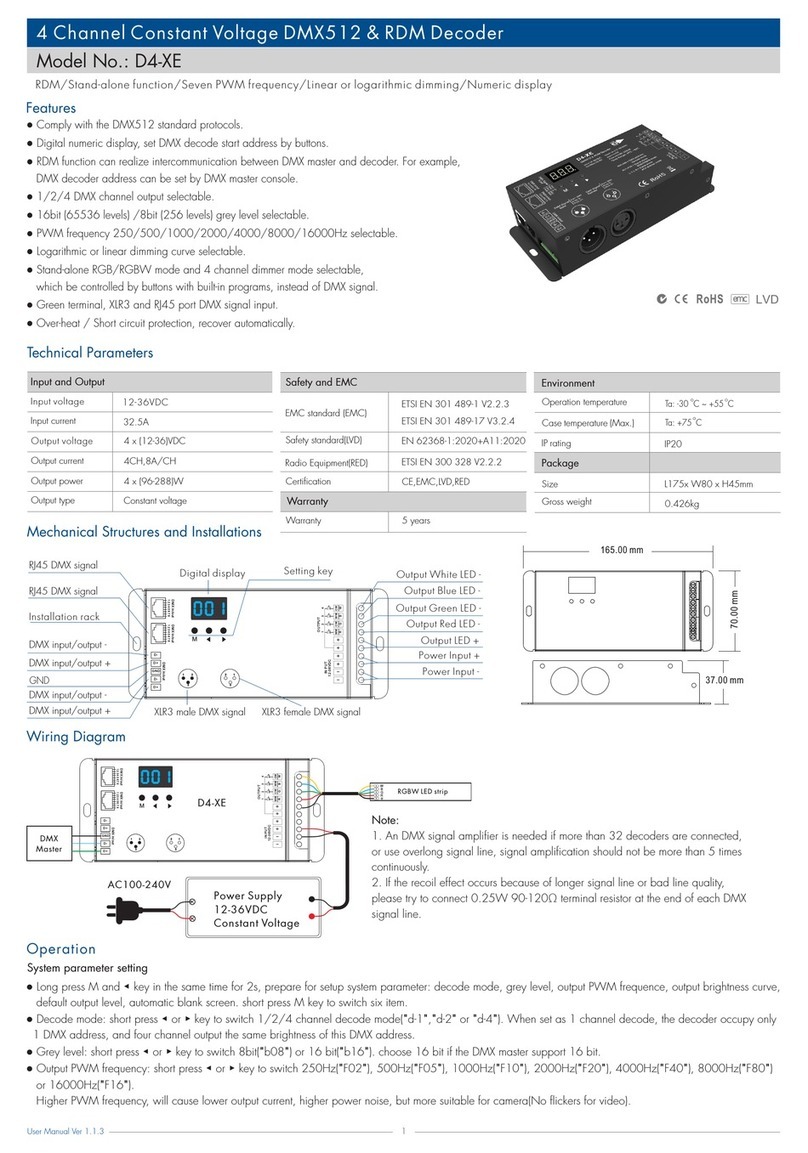

Figure 1. DLC300/400 Dimensions ...................................3

Figure 2. DIP Switch Location . . ....................................12

Figure 3. DLC300/400 connections . .................................15

iv

Illustrations

250-0112-rev3.qxd 7/18/00 10:46 AM Page iv

v

Minarik Models DLC300 and DLC400 Digi-Lok® Converters are

used with conventional analog speed controls to produce closed-

loop digital systems capable of controlling motor speed precisely

and with excellent reproducibility.

The Digi-Lok® Converter (DLC) receives the feedback signal

generated by a sensor that monitors a rotating element driven by

the motor. The sensor assembly can be a magnetic pickup with

ferromagnetic gear, or a NPN-type optical encoder or inductive

proximity switch, or a Hall effect sensor with magnetic wheel.

An important distinction exists between any Digi-Lok®

Converter system and a conventional servo drive. The Digi-Lok

Converter reads a velocity-dependent feedback signal and corrects

its output to bring the motor back to its set speed. The Digi-Lok®

Converter will not compensate for any positioning errors caused

by very minor speed fluctuation.

