Innovitech X Filter 1.0 User manual

Copyright –Innovitech LTD

2

Version: 1.3

Contents

X Filter Installation ........................................................................................................................................3

Plumbing Installation Options....................................................................................................................7

Vortex Generating Bypass Controllers..................................................................................................... 9

Fine tuning based on pipe positioning............................................................................................. 10

Filter Media Installation .............................................................................................................................11

Filter Media Replacement........................................................................................................................ 16

Maintenance ...............................................................................................................................................17

Alarm & Redundancies............................................................................................................................. 18

Alarm....................................................................................................................................................... 18

Self-cleaning function .......................................................................................................................... 19

Unit Assembly............................................................................................................................................ 20

Detailed Measurements............................................................................................................................23

Troubleshooting........................................................................................................................................ 24

User Manual

3

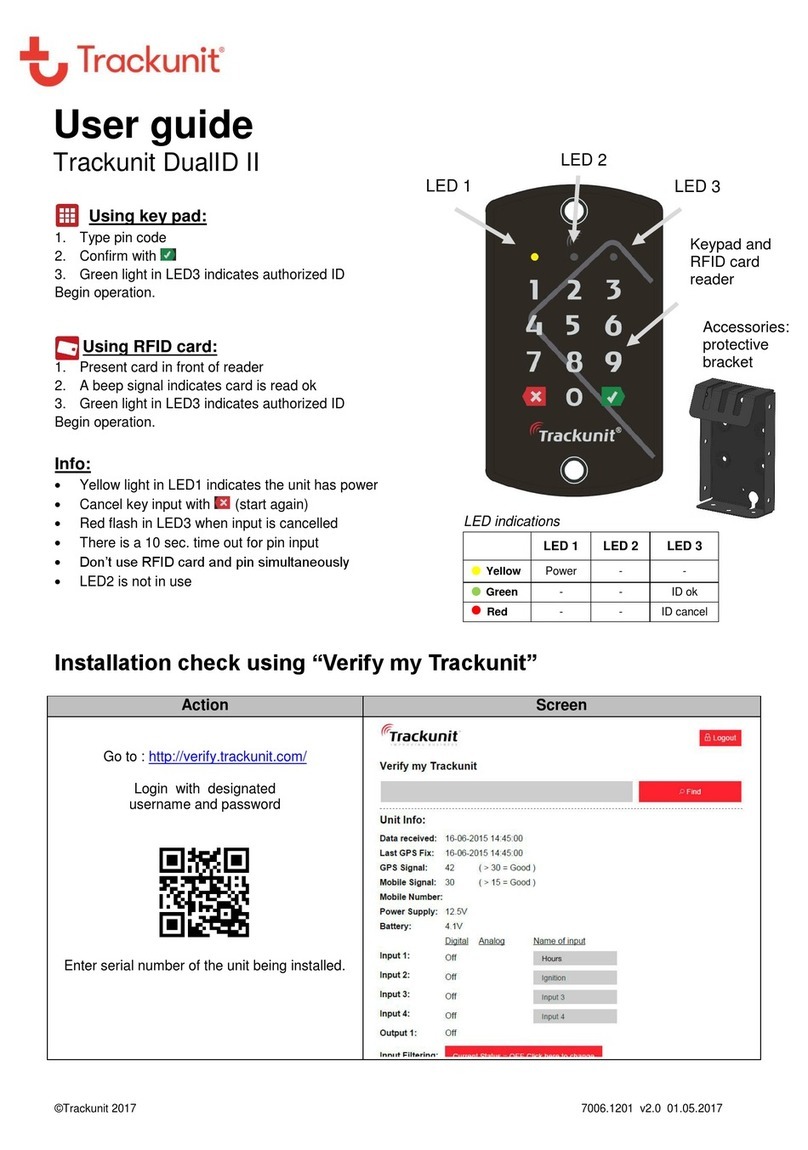

X Filter Installation

The X Filter can be separated into

three major sections to aid fitting if

required.

The bottom section could be fully

submerged and manouvered to

install on sump glass

WARNING: Black electronics

enclosure should never be

submerged under water

Using the hooks, hang the filter to

the desired position into the sump

Position the X Filter based on the

instructions of the next page

4

X Filter 1.0 placement

Optimum water level:

8 -10cm from bottom of unit

Standpipe/flexpipe depth within

overflow:

7cm from top of overflow section to

magnify the vortex effect when the

vortex generating bypass controllers

are used.

X Filter 1.7 placement

Optimum water level:

12 -15cm from bottom of unit

Standpipe/flexpipe depth within

overflow:

7cm from top of overflow section to

magnify the vortex effect when the

vortex generating bypass controllers

are used.

5

The adjustable spacer should be

used for sump glass thickness up to

6mm. Above 6mm the spacer could

be removed. Removing and

adjusting the spacer

The spacer supports the unit to be

level.

