Mincey Marble Napoli Series User manual

Mincey Marble Mfg., Inc.

1940 New Harvest Road

Gainesville, GA 30507

Ph: 800.533.1806

Fx: 770.531.0935

www.minceymarble.com

MATERIALS / TOOLS NEEDED CHECKLIST

PRE-INSTALLATION PIECES / PARTS LIST

ENCLOSURE SYSTEM INSTALLATION

Installation Instructions for Mincey Marble Manufacturing’s

Reversed Napoli Straight Barn Door Shower Enclosures

ATTENTION: Prior to starting the installation, please read through these instructions. This will

help avoid any unneccesary breakage. Any breakage due to handling or installing this enclosure

system is the responsibility of the installer and is not covered under the Mincey Warranty. Mincey

recommends that two people are used to install this shower enclosure system due to the weight

and fragility of the glass panels. Mincey also recommends that you protect the glass, especially

the bottoms, and the shower pan during installation. If your doors have frosted glass, the frosted

side of the glass goes to the outside of the shower.

These installation instructions apply to the Mincey Reversed Napoli Straight Barn Door Shower Enclosure System.

The Reversed Napoli Straight Barn Door Shower Enclosure System is to be used when the shower door closes

opposite the shower head and wet wall. In these instructions we are going to use an example with a 58” wide

VKRZHUZLWKWKHRSHQLQJGRRUORFDWHGRQWKHULJKWVLGHRIWKHVKRZHUDQGWKH¿[HGJODVVSDQHORQWKHOHIW

All Drawings Are Not To Scale.

8QFUDWHDOORIWKHPDWHULDOVDQGFRQ¿UPWKDWDOORIWKHSDUWVDQGSLHFHVDUHSUHVHQW The Required

Tools are listed below. The contents of the Hardware Kit are listed below. The Parts Diagram is on the following

page. Before you begin the installation, make sure that all of the pertinent surfaces are clean and free of dust,

debris and any shavings. After you perform any drilling, you will want to make sure the surfaces are clean again

- this includes the Shower Pan and the Shower Panel Walls.

INCLUDED IN THE HARDWARE KIT

MATERIALS / TOOLS NEEDED

DRILL (CORDED OR CORDLESS),

3/16” 1/4” & 5/16” MASONRY

DRILL BITS

TAPE MEASURE

PENCIL

LEVEL

CAULK GUN,

100% SILICONE

RUBBER MALLET

PORTABLE BAND SAW

(PREFERRED METHOD)

HACK SAW- OR -

PHILLIPS HEAD SCREWDRIVER LOCTITE

BLUE 243

THREADLOCKER

FIXED GLASS

BRACKET QTY: 1

ROLLERS QTY: 4

GUIDE RAIL HOLDER TOOL QTY: 1

DOOR STOPS

QTY: 2

ALLEN WRENCHES:

1/4”, 3/16”, 1/8”, 5/32”, 3/32”

CLEAR SETTING

BLOCKS

QTY: 4

FLAT HEAD SCREWS:

1 1/8 X 3/16” (QTY: 2)

1 1/8 X 1/8” (QTY: 5)

PAN HEAD SCREWS:

1 1/4 X 1/8” (QTY: 2)

2 X 3/16” (QTY: 2)

WALL ANCHORS:

5/16” (QTY: 2)

LIGHT BLUE

5/16” (QTY: 2)

CLEAR

3/16” (QTY: 7)

GREEN

GUIDE RAIL

END CAPS

QTY: 2

DIVERTER

BAR QTY: 1

DOOR GUIDE QTY: 1

(Set to position 12 on

bottom)

If you have any questions, please call MINCEY MARBLE CUSTOMER SERVICE at 1-800-533-1806.

