MITSUBISHI ELECTRIC ENGINEERING DG2BK1TB Series User manual

Drive Goods

Relay Terminal Block with Brake Contact Output

Model Name

DG2BK1TB-□-□

User’s Manual

Before Using the Product

Thank you for purchasing these Drive Goods product.

Before using the product, this document and our MEEFAN homepage obtain

the User’s Manual of the publication, and please read the following items.

・SAFETY PRECAUTIONS

・FOR YOUR SAFETY

Please read the User’s Manual of the homepage publishing, and use details

correctly after understanding the function and the performance of this product

enough.

MEEFAN homepage URL

http://www.mee.co.jp/sales/fa/meefan/

●SAFETY PRECAUTIONS ●

(Always read these precautions prior to use.)

Do not attempt to install, operate, maintain, or inspect this product until you have carefully read through

this instruction manual and relevant documents and can use the equipment correctly. Do not use this

product until you have a full knowledge of the equipment, safety information, and instructions. In this

manual, the safety instruction levels are classified into "WARNING" and "CAUTION.”

WARNING

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

CAUTION

Indicates that incorrect handling may cause hazardous conditions,

resulting in minor or moderate injury or property damage.

Under some circumstances, failure to observe the precautions given under " CAUTION" may lead to

serious consequences. Observe the precautions of both levels because they are important for personal

and system safety.

After reading this manual, keep the manual in a safe place for future reference.

1. Electric Shock Prevention

WARNING

Make sure that all wiring work and inspections are performed by professional engineers.

Do not damage, apply unreasonable stress to, place heavy objects on, or pinch the cables. Doing so

results in the risk of electric shock.

To avoid electric shock, insulate the connection area of the power supply terminal.

Be sure to shut off all phases of the external power supply used by the system before performing work

such as installation and wiring. Failure to do so results in the risk of electric shock and product damage.

2. Fire Prevention

CAUTION

Be sure to install this product in a non-flammable object. Directly installing the product in a flammable

object or installing the product near a flammable object results in the risk of fire.

Do not allow any conductive foreign objects, such as a screw or metal fragments, or flammable foreign

objects, such as oil, to enter the product interior.

3. Injury Prevention

CAUTION

Be careful to connect terminals correctly. Failure to do so results in the risk of explosion, damage, and

the like.

Do not mistaken the polarity (positive and negative charges). Doing so results in the risk of explosion,

damage, and the like.

4. General Precautions

Also note the following precautions. Incorrect handling may cause failure, injury, electric shock, and the

like.

(1) Transport and Installation

CAUTION

This product is a precision instrument. During transport, avoid impacts larger than those specified in

general specifications. Failure to do so results in the risk of failure.

Do not stand or rest heavy objects on the product.

Do not install or operate units that are damaged or have missing parts.

This product is a precision instrument. Do not drop or apply strong impact to the product.

Use this product in an environment that reflects the general specifications set forth in the User’s Manual.

Usage in an environment outside of the scope of the general specifications results in the risk of electric

shock, fire, malfunction, product damage, and/or product deterioration.

When handling the product, be careful of sharp areas such as product corners.

Be sure to place this product inside a metal control panel.

Reliably secure the module using a DIN rail or screws. If the module is not properly mounted, risk of

malfunction, failure, and falling results. If using the product in an environment with high vibration, secure

the product with screws.

Tighten the screws within the specified torque range. Loose screws results in the risk of falling, a short

circuit, and malfunction. Excessively tightened screws may damage the screws and product, resulting in

the risk of falling, a short circuit, and malfunction.

Fumigants that contain halogen materials such as fluorine, chlorine, bromine, and iodine used for

disinfecting and protecting wooden packaging from insects will cause malfunction in Mitsubishi Electric

Engineering products. Please take necessary precautions to ensure that residual fumigants do not enter

the product, or treat packaging with methods other than fumigation (heat method, etc.).Additionally,

disinfect and protect wood from insects before packing.

(2) Wiring

CAUTION

This product is a Mitsubishi Electric general-purposeAC servo amplifier MR-J4-B and MR-J3-B series

dedicated product. Do not use the product with any servo amplifier or servo motor with an

electromagnetic break other than the MR-J4-B and MR-J3-B series.

Be sure to wire the product correctly. Failure to do so results in the risk of unexpected servo motor

operation.

The connection drawings in this manual are based on a sink interface, unless otherwise specified.

Be careful to properly set the orientation of the diodes for surge absorption, which are attached to the

DC relay for servo amplifier control signal output signals. Incorrect orientation results in the risk of the

servo amplifier failure, which can cause signal output failure and malfunction of protective circuits such

as emergency stop.

