*NOTE: The deck space of MIRGA6042, MIRGA7242 and MIRWH7140 have only the width of the deck given, since

there is no deck space available in the corners as it is depicted in the graphic above.

Additional Note: On the MIRED6032, MIRED6036, MIRED6636, MIRED7232, MIRED7236, inside corners are square.

†NOTE: Thereis no deck space on the MIRB6640 & MIRB7242 models.

Illustration J

Faucet Deck Mount

Dimensions

Deck space where faucets can be mounted is given in a

diagonal dimension Y and a base line dimension Z, which

is the long side of the deck corner.

“L”

LENGTH

“W”

WIDTH

“Y”

DIAGONAL

DECK DIM

“Z”

BASE LINE

DECK DIM

DROP-IN MODEL

SEE ILLUSTRATION J

MIRBDA6032, MIRBDS6032, MIRBDT6032, MIRBDW6032 60" 32" 6-1/2" 14"

MIRBRA6640V, MIRBRS6640V, MIRBRT6640V, MIRBRW6640V 66" 40" N/A†N/A†

MIRBRA7242V, MIRBRS7242V, MIRBRT7242V, MIRBRS7242V 71-1/2" 42" N/A†N/A†

MIREDA6032, MIREDS6032, MIREDT6032, MIREDT6032 59-3/4" 31-7/8" 2-3/4" 8"

MIREDA6036, MIREDS6036, MIREDT6036, MIREDW6036 59-3/4" 35-3/4" 3-1/4" 10-3/4"

MIREDA6636, MIREDS6636, MIREDT6636, MIREDW6636 66" 36" 3"* 11"*

MIREDA7236, MIREDS7236, MIREDT7236, MIREDW7236 71-1/2" 35-3/4" 3" 10-3/4"

MIRGAA6042, MIRGAS6042, MIRGAT6042, MIRGAW6042 60" 42" 3"* 3"*

MIRGAA7242, MIRGAS7242, MIRGAT7242, MIRGAW7242 72" 42" 3"* 3"*

MIRKWA6036, MIRKWS6036, MIRKWT6036, MIRKWW6036 60" 36" 6-1/2" 14"

MIRKWA7236, MIRKWS7236, MIRKWT7236, MIRKWW7236 72" 36" 6-1/2" 14"

MIRPRA6032, MIRPRS6032, MIRPRT6032, MIRPRW6032 60" 32" 7-1/2" 15-1/2"

MIRSAA6042, MIRSAS6042, MIRSAT6042, MIRSAW6042 60" 42" 7-1/2" 15"

MIRSAA6060, MIRSAS6060, MIRSAT6060, MIRSAW6060 60" 60" 9" 18"

MIRSAA7242, MIRSAS7242, MIRSAT7242, MIRSAW7242 72" 42" 7-1/2" 15"

