1. Introduction.............................................................................................................................4

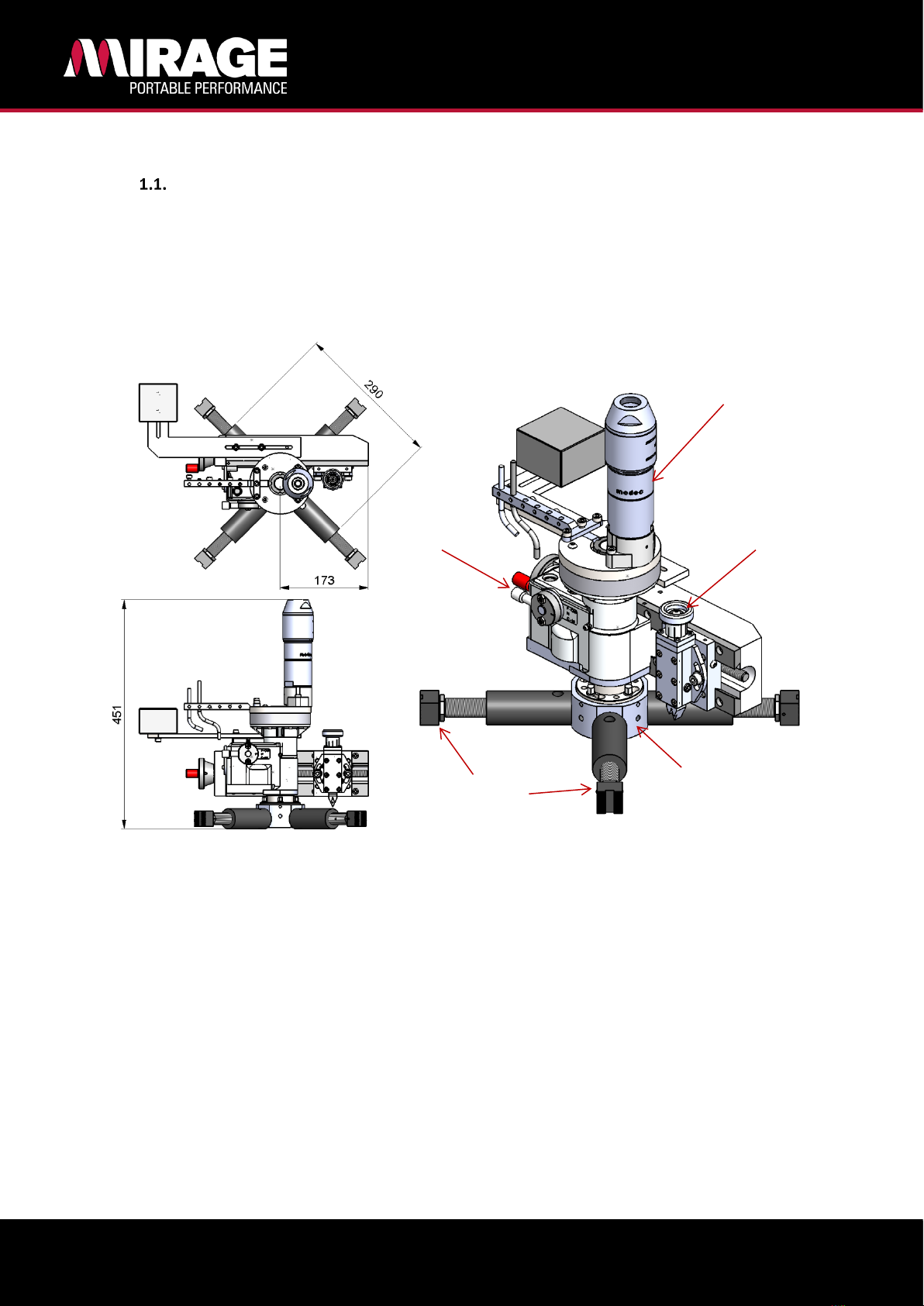

Overall Equipment Description ...............................................................................................4

Machine safety features..........................................................................................................5

2. Machine Warranty...................................................................................................................5

3. Health and Safety ....................................................................................................................6