Always verify that the wiring is properly secured to the terminal block. Failure to adequately secure the

wiring results in the risk of poor contact, which can cause heat generation from the wiring and terminal

block.

Properly connect the wiring to the module after first verifying the module rated voltage and terminal

layout. Inputting or connecting the power supply to voltage that differs from the rated voltage and

miswiring result in the risk of fire and product failure.

Securely install the connector to the module. Failure to do so results in the risk of malfunction.

Be sure that foreign matter such as dust and wire shavings does not enter the module interior. Failure to

do so results in the risk of fire, failure, and malfunction.

CAUTION

Be sure to secure the power lines and cables connected to the module by placing them in a duct or

clamping them. If not, dangling cables may swing, move, or inadvertently be pulled, resulting in damage

to the module or cables, or malfunction due to poor cable connection.

When disconnecting the cable connected to the module, do not pull the cable by the cable part. For

cables with connectors, take hold of the connector connected to the module and then disconnect the

connector. For cables connected to the terminal block, unlock the terminal board spring lock and then

disconnect the connector. Pulling the connected cable may result in malfunction or damage to the

module or cable.

When connecting the servo amplifier, first verify that the product configuration is correct. Connecting the

servo amplifier with a wrong configuration results in the risk of failure and malfunction.

Securely mount the relay module to the module. Incorrect mounting results in the risk of damage, falling,

and malfunction due to poor contact.Additionally, be sure to attach and detach the relay module

following the correct procedure. Failure to do so results in the risk of damage, falling, and malfunction

due to poor contact.

(3) Usage

CAUTION

Do not disassemble, repair, or modify the product.

Never attempt to burn or disassemble the product. Doing so may cause generation of a poisonous gas.

Be careful when changing the output device assignments in servo amplifier parameters. Changing the

MBR (electromagnetic brake interlock) signal assignments, in particular, may cause unexpected

operation of the servo motor, damage, falling, and malfunction.

Make sure to set up external safety circuits outside the product to ensure safe system operation even

during external power supply problems or servo amplifier or product failure. Otherwise, erroneous output

or malfunction may cause serious accidents.

Relay or other similar failure may cause output to remain ON or OFF. Be sure to provide a circuit outside

the product that monitors output signals that may lead to serious accidents.

When a load current exceeding the current rating or an overcurrent caused by a load short-circuit flows

for a long time, it may cause smoke and fire. To prevent this, provide an external safety circuit.

(4) Emergency Handling

CAUTION

Connect the emergency stop switch to the EMG1 terminal and EMG2 terminal to ensure that the

electromagnetic brake activation output is linked to the external emergency stop switch.

(5) Maintenance and Inspection

CAUTION

Before removing or installing the module, cut off all phases of the power supply externally. Failure to do

so may cause module failure, malfunction, or damage.

Connection/disconnection of the module and cables after the first use of the product shall be limited to

50 times. (JIS B 3502 compliant)

Before handling the module, touch a grounded metal object to discharge the static electricity from your

body. Failure to release the static electricity may cause the module to fail or malfunction.

(6) Disposal

CAUTION

When disposing of this product, treat it as industrial waste.

1. Over view

This User’s Manual describes the specifications of the relay terminal block with brake contact

output that is used in combination with the Mitsubishi Electric general-purpose AC servo amplifier

MR-J4-B series and MR-J3-B series.

2. GENERAL SPECIFICATIONS

Item

Environment Conditions

Ambient

temperature

Operating

0°C to 55°C (non-condensing)

Storage

-20°C to 65°C (non-condensing)

Ambient

humidity

Operating

90% RH or less (non-condensing)

Storage

Environment

Indoors (not exposed to direct sunlight), free of corrosive gas, combustible

gas, oil mist, and dust

Elevation

Within 1000m above sea level

Vibration resistance

5.9m/s2, 10Hz to 55Hz (X, Y, and Z directions)

3. PERFORMANCE SPECIFICATIONS

Model name

DG2BK1TB

DG2BK1TB-D

KG2BK1TB-P01

DG2BK1TB-P01-D

Connected servo amplifier

MR-J4-B series, MR-J3-B series

Compatible servo motor capacity

0.05kW to 22kW

Servo amplifier interface connector

MDR20P connector

Control logic

Sink logic

Source logic

External

signal relay

terminal

block

Terminal area

Recommended tool: SZF0-0, 4x2, 5 (Phoenix Contact) or

equivalent product

No. of terminals: 11P, 3.5-mm pitch, No. of line insertions: 1 per

insertion port

Compatible wiring

Single wire, base wire: 0.2mm2to 1.5mm2, AWG24 to AWG16

Brake output

terminal

block

Terminal area

Recommended tool: SZF0-0, 4x2, 5 (Phoenix Contact) or

equivalent product

No. of terminals: 6P, 3.81-mm pitch, No. of line insertions:

1 per insertion port

Compatible wiring

Single wire, base wire: 0.2mm2to 1.5mm2, AWG24 to AWG16

External

powersupply

For servo amplifier interface

Voltage: 24 VDC ± 10%, Current capacity: 0.3A(max)

For electromagnetic brake

Voltage 24 VDC 0/-10%, Current capacity 1.43A (max)

MBR signal

relay

Response

time

OFFON

10ms or less

ONOFF

5ms or less

Mechanical service life

50 million times or more (switch frequency: 180 times/minute)

Electrical service life

100,000 times or more (resistance load)

Operation display

LED illumination display at relay coil ON

Socket

Yes (relay module replaceable)

Overseas

compliant

standards

UL standards

UL61800-5-1

Module installation

Screw/

DIN rail

DIN rail

Screw/

DIN rail

DIN rail

Installation

screws

Screw size

M4x0.7mm

x10mmor

greater

-

M4 x 0.7mm x

10mm or

greater

-

Tightening torque

78 to

118Ncm

78 to 118Ncm

Compatible DIN rail

TH35-7.5Fe, TH35-7.5Al (JIS C2812 compliant)

Weight

Approx. 57g

Approx. 56g

Approx. 57g

Approx. 56g

Relay terminal block with brake

contact output

DOCOM

Control output

signal

24 VDC

RA

With sink output interface

Connect the emergency stop switch

Relay terminal block with brake

contact output

24V

0V

B1

B2

EMG1

EMG2

TE2

U

B

24 VDC

Servo motor

Electromagnetic

brake

DOCOM

Control output

signal

24 VDC

Relay terminal block with brake

contact output

RA

With source output interface

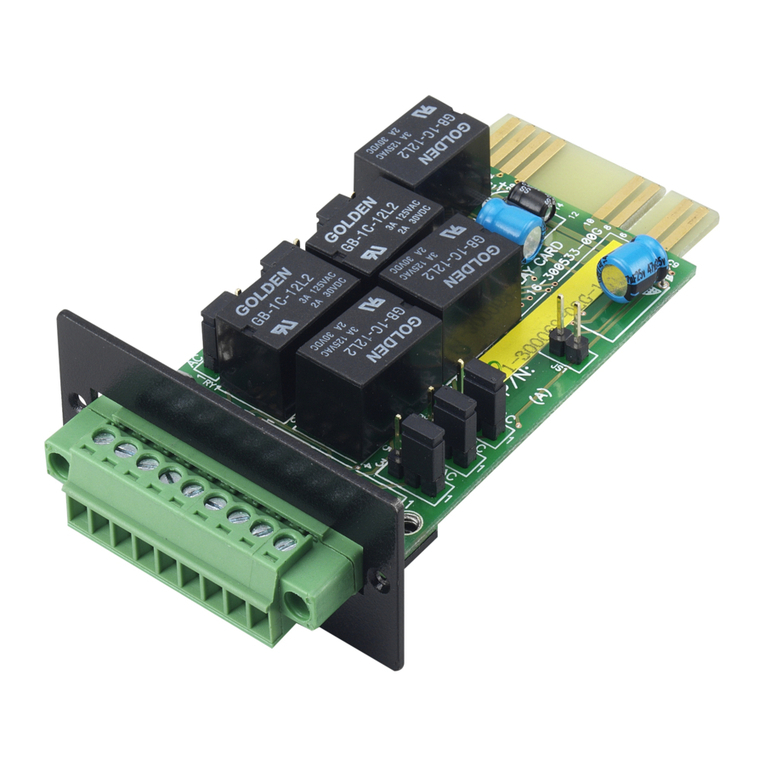

4. EXTERNAL DIMENSION DIAGRAM AND PART NAMES

DG2BK1TB, DG2BK1TB-P01 [Unit: mm]

DG2BK1TB-D, DG2BK1TB-P01-D

No.

Name and Application

[1]

MBR signal relay operation indicator LED

Illuminates when the MBR signal relay coil turns ON.

[2]

Servo amplifier interface connector (CON1)

Connects to the servo amplifier input/output connector (CN3).

[3]

MBR signal relay (RA1)

The relay coil turns ON when the servo amplifier MBR signal output turns ON.

[4]

Brake output terminal block (TE2)

Connects the brake power supply, brake output, and emergency stop switch of the servo motor

with an electromagnetic brake.

