-

1

-

'19 • KX-T-336

Contents

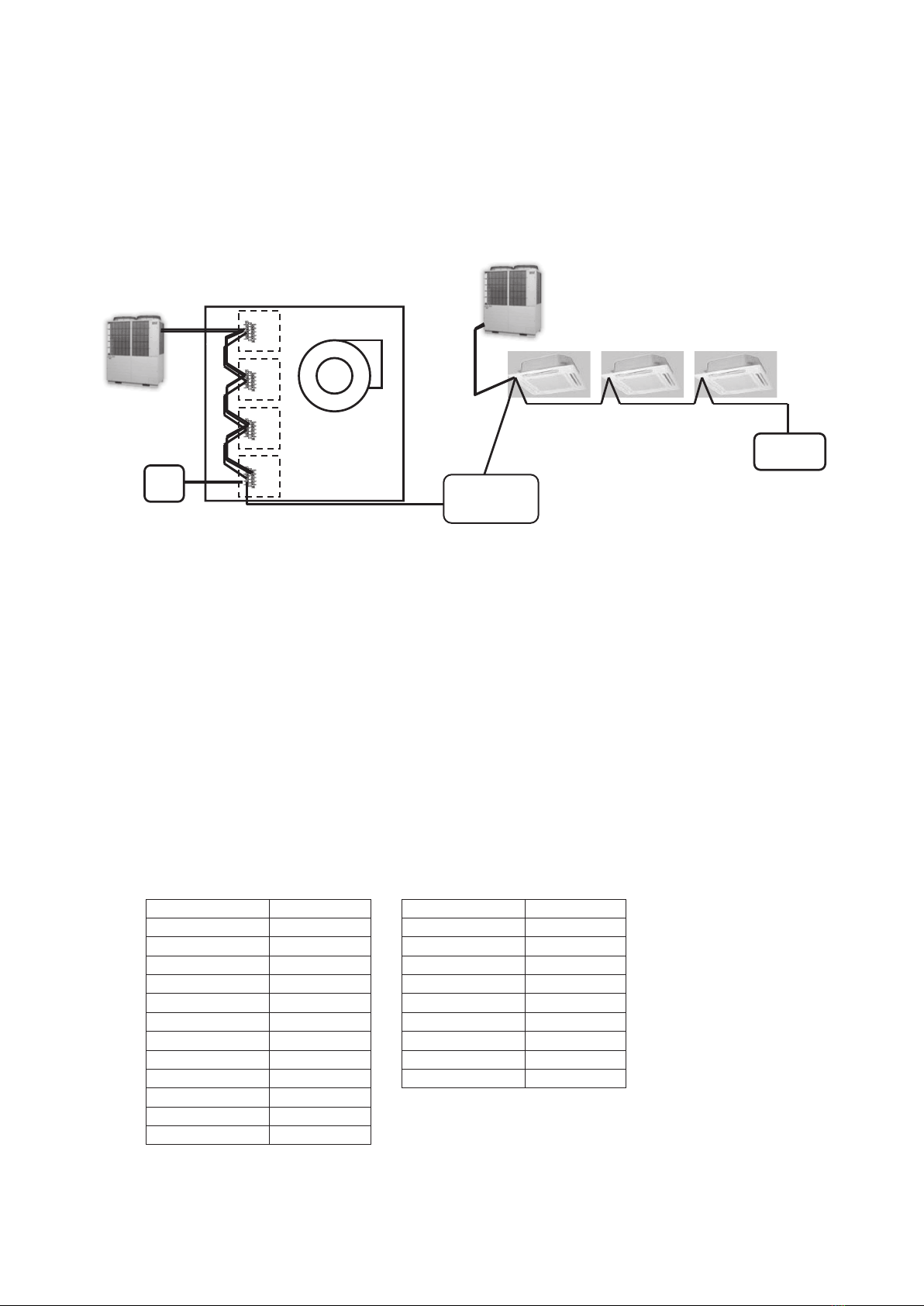

1. What is a single refrigeration system ....................................................... 2

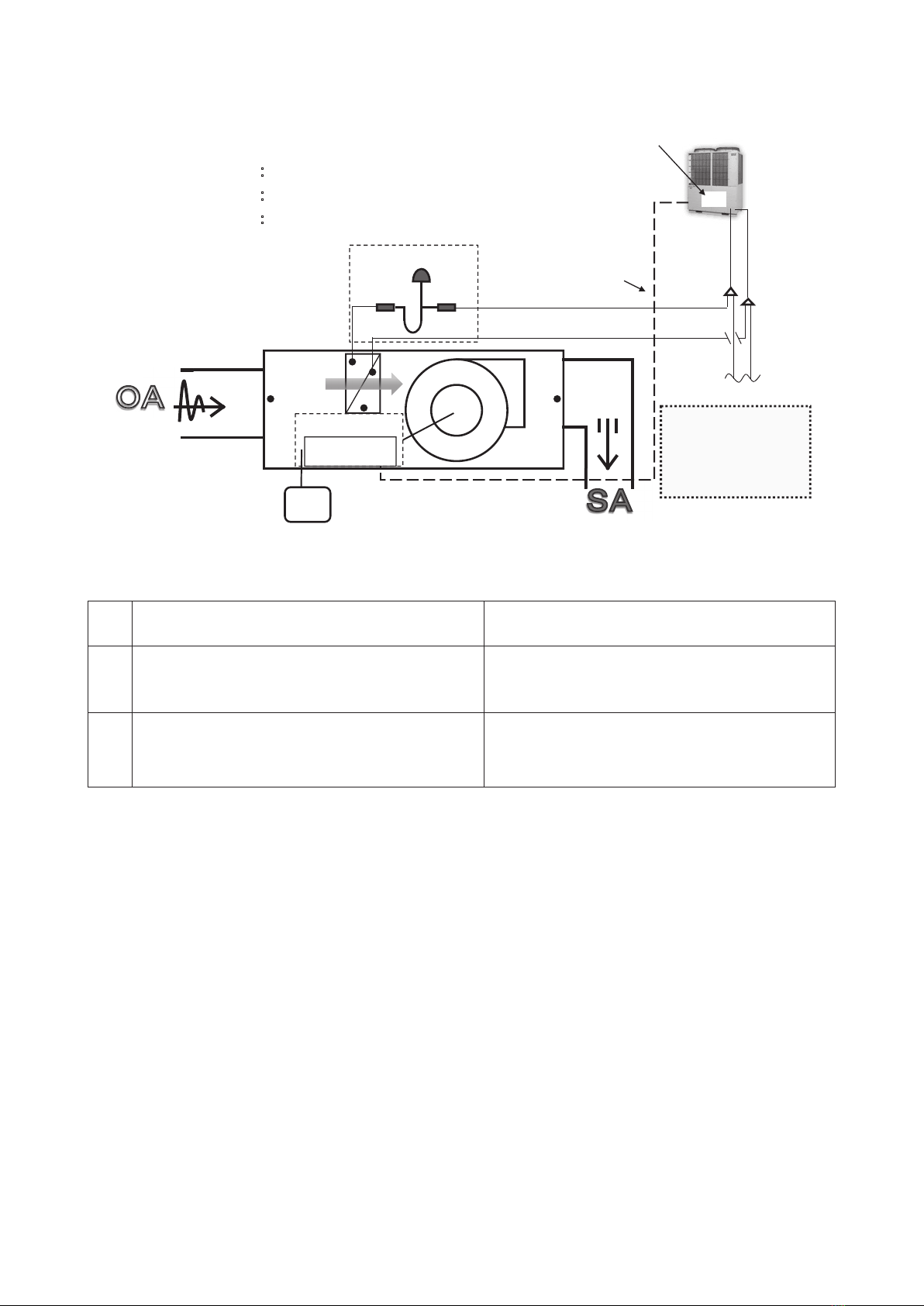

1.1 System A ................................................................................................. 2

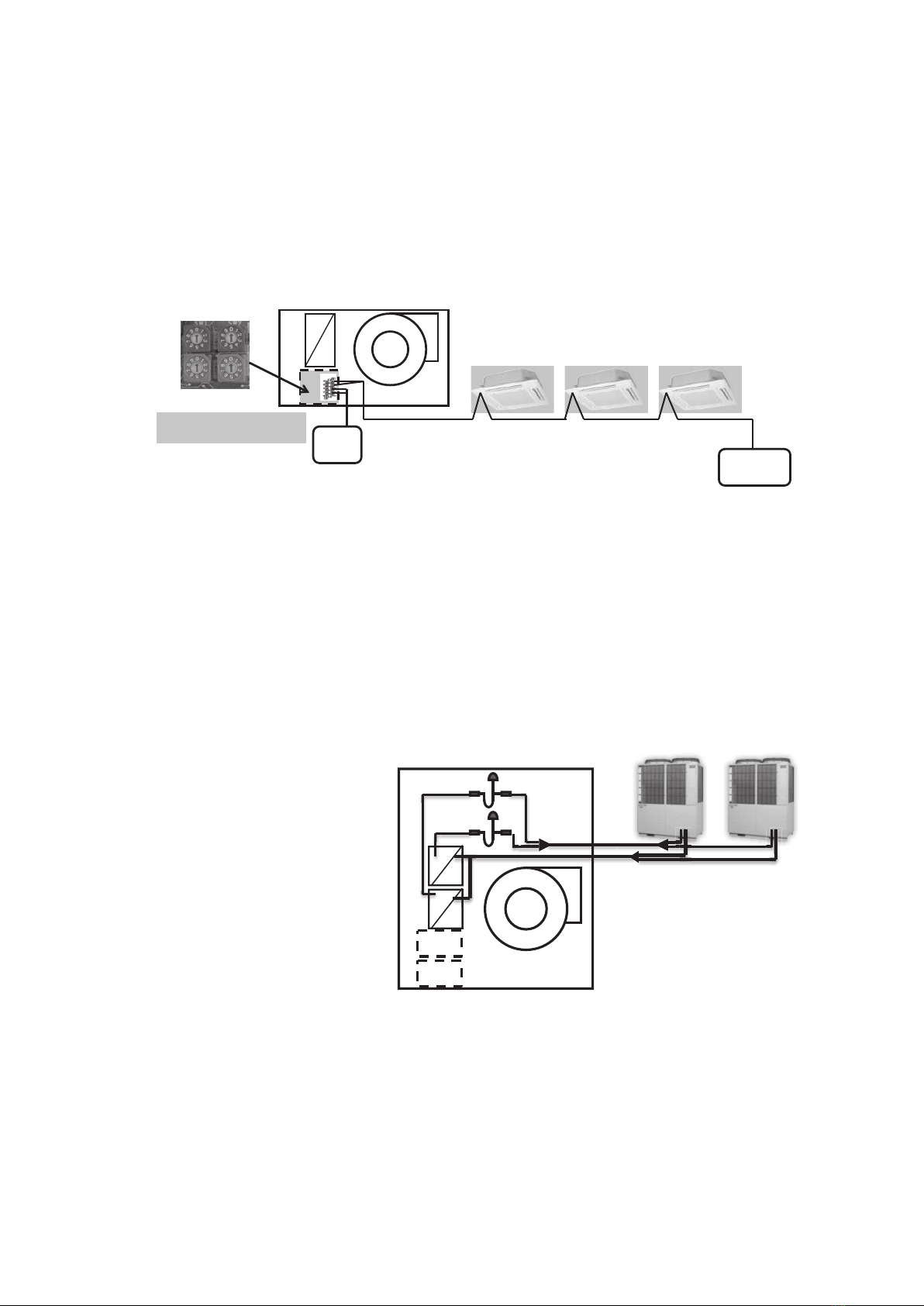