MIRWHA7140, MIRWHS7140, MIRWHT7140, MIRWHW7140 71-1/2" 40" 5"* 5"*

7

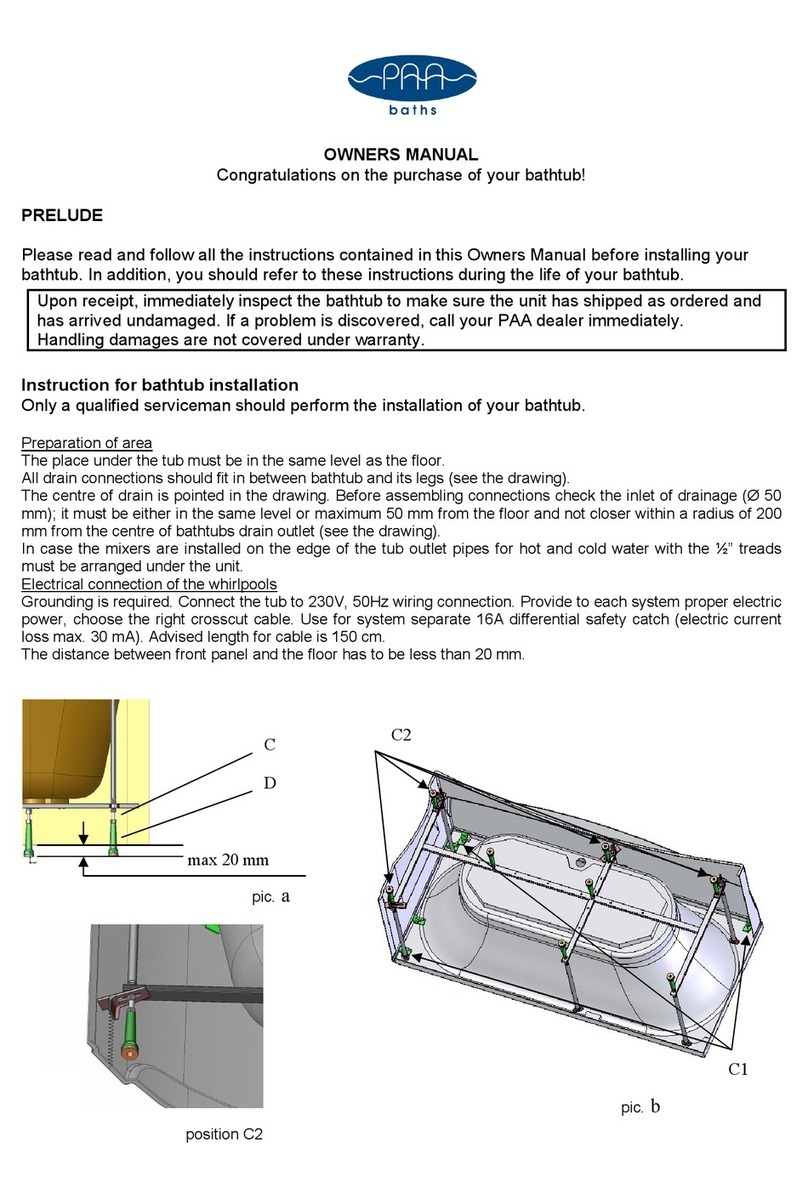

INSTALLATION PLANNING AND PREPARATION

1. NEVER LIFT THE TUB BY THE PLUMBING.Doing so can result in leaks.

2. Check if the floor is level and of good quality. An uneven floor may impede

proper installation of the product. The floor structure must be capable of

supporting at least 100 pounds per square foot.

a. Clean the area of any debris or trash.

b. Use setting compound if the floor is level. If it is not, calculate how much

you have to use to level the tub.

c. Insure that you place the drain

rough at the proper location.

d. Check if the installer placed the

proper electrical service near the

pump location. See electrical

requirements for specifications.

3. If this is a deck installation, measure

from the floor to the bottom of the

rim to ensure that the tub is not

suspended by its rim.

You should always have the entire tub floor fully supported

with setting compound.

TYPICAL FLANGE MOUNTING DETAIL

1 x 4 (25 x 76mm) WOOD

STRINGER FULL LENGTH

TUB

STUD

WATERPROOF DRYWALL

OR CEMENT BOARD TILE

SEALANT

ROOFING NAIL

SUGGESTED WHIRLPOOL/BATH

INSTALLATION METHOD

WOOD

STUDS

HEIGHT TO LIP

SETTING COMPOUND

*NOTE: The deck space of MIRGA6042, MIRGA7242 and MIRWH7140 have only the width of the deck given, since

there is no deck space available in the corners as it is depicted in the graphic above.

Additional Note: On the MIRED6032, MIRED6036, MIRED6636, MIRED7232, MIRED7236, inside corners are square.

†NOTE: Thereis no deck space on the MIRB6640 & MIRB7242 models.

Illustration J

Faucet Deck Mount

Dimensions

Deck space where faucets can be mounted is given in a

diagonal dimension Y and a base line dimension Z, which

is the long side of the deck corner.

“L”

LENGTH

“W”

WIDTH

“Y”

DIAGONAL

DECK DIM

“Z”

BASE LINE

DECK DIM

DROP-IN MODEL

SEE ILLUSTRATION J

MIRBDA6032, MIRBDS6032, MIRBDT6032, MIRBDW6032 60" 32" 6-1/2" 14"

MIRBRA6640V, MIRBRS6640V, MIRBRT6640V, MIRBRW6640V 66" 40" N/A†N/A†

MIRBRA7242V, MIRBRS7242V, MIRBRT7242V, MIRBRS7242V 71-1/2" 42" N/A†N/A†

MIREDA6032, MIREDS6032, MIREDT6032, MIREDT6032 59-3/4" 31-7/8" 2-3/4" 8"

