- III -

1

5

2

6

3

7

9

4

8

10

Contents

Purpose of use and application- I

Important information------------ I

Operation manual ----------------II

For disposal -----------------------II

Contents-------------------------- III

1 Function of Refrigeration

Unit------------------------- 1

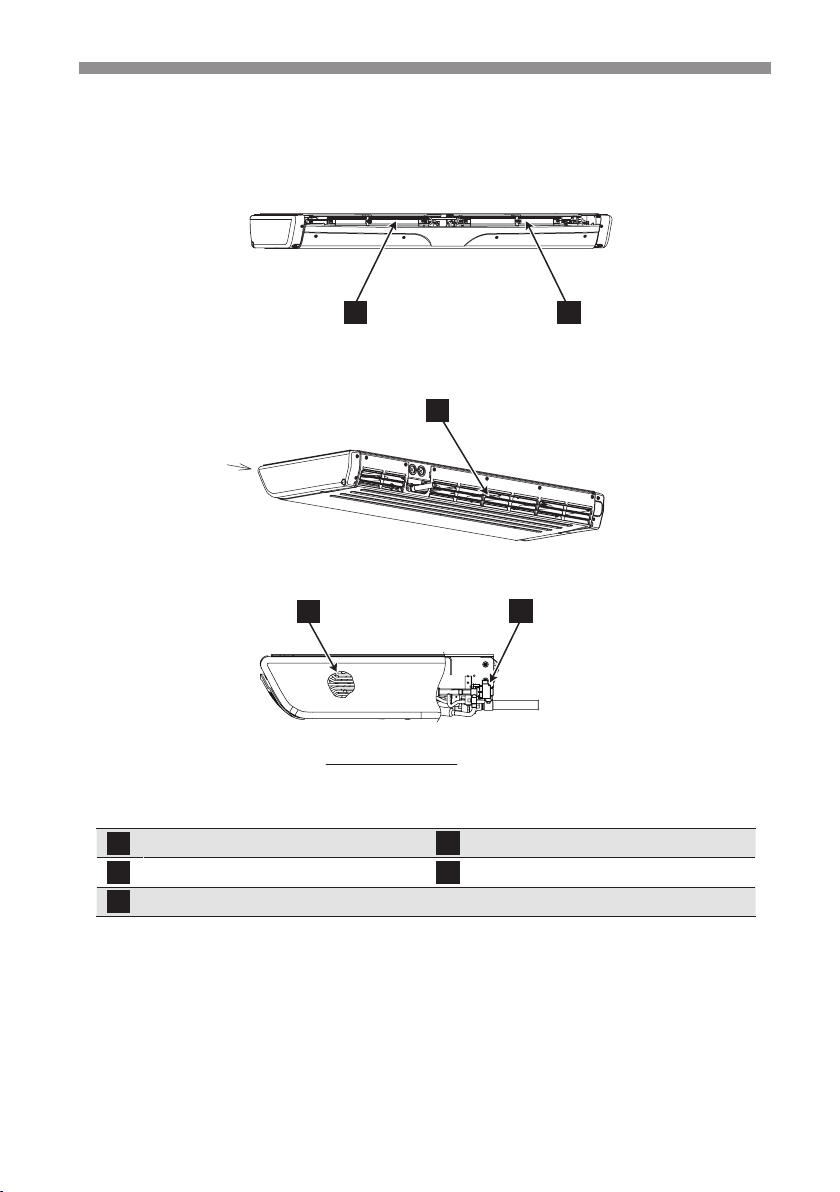

2 Name of each part ------- 3

Arrangement plan for main parts

--3

Evaporator unit -------------------4

Condensing unit -----------------5

Cabin controller ------------------6

Digital display area ---------------7

Protective devices----------------9

3 Precaution for safety---- 10

Signs on safety ----------------- 10

Precautions --------------------- 11

General precautions ---------------- 11

During and after the operation ---- 12

Inspection/Cleaning/Repair-------- 13

Loading ------------------------------ 14

Handling of electric equipment and

power codes------------------------- 14

Reinstallation of refrigeration unit

--- 16

Modification of refrigeration unit and

specification change

---------------- 16

Power supply equipment ---------- 16

Emergency measure ----------- 17

Handling of warning labels ---- 19

Prevention of start during

inspection work----------------- 21

Clothing and protective equipment

-- 21

Handling of grease and oil----- 21

When abnormal conditions are

detected ------------------------- 21

For emergency------------------ 21

4 Initial setting ------------- 22

Mode displays and functions

-- 22

Outline of the user setting mode

-- 25

Setting the clock/calendar ---- 27

Setting the defrost interval timer

-- 29

Displaying the operation time/

cycles ---------------------------- 30

Forced fuel circulating method

-- 32

5 Operation----------------- 33

Power on ------------------------ 34

Switching the drive ------------ 35

Operating with the engine --------- 35

Operating with the motor ---------- 35

Selecting the operation pattern

-- 36

Operation------------------------ 38

Stopping the operation -------- 39

Normal stop ------------------------- 39

Setting temperature ------------ 40

Whisper operation

(Only for engine drive)---------- 41

Manual defrost operation------ 42

Starting------------------------------- 42

Stopping ----------------------------- 42