Mincey Marble Mfg., Inc. |1940 New Harvest Road, Gainesville, GA 30507 |800.533.1806 |minceymarble.com

SHOWER ENCLOSURE PARTS LIST

ASSEMBLY CODE ASSEMBLY NAME QTY

1 FIXED GLASS PANEL 1

2 SLIDING GLASS PANEL 1

3 VERTICAL U CHANNEL 1

4 BOTTOM U CHANNEL 1

5DIVERTER BAR1

6 FIXED GLASS BRACKET 1

7GUIDE RAIL1

8 GUIDE RAIL END CAPS 2

9 ROLLERS 4

10 DOOR STOPS 2

11 DOOR GUIDE 1

12 SHORT F-SEAL 1

13 LONG F-SEAL 1

14 BUBBLE SEAL 1

15 5/16" CLEAR WALL ANCHORS 2

16 5/16" BLUE WALL ANCHORS 2

17 3/16" GREEN WALL ANCHORS 7

18 CLEAR SETTING BLOCKS 4

19 HANDLE 1

20 2" X 3/16" PAN HEAD SCREWS 2

21 1 1/4" X 1/8" PAN HEAD SCREWS 3

22 1 1/8" X 1/8" FLAT HEAD SCREWS 5

PRE-INSTALLATION PIECES / PARTS LIST (cont.) 2

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8) (9)

(10)

(11)

(12)

(13)

(14)

(15)

(16)

(17)

(18)

(19)

(20)

(22)

(21)

(8)

(10)

(15)

(20)

If you have any questions, please call MINCEY MARBLE CUSTOMER SERVICE at 1-800-533-1806.

Mincey Marble Mfg., Inc. |1940 New Harvest Road, Gainesville, GA 30507 |800.533.1806 |minceymarble.com

NAPOLI STRAIGHT BARN DOOR ENCLOSURE SYSTEM INSTALLATION 3

These instructions are to be followed assuming the Shower Pan is level and the Walls are plumb. In these

instructions and as an example, we will be installing the Napoli Straight Barn Door Shower Enclosure in a 58”

ZLGHVKRZHU$IWHU\RXKDYHFRQ¿UPHGWKDWDOORIWKHUHPDLQLQJSDUWVDQGSLHFHVDUHSUHVHQW\RXDUHUHDG\WR

begin by preparing to install the LEFT VERTICAL U CHANNEL.

Begin by making marks on the top of the Shower Pan Curb 3/8” from the inside edge of the Curb. Place marks

at the Left Panel Wall, in the Center of the Pan and one in-between those two marks. Hold LEFT VERTICAL U

CHANNEL up against the Left Wall Panel, plumb with the Level and mark where the three holes are to be

drilled in the Top, Center and Bottom locations.

PLUMB LEFT VERTICAL

U CHANNEL WITH LEVEL,

MARK HOLE LOCATIONS

AND REMOVE

SCREW

HOLES

HAMMER

IN ALL

THREE

ANCHORS

SCREW

IN U

CHANNEL

REMOVE U

CHANNEL, DRILL HOLES

WITH 5/16” MASONRY

BIT, HAMMER IN

WALL ANCHORS

CLEAN DEBRIS AND

SHAVINGS, PLACE U

CHANNEL AND SCREW

INTO PLACE

1 1/8”

FLAT HEAD

SCREWS

3/16”

GREEN

WALL

ANCHORS

PAN

RUN A BEAD OF 100% SILICONE

ON THE BOTTOM OF THE BOTTOM

U CHANNEL AND CAREFULLY PLACE

ON THE 3/8” MARKS ON THE CURB

3/8”

FROM

INSIDE

EDGE OF

CURB

MEASURE

AND MARK

IN ALL

THREE PAN

CURB

LOCATIONS

PAN

Next, run a bead of 100% Silicone the length of the bottom of the BOTTOM U CHANNEL. Carefully place the

BOTTOM U CHANNEL onto the Shower Pan Curb on the edge of the marks at 3/8” from the inside of the shower

FXUE7KH%277208&+$11(/VKRXOGEHÀXVKDJDLQVWWKH9(57,&$/8&+$11(/DOLJQLQJWKHLUFHQWHUVVRWKDW

the Fixed Glass Panel will slide into place into both channels.