MIREDA6036, MIREDS6036, MIREDT6036, MIREDW6036 59-3/4" 35-3/4" 3-1/4" 10-3/4"

MIREDA6636, MIREDS6636, MIREDT6636, MIREDW6636 66" 36" 3"* 11"*

MIREDA7236, MIREDS7236, MIREDT7236, MIREDW7236 71-1/2" 35-3/4" 3" 10-3/4"

MIRGAA6042, MIRGAS6042, MIRGAT6042, MIRGAW6042 60" 42" 3"* 3"*

MIRGAA7242, MIRGAS7242, MIRGAT7242, MIRGAW7242 72" 42" 3"* 3"*

MIRKWA6036, MIRKWS6036, MIRKWT6036, MIRKWW6036 60" 36" 6-1/2" 14"

MIRKWA7236, MIRKWS7236, MIRKWT7236, MIRKWW7236 72" 36" 6-1/2" 14"

MIRPRA6032, MIRPRS6032, MIRPRT6032, MIRPRW6032 60" 32" 7-1/2" 15-1/2"

MIRSAA6042, MIRSAS6042, MIRSAT6042, MIRSAW6042 60" 42" 7-1/2" 15"

MIRSAA6060, MIRSAS6060, MIRSAT6060, MIRSAW6060 60" 60" 9" 18"

MIRSAA7242, MIRSAS7242, MIRSAT7242, MIRSAW7242 72" 42" 7-1/2" 15"

MIRWHA7140, MIRWHS7140, MIRWHT7140, MIRWHW7140 71-1/2" 40" 5"* 5"*

7

INSTALLATION PLANNING AND PREPARATION

1. NEVER LIFT THE TUB BY THE PLUMBING.Doing so can result in leaks.

2. Check if the floor is level and of good quality. An uneven floor may impede

proper installation of the product. The floor structure must be capable of

supporting at least 100 pounds per square foot.

a. Clean the area of any debris or trash.

b. Use setting compound if the floor is level. If it is not, calculate how much

you have to use to level the tub.

c. Insure that you place the drain

rough at the proper location.

d. Check if the installer placed the

proper electrical service near the

pump location. See electrical

requirements for specifications.

3. If this is a deck installation, measure

from the floor to the bottom of the

rim to ensure that the tub is not

suspended by its rim.

You should always have the entire tub floor fully supported

with setting compound.

TYPICAL FLANGE MOUNTING DETAIL

1 x 4 (25 x 76mm) WOOD

STRINGER FULL LENGTH

TUB

STUD

WATERPROOF DRYWALL

OR CEMENT BOARD TILE

SEALANT

ROOFING NAIL

SUGGESTED WHIRLPOOL/BATH

INSTALLATION METHOD

WOOD

STUDS

HEIGHT TO LIP

SETTING COMPOUND

*NOTE: The deck space of MIRGA6042, MIRGA7242 and MIRWH7140 have only the width of the deck given, since

there is no deck space available in the corners as it is depicted in the graphic above.

Additional Note: On the MIRED6032, MIRED6036, MIRED6636, MIRED7232, MIRED7236, inside corners are square.

†NOTE: Thereis no deck space on the MIRB6640 & MIRB7242 models.

Illustration J

Faucet Deck Mount

Dimensions

Deck space where faucets can be mounted is given in a

diagonal dimension Y and a base line dimension Z, which

is the long side of the deck corner.

“L”

LENGTH

“W”

WIDTH

“Y”

DIAGONAL

DECK DIM

“Z”

BASE LINE

DECK DIM

DROP-IN MODEL

SEE ILLUSTRATION J

MIRBDA6032, MIRBDS6032, MIRBDT6032, MIRBDW6032 60" 32" 6-1/2" 14"

MIRBRA6640V, MIRBRS6640V, MIRBRT6640V, MIRBRW6640V 66" 40" N/A†N/A†

MIRBRA7242V, MIRBRS7242V, MIRBRT7242V, MIRBRS7242V 71-1/2" 42" N/A†N/A†

MIREDA6032, MIREDS6032, MIREDT6032, MIREDT6032 59-3/4" 31-7/8" 2-3/4" 8"

MIREDA6036, MIREDS6036, MIREDT6036, MIREDW6036 59-3/4" 35-3/4" 3-1/4" 10-3/4"

