1

Contents

1. Safety precautions

► Beforeinstallingtheunit,makesureyoureadallthe“Safetyprecau-

tions”.

► Pleasereporttoortakeconsentbythesupplyauthoritybeforecon-

nectiontothesystem.

► EquipmentcomplyingwithIEC/EN61000-3-12

► Itisdesignedforuseintheresidential,commercialandlight-indus-

trialenvironment.

► PUMY-P250YBM,PUMY-P300YBM

“ThisequipmentcomplieswithIEC61000-3-12providedthatthe

short-circuitpowerSscisgreaterthanorequaltoSsc(*1)atthe

interfacepointbetweentheuser’ssupplyandthepublicsystem.Itis

theresponsibilityoftheinstalleroruseroftheequipmenttoensure,

byconsulationwiththedistributionnetworkoperatorifnecessary,

thattheequipmentisconnectedonlytoasupplywithashort-circuit

powerSscgreaterthanorequaltoSsc (*1)”

Ssc (*1)

Model Ssc (MVA)

PUMY-P250YBM 2.00

PUMY-P300YBM 2.28

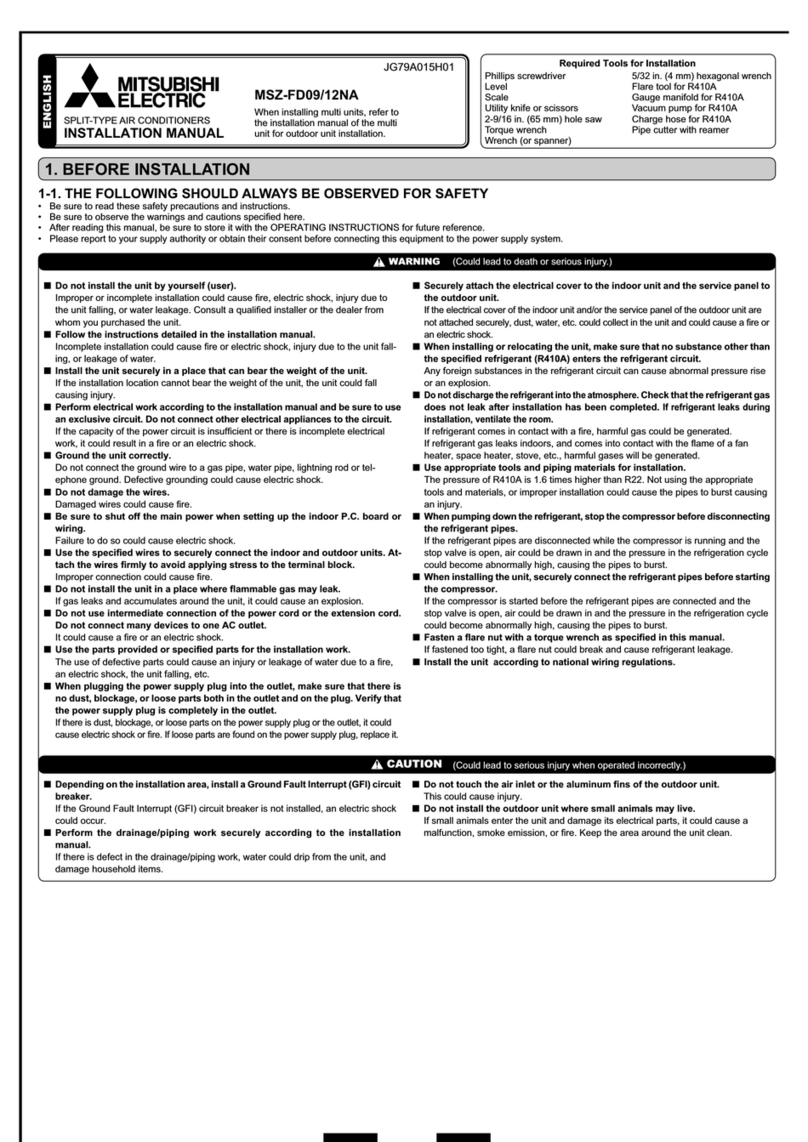

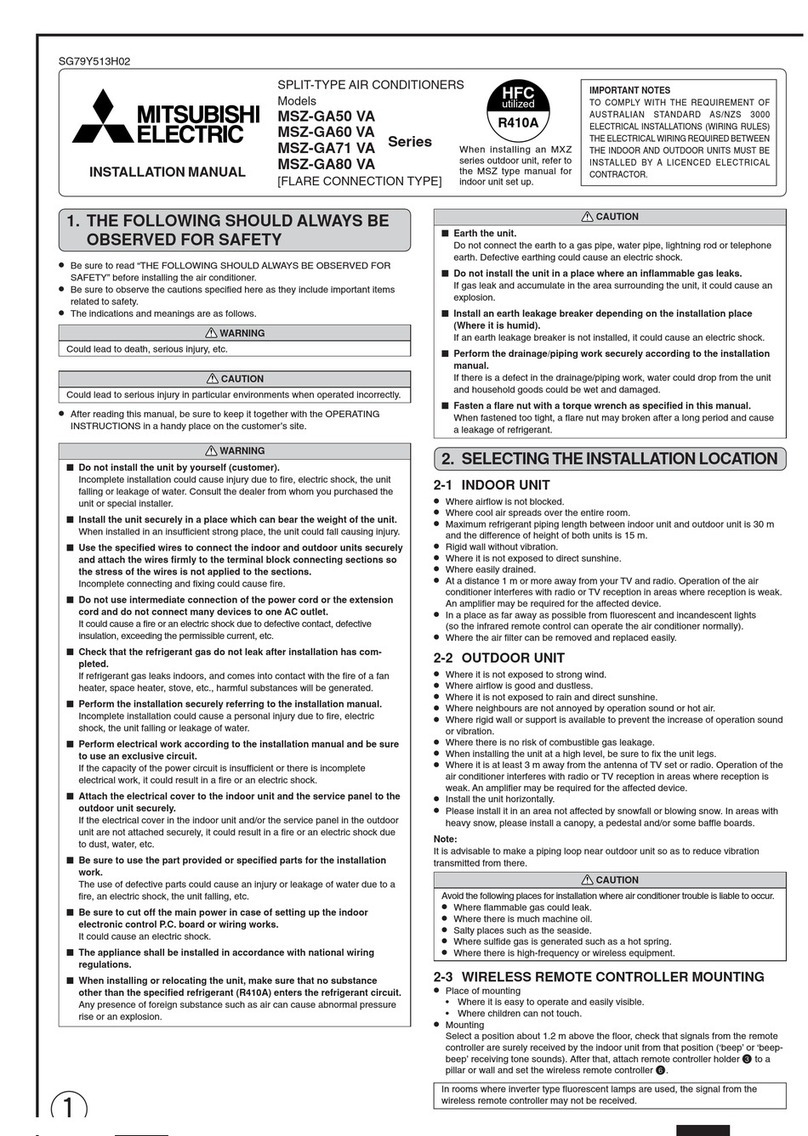

Warning:

Describesprecautionsthatmustbeobservedtopreventdangerofinjuryor

deathtotheuser.

Caution:

Describesprecautionsthatmustbeobservedtopreventdamagetotheunit.

After installation work has been completed, explain the “Safety Precautions” use,

and maintenance of the unit to the customer according to the information in the

Operation Manual and perform the test run to ensure normal operation. Both the

Installation Manual and Operation Manual must be given to the user for keeping.

These manuals must be passed on to subsequent users.

: Indicates a part which must be grounded.

Warning:

Carefullyreadthelabelsafxedtothemainunit.

Conrmationofpartsattached

In addition to this manual, the following part is supplied with the outdoor unit.