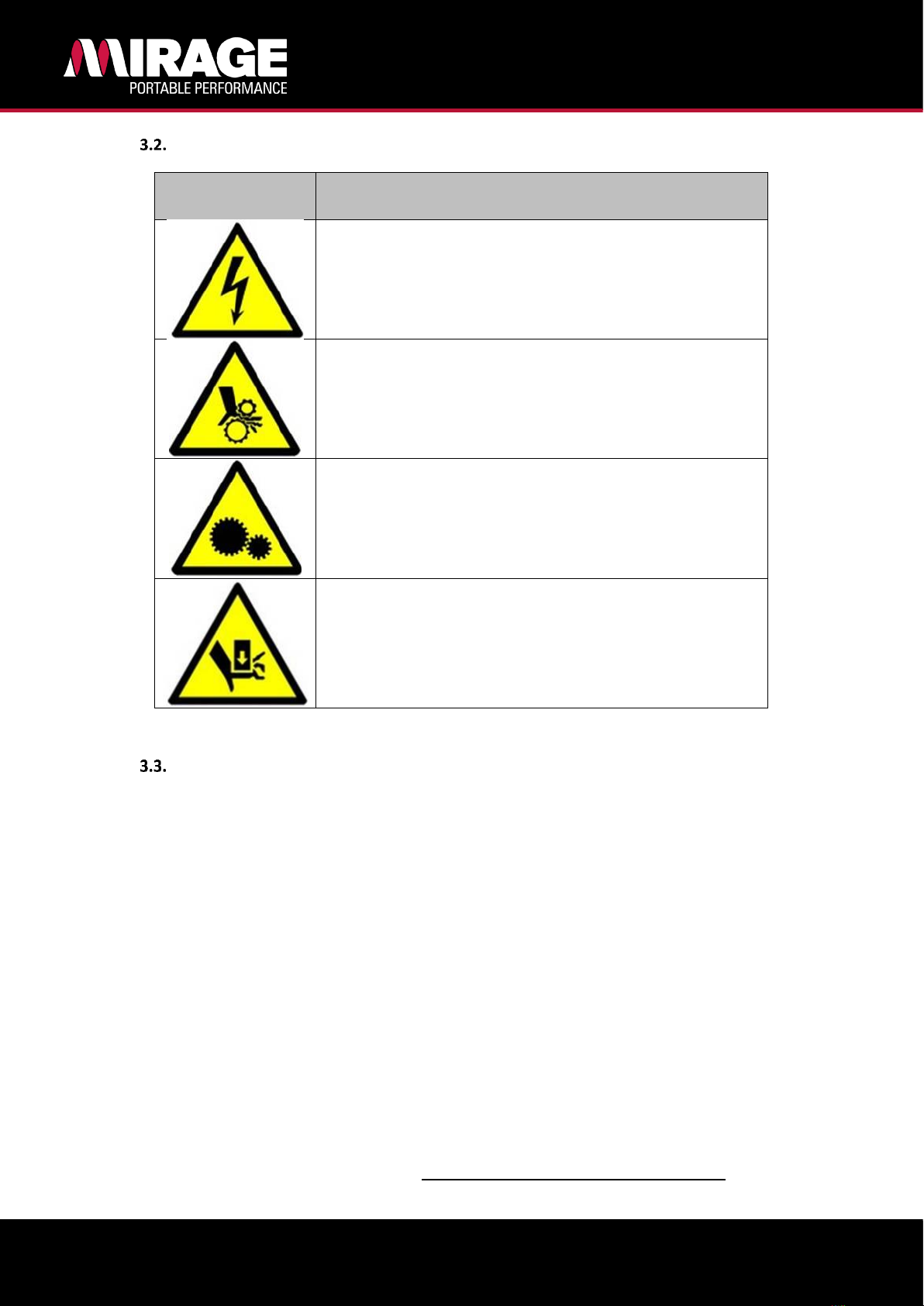

Mandatory Safety Signs (for the purpose of trials at Mirage Machines Ltd)..........................6

Machine Hazards Signs............................................................................................................7

Safety Procedures....................................................................................................................7

3.3.1. Pre-Operational Safety Checks................................................................................................7

Operational Safety Checks.......................................................................................................8

3.4.1. Housekeeping..........................................................................................................................8

3.4.2. Potential Hazards.....................................................................................................................8

4. Handling...................................................................................................................................8