MIREDA6636, MIREDS6636, MIREDT6636, MIREDW6636 66" 36" 3"* 11"*

MIREDA7236, MIREDS7236, MIREDT7236, MIREDW7236 71-1/2" 35-3/4" 3" 10-3/4"

MIRGAA6042, MIRGAS6042, MIRGAT6042, MIRGAW6042 60" 42" 3"* 3"*

MIRGAA7242, MIRGAS7242, MIRGAT7242, MIRGAW7242 72" 42" 3"* 3"*

MIRKWA6036, MIRKWS6036, MIRKWT6036, MIRKWW6036 60" 36" 6-1/2" 14"

MIRKWA7236, MIRKWS7236, MIRKWT7236, MIRKWW7236 72" 36" 6-1/2" 14"

MIRPRA6032, MIRPRS6032, MIRPRT6032, MIRPRW6032 60" 32" 7-1/2" 15-1/2"

MIRSAA6042, MIRSAS6042, MIRSAT6042, MIRSAW6042 60" 42" 7-1/2" 15"

MIRSAA6060, MIRSAS6060, MIRSAT6060, MIRSAW6060 60" 60" 9" 18"

MIRSAA7242, MIRSAS7242, MIRSAT7242, MIRSAW7242 72" 42" 7-1/2" 15"

MIRWHA7140, MIRWHS7140, MIRWHT7140, MIRWHW7140 71-1/2" 40" 5"* 5"*

7

INSTALLATION PLANNING AND PREPARATION

1. NEVER LIFT THE TUB BY THE PLUMBING.Doing so can result in leaks.

2. Check if the floor is level and of good quality. An uneven floor may impede

proper installation of the product. The floor structure must be capable of

supporting at least 100 pounds per square foot.

a. Clean the area of any debris or trash.

b. Use setting compound if the floor is level. If it is not, calculate how much

you have to use to level the tub.

c. Insure that you place the drain

rough at the proper location.

d. Check if the installer placed the

proper electrical service near the

pump location. See electrical

requirements for specifications.

3. If this is a deck installation, measure

from the floor to the bottom of the

rim to ensure that the tub is not

suspended by its rim.

You should always have the entire tub floor fully supported

with setting compound.

TYPICAL FLANGE MOUNTING DETAIL

1 x 4 (25 x 76mm) WOOD

STRINGER FULL LENGTH

TUB

STUD

WATERPROOF DRYWALL

OR CEMENT BOARD TILE

SEALANT

ROOFING NAIL

SUGGESTED WHIRLPOOL/BATH

INSTALLATION METHOD

WOOD

STUDS

HEIGHT TO LIP

SETTING COMPOUND

*NOTE: The deck space of MIRGA6042, MIRGA7242 and MIRWH7140 have only the width of the deck given, since

there is no deck space available in the corners as it is depicted in the graphic above.

Additional Note: On the MIRED6032, MIRED6036, MIRED6636, MIRED7232, MIRED7236, inside corners are square.

†NOTE: Thereis no deck space on the MIRB6640 & MIRB7242 models.

Illustration J

Faucet Deck Mount

Dimensions

Deck space where faucets can be mounted is given in a

diagonal dimension Y and a base line dimension Z, which

is the long side of the deck corner.

“L”

LENGTH

“W”

WIDTH

“Y”

DIAGONAL

DECK DIM

“Z”

BASE LINE

DECK DIM

DROP-IN MODEL

SEE ILLUSTRATION J

MIRBDA6032, MIRBDS6032, MIRBDT6032, MIRBDW6032 60" 32" 6-1/2" 14"

MIRBRA6640V, MIRBRS6640V, MIRBRT6640V, MIRBRW6640V 66" 40" N/A†N/A†

MIRBRA7242V, MIRBRS7242V, MIRBRT7242V, MIRBRS7242V 71-1/2" 42" N/A†N/A†

MIREDA6032, MIREDS6032, MIREDT6032, MIREDT6032 59-3/4" 31-7/8" 2-3/4" 8"

MIREDA6036, MIREDS6036, MIREDT6036, MIREDW6036 59-3/4" 35-3/4" 3-1/4" 10-3/4"

MIREDA6636, MIREDS6636, MIREDT6636, MIREDW6636 66" 36" 3"* 11"*

MIREDA7236, MIREDS7236, MIREDT7236, MIREDW7236 71-1/2" 35-3/4" 3" 10-3/4"