IMPORTANT NOTICE: It’s important

the unit to be set as level as possible

in order for the optical sensor to

detect water level more accurately

and fully take advantage of the

fleece media

The hooks allow the unit to be set

into different heights

The middle holes provide the ideal

height, as the top section can move

over the sump glass

WARNING: Do not use the higher

section (upper holes) unless

absolutely necessary

HIGH RISK OF WATER SPILLING

OVER SUMP GLASS

There’s a second set of hooks

provided that are designed to

elevate the unit even higher in

order to obtain ideal water level for

the filter.

WARNING/DISCLAIMER: These

hooks should be used under your

own risk. There’s a risk of water

spilling over the sump glass if not

installed properly or excessive flow

is used.

6

The top module can be placed

left or right from the centre,

depending on installation

requirements or clearance

Top module moves on a track of

7,5cm from one end to another

By releasing or tightening the

white screws (front screw shown)

will allow or restrict movement

After setting the position of the

top module, ensure front and

back screws (back screw shown)

are tight enough to restrict

movement of the top module

7

Plumbing Installation Options

The X Filter doesn’t required hard

plumbing, as it features an

overflow box to support different

types of plumbing

X Filter 1.0: Overflow box

measures 6,5cm depth (front to

back from sump glass) & 11cm

width

X Filter 1.7: Overflow box measures

6,5cm depth (front to back from

sump glass) & 17cm width

X Filter 1.0 overflow box can hold

a single 50mm (2 in.) or up to two

40mm (1 ½ in.) hard PVC or

flexible pipes

X Filter 1.7 overflow box can hold a

up to two 50mm (2 in.) or up to

three 40mm (1 ½ in.) hard PVC or

flexible pipes

Pipes should sit as close as possible towards the back of the filter (black plate)

The openings on the white plate

should never be blocked!

WARNING: Pipes should have a

clearance of at least 16cm from the

bottom of the box in order to let the flow move freely. Picture only for illustration purposes.

RISK OF SPILLAGE ON HIGH FLOWRATES

8

If flow rate allows it, a hose from

another component, such as a

reactor, could compliment the

filtering and clarity of the water

After installation, use the power

supply provided and connect it

with the cable from the black

box with.

After powering on the power

supply, the green LED on the

bottom of the black box will turn

on.

WARNING: Keep the connector

clear and safe from water or

potential risks of water spillages

as it will void warranty.

9

Vortex Generating Bypass Controllers

The Vortex Generating Bypass

Controllers are positioned at the

bottom of the overflow section

of the unit.

X Filter 1.0 has two (2) bypass

controller.

X Filter 1.7 has three (3) bypass

controllers.

The Vortex Generating Bypass

Controllers are used to make the

media fleece consumption more

efficient and effective and allow

any microlife to exit the unit

(copepods etc.)

NOTE: The water clarity and effectiveness of the unit is not compromised by the use of this

mechanism. The vortex generated when unit is installed as advised, will help effectively swirl

detritus to the filtering section of the unit.

The bypass controllers are

controlled by the external white

discs at the bottom of the unit, as

displayed.

Open controller by turning

counter clockwise (CCW)

Close controller by turning

clockwise (CW)

NOTE: The Vortex Generating

Bypass Controllers allow fine

tuning of flow at extreme

precision they way they have

been designed.

It is advised to use the controllers

open on new installations and

fine tune when the filter has

gone through the breaking in

period.

10

Fine tuning based on pipe positioning

If there is a single pipe

installed, it is advised to be

installed towards the side of

the overflow box (left or right).

This will enhance the vortex

generated and aid in better

catchment of particles into the

filtering section.

The opposite bypass generator should be used as the main bypass, while the one directly

below the standpipe could be used if more flow is required to pass as a secondary.

If two or more standpipes are

used, the vortex generating

bypass controllers should open

equally.

11

Filter Media Installation

The clear tube provided is used

to hold the roll in place

Note: This part is reusable. Do not

throw away on filter media

change

Set the tube through the roll

opening

The tube is longer than the width

of the roll

Allow the tube to protrude from

the roll equally on each end

12

Set the media on the side of the unit

where the “Innovitech”logo is shown

on the black box

IMPORTANT: Ensure the outer layer of

the roll faces the outer side of the unit

Set the media with the clear tube on

the designated slots

Pass the media over the top rod and

under the lower rod as shown

13

Take the media across and below the

optical sensor

Pass the media under the lower rod

and over the upper rod

TIP: At the four (4) top rods, the

correct placement of the fleece is

OVER –UNDER –UNDER –OVER, as

shown in the picture.

WARNING: Incorrect placement of

the media through the rods might

lead undesired results that could void

warranty.

At the bottom of the unit, unscrew

both rods by turning the “X” shaped

knobs counter clockwise

By using the long “L” shape tool

provided, from the top, push the

media towards the bottom of the unit

Set the media towards one corner of

the bottom of the unit as shown

With the help of the tool, hold the

media in place while (if required) and

pry the rod through the opening and

over the media

14

Locate the threaded hole on the

white backing and screw the rod into

place until tight enough to provide a

good seal

Repeat process on the opposite end

WARNING: While screwing rods back

into place, do not apply too much

force as there’s a risk of breaking the

rods off or damaging the thread. A

good seal is achieved as long as the

rods don’t move freely. The gasket

should be tight enough to keep the

rod from turning.