[5]

External signal relay terminal block (TE1)

Connects the servo amplifier input/output signal and the input/output signal power supply.

5. EXTERNAL CONNECTION DIAGRAM

ピン番

信号名

SD

INP

ALM

MBR

DICOM

DICOM

DOCOM

EM2

DI1

DI2

DI3

プレート

9

15

13

5

10

3

20

2

12

19

信号名

信号名

24

0V

B1

B2

EMG1

EMG2

SD

INP

ALM

MBR

DICOM

DICOM

DOCOM

EM2

DI1

DI2

DI3

CON1 TE1

TE2

CN3

RA

RA

RA

RA

1

RA1

U

B

インポジション

サーボモータ

電磁

ブレーキ

DC24V

電磁ブレーキ用

非常停止スイッチ

FLS

RLS

DOG

強制停止2

DC24V

サーボI/F用

主回路電源

故障

電磁ブレーキ

インターロック

サージアブソーバ

6. WIRING METHOD

When wiring the terminal blocks (TE1, TE2), use a rod-shaped terminal with the sheath removed. In the

case of a single wire, you can use the wire as is with the sheath removed. Insert the rod-shaped terminal

or single wire from the wiring opening and execute wiring.

(1) Remove the sheath in an amount equivalent to the dimensions below. If the amount of removed

sheath is too long, a short circuit may occur with adjacent wires. If the amount of removed sheath is too

short, the wiring may disengage. Be sure to process the wiring to ensure that it does not come apart.

Do not solder the wiring.

10mm

Cable sheath removal size

(2) Insert the rod-shaped terminal into the wire and crimp the wire. Insert the terminal until the wire

core section sticks out from the sleeve section by about 0 to 0.5mm.After crimping, check the outer

appearance of the rod-shaped terminal. Do not use any rod-shaped terminal that is not properly

crimped or is damaged on the side surface.

0 to 0.5mm

Wire

Damage Wire is not

inside sleeve

Tip crushed

Exposed strand

of wire

Sleeve

Wire Size

(mm2)

Rod-Shaped Terminal Form

Manufacturer name

Crimping Tool Model

Name

With insulated sleeve

Without insulated sleeve

0.3 to 0.5

AI0.5 - 10WH

-

Phoenix Contact

CRIMPFOX6

0.75

AI0.75 - 10GY

A0.75-10

0.75 (for 2)

AI-TWIN2×0.75-GY

-

Wire Size (mm2)

Rod-Shaped Terminal Part Number

Cap Part Number

Manufacturer name

Crimping Tool Model Name

0.3 to 0.75

BT0.75-11

VC 0.75

Nichifu Co., Ltd.

NH69

(3) Insert the wire into the terminal.

TE1

TE2

TE1

TE2

(4) Removing the wire

Remove the wire by pulling the wire with the operation hole or open/close button fully pressed

using a flathead screw driver.

7. ATTACHING AND REMOVING THE RELAY MODULE

(1) Attaching the Relay Module

Align the relay and socket.

Fully insert both ends until the hooks catch on

the relay ceiling.

(2) Removing the Relay Module

Pull the relay module while applying pressure in the

direction that releases the hooks from the ceiling.

If it is difficult to pinch the relay, remove the relay

using a screwdriver as shown in the figure while

applying pressure in the direction that releases

the hooks from the ceiling.

Part Name

Model

Manufacturer Name

Power relay

DSP1a-DC24V

Panasonic Corporation

[QUALITY WARRANTY]

1. Gratis Warranty Terms and Gratis Warranty Range

If any fault or defect (hereinafter referred to as “Failure”) attributable to Mitsubishi Electric Engineering

should occur within the gratis warranty period, Mitsubishi Electric Engineering shall replace the product

free of charge via the distributor from whom you made your purchase. Mitsubishi Electric Engineering

shall not be held responsible for any on-site readjustment and/or trial run that may be required in

association with replacement of a faulty unit.

[Gratis Warranty Period]

The gratis warranty period of this product shall be twelve (12) months from the date of purchase or

delivery to the designated place. Note that after shipment from Mitsubishi Electric Engineering, the

maximum distribution period shall be six (6) months, and the gratis warranty period after manufacturing

shall be limited to eighteen (18) months. The gratis warranty period of a repaired product shall not

exceed the gratis warranty period prior to repair.

[Gratis Warranty Range]

(1) The gratis warranty range shall be limited to normal use based on the usage conditions, methods,

and environment, etc., defined by the product specifications, terms, and precautions, etc., given in

the user’s manual and the like.