MIRGAA6042, MIRGAS6042, MIRGAT6042, MIRGAW6042 60" 42" 3"* 3"*

MIRGAA7242, MIRGAS7242, MIRGAT7242, MIRGAW7242 72" 42" 3"* 3"*

MIRKWA6036, MIRKWS6036, MIRKWT6036, MIRKWW6036 60" 36" 6-1/2" 14"

MIRKWA7236, MIRKWS7236, MIRKWT7236, MIRKWW7236 72" 36" 6-1/2" 14"

MIRPRA6032, MIRPRS6032, MIRPRT6032, MIRPRW6032 60" 32" 7-1/2" 15-1/2"

MIRSAA6042, MIRSAS6042, MIRSAT6042, MIRSAW6042 60" 42" 7-1/2" 15"

MIRSAA6060, MIRSAS6060, MIRSAT6060, MIRSAW6060 60" 60" 9" 18"

MIRSAA7242, MIRSAS7242, MIRSAT7242, MIRSAW7242 72" 42" 7-1/2" 15"

MIRWHA7140, MIRWHS7140, MIRWHT7140, MIRWHW7140 71-1/2" 40" 5"* 5"*

7

INSTALLATION PLANNING AND PREPARATION

1. NEVER LIFT THE TUB BY THE PLUMBING.Doing so can result in leaks.

2. Check if the floor is level and of good quality. An uneven floor may impede

proper installation of the product. The floor structure must be capable of

supporting at least 100 pounds per square foot.

a. Clean the area of any debris or trash.

b. Use setting compound if the floor is level. If it is not, calculate how much

you have to use to level the tub.

c. Insure that you place the drain

rough at the proper location.

d. Check if the installer placed the

proper electrical service near the

pump location. See electrical

requirements for specifications.

3. If this is a deck installation, measure

from the floor to the bottom of the

rim to ensure that the tub is not

suspended by its rim.

You should always have the entire tub floor fully supported

with setting compound.

TYPICAL FLANGE MOUNTING DETAIL

1 x 4 (25 x 76mm) WOOD

STRINGER FULL LENGTH

TUB

STUD

WATERPROOF DRYWALL

OR CEMENT BOARD TILE

SEALANT

ROOFING NAIL

SUGGESTED WHIRLPOOL/BATH

INSTALLATION METHOD

WOOD

STUDS

HEIGHT TO LIP

SETTING COMPOUND

INSTALLATION PLANNING AND PREPARATION

1. NEVER LIFT THE TUB BY THE PLUMBING. Doing so can result in leaks.

2. Check if the floor is level and of good quality. An uneven floor may impede proper installation of the

product. The floor structure must be capable of supporting at least 100 pounds per square foot.

a. Clean the area of any debris or trash.

b. Use setting compound if the floor is level. If it is not, calculate how much

you have to use to level the tub.

c. Insure that you place the drain rough at the proper location.

d. Check if the installer placed the proper electrical service near the pump

location. See electrical requirements

for specifications.

3. If this is a deck installation, measure from

the floor to the bottom of the rim to

ensure that the tub is not suspended by

its rim.

You should always have the entire tub floor

fully supported with setting compound.

Faucet Deck Mount

Dimensions

Deck space where faucets can be mounted is given in a

diagonal dimension Y and a base line dimension Z, which

is the long side of the deck corner.

*NOTE: The deck space of MIRGA6042, MIRGA7242 and MIRWH7140 have only the width of the deck given, since there

is no deck space available in the corners as it is depicted in the graphic above. Additional Note: On the MIRED6032,

MIRED6036, MIRED6636, MIRED7232, MIRED7236, inside corners are square.

†NOTE: There is no deck space on the MIRB6640 & MIRB7242 models.

WHIRLPOOL CONTROL CENTER FEATURES

The whirlpool is controlled by a three button control.

1. The first button switches the water-pump on or off. The

other features will not operate unless the pump is turned on.

2. The second button sets the power level of the pump. Holding

the button depressed will cycle the pump power from low to

high in a continuous cycle. When the desired level is reached,

remove your finger quickly from the button to maintain that

power setting.

3. The third button is a three step wave action button. Once

activated, the jets expel water in a slow pulsating flow called

wave action. There are 3 steps or positions for wave strength.

a. Position #1 operates the pump at a steady flow.

b. Position #2 operates the pump at a quick wave action.

c. Position #3 operates the pump at a slower wave action.

