- 3 -

Table of Contents

Operational Parameters: ...................................................................................................................................... 3

Contents of MINERALPRO....................................................................................................................................... 4

Tools Recommended For Installation................................................................................................................... 4

Step 1 –Determine Location for the Faucet ........................................................................................................ 5

Step 2 –Drill a Hole for the Faucet in a Stainless Steel Sink ................................................................................ 5

Step 3 –Drill a Hole for the Faucet in a Porcelain, Enamel, Ceramic on Metal or Cast Iron ............................... 6

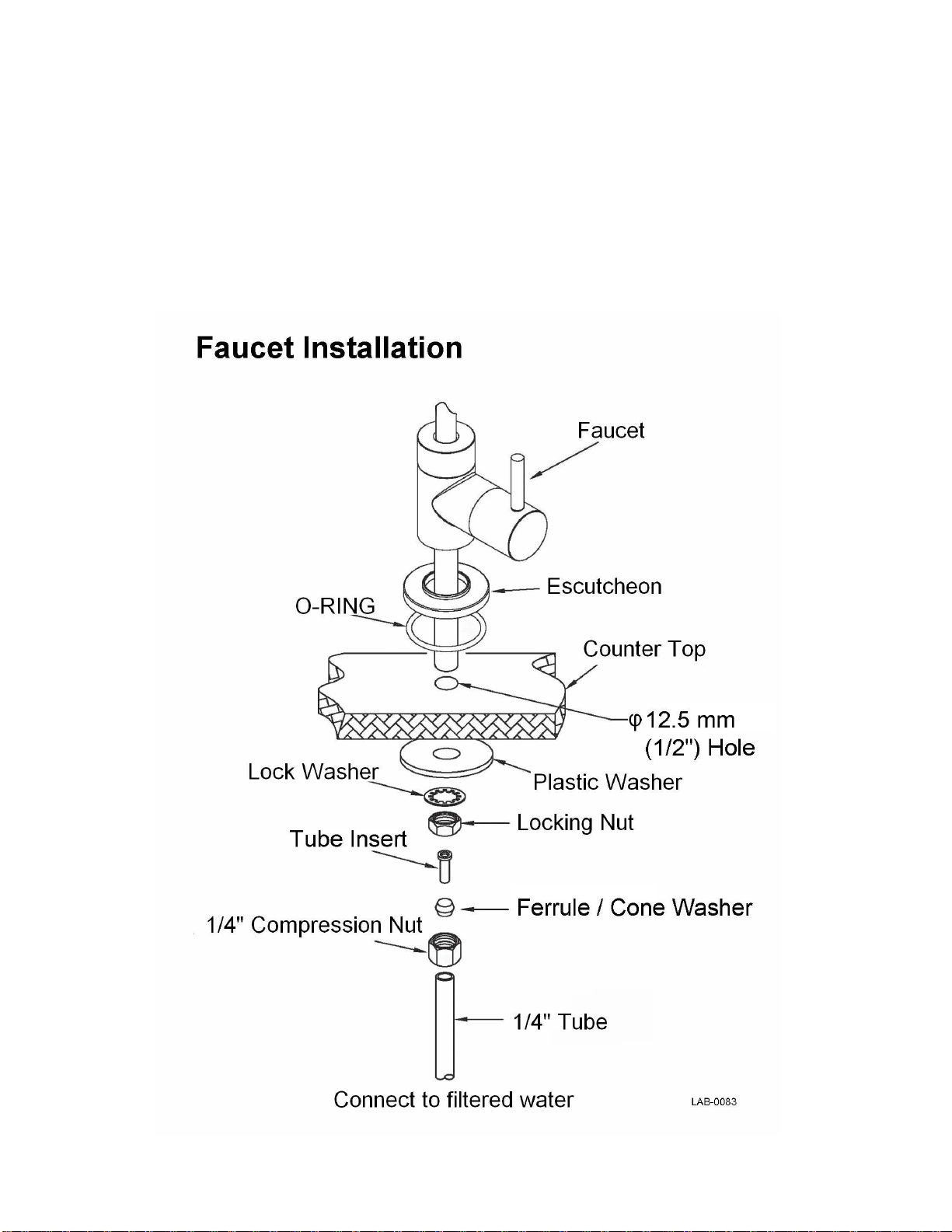

Step 4 –Faucet Installation .................................................................................................................................. 7

