12

1

Contents

1.SafetyPrecautions 1

2.EquipmentFeatures 3

3.SpecificationsandDimensions3

3‑1Specifications

3‑2DimensionsofExternalAppearance

3‑3TorqueOutputCharacteristics

3‑4Theconfirmationofalevel

meterusedconsecutively

3‑5Accessories

4.NamesandFunctionsofEachComponent5

4‑1OverallConfiguration

4‑2DetailsofOperationPanel

5.OperatingProcedure7

5‑1TypeofOperationMode

5‑2PanelOperationMode

5‑3Panel/RemoteOperationMode

5‑4RemoteOperationMode

5‑5SettingoftheFunction

5‑6InitializationofSettings

6.Connectionmethod10

6‑1ConnectionofPowerCable

6‑2ConnectionofSpindleConnectionCord

6‑3ConnectionofAirHose

7.Mountingofbrackets 12

8.Replacementofoperationpanel13

8‑1ChangeofMountingDirectionof

OperationPanel

8‑2ReplacementofOperationPaneland

FilterPanel

8‑3CleaningofFilter

9.ErrorNumberDisplay

14

9‑1HowErrorNumberIsDisplayed

9‑2WhenMalfunctionsAreDetected

9‑3ErrorNumbersandTheirContents

10.Externalinput/outputsignals16

10‑1ExternalInputSignals

10‑2ExternalOutputSignals

10‑3SerialSignals

11.SignalContentofSAFETYConnector21

12.SignalContentofCONTROLConnector22

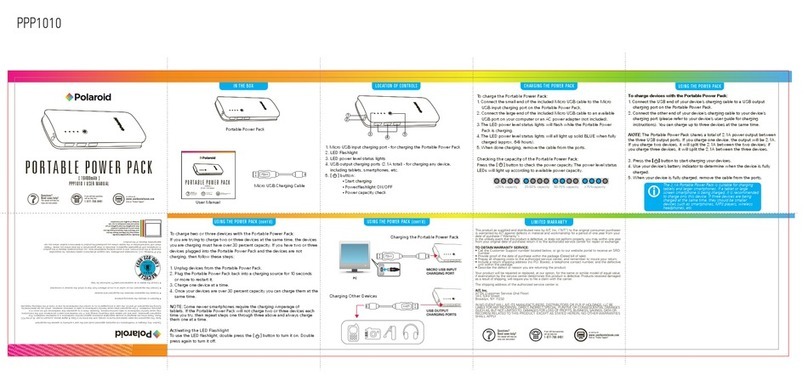

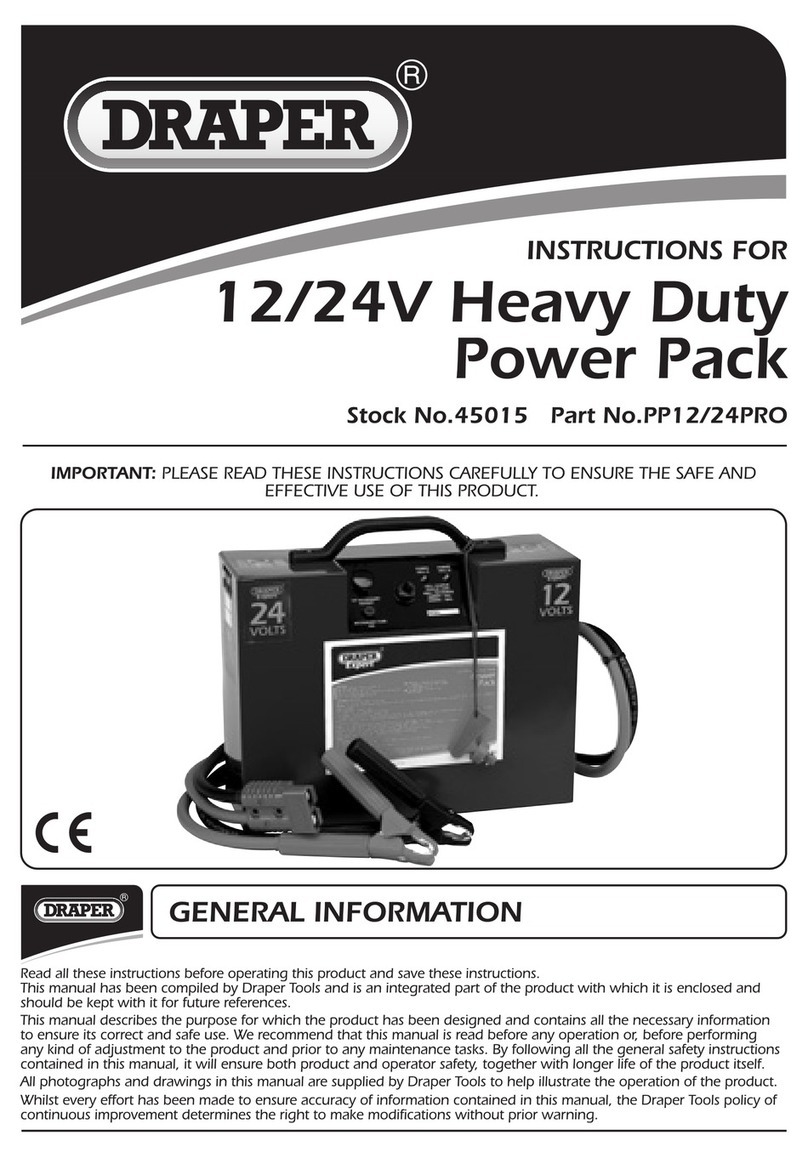

Thank you for buying the SFIDA 01 series Control‑pack MT01CP. When using this equip‑