AIR BATH CONTROL CENTER FEATURES

The air bath is controlled by a three button control.

1. The first button switches the blower on or off. The other

features will not operate unless the blower is turned on.

2. The second button sets the power level of the blower.Holding

the button depressed will cycle the blower power from low to

high in a continuous cycle. When the desired level is reached,

remove your finger quickly from the button to maintain that

power setting.

3. The thirdbutton is a three step wave action button. Once

activated, the air holes expel air in a slow pulsating flow called

wave action. There are 3 steps or positions for wave strength.

a. Position #1 operates the blower at a steady flow.

b. Position #2 operates the blower at a quick wave action.

c. Position #3 operates the blower at a slower wave action.

TOTAL MASSAGE BATHS

Total Massage units are a combination of whirlpool and air

massages. The top three controls on the “Therapy Control Center”

operate the whirlpool and the bottom three controls operate the air

system. The whirlpool and air massage systems may be used at

the same time if desired. The air bath control center is explained in

the section above.

The whirlpool is controlled by a three button control.

1. The first button switches the pump on or off. The other features

will not operate unless the pump is turned on.

2. The second button sets the power level of the pump. Holding

the button depressed will cycle the pump power from low to

high in a continuous cycle. When the desired level is reached,

remove your finger quickly from the button to maintain that

power setting.

3. The third button is a three step wave action button:

a. Position #1 operates the pump at a steady flow.

b. Position #2 operates the pump at a quick wave action.

c. Position #3 operates the pump with a slower wave action.

10

Illustration K

Illustration N

Illustration M

Illustration L

JET OPERATION AND ADJUSTMENT

The jets can be easily adjusted by pointing the jet-nozzle in the desired direction. The

strength of the water flow and air induction can be regulated through twisting the jet- nozzle.

Twisting the nozzle clockwise will decrease the water flow and finally completely turn off the

water flow of that particular jet. If the nozzle is twisted counter clockwise then the water flow

will increase up to its maximum flow. Only a 1/4 turn or 90oturn is required from the OFF

position to the fully OPEN position.

JET OPERATION AND ADJUSTMENT

The jets can be easily adjusted by pointing the jet-nozzle in the desired direction. The strength

of the water flow and air induction can be regulated through twisting the jet- nozzle. Twisting

the nozzle clockwise will decrease the water flow and finally completely turn off the water

flow of that particular jet. If the nozzle is twisted counter clockwise then the water flow will

increase up to its maximum flow. Only a 1/4 turn or 90° turn is required from the OFF position

to the fully OPEN position.

WHIRLPOOL CONTROL CENTER FEATURES

The whirlpool is controlled by a three button control.

1. The first button switches the water-pump on or off. The other

features will not operate unless the pump is turned on.

2. The second button sets the power level of the pump. Holding

the button depressed will cycle the pump power from low to

high in a continuous cycle. When the desired level is reached,

remove your finger quickly from the button to maintain that

power setting.

3. The third button is a three step wave action button. Once

activated, the jets expel water in a slow pulsating flow called

wave action. There are 3 steps or positions for wave strength.

a. Position #1 operates the pump at a steady flow.

b. Position #2 operates the pump at a quick wave action.

c. Position #3 operates the pump at a slower wave action.

AIR BATH CONTROL CENTER FEATURES

The air bath is controlled by a three button control.

1. The first button switches the blower on or off. The other

features will not operate unless the blower is turned on.

2. The second button sets the power level of the blower. Holding

the button depressed will cycle the blower power from low to

high in a continuous cycle. When the desired level is reached,

remove your finger quickly from the button to maintain that

power setting.

3. The third button is a three step wave action button. Once

activated, the air holes expel air in a slow pulsating flow called

wave action. There are 3 steps or positions for wave strength.

a. Position #1 operates the blower at a steady flow.

b. Position #2 operates the blower at a quick wave action.

c. Position #3 operates the blower at a slower wave action.

TOTAL MASSAGE BATHS

Total Massage units are a combination of whirlpool and air massages.

The top three controls on the “Therapy Control Center” operate the

whirlpool and the bottom three controls operate the air system. The

whirlpool and air massage systems may be used at the same time

if desired. The air bath control center is explained in the section

above.

The whirlpool is controlled by a three button control.

