4

Introduction

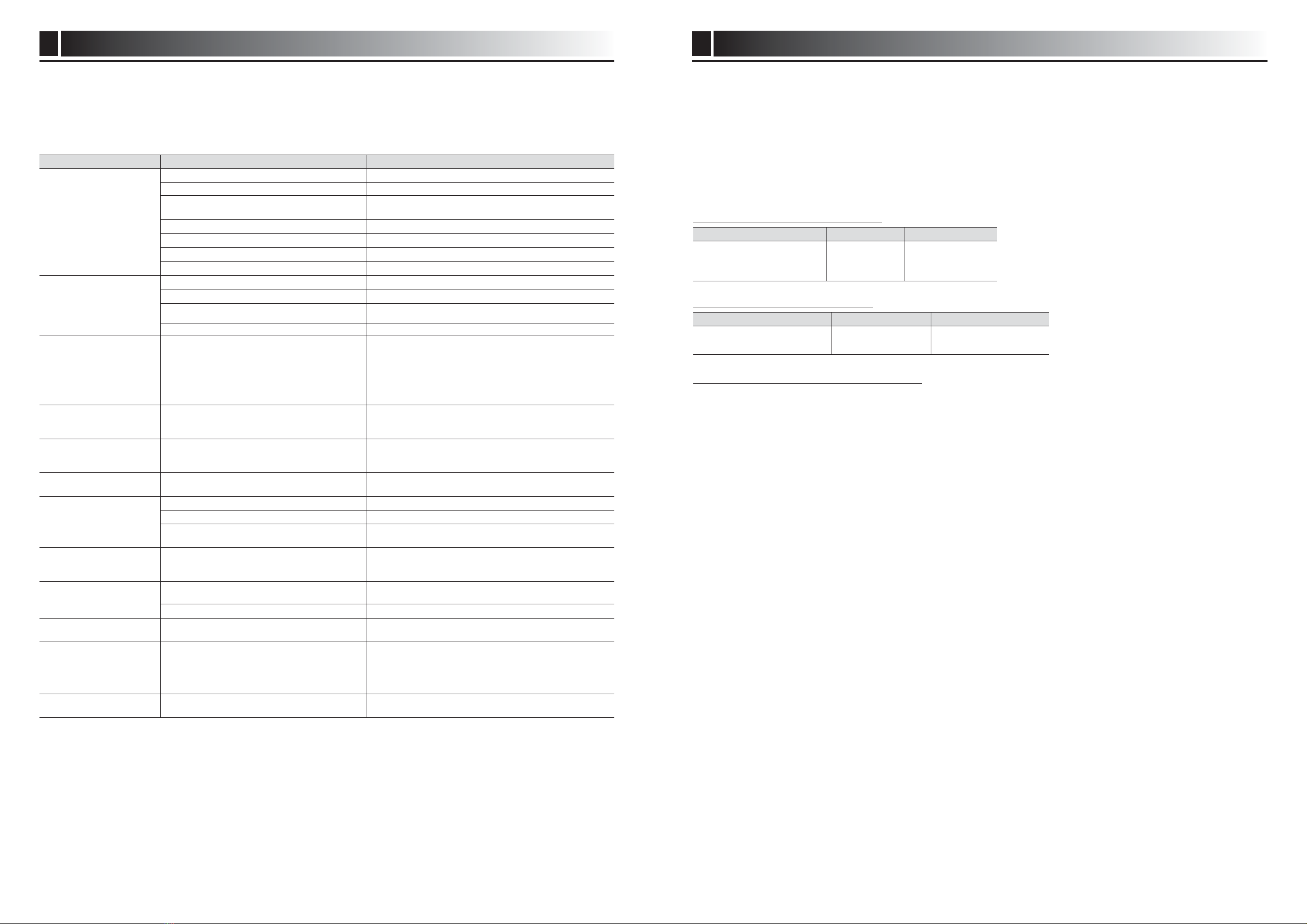

2

4. Evaporator

(Outdoor unit air heat exchanger)

1. Compressor

3. Expansion valve

1. The refrigerant within the circuit is compressed as it passes

through the compressor. It then becomes a hot highly pressurised

gas. The temperature also rises typically to 90°C.

2. The hot refrigerant gas then passes across one side of a heat ex-

changer. Heat from the refrigerant gas is naturally transferred to

the cooler side (water side) of the heat exchanger. As the tem-

perature of the refrigerant decreases, it naturally changes state

from a gas to a liquid.

3. Now as a cold liquid it still has a high pressure. To reduce the

pressure the liquid passes through an expansion valve. The pres-

sure drops but the refrigerant remains a cold liquid.