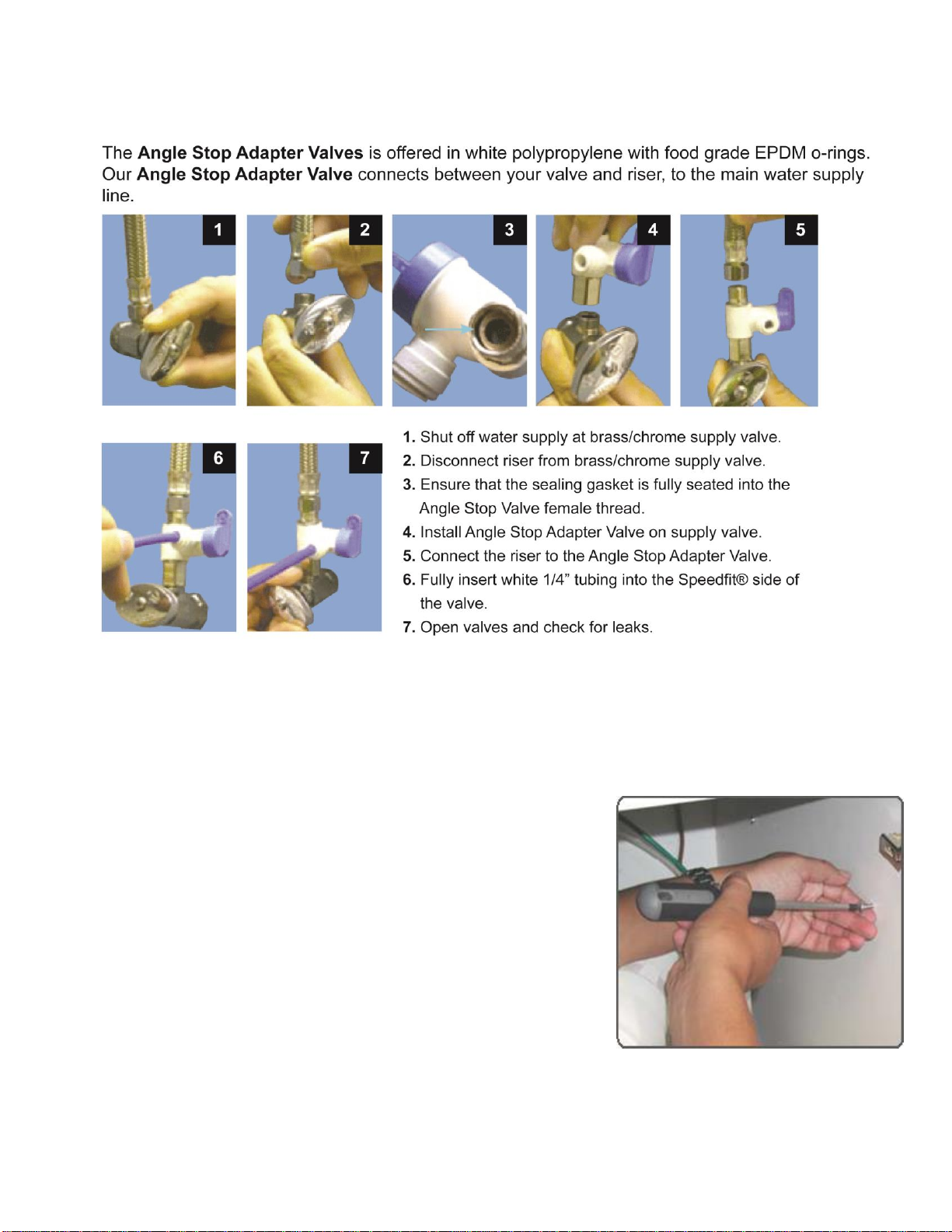

Step 5 –Water Valve (Angle-Valve) Installation .................................................................................................. 8

Step 6 –MINERALPRO Module Mounting .............................................................................................................. 8