Then, you will place TWO CLEAR SETTING BLOCKS near the ends of the BOTTOM U CHANNEL for the Fixed

Glass Panel to rest on. These CLEAR SETTING BLOCKS can be cut and doubled-up if necessary for leveling.

MAKE SURE BOTTOM U CHANNEL

IS FLUSH WITH THE VERTICAL U

CHANNEL AND THE CHANNELS ARE

ALIGNED TO ACCEPT THE FIXED

GLASS PANEL

PLACE SETTING

BLOCKS INTO

BOTTOM U CHANNEL

TO LEVEL FIXED

GLASS PANEL

VERTICAL U CHANNEL

AND BOTTOM U

CHANNEL

If you have any questions, please call MINCEY MARBLE CUSTOMER SERVICE at 1-800-533-1806.

Mincey Marble Mfg., Inc. |1940 New Harvest Road, Gainesville, GA 30507 |800.533.1806 |minceymarble.com

NAPOLI STRAIGHT BARN DOOR ENCLOSURE SYSTEM INSTALLATION (cont.) 4

1RZ\RXDUHUHDG\WRLQVWDOOWKH),;('*/$663$1(/<RXZLOOEHJLQE\WHVW¿WWLQJWKH),;('*/$663$1(/

3ODFHWKHSDQHOLQWRWKHWKH9HUWLFDODQG%RWWRP8&KDQQHOVPDNLQJVXUHWKHSDQHOLVÀXVKWRWKHZDOOThe

hole closest to the edge of the FIXED GLASS PANEL is to be located furthest from the Wall. Check

for level. Add CLEAR SETTING BLOCKS into the Bottom U Channel at either end to Level the FIXED GLASS

PANEL. You can trim and stack the CLEAR SETTING BLOCKS if necessary to Level the panel. Once Level,

place the FIXED GLASS PANEL BRACKET and mark where to drill the hole.

LEVEL FIXED

GLASS PANEL

WITH CLEAR

SETTING

BLOCKS,

THEY CAN BE

DOUBLED IF

NECESSARY

MAKE SURE

FLUSH TO

WALL

PAN

FILL THE CORNER AREA

WHERE THE BOTTOM U

CHANNEL AND THE

VERTICAL U CHANNEL

MEET WITH 100%

SILICONE.

THEN, CAREFULLY REPLACE

THE FIXED GLASS PANEL

BACK INTO THE U

CHANNELS MAKING SURE IT

IS FLUSH WITH THE WALL.

FILL WITH

100% SILICONE

AFTER LEVELING THE FIXED GLASS

PANEL, PLACE THE FIXED GLASS PANEL

BRACKET IN POSITION. MARK THE

HOLE WHERE TO DRILL THE

MOUNTING SCREW ON THE CURB.

CAREFULLY REMOVE THE BRACKET

AND THE FIXED GLASS PANEL.

FIXED GLASS PANEL

MARK BRACKET

HOLE

DRILL HOLE WITH

3/16” MASONRY BIT,

CLEAN UP DEBRIS,

FILL HOLE WITH

SILICONE, HAMMER

IN GREEN 3/16”

PLASTIC ANCHOR,

CLEAN EXCESS

SILICONE

INSTALL THE

FIXED GLASS

PANEL BRACKET

AND CLEAN

ANY EXCESS

SILICONE

1H[W\RXDUHUHDG\WRLQVWDOOWKH'225*8,'(&RQ¿UPWKH'225*8,'(LV

set in the #12 Position by looking at the bottom. Place the DOOR GUIDE at

1 7/16” from the Outside edge of the Fixed Glass Panel to the Inside DOOR

GUIDE channel, align the Right Side Screw Hole and the Fixed Glass Panel

Bracket Screw Hole and Mark the outline around the DOOR GUIDE. Remove

the DOOR GUIDE.