Industrial applications for Digi-Lok® Converter control systems

include many within the food processing, chemical, and

pharmaceutical industries, for example. Blending, mixing,

grinding, pumping, and other such processes often require strict

repeatability to ensure product uniformity. The digital speed-

setting feature of the Digi-Lok® Converter and the closed-loop

design provide that reliability and reproducibility.

Introduction

250-0112-rev3.qxd 7/18/00 10:46 AM Page v

vi

DLC Compatibility

The DLC is compatible with positive reference-voltage speed

controls only – controls that drive the motor when the speed

adjust pot wiper is at a positive potential relative to the CCW side

of the speed adjust pot.

With few exceptions, speed controls currently being manufactured

meet this requirement. A few older design speed control models,

including Minarik Models SL31UD4 and SL51UD4, operate with

a negative reference voltage. Such controls will require use of

Model DLC100 instead of the DLC300.

Feedback device selection

Acceptable feedback frequency at any set speed in an application

must lie within the 10-2000 Hz range. Feedback frequency is

directly proportional to the number of feedback pulses per

revolution (PPR) and to the speed of the shaft (RPM) that the

feedback transducer monitors.

Since the application requirements determine the shaft speed

range, they also will determine the range within which the

number of feedback pulses per revolution must lie:

PPRminimum = 600/(RPMminimum)

PPRmaximum = 120,000/(RPMmaximurn)

250-0112-rev3.qxd 7/18/00 10:46 AM Page vi

As an example, consider an application in which the feedback

source is monitoring a driven shaft, and not the motor armature

shaft. This shaft is to be run at speeds as low as 1 rpm. The

feedback device that you select must produce at least 600 pulses

per revolution.

Conversely, if the application were one that required monitoring

and controlling a driven shaft at speeds as high as 4000 rpm, the

feedback device would be limited to one that produced 30 or

fewer pulses per revolution.

The Digi-Lok® Converter system can control armature shaft

speeds within a 30:1 range. Under no circumstances can the DLC

be expected to control motor speed beyond the speed rating of the

motor.

vii

250-0112-rev3.qxd 7/18/00 10:46 AM Page vii

viii

250-0112-rev3.qxd 7/18/00 10:46 AM Page viii

1

Line input voltage, 50-60 Hz, single phase

DLC300 115 VAC (+/-10%)

DLC400 230 VAC (+/-10%)

Line power 5.5 watts nominally

Acceptable feedback sources

5V NPN-type encoder

5V NPN-type proximity switch Hall effect sensor

Electromagnetic pickup device

Feedback frequency range 10-2,000 Hz

Maximum speed range 30:1 typical

Speed control reference voltage, maximum +20VDC

Ambient operating temperature 10ºC to 40ºC

Approximate weight 1 lb.

Specifications

250-0112-rev3.qxd 7/18/00 10:46 AM Page 1

2

250-0112-rev3.qxd 7/18/00 10:46 AM Page 2

3

Dimensions

Figure 1. DLC300/400 Dimensions

ALL DIMENSIONS IN INCHES [MILLIMETERS]

250-0112-rev3.qxd 7/18/00 10:46 AM Page 3

4

250-0112-rev3.qxd 7/18/00 10:46 AM Page 4

5

Installation

Warning

Do not install, rewire, or remove this control with input

power applied. Doing so may cause fire or serious injury.

Make sure you have read and understood the Safety

Warnings before attempting installation.

Mounting

Motor speed controls manufactured by other companies may

require hookup procedures that differ from those given in this

manual. Please contact your Minarik representative for

assistance.

A schematic diagram and the manufacturer’s instructions for

interfacing the control with an external speed-setting signal will

probably be required before the correct wiring scheme can be

determined.

Install the Digi-Lok Converter in an area that is protected from

exposure to dirt or moisture and from accidental contact. Provide

clearance that permits access for connecting wires. Do not mount

the device near other heat-producing objects, nor in an area

subject to cold and moisture. Ambient temperature within the

range of 10º to 40ºC must be maintained.

250-0112-rev3.qxd 7/18/00 10:46 AM Page 5

6Installation

• Use 16–20 AWG wire for speed adjust potentiometer wiring.