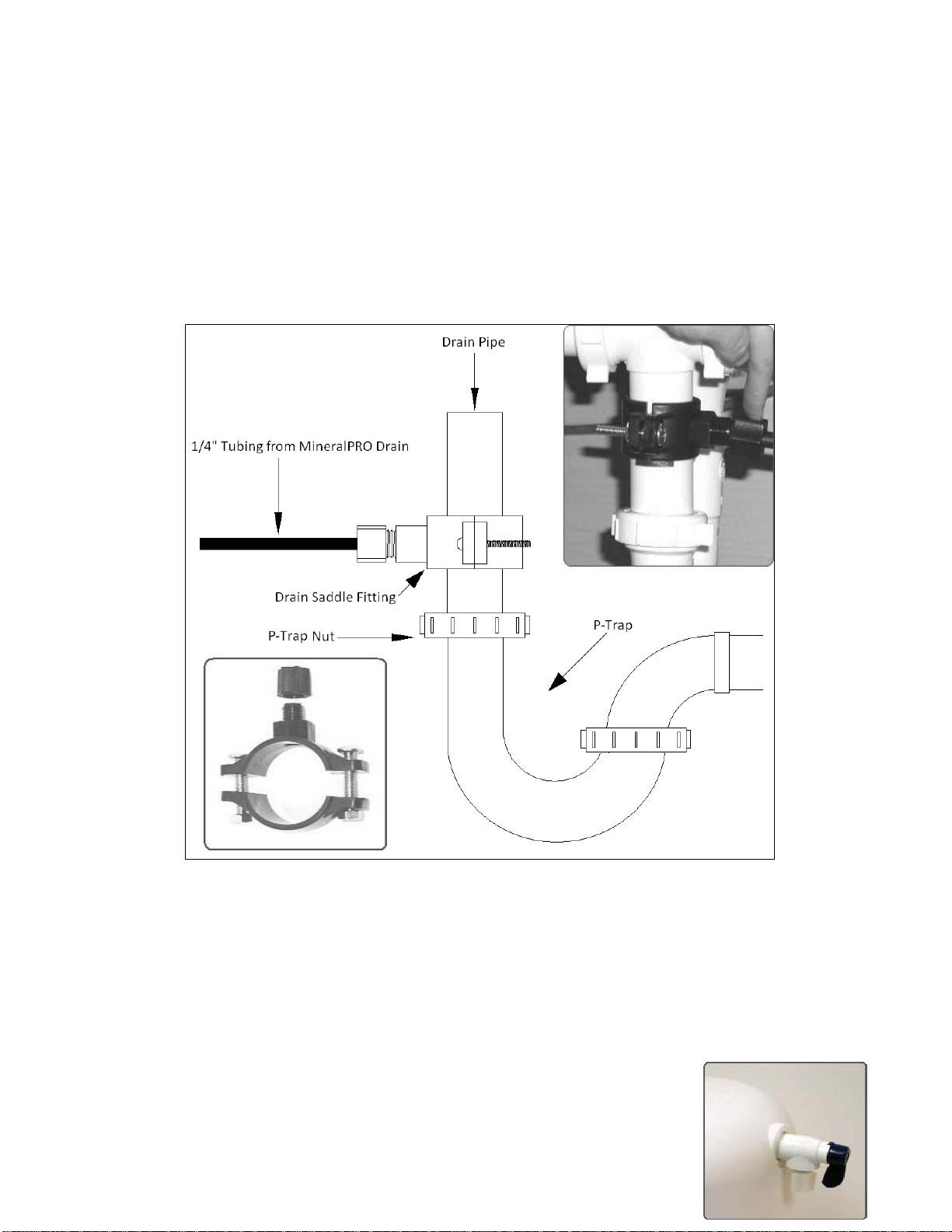

Step 7 –Drain Saddle Installation......................................................................................................................... 8

Step 8 –Tank Valve Installation............................................................................................................................ 9

Steps 9 through 13 (Tube Connections)............................................................................................................. 10

Quick Reference Tube Connections ............................................................................................................. 10

How to Use the Quick Connect Fittings on the RO Module......................................................................... 10

Step 9 –White ¼ " Tube Connection (Tank <---> MINERALPRO).......................................................................... 10

Step 10 –White ¼" Tube Connection (Angle-Valve <---> MINERALPRO)............................................................. 10

Step 11 –White ¼" Tube Connection (Faucet <---> MINERALPRO) ..................................................................... 11

Step 12 –Red ¼" Tube Connection (MINERAL PRO <---> Drain Saddle) .............................................................. 11

Step 13 –Install Cartridges................................................................................................................................. 12

Step 14 –Start-Up Instructions .......................................................................................................................... 12

Maintenance Instructions................................................................................................................................... 13

Cartridge Replacement Instructions............................................................................................................ 13

Cartridge Replacement Schedule................................................................................................................. 14

Annual Maintenance ................................................................................................................................... 14

Storage Tank Sanitization ............................................................................................................................................. 14

Tank Air Pressure .......................................................................................................................................................... 14

Procedure for Extended Non-Use (2 months or longer) .............................................................................................. 16

Manifold Assembly - Back View Diagram.......................................................................................................17

Troubleshooting ................................................................................................................................................. 17

Service Record..................................................................................................................................................... 19

Limited Warranty................................................................................................................................................ 20

NOTE: PLEASE FOLLOW THESE INSTRUCTIONS FOR FAUCET INSTALL< NOT INSTRUCTIONS ON FAUCET BOX