1. The first button switches the pump on or off. The other features

will not operate unless the pump is turned on.

2. The second button sets the power level of the pump. Holding

the button depressed will cycle the pump power from low to

high in a continuous cycle. When the desired level is reached,

remove your finger quickly from the button to maintain that

power setting.

3. The third button is a three step wave action button:

a. Position #1 operates the pump at a steady flow.

b. Position #2 operates the pump at a quick wave action.

c. Position #3 operates the pump with a slower wave action.

WHIRLPOOL CONTROL CENTER FEATURES

The whirlpool is controlled by a three button control.

1. The first button switches the water-pump on or off. The

other features will not operate unless the pump is turned on.

2. The second button sets the power level of the pump. Holding

the button depressed will cycle the pump power from low to

high in a continuous cycle. When the desired level is reached,

remove your finger quickly from the button to maintain that

power setting.

3. The third button is a three step wave action button. Once

activated, the jets expel water in a slow pulsating flow called

wave action. There are 3 steps or positions for wave strength.

a. Position #1 operates the pump at a steady flow.

b. Position #2 operates the pump at a quick wave action.

c. Position #3 operates the pump at a slower wave action.

AIR BATH CONTROL CENTER FEATURES

The air bath is controlled by a three button control.

1. The first button switches the blower on or off. The other

features will not operate unless the blower is turned on.

2. The second button sets the power level of the blower.Holding

the button depressed will cycle the blower power from low to

high in a continuous cycle. When the desired level is reached,

remove your finger quickly from the button to maintain that

power setting.

3. The thirdbutton is a three step wave action button. Once

activated, the air holes expel air in a slow pulsating flow called

wave action. There are 3 steps or positions for wave strength.

a. Position #1 operates the blower at a steady flow.

b. Position #2 operates the blower at a quick wave action.

c. Position #3 operates the blower at a slower wave action.

TOTAL MASSAGE BATHS

Total Massage units are a combination of whirlpool and air

massages. The top three controls on the “Therapy Control Center”

operate the whirlpool and the bottom three controls operate the air

system. The whirlpool and air massage systems may be used at

the same time if desired. The air bath control center is explained in

the section above.

The whirlpool is controlled by a three button control.

1. The first button switches the pump on or off. The other features

will not operate unless the pump is turned on.

2. The second button sets the power level of the pump. Holding

the button depressed will cycle the pump power from low to

high in a continuous cycle. When the desired level is reached,

remove your finger quickly from the button to maintain that

power setting.

3. The third button is a three step wave action button:

a. Position #1 operates the pump at a steady flow.

b. Position #2 operates the pump at a quick wave action.

c. Position #3 operates the pump with a slower wave action.

10

Illustration K

Illustration N

Illustration M

Illustration L

JET OPERATION AND ADJUSTMENT

The jets can be easily adjusted by pointing the jet-nozzle in the desired direction. The

strength of the water flow and air induction can be regulated through twisting the jet- nozzle.

Twisting the nozzle clockwise will decrease the water flow and finally completely turn off the

water flow of that particular jet. If the nozzle is twisted counter clockwise then the water flow

will increase up to its maximum flow. Only a 1/4 turn or 90oturn is required from the OFF

position to the fully OPEN position.

WHIRLPOOL CONTROL CENTER FEATURES

The whirlpool is controlled by a three button control.

1. The first button switches the water-pump on or off. The

other features will not operate unless the pump is turned on.

2. The second button sets the power level of the pump. Holding

the button depressed will cycle the pump power from low to

high in a continuous cycle. When the desired level is reached,

remove your finger quickly from the button to maintain that

power setting.

3. The third button is a three step wave action button. Once

activated, the jets expel water in a slow pulsating flow called

wave action. There are 3 steps or positions for wave strength.

a. Position #1 operates the pump at a steady flow.

b. Position #2 operates the pump at a quick wave action.

c. Position #3 operates the pump at a slower wave action.

AIR BATH CONTROL CENTER FEATURES

The air bath is controlled by a three button control.

1. The first button switches the blower on or off. The other

features will not operate unless the blower is turned on.

2. The second button sets the power level of the blower.Holding

the button depressed will cycle the blower power from low to

high in a continuous cycle. When the desired level is reached,

remove your finger quickly from the button to maintain that

power setting.