Place the DOOR GUIDE and Mark the holes to be drilled on the Shower Pan

Curb. Drill holes using a 1/4” Masonry Bit, Fill holes with 100% Silicone,

Hammer in Plastic Anchors, Clean any excess silicone, Install DOOR GUIDE

with 1 1/8” x 3/16” Flat Head Screws.

Measure, Trim and Install the DIVERTER BAR using

Silicone and Pressing into place. The Bubble Edge

installs to the outside of the shower.

OUTSIDE FIXED

GLASS PANEL TO

INSIDE DOOR

GLASS MEASURES

1 7/16”

LINE UP SCREW HOLES

MARK

OUTLINE

OF DOOR

GUIDE

RUN A HEALTHY BEAD OF

SILICONE ON ENTIRE BOTTOM

OF THE DIVERTER BAR AND

PRESS INTO PLACE, THEN CLEAN

MEASURE FROM THE DOOR GUIDE TO THE WALL

PANEL, TRIM THE DIVERTER BAR TO FIT

BUBBLE EDGE TO OUTSIDE OF SHOWER

If you have any questions, please call MINCEY MARBLE CUSTOMER SERVICE at 1-800-533-1806.

Mincey Marble Mfg., Inc. |1940 New Harvest Road, Gainesville, GA 30507 |800.533.1806 |minceymarble.com

