MODEL: HD-6000

Page 3

INTRODUCTION ................................................................................................................................5

PRODUCTSAFETYNOTICE ............................................................................................................. 5

SAFETYPRECAUTIONS ...................................................................................................................6

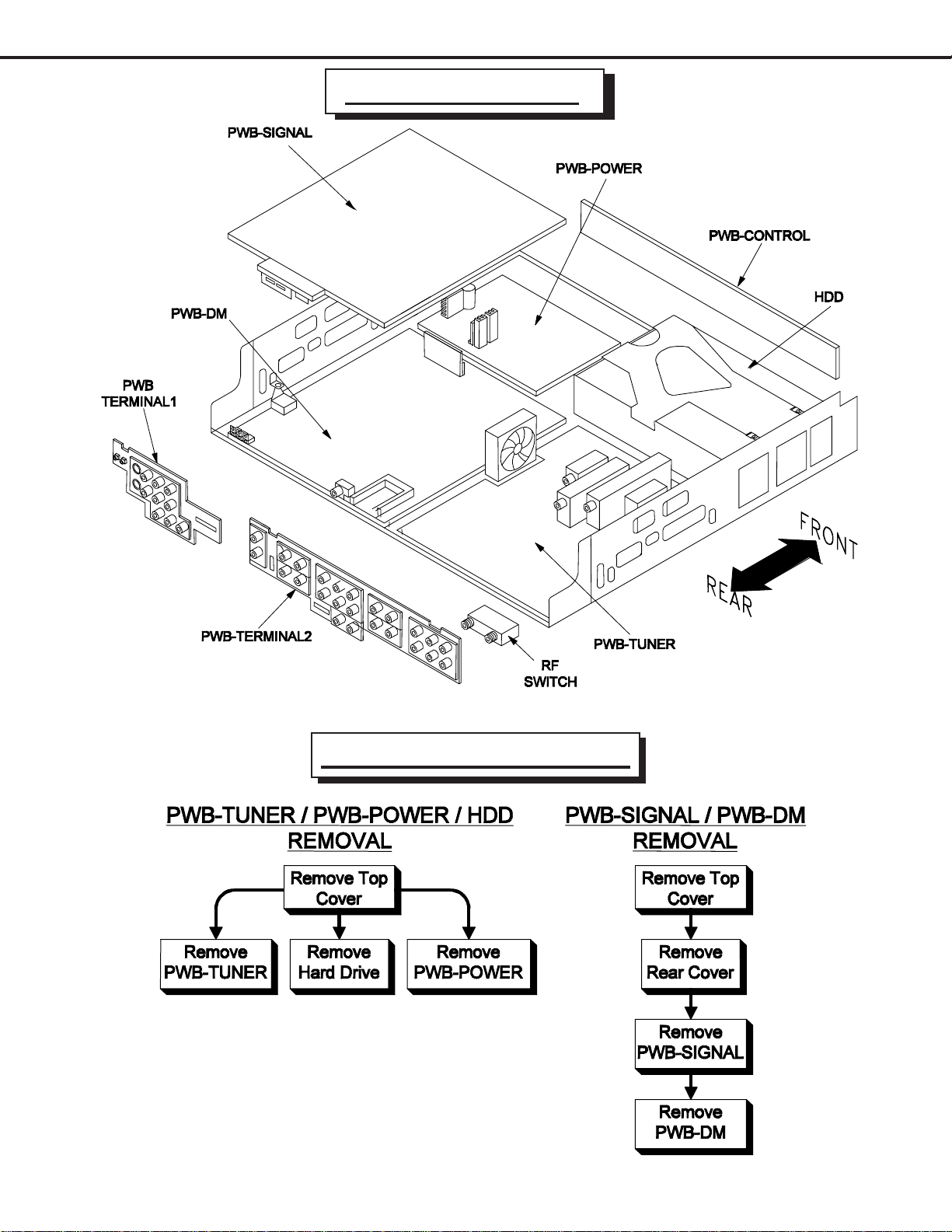

PWB-LOCATIONS .............................................................................................................................7

DISASSEMBLY ..................................................................................................................................7

DisassemblyProcedures Sequence ...................................................................................... 7

