*Nagoya Works **Himeji Works 10

TECHNICAL REPORTS

GOT1000 Series

New Functions and New Products

Authors: Takahiro Kaneko* and Tsuguo Kawasaki**

1. Introduction

Aiming at a “true” display at factory automation

(FA) workstations, the GT15 model of the GOT1000

series (hereafter, “GOT”) and the GT11 standard model

were released in July 2004 with enhanced functions for

stand-alone use, to provide a rapid response,

high-definition display, enhanced troubleshooting,

greater work efficiency such as reduced downtime, high

value-added equipment, and lower total cost. The GT16

model, which is the successor to the GT15, was re-

leased in August 2008 to meet the user demand for

easy-to-understand solutions using moving images for

large-volume data processing, troubleshooting and

downtime reduction, and for network I/F standard fea-

tures. As a lower-cost medium-size model, the GT14

was released in July 2011 featuring improved display

performance and added functionality for data acquisi-

tion (logging), to raise the position of the medium-sized

model to compete with new products and improved

functions introducedby competitors.

Here, we introduce the new functions of the GOT

and the development of the recently-launched me-

dium-sized display GT14 model, in order to meet user

demands such as for uniform management of informa-

tion shared between personal computers connected to

a network.

2. Functional Enhancement of GOT1000

Series

2.1 GOT Solutions

When a failure occurs in production equipment,

rapid detection of the cause and measures to prevent

recurrence are essential for reducing downtime. Thus,

there is a high demand for various troubleshooting

functions on the display for monitoring and viewing the

condition of manufacturing equipment. Table 1 shows

the main GOT functions as indicators for efficiency and

visualization.

With regard to the GOT incorporated in manufac-

turing equipment, many functions have already been

developed not only to improve the equipment operation

and status check, but also to ensure a quick response

to failures on site by identifying the location and cause

of the failure, and to confirm the measures to be taken.