4. The final stage of the cycle is when the refrigerant passes into the

evaporator and evaporates. It is at this point when some of the

free heat energy in the outside air is absorbed by the refrigerant

and it returns to its original gas state.

The Mitsubishi Electric Air to Water (ATW) heat pump system con-

sists of the following components; outdoor heat pump unit and indoor

cylinder unit incorporating main controller.

The purpose of this Operational Manual is to inform users how their air source heatpump heating system works, how

to run the system at its most efficient and howto change settings on the main controller.

This should be kept safe with the unit or in an accessible place for future reference.

Ű2YHUYLHZRIWKH6\VWHP

Schematic of packaged cylinder system

6SDFHKHDWLQJDQG'+:

Heat pumps take electric energy and low grade heat energy from the

outdoor air to heat refrigerant which in turn heats water for domestic

use and space heating.

The efficiency of a heat pump is known as the Coefficient of Perfor-

mance or COP. This is the ratio of heat delivered to power con-

sumed.

Heat pumps are generally most efficient when providing water at

lower temperatures and when temperature difference between inlet

and outlet of the outdoor unit is large.

The operation of a heat pump is similar to a refrigerator in reverse.

This process is known as the vapour-compression cycle and the fol-

lowing is a more detailed explanation.

The first phase begins with the refrigerant being cold and low pres-

sure.

It is only the refrigerant that passes through this cycle; the water is

heated as it travels through the heat exchanger (Gas cooler). The

heat energy from the refrigerant passes through the heat exchanger

to the cooler water which increases in temperature. This heated

water forms the primary circuit and is circulated and used to serve

the space heating system and the thermal store tank.

The hot water stored within the tank is subsequently used to gener-

ate domestic hot water. (The tank water is NOT the actual hot water

that is typically used for shower or sink appliances.)

Ű+RZWKH+HDW3XPS:RUNV

Low temperature renewable

heat energy taken from the

environment (i.e. fresh air).

N:

N:N:

Heat energy

output

Electrical energy

input

2.Gas cooler

(water-refrigerant

heat exchanger)

5

Room temp.

sensor

Return temp. sensor

Flow temp. sensor

FTC

Built into the cylinder unit is the Flow Temperature Controller

(FTC).This device controls the function of both the outdoor

heat pump unit and the cylinder unit. The advanced technology

means that by using an FTC controlled heat pump you can not

only make savings compared to traditional fossil fuel type heat-

ing systems but also compared to many other heat pumps on

the market.

As explained in the earlier section, ‘How the Heat Pump

Works,’ heat pumps are most efficient when providing low flow

temperature water. The FTC advanced technology enables the

room temperature to be kept at the desired level whilst utilising

the lowest possible flow temperature from the heat pump, i.e.

operate most efficiently.

In room temp. (Auto adaptation) mode the controller uses tem-

perature sensors around the heating system to monitor space

and flow temperatures. This data is regularly updated and com-

pared to previous data by the controller to predict changes in

room temperature and adjust the temperature of water flowing

to the space heating circuit accordingly. By monitoring not only

the outdoor ambient, but the room and heating circuit water

temperatures, the heating is more consistent and sudden

spikes in required heat output are reduced. This results in a

lower overall flow temperature being required.

Important points about heat pump systems

ƔThe hot water produced by the heat pump is typically at a lower temperature than a fossil fuel boiler.

Implications

ƔIf the heat pump is being used for DHW the time at which tank heat up occurs should be scheduled using the

SCHEDULE function (see page 12). Ideally this should be during the night time when normally, less space heating

is required and economy electricity tariffs can be taken advantage of (see page 10).

ƔIn most situations space heating is best performed using the room temperature mode. This enables the heat pump

to analyse current room temperature and react to changes in a controlled manner utilising the specialised Mitsubishi

Electric controls.

ƔUsing the SCHEDULE and HOLIDAY functions prevent unnecessary Space or DHW heating when the property is

known to be unoccupied, for instance during the working day.

ƔDue to lower flow temperatures, heat pump heating systems should be used with large surface area radiators or

under-floor heating. This will provide a steady heat to the room whilst improving efficiency and so lowering running

costs of the system as the heat pump does not have to produce water at very high flow temperatures.

Ambient temp.

sensor

Air source heat pumps can provide both hot water and space heating all year. The system is different to a conven-

tional fossil fuel heating and hot water system. The efficiency of a heat pump is shown by its coefficient of perfor-

mance as explained in the introduction. The following points should be noted to achieve the most efficient and eco-

nomical operation of your heating system.

Ű(FRQRPLFDO%HVW3UDFWLFH

Ű2YHUYLHZRI&RQWUROV

Introduction

2