3. The thirdbutton is a three step wave action button. Once

activated, the air holes expel air in a slow pulsating flow called

wave action. There are 3 steps or positions for wave strength.

a. Position #1 operates the blower at a steady flow.

b. Position #2 operates the blower at a quick wave action.

c. Position #3 operates the blower at a slower wave action.

TOTAL MASSAGE BATHS

Total Massage units are a combination of whirlpool and air

massages. The top three controls on the “Therapy Control Center”

operate the whirlpool and the bottom three controls operate the air

system. The whirlpool and air massage systems may be used at

the same time if desired. The air bath control center is explained in

the section above.

The whirlpool is controlled by a three button control.

1. The first button switches the pump on or off. The other features

will not operate unless the pump is turned on.

2. The second button sets the power level of the pump. Holding

the button depressed will cycle the pump power from low to

high in a continuous cycle. When the desired level is reached,

remove your finger quickly from the button to maintain that

power setting.

3. The third button is a three step wave action button:

a. Position #1 operates the pump at a steady flow.

b. Position #2 operates the pump at a quick wave action.

c. Position #3 operates the pump with a slower wave action.

10

Illustration K

Illustration N

Illustration M

Illustration L

JET OPERATION AND ADJUSTMENT

The jets can be easily adjusted by pointing the jet-nozzle in the desired direction. The

strength of the water flow and air induction can be regulated through twisting the jet- nozzle.

Twisting the nozzle clockwise will decrease the water flow and finally completely turn off the

water flow of that particular jet. If the nozzle is twisted counter clockwise then the water flow

will increase up to its maximum flow. Only a 1/4 turn or 90oturn is required from the OFF

position to the fully OPEN position.

WHIRLPOOL CONTROL CENTER FEATURES

The whirlpool is controlled by a three button control.

1. The first button switches the water-pump on or off. The

other features will not operate unless the pump is turned on.

2. The second button sets the power level of the pump. Holding

the button depressed will cycle the pump power from low to

high in a continuous cycle. When the desired level is reached,

remove your finger quickly from the button to maintain that

power setting.

3. The third button is a three step wave action button. Once

activated, the jets expel water in a slow pulsating flow called

wave action. There are 3 steps or positions for wave strength.

a. Position #1 operates the pump at a steady flow.

b. Position #2 operates the pump at a quick wave action.

c. Position #3 operates the pump at a slower wave action.

AIR BATH CONTROL CENTER FEATURES

The air bath is controlled by a three button control.

1. The first button switches the blower on or off. The other

features will not operate unless the blower is turned on.

2. The second button sets the power level of the blower.Holding

the button depressed will cycle the blower power from low to

high in a continuous cycle. When the desired level is reached,

remove your finger quickly from the button to maintain that

power setting.

3. The thirdbutton is a three step wave action button. Once

activated, the air holes expel air in a slow pulsating flow called

wave action. There are 3 steps or positions for wave strength.

a. Position #1 operates the blower at a steady flow.

b. Position #2 operates the blower at a quick wave action.

c. Position #3 operates the blower at a slower wave action.

TOTAL MASSAGE BATHS

Total Massage units are a combination of whirlpool and air

massages. The top three controls on the “Therapy Control Center”

operate the whirlpool and the bottom three controls operate the air

system. The whirlpool and air massage systems may be used at

the same time if desired. The air bath control center is explained in

the section above.

The whirlpool is controlled by a three button control.

1. The first button switches the pump on or off. The other features

will not operate unless the pump is turned on.

2. The second button sets the power level of the pump. Holding

the button depressed will cycle the pump power from low to

high in a continuous cycle. When the desired level is reached,

remove your finger quickly from the button to maintain that

power setting.

3. The third button is a three step wave action button:

a. Position #1 operates the pump at a steady flow.

b. Position #2 operates the pump at a quick wave action.

c. Position #3 operates the pump with a slower wave action.

10

Illustration K

Illustration N

Illustration M

Illustration L

JET OPERATION AND ADJUSTMENT

The jets can be easily adjusted by pointing the jet-nozzle in the desired direction. The

strength of the water flow and air induction can be regulated through twisting the jet- nozzle.

Twisting the nozzle clockwise will decrease the water flow and finally completely turn off the

water flow of that particular jet. If the nozzle is twisted counter clockwise then the water flow

will increase up to its maximum flow. Only a 1/4 turn or 90oturn is required from the OFF

position to the fully OPEN position.