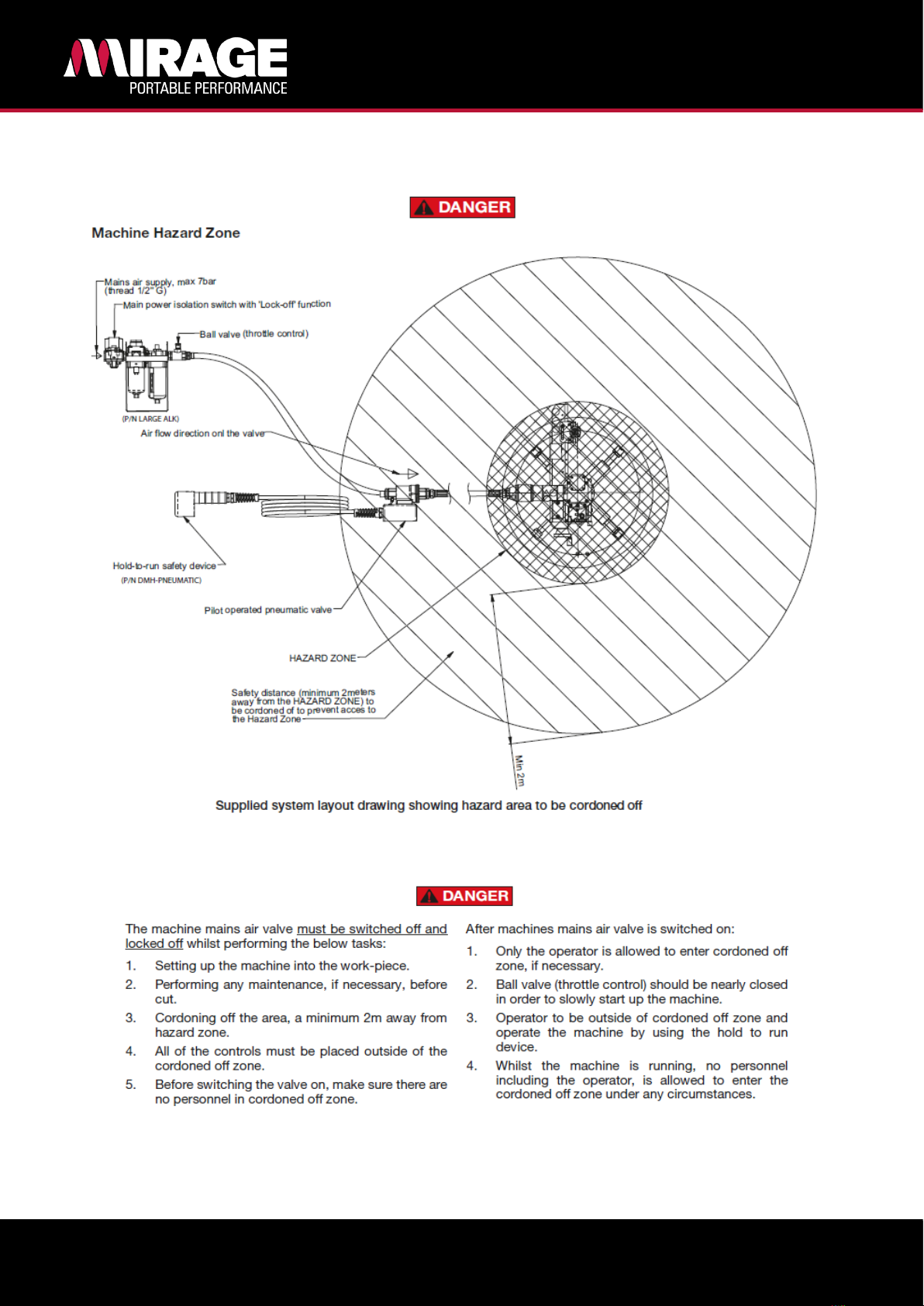

5. Machine Hazard zone..............................................................................................................9

6. Machine Specification ...........................................................................................................10

General Assembly Drawings..................................................................................................11

7. Installation.............................................................................................................................23