It is used for grounding the S terminal of transmission terminal block TB7.

For details refer to “6. Electrical work”. Grounding lead wire

1. Safety precautions................................................ 1

2. Installation location ............................................... 3

3. Installing the outdoor unit .......................................... 7

4. Installing the refrigerant piping ...................................... 8

5. Drainage piping work............................................. 18

6. Electrical work .................................................. 19

7. Test run ....................................................... 28

8. Special Functions ............................................... 29

Caution:

• DonotventR410Aintotheatmosphere.

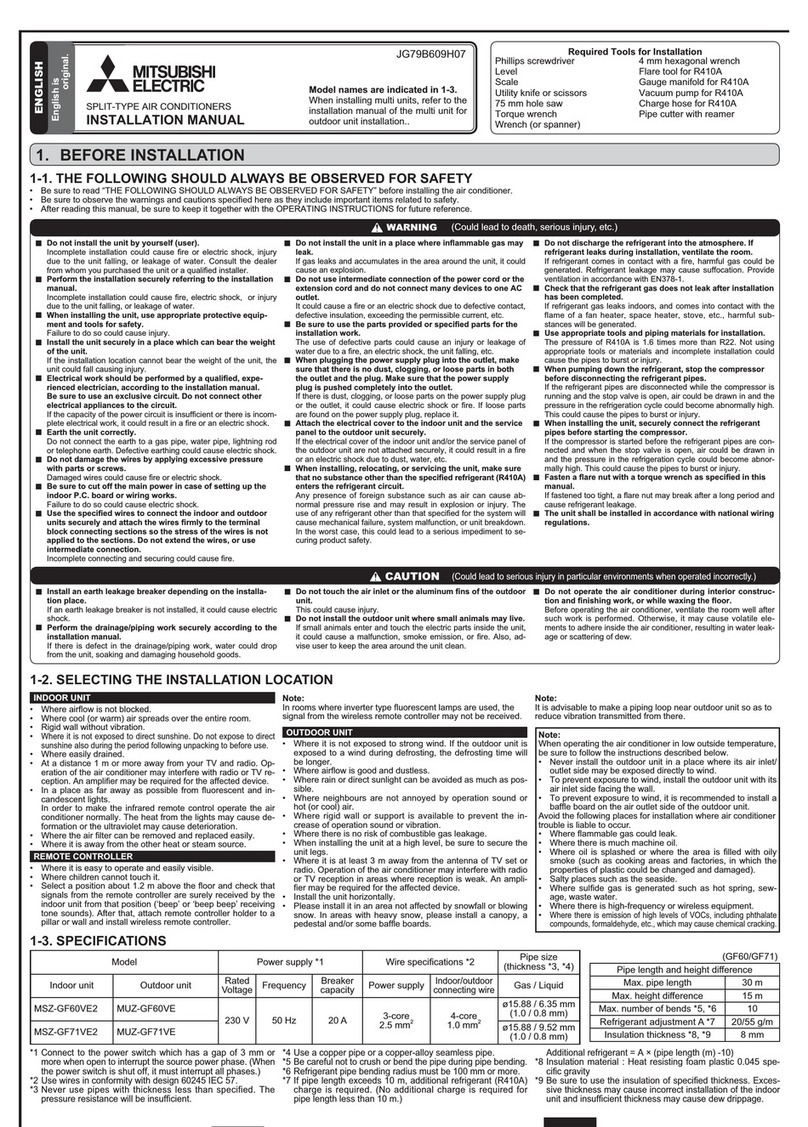

For safe and correct use, read this manual and the indoor unit installation manual thoroughly before installing the air-conditioner unit.

Warning:

• Theunitmustnotbeinstalledbytheuser.Askadealeroranauthorized

techniciantoinstalltheunit.Iftheunitisinstalledincorrectly,waterleakage,

electricshock,orremayresult.