NAPOLI STRAIGHT BARN DOOR ENCLOSURE SYSTEM INSTALLATION (cont.) 5

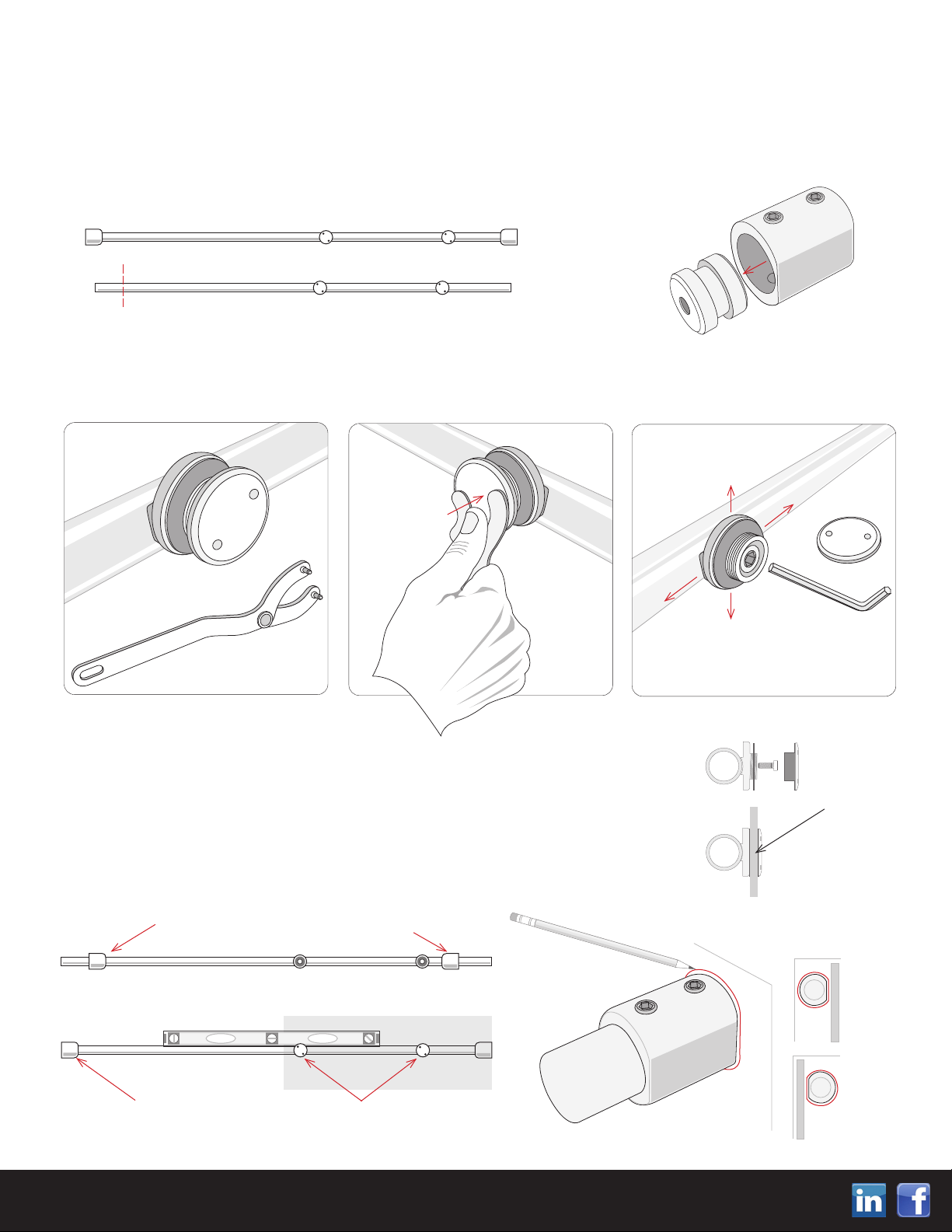

You are now ready to install the GUIDE RAIL. First, measure 72” up from the Shower Pan and measure the

distance between the Wall Panels. In this example, the measurement will be 58”. The Napoli Shower Enclosure

GUIDE RAIL measures 60” when fully assembled with the End Caps installed. Therefore in this example, 2” will

QHHGWREHWULPPHGRRIWKH*8,'(5$,/7ULP´RWKH*8,'(5$,/IURPWKHHQGZKHUHWKH6KRZHU

Door will be located, not the end to be installed to the Wall on the Fixed Glass Panel side.

(Trim the end where the Fixed Glass Panel Holders are not located.) Then, disassemble the END CAPS.

Disassemble the two GUIDE RAIL END CAPS and slide the Outside Sleeves onto the

GUIDE RAIL without the Inner Mounting Cogs. Install the GUIDE RAIL onto the Fixed

Glass Panel. LEVEL the GUIDE RAIL and snug the GUIDE RAIL HOLDERS. Push the

GUIDE RAIL END CAPS to the Wall Panels and Mark the ends by outlining the END CAPS

onto the Wall Panels. Make sure the END CAP on the FIXED GLASS PANEL side

has the FLAT SIDE facing the Glass Panel. The Shower Door side END CAP

should have the FLAT SIDE facing outward from the Shower, towards where

the Shower Door will be installed.

DISASSEMBLE THE GUIDE

RAIL HOLDERS

USE TOOL TO CAREFULLY

UNSCREW CAPS

USE FIRM

THUMB

PRESSURE TO

PREVENT

SLIPPAGE AND

SCRATCHING

THE CAP

WHEN

LOOSENING

OR TIGHTENING

THE CAP

USE 1/4” ALLEN WRENCH

TO TIGHTEN WHEN LEVEL

LOOSEN SLIGHTLY TO

ADJUST

Next, disassemble the GUIDE RAIL by carefully removing the Fixed Glass Panel Holders using the Fixed Glass

Panel Holders Tool. Use thumb pressure to carefully remove the Holders without scratching them by allowing

the tool to slip out of the designated holes.