ment,aMotorSpindleisnecessary.ReadtheOperationManualforthemotorspindleand

therobot/NCmachinetoolsetc.,tounderstandallofitsfunctions.

Keepthisoperationmanualinasafeplaceandreaditwhenrequired.

SafetyPrecautions

DefinitionsofWarningSymbols

Inthismanual,symbolsareusedtohighlightwarningsandcautionsforyoutoreadso

thataccidentscanbeprevented.Themeaningsofthesesymbolsareasfollows:

Warning

Caution

Thissymbolindicatesexplanationsaboutextremelydangerousmatter.

Ifusersignorethissymbolandthemattersappearinginthismanual,

seriousinjuryordeathbyfireorelectricshockcouldresult.

Thissymbolindicatesexplanationsaboutdangerousmatters.

Ifusersignorethissymbolandthemattersappearinginthismanual,

bodilyinjuryanddamagetotheequipmentcouldresult.

Warning

○Thisdeviceshallbegroundedusingthegroundwireofthepowercord. Makesurethat

thegroundwireisconnectedtotheearthtoavoidanelectricshockwhenusingthisdevice.

Inaddition,confirmthatthegroundwirehasbeengroundedcorrectlybeforeconnectingacable

tothisdevice.

○Ifanymalfunctionssuchassmoke,peculiarsmellsand/orsoundsarepresent,turnoffthemain

switchandunplugthepowersupplyimmediately.

Consultanelectricianforrepairafterconfirmingthatallsmokinghasstopped.Ifthemachine

isdamagedandusedwithoutproperrepair,fireandelectricshockcouldresult.

○Donotattempttomodifyordisassemblethemachinesincethiscancauseseriouslossin

performanceandsafety;otherwise,fireandelectricshockcouldresult.

○Besuretoonlyusetheinputvoltagespecifiedinthisdevicesincefireandelectricshock

couldresult.

○Donotblockventilationopeningssincethiscanresultinafailureorfirefromheat.

○DonotputControlPackonunstablelocationssuchasashakystandoraleaningsurface,etc.

Ifitfallsortopplesoveritcancauseinjury.

○Donotusethisdeviceunderanenvironmentwherecorrosivegas(chlorinegas,hydrogensulfide,

sulfurousacidgas,etc.)generates,becauseitmayleadtoanunexpectedfailureofparts.

○Whenthepowersupplycordorplugisdamaged,replaceitwiththenormalcord(option).

Continuoususemaycausefireand/orelectricshock.

○Topreventtheriskoffireandelectricshock,donotplugorunplugthemachinefromtheAC

outletwithwethands.

○Wearsafetyprotectiveglassestoprotecteyesandananti‑dustmasktopreventinhalationof

debris.Youmaysufferfromunexpectedinjuriescausedbyflyingdebrisgeneratedthroughuseof

thismachine.

Caution

○Operatemachineryinadrylocationfreeofcondensation,otherwisethiscouldresultinafire

and/orelectricshock.

○Operateintemperaturesof0〜40℃.

○Wheninstallingdonotblockthefilterpanelwherecoolairistakeninortheexhaustventilation

slits.

○Donotallowchildrentooperatemachinerybyanymeans;keepmachineoutoftheirreach.

○Donothitordropobjectsonthedeviceasthismaydamageit.

○Becarefulsothatdust,oilandwaterdonotenterthedevice.Whenforeignsubstancessuchas

liquidenterthedevice,turnoffthemainswitch,unplugthepowersupplyfromtheACoutletand

consultwithaqualifiedtechnician.Fireandelectricshockcouldresultifusedasis.

○Donotplaceheavyobjectsonthepowercordasthismaydamagethecordresultinginafireandor

electricshock.

○Donotplacepowercordnearheatsources.Thecordcasingmaymeltresultinginafireandelectric

shock.

○Whenunpluggingthepowercord,alwaysgrasptheplugitselfanddonotpullatthecord;otherwise,

thismaydamagethecordresultinginafireandelectricshock.

○Beforemaintenancecleaning,unplugthepowercordfromtheACoutletforsafety.

○Usecuttingtoolsandmagnetsatthenumberofrevolutionsrecommendedbythemanufacturer.Donot

useitatthenumberofrevolutionsbeyondthepermissiblerange,sincethiscanresultindamageto

thedevice.

○Inthecaseofelectricoverload,useitafterreducingtheloadsinceitmeansthestateusedin

theloadbeyondsetting.