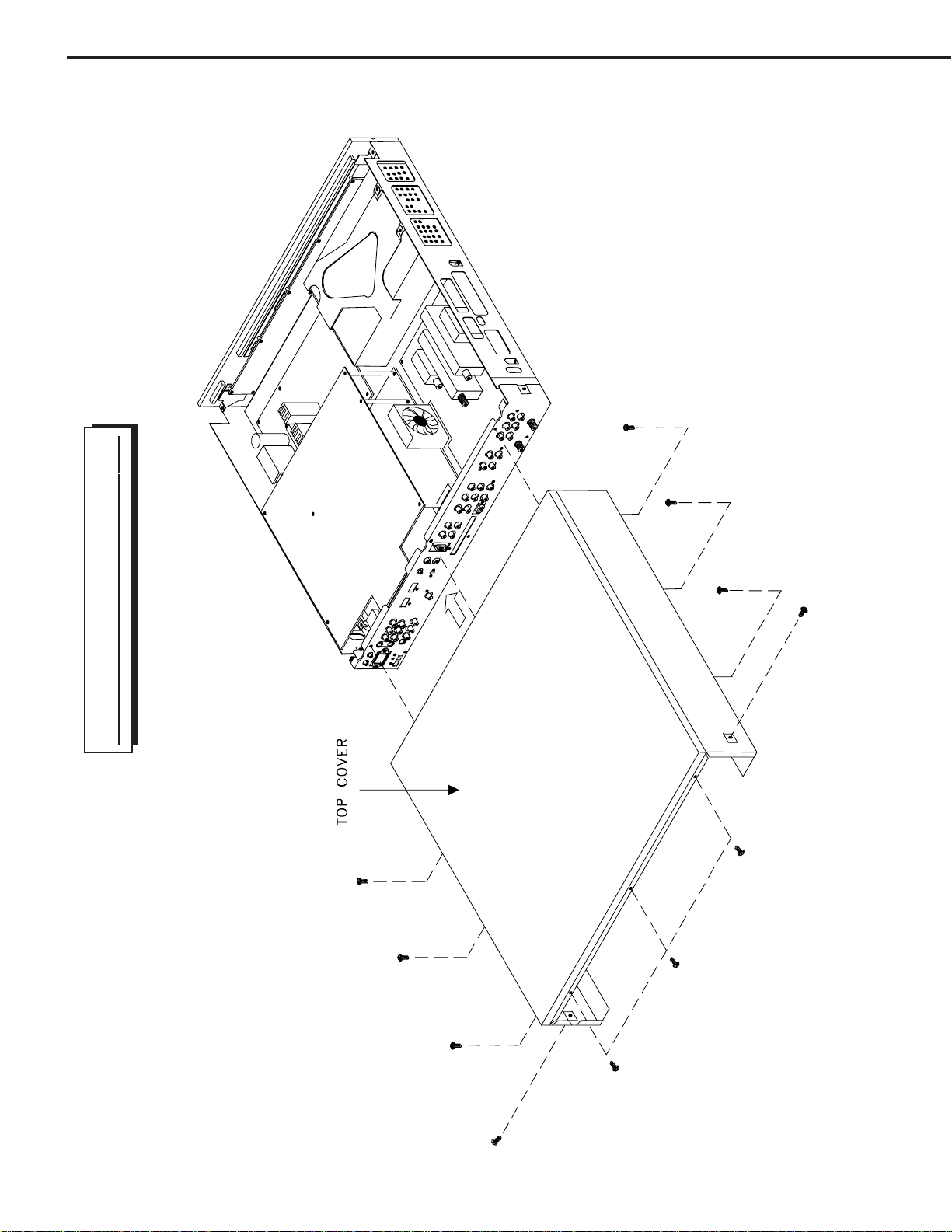

TopCoverremoval ..................................................................................................................8

HDD(HardDrive)removal .......................................................................................................9

PWB’Sremoval ................................................................................................................... 10