FULLY ASSEMBLED, THE GUIDE RAIL MEASURES 60”

IN THIS EXAMPLE THE SHOWER MEASURES 58”

TRIM 2” OFF THE END WHERE THE SHOWER DOOR WILL BE,

WHEN FULLY RE-ASSEMBLED, THE GUIDE RAIL WILL MEASURE 58”

DISASSEMBLE THE GUIDE

RAIL END CAPS USING

THE 5/32” ALLEN

WRENCH

SLIDE GUIDE RAIL END CAPS ONTO RAIL WITH

FLAT ENDS TOWARDS THE WALL PANELS

INSTALL GUIDE RAIL ONTO

FIXED GLASS PANEL, SNUG

GLASS PANEL HOLDERS AT LEVEL

PUSH END CAPS TO WALL

PANELS AND MARK OUTLINES

RIGHT

SIDE

END CAP

FLAT SIDE

TO GLASS

PANEL

LEFT SIDE

END CAP

FLAT SIDE

TO GLASS

DOOR

MARK END CAPS

ON WALL WITH

OUTLINE

VIEW IS FROM INSIDE THE SHOWER

RIGHT SIDE

SHOWN

GUIDE

RAIL

INSTALLED

ONTO

FIXED

GLASS

PANEL

If you have any questions, please call MINCEY MARBLE CUSTOMER SERVICE at 1-800-533-1806.

Mincey Marble Mfg., Inc. |1940 New Harvest Road, Gainesville, GA 30507 |800.533.1806 |minceymarble.com

6

NAPOLI STRAIGHT BARN DOOR ENCLOSURE SYSTEM INSTALLATION (cont.)

After you have marked where the Guide Rail End Caps are located on the Wall Panels. Re-assemble the End

&DSVZLWKWKHUHFHVVHGVLGHRIWKH(QG&DS&RJWRWKHLQVLGHDQGWKHÀDWVLGHWRWKH:DOO3DQHO+ROG(QG

Caps back in place on the wall and Mark the inside holes, where you will drill. Drill End Cap mounting holes

into Wall Panels using 5/16” Masonry Bit, Hammer in Clear 5/16” Wall Anchors and Install End Cap Cogs.

NOTE: LOCTITE BLUE 243 is required

as a threadlocker to secure the

installation of the Roller Screws.

LOCTITE is NOT provided with the doors,

but is readily available at many hardware

stores, online at mscdirect.com or through

Mincey Marble at 1-800-533-1806.

FLAT END GOES

TOWARDS WALL

RE-ASSEMBLE

END CAPS

DRILL HOLE USING 5/16”

MASONRY BIT, HAMMER

IN CLEAR 5/16” WALL

ANCHOR

MARK HOLES,

REMOVE

END

CAPS

RECESSED END

GOES TOWARDS

GUIDE RAIL

WALL PANEL

INSTALL END CAP

COGS WITH

2” x 3/16”

PAN HEAD SCREWS

With the Guide Rail End Cap Cogs installed to the Wall Panels, you can now assemble the ROLLERS onto the

GLASS DOOR. Disassemble the ROLLERS using the 3/16” Allen Wrench. Install the Top Two ROLLERS into

the top two factory holes in the GLASS DOOR with the ROLLERS on the Inside of the GLASS DOOR and with

the Door Handle to the Right. Be sure to use LOCTITE Blue 243 threadlocker when installing the

ROLLERS onto the GLASS DOOR.

CAM LOBE UP = GLASS UP

CAM LOBE DOWN = GLASS DOWN

DISASSEMBLE ROLLER

USING 3/16” ALLEN

WRENCH

FELT WASHERS

TOOTH WASHER

ASSEMBLE TO GLASS

PANEL USING LOCTITE

BLUE 243 ON SCREW

INSTALL THE ROLLERS

IN THE GLASS DOWN

POSITION / CAM

DOWN POSITION

ONCE THE DOOR IS

INSTALLED ADJUST

CAM LOBE WITH A 1/8”

ALLEN WRENCH FOR

FLUSH, LEVEL

OPERATION

CAM LOBE

BACK

OF SHOWER

FRONT

OF SHOWER

If you have any questions, please call MINCEY MARBLE CUSTOMER SERVICE at 1-800-533-1806.