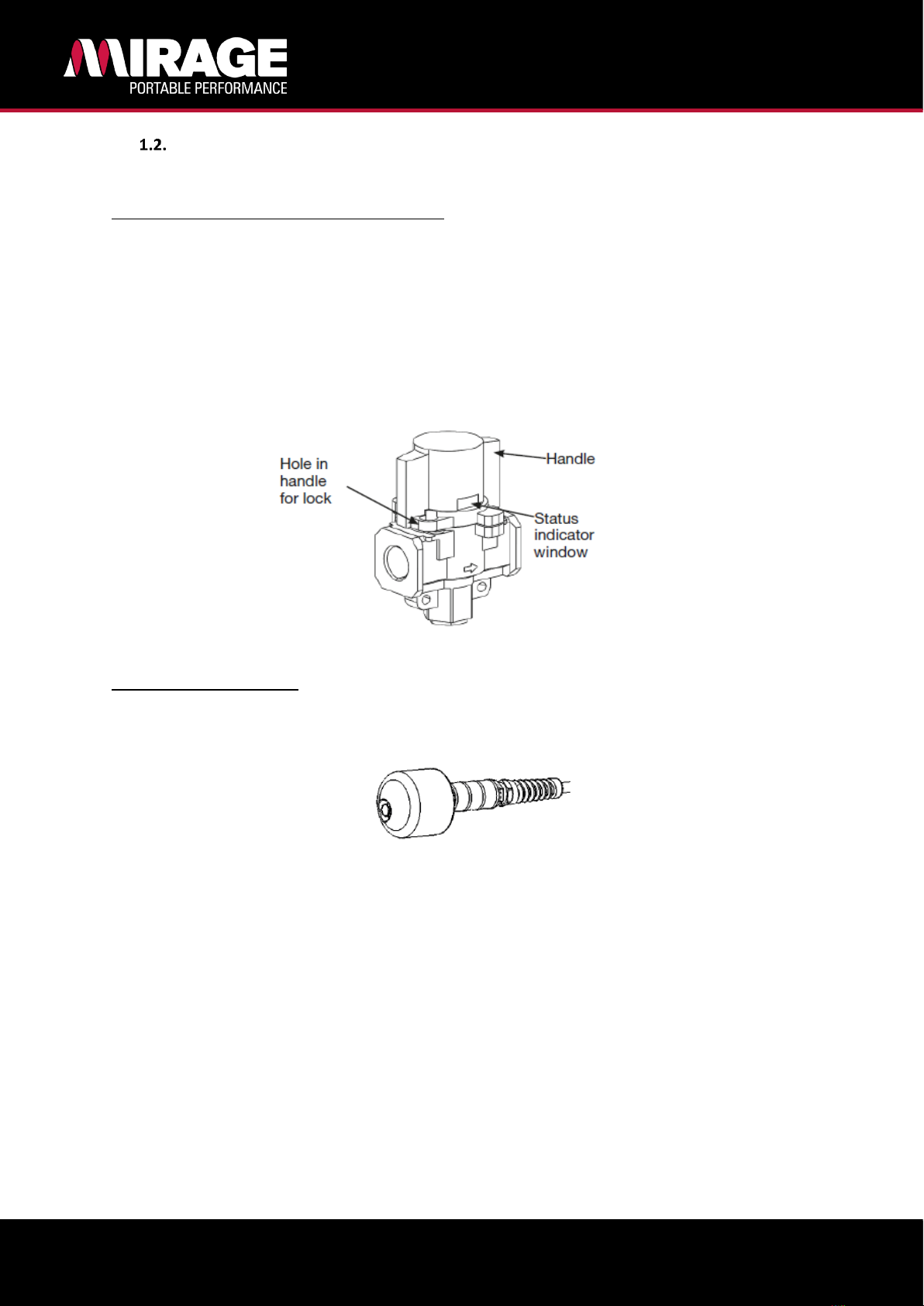

Air Preparation unit...............................................................................................................24

Service and Supplies..............................................................................................................25

7.2.1. Personnel...............................................................................................................................25

8. Machine Operation................................................................................................................26

Tool Post Setting....................................................................................................................26

Striker Boring Feed Setting....................................................................................................27

Facing Feed Gear Selection ...................................................................................................28

Machine Balancing ................................................................................................................29

Operating Hold-to-run Device...............................................................................................30

9. Machine Maintenance...........................................................................................................31

10. Troubleshooting Guide..........................................................................................................32

11. Appendices ............................................................................................................................35

Changing Facing Arms ...........................................................................................................35

Recommended torque settings for fasteners .......................................................................36

Cutting feed and speed calculations .....................................................................................37

General Notes........................................................................................................................39