(2) In the following cases, a replacement fee shall be applied even if within the gratis warranty period.

(i) Failure resulting from inappropriate storage or handling, carelessness, or negligence by the

user, or Failure caused by the user’s hardware or software design.

(ii) Failure caused by unapproved modifications, etc., to the product by the user.

(iii) Failure that could have been avoided if, when the Mitsubishi Electric Engineering product was

assembled into the user’s device, safeguards defined by legal regulations applicable to the

user’s device or functions or structures considered standard by the industry had been provided.

(iv)Failure recognized as preventable if consumable products (relays and the like) were normally

maintained and replaced.

(v) Replacement of consumable products (relays and the like).

(vi)Failure caused by external factors beyond anyone’s control such as fires or abnormal voltage,

and Failure caused by Force Majeure such as earthquakes, lightning, or wind and water

damage.

(vii) Failure caused by reasons unpredictable by scientific technology standards at the time of

shipment from Mitsubishi Electric Engineering.

(viii)Any other failure not attributable to Mitsubishi Electric Engineering or found by the user to not

be attributable to Mitsubishi Electric Engineering.

2. Warranty period after discontinuation of production (fee applied)

(1) Mitsubishi Electric Engineering shall accept products for repair (fee applied) for a period of seven

(7) years after production cancellation. Product cancellation shall be announced on the MEEFAN

website. (URL: http://wwww.mee.co.jp/sales/fa/meefan/)

(2) Product supply (including spare parts) is not possible after production has been discontinued.

3. Overseas services

Overseas services are out of scope.

4. Exclusion of opportunity loss and secondary loss from warranty liability

Regardless of the gratis warranty period, Mitsubishi Electric Engineering shall not be liable for

compensation for damages arising from causes not attributable to Mitsubishi Electric Engineering,

opportunity losses or lost profits incurred by the user due to Failures of Mitsubishi Electric Engineering

products, damages or secondary damages arising from special circumstances, whether foreseen or

unforeseen by Mitsubishi Electric Engineering, compensation for accidents, compensation for

damages to products other than Mitsubishi Electric Engineering products, or compensation for

replacement work, readjustment of onsite machinery and equipment, startup test runs, or other duties

carried out by the user.

5. Changes in product specifications

The specifications given in the catalogs, manuals, technical documents, and the like are subject to

change without notice.

6. Product application

(1) This product shall be used in applications that will not lead to a major accident even in the unlikely

event any failure or defect should occur in the device, and shall be systematically provided with

backup and fail-safe functions that operate in the event of any failure or defect.

(2) This product has been designed and manufactured as a general-purpose product for general

industry applications, etc. Thus, the product shall be excluded from use in applications in which the

public could be greatly affected such as the applications of the nuclear and other power plants

operated by the respective power companies, and applications in which a special quality assurance

system is required, such as the applications of railway companies or government or other public

offices. The product shall also be excluded from use in aircraft, medical applications, railways,

incineration and fuel devices, manned transport devices, equipment for recreation and amusement,

and safety devices, in which human life or assets could be greatly affected. Note that if the user

consults with Mitsubishi Electric Engineering customer service in advance with regard to such an

application and the user accepts that the application is to be limited and a special quality is not to

be required, application shall be made possible upon exchange of required documents.

MITSUBISHI ELECTRIC ENGINEERING COMPANY LIMITED

Hulic Kudan Building, 1-13-5 Kudan Kita Chiyoda-ku Tokyo 102-0073 Japan

URL: http://www.mee.co.jp/

50EN-070163-A The specifications set forth in this document are subject to change without notice.

Created: June 2015

[1]

[2]

[3]

[4]

[5]

DIN rail

center

long holes

DIN rail

center

[1]

[2]

[3]

[4]

[5]

If a rod-shaped terminal is not used with the

base line, or if a single wire is used, insert the

wire with the operation hole or open/close button

fully pressed using a flathead screw driver.

○×

Relay terminal block cable

MR-J2HBUS_M

Manufactured by Mitsubishi

Electric

Servo amplifier

MR-J4-B series

MR-J3-B series

Relay terminal block with brake contact output

In position

Failure

Electromagnetic

brake

Interlock

24 VDC for servo

interface

Forced stop 2

FLS

RLS

DOG

24 VDC for

electromagnetic

brake

Servo motor

Surge absorber

Emergency stop switch

Electromag

netic brake

Signal name

* For actual wiring, be sure to refer to the “Servo Amplifier

Technical Materials” and “Servo Motor Technical Materials.”

Connection example*

Signal Name

Pin No.

Signal name

Main circuit power supply

Plate

TE1

TE2

This manual suits for next models

4