Illustrated is the uptake spool (actual

might vary in size and colour). This

can be reused as many times

required and purchased separately.

The spool has an anti-slip tape to set

the media without the requirement of

an adhesive.

The side of the spool with the larger

diameter should be set facing

towards the black box

Set the media flush on the side of the

spool, with the media rolled from the

outer side of the spool as shown

Roll at least two to four layers of

media tightly

15

Hold the media tightly on the spool

until the spool is set to its final

destination otherwise there’s a risk

the media will unwind or not set

properly

TIP: Media sets better on the spool if

it’s wet.

By sliding the black box outwards,

clearance will be created from the

direct drive to let the spool sit into

place

Let the black box spring back into

position for the direct drive to come

into contact with the spool

Twist the spool if required for the

direct drive to lock into place

The button on the other end of the

black box is the manual media feed

Push the button to roll the media

manually

Apply pressure to the uptake spool if

required to achieve a tight fit of the

media on the spool

WARNING: Failure to achieve a tight

fit of the media on the spool, might

result to the media slipping under

pressure

16

Filter Media Replacement

When the media has finished or is about to finish, prepare to remove the old filter media by

slightly tilting the black box to unlock the direct drive.

ATTENTION: Before tilting the black

box, move the used media roll

manually back and forth to UNLOCK

the direct drive.

In case the black box won’t tilt, move

the spool slightly by hand while tilting

the black box to break the lock

While the direct drive is unlocked and

the old media is moving freely, there

are two options available

Option 1: Unroll the remaining media and remove the spool. Set the new media as explained in

the “Filter Media Installation” section

Option 2: Cut the old media loose, leaving the rest of the unused media on the unit. By using the

media left over, it can be used to pull the media in from a new roll

Remove the old media and dispose

appropriately

Note: The uptake spool may be

reused as many times required by

unwinding or cutting the old media.

The uptake spool might be disposed

with the old media or after natural

wear and tear (if reused).

The uptake spool is purchased

separately for a small fee.

17

Maintenance

After every media change, it’s suggested to wipe the optical sensor with a soft cloth to ensure

accuracy and precision is always in check

Ensure the sensor is wiped clean at the tip

Ensure that the filter is in good condition. There could be some excessive build-up of slime on

the rolls. The rolls are designed to be cleaned by the media (usually resulting by dirt patches on

the media), but it is advised to give the unit a thorough clean 1-4 times per year, depending on

water conditions.

TIP: If system is planned to be left unattended for a long period of time, it’s advised to give the

sensor and the unit a good clean and ensure a fresh media roll is installed.

18

Alarm & Redundancies

Alarm

There are two LED

indicators on the top of

the black box:

A. Motor turning

B. Alarm (Red flashing

LED)

The alarm will set and

permanently stop the

motor if the sensor

detects an abnormal

operation which is tied

to the water level not

dropping within the

filter. The water will

overflow and spill out of the front of the unit in way to create as much sound as possible. The

overflow is designed that way to create an audible “alarm” if the unit overflows.

The motor is very powerful and in order to avoid any damage to the unit or the motor, the unit

is programmed to stop the motor UNTIL THE WATER LEVEL DROPS WITHIN THE UNIT.

NOTE: The alarm will set if the water level increases in the sump above sensor level (ie. Return

pump turned off). When the water level is restored, the alarm will turn off AUTOMATICALLY and

the filter will continue its normal operation without any intervention to the filter.

If the media gets jammed either from a foreign object or the filter operates constantly

(overwhelmed by really dirty water), the alarm will set.

RESETING THE ALARM: There are three ways to reset the alarm after it’s ensured that all faults

have been rectified:

1. Advance media manually using the feed button

19

2. Reset unit by turning power Off and On

3. Automatic reset if the water level drops below the sensor

Designed redundancy: In case there is a serious blockage of the media before the alarm reacts,

the designed first point of failure is the uptake spool plastic hex. The hex will snap and allow the

powerful motor to move freely till the alarm sets. Since the uptake spool is disposable, it could

be replaced with a new one.

Self-cleaning function

When the sensor becomes too dirty, the unit will try to clean it automatically by overflowing the

unit but without the alarm LED turning on.

If this gets into your attention, clean the sensor manually to aid the cleaning of the sensor. Once

the sensor is cleaned, the media will automatically advance and restore to normal operation.

WARNING: There’s a risk that the sensor is too dirty and will never restore, especially if there is

algae build-up on the sensor. It’s advised to keep the sensor out of light sources.

If the media gets oversaturated, there’s a potential to get jammed and manual intervention will

be required to restore normal operation.

20

Unit Assembly

Unit is consisted from three main

components: Bottom unit (main

unit), top unit and

electronics/motor assembly

Place the top unit on the rails of

the bottom unit. The black

stoppers of the top unit should

face backwards (towards the

overflow section of the bottom

unit)

Insert the white screw through

the slot of the top unit and the

hole of the bracket that

protrudes from the bottom unit.

This manual suits for next models

1

Table of contents