• Forinstallationwork,followtheinstructionsintheinstallationmanualand

usetoolsandpipecomponentsspecicallymadeforusewithR410Arefrig-

erant.

TheR410ArefrigerantintheHFCsystemispressurized1.6timesthepres-

sureofusualrefrigerants.IfpipecomponentsnotdesignedforR410Arefrig-

erantareusedandtheunitisnotinstalledcorrectly,thepipesmayburstand

causedamageorinjuries.Inaddition,waterleakage,electricshock,orre

mayresult.

• Wheninstallingtheunit,useappropriateprotectiveequipmentandtoolsfor

safety.Failuretodosocouldcauseinjuries.

• Theunitmustbeinstalledaccordingtotheinstructionsinordertominimize

theriskofdamagefromearthquakes,typhoons,orstrongwinds.Anincor-

rectlyinstalledunitmayfalldownandcausedamageorinjuries.

• Theunitmustbesecurelyinstalledonastructurethatcansustainitsweight.

Iftheunitismountedonanunstablestructure,itmayfalldownandcause

damageorinjuries.

• Iftheairconditionerisinstalledinasmallroom,measuresmustbetaken

to prevent the refrigerant concentration in the room from exceeding the

safetylimit in theeventofrefrigerantleakage. Consult a dealerregarding

theappropriatemeasurestopreventtheallowableconcentrationfrombeing

exceeded.

Shouldtherefrigerantleakandcausetheconcentrationlimittobeexceeded,

hazardsduetolackofoxygenintheroommayresult.

• Ventilatetheroomifrefrigerantleaksduringoperation.Ifrefrigerantcomes

intocontactwithaame,poisonousgaseswillbereleased.

• Allelectricworkmustbeperformedbyaqualiedtechnicianaccordingto

localregulationsandtheinstructionsgiveninthismanual.Theunitsmust

be powered by dedicated power lines and the correct voltage and circuit

breakersmustbeused.Powerlineswithinsufcientcapacityorincorrect

electricalworkmayresultinelectricshockorre.

• UseC1220copperphosphorus,forcopperandcopperalloyseamlesspipes,

toconnecttherefrigerantpipes.Ifthepipesarenotconnectedcorrectly,the

unitwillnotbeproperlygroundedandelectricshockmayresult.

• Useonlyspeciedcablesforwiring.Thewiringconnectionsmustbemade

securelywithnotensionappliedontheterminalconnections.Also,never

splicethecablesforwiring(unlessotherwiseindicatedinthisdocument).

Failuretoobservetheseinstructionsmayresultinoverheatingorare.

• Theterminalblockcoverpaneloftheoutdoorunitmustbermlyattached.If

thecoverpanelismountedincorrectlyanddustandmoistureentertheunit,

electricshockorremayresult.

• Theapplianceshallbeinstalledinaccordancewithnationalwiringregula-

tions.

• Ifthesupplycordisdamaged,itmustbereplacedbythemanufacturer,its

serviceagentorsimilarlyqualiedpersonsinordertoavoidahazard.

• Wheninstallingorrelocating,orservicingtheairconditioner,useonlythe

speciedrefrigerant(R410A)tocharge the refrigerant lines. Do not mix it

withanyotherrefrigerantanddonotallowairtoremaininthelines.

Ifairismixedwiththerefrigerant,thenitcanbethecauseofabnormalhighpres-

sureintherefrigerantline,andmayresultinanexplosionandotherhazards.

Theuseofanyrefrigerantotherthanthatspeciedforthesystemwillcause

mechanicalfailureorsystemmalfunctionorunitbreakdown.Intheworst

case,thiscouldleadtoaseriousimpedimenttosecuringproductsafety.

• Donotperformpumpdownworkwhenthereisagasleak.Theintakeofair

orothergasescausesabnormallyhighpressureintherefrigerationcycle,

whichmaycauseexplosionorinjury.

en

BT79A020W01_01en.indd 1 2021/02/26 17:11:58