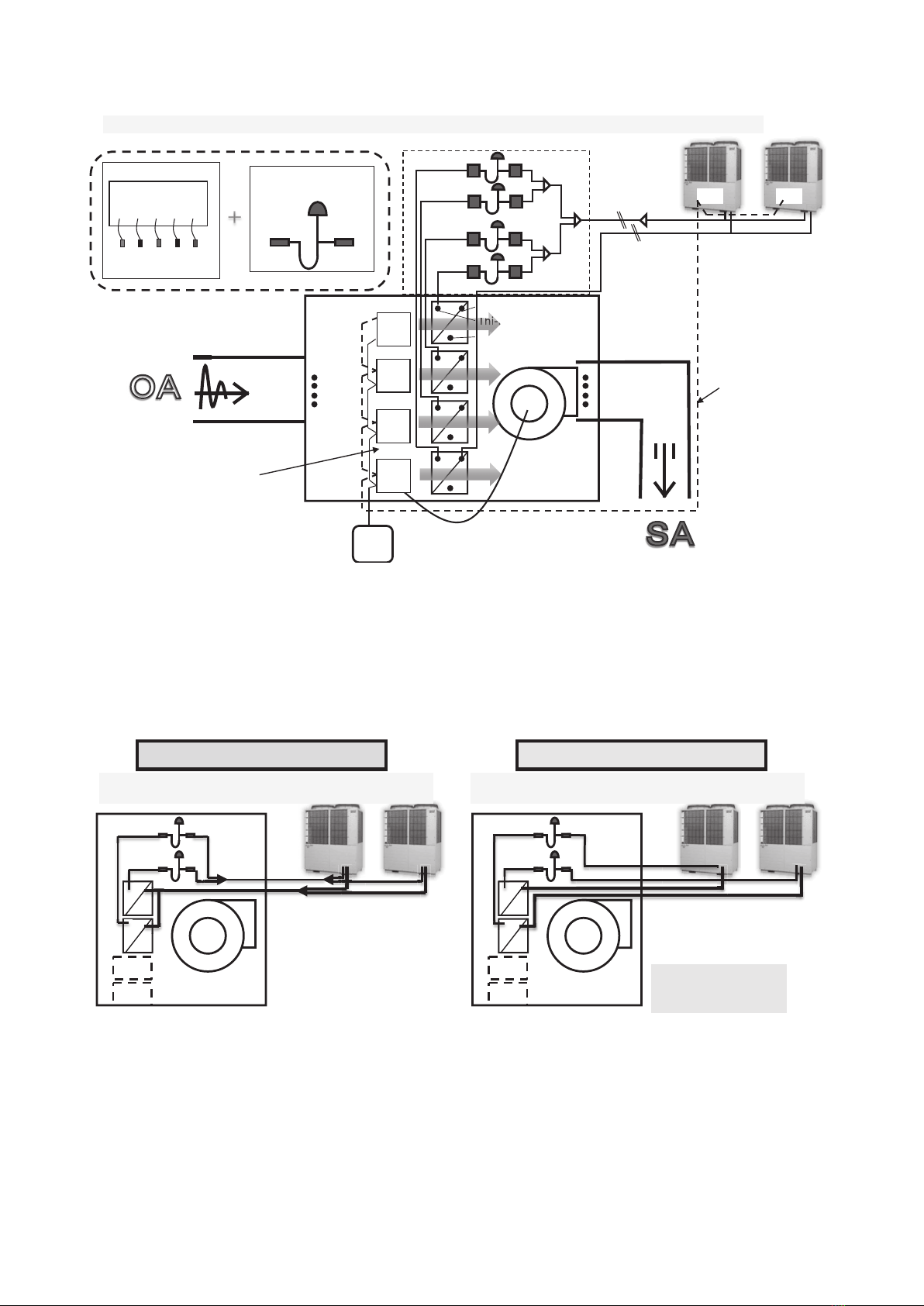

1.2 System B ................................................................................................. 5

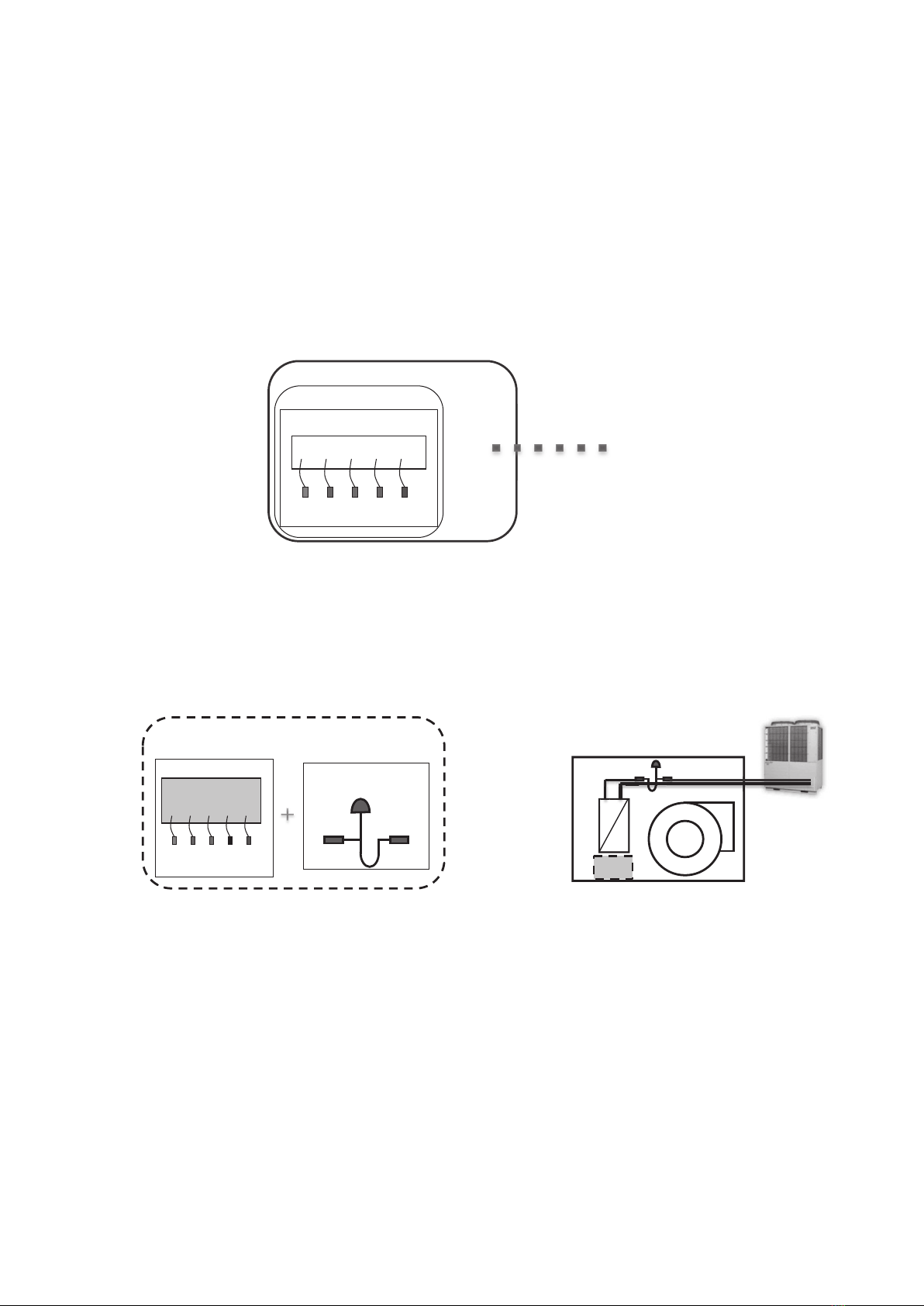

2. Components of a single refrigeration system ......................................... 8

3. Functions ..................................................................................................... 9

3.1 SW1- SW5 (Address setting) .................................................................. 17

3.2 SW6 (Model capacity selection) ............................................................. 18

3.3 SW7 (Function setting) ........................................................................... 18

3.4 Switching return/supply air temperature control ................................. 19

3.5 Target supply air temperature adjustment (heating mode) ................. 26

3.6 Auto mode changeover temperature ..................................................... 26

3.7 Automatic supply air temperature adjust control ................................ 27

3.8 Free cooling control ................................................................................ 27

4. Outdoor unit ................................................................................................. 28

5. Summary ...................................................................................................... 31

6. Instruction of how to replace indoor unit control PCB ............................ 32