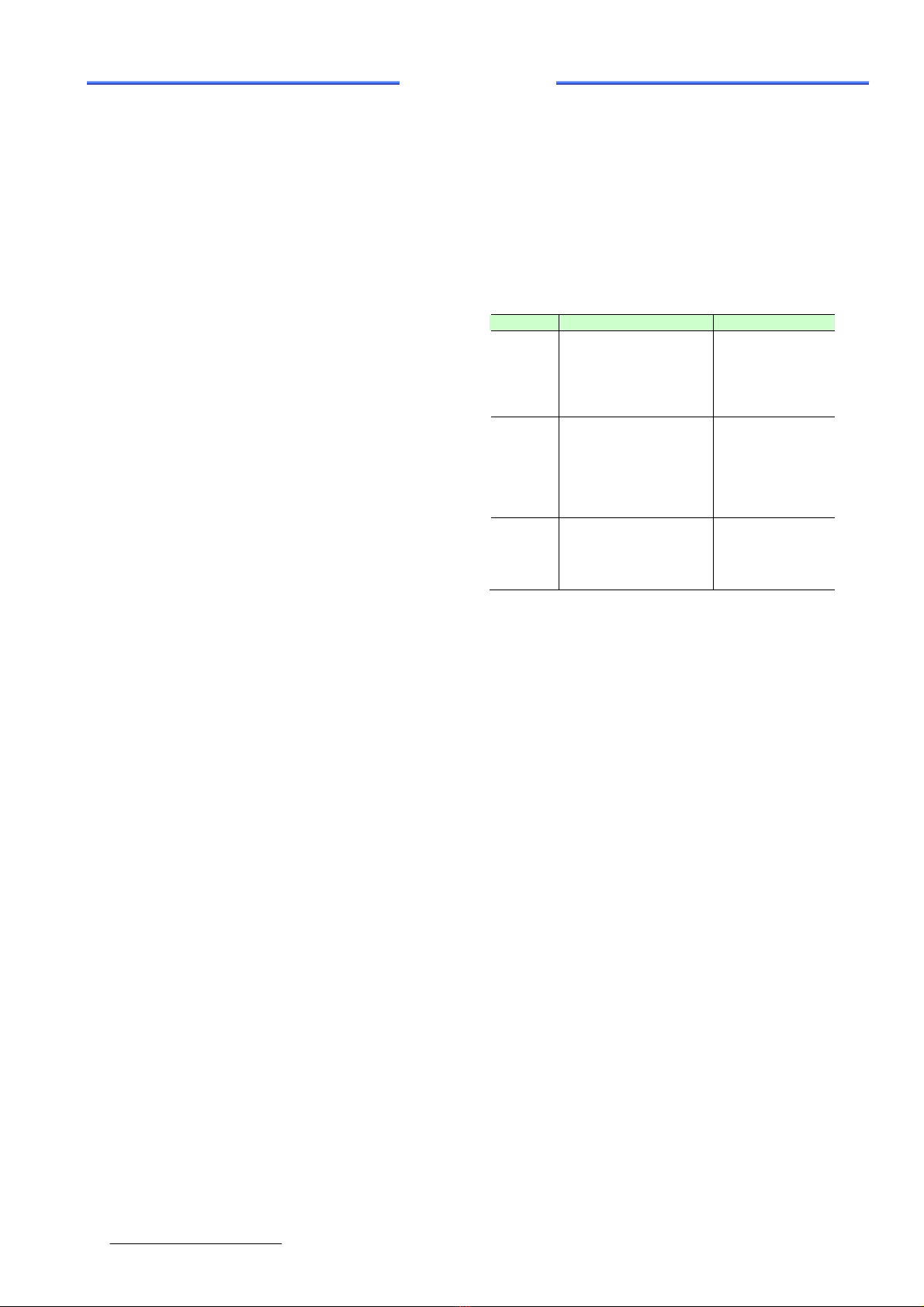

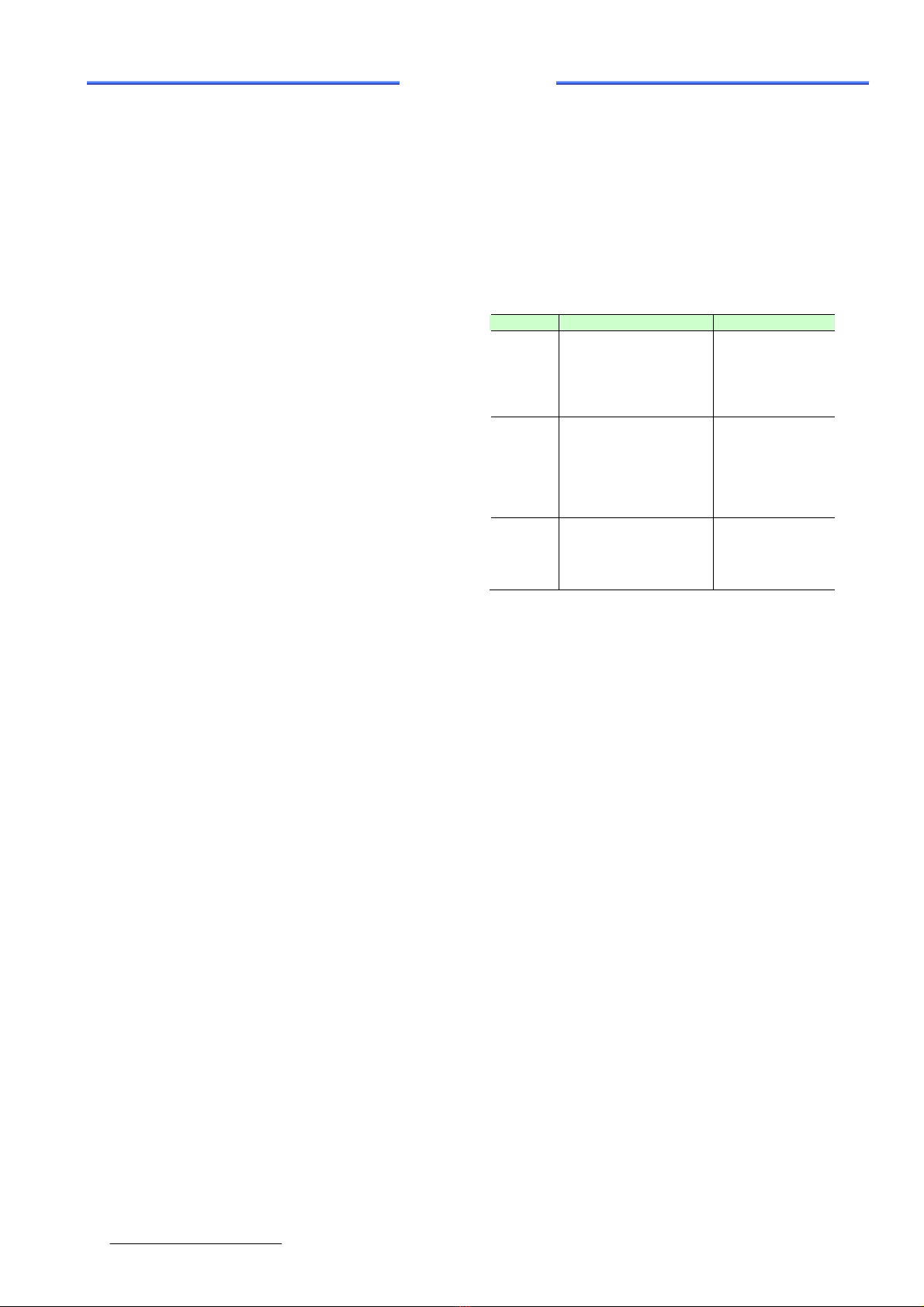

Table 1 GOT Solutions

Solution Efficiency and visualization GOT functions

Trouble-

shooting Efficiency of troubleshooting

Early investigation and

analysis of the cause of

troubles on site, and reduc-

tion of down-time

Ladder monitor

function

Operation log function

Remote personal

computer operation

function

Production/

manage-

ment

cooperation

Visualize manufacturing

information by linked per-

sonal computer

Monitor the entire system (on

site) and collectively manage

data by the personal com-

puter in the office

MES interface

FTP server function

On-site

monitoring

and coop-

eration

Remotely visualize the

screen of the on-site GOT

Monitor and maintain the

remote system and equip-

ment

SoftGOT-GOT link

function

FTP client function

VNC server function

As troubleshooting solutions, GOT has a ladder

monitor function that searches for the circuit causing

equipment failure in order to change the value of the faulty

device; a remote operation function for operating a remote

personal computer on which an operator is checking the

manual; and an operation log function for saving historical

data on operations performed on the GOT, to help identify

and analyze the cause of faults. These functions facilitate

troubleshooting at production sites.

The following functions can be used as produc-

tion/management joint solutions with the GOT: an MES

interface function for promptly transmitting the device

values of connected equipment directly to an MES

database to save and manage the data; and an FTP

server function that allows a computer at an office to

read and write information files collected by the GOT

and files with the production control data such as mix-

ing conditions and processing conditions of materials.

In recent years, demand has increased for remote

monitoring and maintenance of overseas factories, in

particular, for viewing and operating GOT screens at

production sites. In response, we have provided a

SoftGOT-GOT link function as a joint solution for on-site

monitoring. With this function, it is possible to display

and operate the same screen as that of the on-site

GOT using SoftGOT on a personal computer with a

network connection to the GOT. The SoftGOT-GOT link

function enables monitoring of manufacturing equip-

ment by collecting screen data from the target GOT and

using it as the screen data for the SoftGOT to display