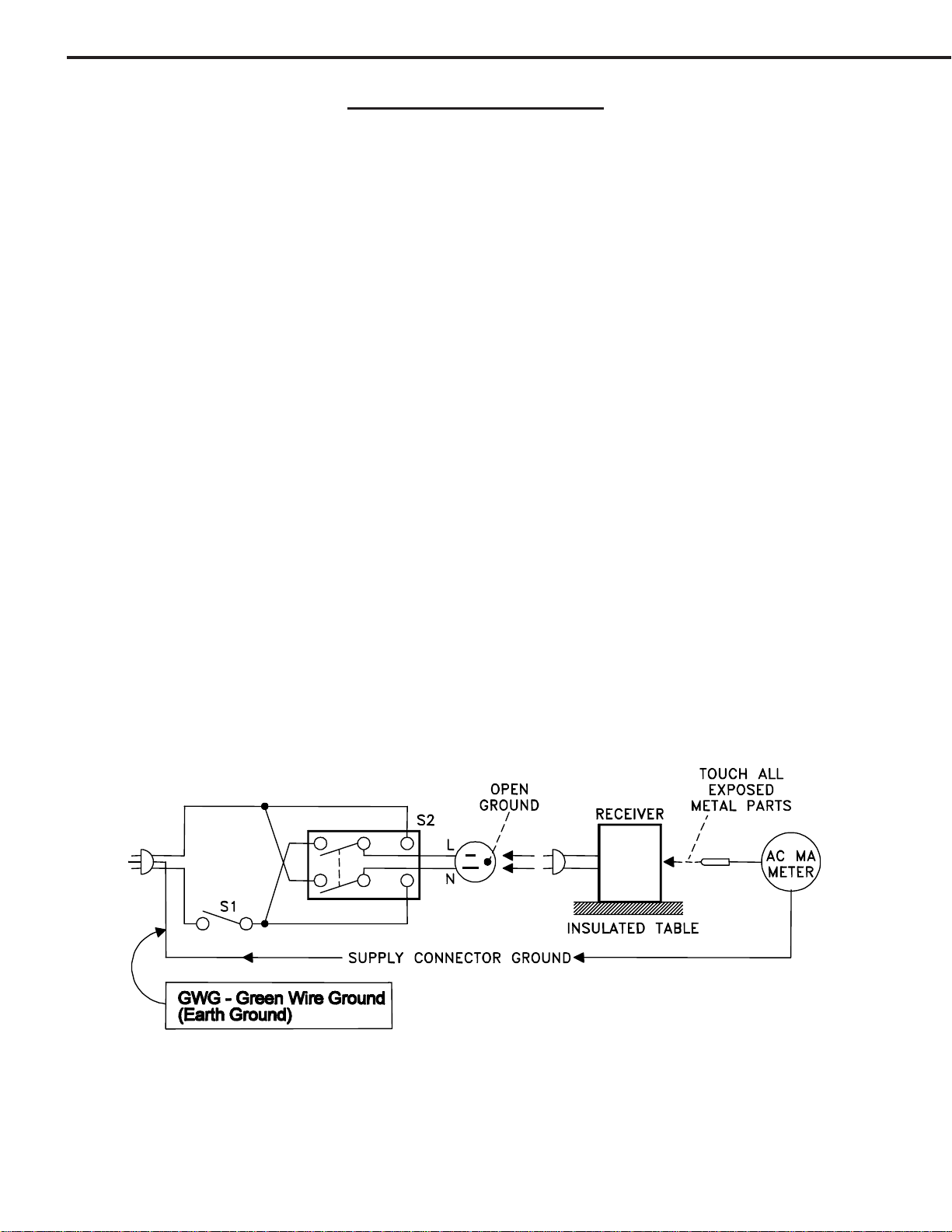

ELECTRICALADJUSTMENTS ........................................................................................................ 11

Equipment .................................................................................................................................... 11

Option Menu / Initialization Defaults /AV Defaults ......................................................................... 12

LED Diagnostics ........................................................................................................................... 13

RemoteControl OperationalMode ................................................................................................ 13

CircuitAdjustment Mode ............................................................................................................... 14

Transferingdata ............................................................................................................................ 15

Adjustment Items List................................................................................................................... 15

AdjustmentProcedures ................................................................................................................ 16

Test Points .......................................................................................................................... 16

Main-YGain......................................................................................................................... 16

Sub-YGain .......................................................................................................................... 17

SubPictureOffset ............................................................................................................... 17

CHIPPARTS REPLACEMENT ......................................................................................................... 18

REPLACEMENTPARTS .................................................................................................................. 19

PartsOrdering .............................................................................................................................. 19

CriticalandWarranty Parts Designation........................................................................................ 19

PartsTolerance Codes.................................................................................................................. 19

SERVICE PARTS LIST .................................................................................................................... 20

CIRCUITRYBLOCK DIAGRAMS ..................................................................................................... 29

StandbyPowerSupplies ............................................................................................................... 29

PWB-DM PowerSupplies ............................................................................................................. 30

PWB-SIGNALSwitchedPowerSupplies ...................................................................................... 30

Video Select Circuitry ................................................................................................................... 31

VideoOutputCircuitry................................................................................................................... 32

Sync Signal Selection................................................................................................................... 33

Sync Signal Output Path .............................................................................................................. 34

RecordSignalPath....................................................................................................................... 34

SoundSignalPath ........................................................................................................................ 35

Control Circuitry ............................................................................................................................ 36

CommandInput Circuitry............................................................................................................... 37

MacrovisionDetection ................................................................................................................... 37

PWB-DM Signal Path ................................................................................................................... 38

CONTENTS