2 INSTALLATION

7

2

2INSTALLATION

• The cables should not be damaged, stressed, loaded, or pinched.

• Install the direct drive motor on incombustible material. Installing them directly or close to combustibles will lead to smoke

or a fire.

• Provide an adequate protection to prevent screws and other conductive matter, oil and other combustible matter from

entering the direct drive motor.

• Direct drive motor may be hot depending on the operating method. Take safety measures such as providing covers.

• Stacking in excess of the specified number of product packages is not allowed.

• Do not hold the cables, connectors, rotor, or encoder when carrying the direct drive motor. Otherwise, it may drop.

• Install the direct drive motor in a load-bearing place in accordance with the user’s manual.

• The equipment must be installed in the specified direction.

• Use the product within the specified environment. For the environment, refer to the specifications of the direct drive motor.

• Securely fix the direct drive motor to the machine. If attached insecurely, the motor may come off during operation.

• Do not install or operate a direct drive motor, which has been damaged or has any parts missing.

• To prevent a malfunction on the encoder, do not apply shocks, e.g. hit with a hammer, when coupling the rotor of the direct

drive motor.

• To prevent the rotor from being damaged, do not subject the rotor of the direct drive motor to more than the permissible

load.

• To prevent a connection failure, malfunction, or others, do not strike the connector.

• Be sure to measure the vibration level with the direct drive motor mounted on the machine. A great vibration may cause

early damage to a bearing and encoder. The great vibration may also cause the poor connector connection or screw

looseness.

• For the gain adjustment at the equipment startup, check the torque waveform and the speed waveform with a

measurement device to check that no vibration occurs. If the vibration occurs due to high gain, the vibration may cause

early damage to the direct drive motor.

• To illustrate details, the equipment in the diagrams of this manual may have been drawn without covers and safety guards.

When the equipment is operated, the covers and safety guards must be installed as specified. Operation must be

performed in accordance with this user’s manual.

• To prevent the vibration during direct drive motor operation, or the cause of the damage to the bearings and encoder, the

balance level of the load needs to be as even as possible. To prevent malfunction, do not use the direct drive motor where

the shaft-through portion may be subject to pressure (e.g. compressed air).

• Take safety measures such as providing covers to avoid accidentally touching the rotor of direct drive motor during

operation.

• Do not get on or put heavy load on the equipment.

• Do not drop or strike the direct drive motor.

• To prevent a fire or injury from occurring in case of an earthquake or other natural disasters, securely install, mount, and

wire the linear servo motor in accordance with the user’s manual.

• To prevent an electric shock or a fire, do not disassemble, repair, or modify the product. Disassembled, repaired, and/or

modified products are not covered under warranty.

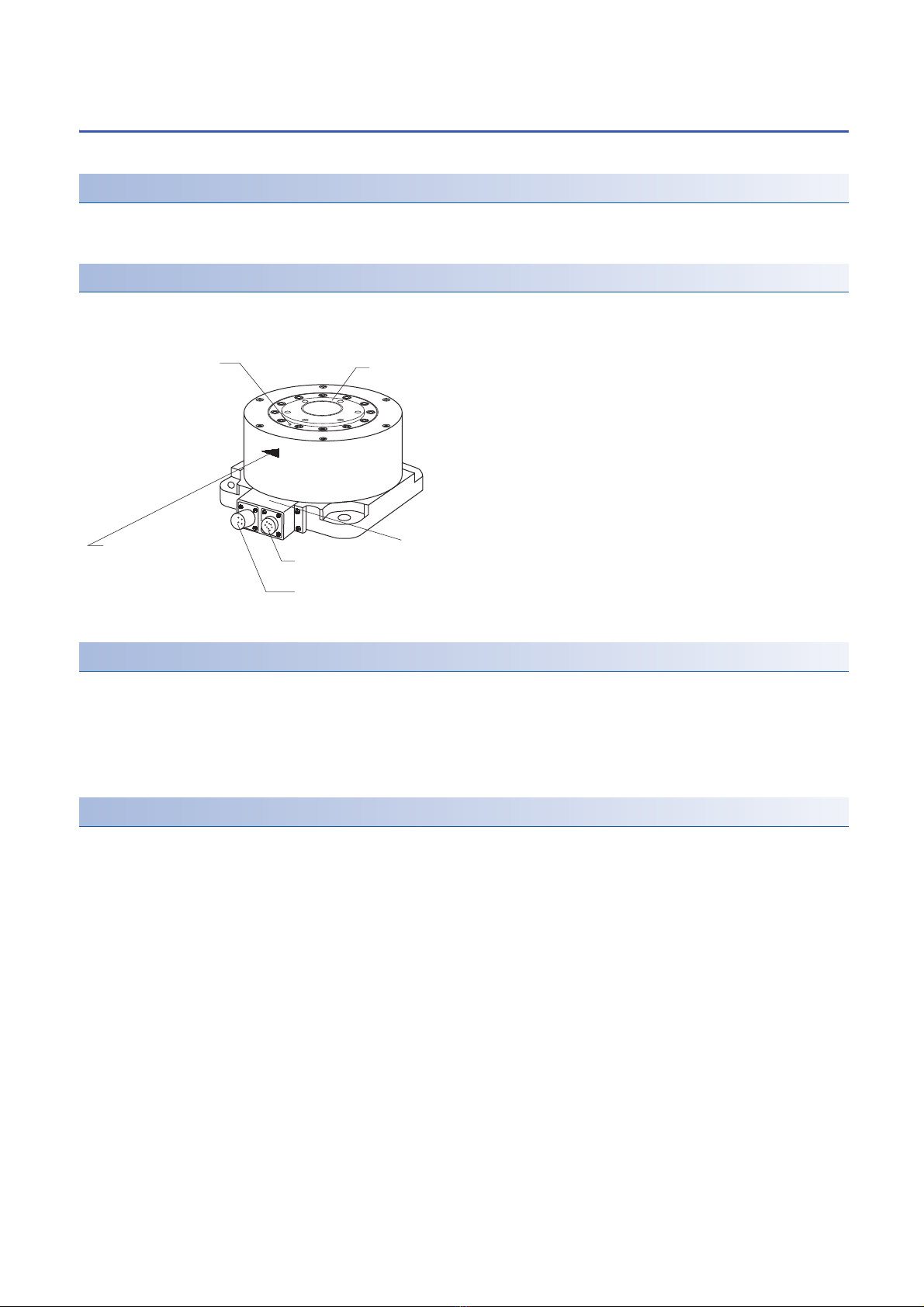

• When coupling a load to the direct drive motor, make sure to align and center the load on the motor flange rabbet.

Particularly, when a rigid coupling is used, even a slight center deviation may reduce position accuracy or damage the rotor.