Mincey Marble Mfg., Inc. |1940 New Harvest Road, Gainesville, GA 30507 |800.533.1806 |minceymarble.com

7

NAPOLI STRAIGHT BARN DOOR ENCLOSURE SYSTEM INSTALLATION (cont.)

You are now ready to re-install the Guide Rail. Slide the two DOOR STOPS onto the Guide Rail tightening them

VOLJKWO\VRWKH\GRQRWVOLGHR$OVRVOLGHWKH*XLGH5DLO(QG&DS6OHHYHVEDFNRQWRWKH*XLGH5DLO5HLQVWDOO

the Guide Rail with the Fixed Glass Panel Holders. Slide the Guide Rail End Caps back to the Wall Panels and

tighten everything making sure the Guide Rail remains Level.

THANK YOU FOR USING OUR MINCEY MARBLE PRODUCT! WE APPRECIATE YOUR BUSINESS!

SLIDE DOOR STOPS

ONTO GUIDE RAIL,

TIGHTEN SLIGHTLY

TO HOLD IN PLACE

SLIDE END CAPS TO

WALLS AND TIGHTEN,

MAKE SURE TO

REMAIN LEVEL

CAM LOBE UP = GLASS UP

CAM LOBE DOWN = GLASS DOWN

Install DOOR F SEALS using Rubber Mallet to tap into place. The SHORT F SEAL installs on the Fixed Glass Panel

with the FIN towards the Shower Door. The LONG F SEAL installs on the Shower Door edge inside the Shower with

the FIN towards the Fixed Glass Panel. The BUBBLE SEAL installs on the Shower Door edge towards the Wall Panel

with the FIN towards the inside of the shower. Then, install the handles.

ASSEMBLE HANDLE USING

SET SCREWS, SET SCREWS

INSTALL TO THE INSIDE

OF THE SHOWER

G

L

A

S

S

G

L

A

S

S

Lastly, use 100% Silicone to run a bead, both inside and outside the shower, where the Vertical U Channel meets the

Wall Panels, where the Bottom U Channel meets the Shower Pan and where the Diverter Bar meets the Shower Pan.

You must allow the Silicone to dry for 24 hours before any exposure to water or moisture.

LONG F SEAL INSTALLS ON

SHOWER DOOR EDGE

SHORT F SEAL INSTALLS ON

FIXED GLASS PANEL EDGE

BUBBLE SEAL INSTALLS ON

EDGE OF SHOWER DOOR

INSTALL BOTTOM ROLLERS

USE LOCTITE BLUE 243

ADJUST DOOR STOPS

ALL ROLLERS

SHOULD ROLL IN

CONTACT WITH

THE GUIDE RAIL

ONCE THE DOOR IS

INSTALLED ADJUST

CAM LOBE WITH A 1/8”

ALLEN WRENCH FOR

FLUSH, LEVEL

OPERATION

VIEW IS FROM INSIDE THE SHOWER

1H[W+DQJWKH*/$66'225RQWRWKH*8,'(5$,/$GMXVWWKH72352//(56VRWKDWWKH*/$66'225LVÀXVKZLWK

the wall. Then, install the TWO BOTTOM ROLLERS. Follow the same instructions as the TOP ROLLERS, including

using LOCTITE BLUE 243 threadlocker on the Screws. Adjust the BOTTOM ROLLERS so that they roll and function

as the Shower Door is opened and closed.

VIEW IS FROM OUTSIDE THE SHOWER

Popular Other manuals by other brands

Task Force Tips

Task Force Tips Crossfire with Safe-Tak 1250 Base INSTRUCTIONS FOR SAFE OPERATION AND MAINTENANCE

ATIKA

ATIKA GHB 760 A Assembly and operating instruction sheet

Hioki

Hioki PW3360-20 Measurement guide

ABB

ABB Vmax 12 Installation and service instructions

Gaggenau

Gaggenau RB491200 - annexe 2 manual

Wigam

Wigam ELD-H user guide