Use 14–16 AWG wire for AC line (L1, L2) and motor (A1 and

A2) wiring.

Wiring

Warning

Do not install, remove, or rewire this equipment with power

applied. Failure to heed this warning may result in fire,

explosion, or serious injury.

Circuit potentials are at 115 or 230 VAC above ground. To

prevent the risk of injury or fatality, avoid direct contact with

the printed circuit board or with circuit elements.

Do not disconnect any of the motor leads from the motor

control unless power is removed. Opening any one motor

lead may destroy the control.

Variable speed DC drives manufactured by other companies

may require hookup procedures that differ from those given

in this manual. Contact your local Minarik branch or

distributor for assistance. A schematic diagram and the

manufacturer’s instruction for interfacing the drive with an

external speed-setting signal may be required before the

correct wiring scheme can be determined.

250-0112-rev3.qxd 7/18/00 10:46 AM Page 6

Installation 7

Shielding guidelines

Warning

Under no circumstances should power and logic leads be

bundled together. Induced voltage can cause unpredictable

behavior in any electronic device, including motor controls.

As a general rule, Minarik recommends the shielding of all

conductors.

If it is not practical to shield power conductors, Minarik

recommends shielding all logic-level leads. If shielding is not

practical, the user should twist all logic leads with themselves to

minimize induced noise.

It may be necessary to earth ground the shielded cable. If noise is

produced by devices other than the drive, ground the shield at the

drive end. If noise is generated by a device on the drive, ground

the shield at the end away from the drive. Do not ground both

ends of the shield.

If the drive continues to pick up noise after grounding the shield,

it may be necessary to add AC line filtering devices, or to mount

the drive in a less noisy environment.

Logic wires from other input devices, such as motion controllers

and PLL velocity controllers, must be separated from power lines

in the same manner as the logic I/O on this drive.

250-0112-rev3.qxd 7/18/00 10:46 AM Page 7

Installation

8

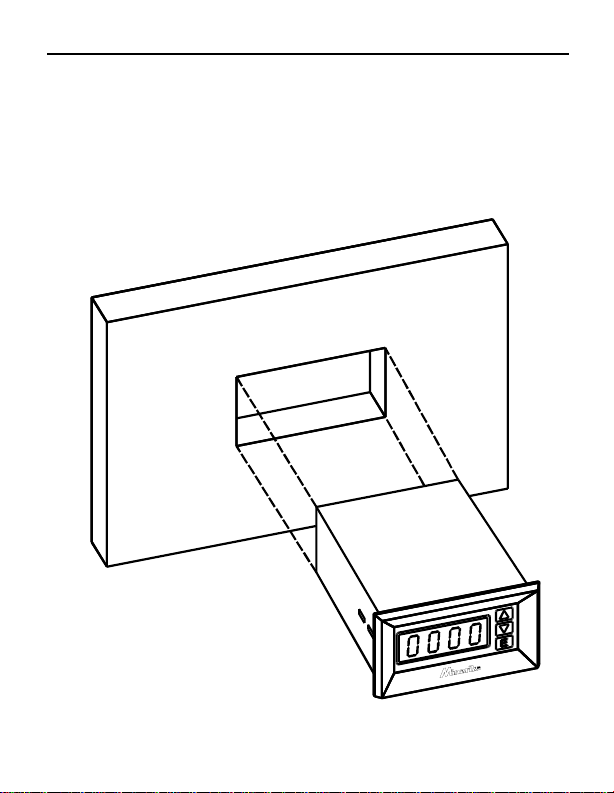

Panel installation

Step 1. Cut a rectangular hole in the panel 1.73 inches

(44 mm) high, and 3.38 inches (86 mm) wide.

1.74

[44]

250-0112-rev3.qxd 7/18/00 10:46 AM Page 8

Installation 9

Step 2. Slide the DLC3/400 into the panel opening.

PANEL

DLC300/400

250-0112-rev3.qxd 7/18/00 10:46 AM Page 9

Installation10

Step 3. Insert the two mounting brackets into each side of the

DLC300/400 case.

250-0112-rev3.qxd 7/18/00 10:46 AM Page 10

This manual suits for next models

1

Table of contents