3

Technical Data

MixRite operates in the following conditions:

From a minimum flow rate of 20 L/H (5.3 Gal/H) and up to 2,500

L/H (660 Gal/H)

Temperature not lower than 4˚C (39˚F) and not higher than

40˚C (104˚F)

Water pressure between 0.2 Bar to 8 Bar (2.9 to 120 PSI)

The additive may be added to the water flow according to the

required dosing percentage:

0.2% to 2% in models: 2502, 12502, 2512, 12512, 2502P,

2512IN, 12512IN.

0.4% to 4% in models: 2504, 12504, 2514, 12514, 2514IN,

12514IN.

3 % to 10% in models: 2510,12510

Fixed dosage 0.2 % in models: 2500, 12500

Fixed dosage 0.8 % in models: 2501, 12501

Fixed dosage 6 % in models: 2506, 12506

Water pressure loss:

Pressure loss in the lower flow rates 0.1 Bar and in the higher flow

rates up to 1 Bar.

Models with 0.2%-2%: from 0.1 Bar up to 1 Bar in proportion to

the water flow

Models with 0.4%-4%: from 0.2 Bar up to 1.2 Bar in proportion to

the water flow

Models with 3%-10%: from 0.5 Bar up to 1.8 Bar in proportion to

the water flow

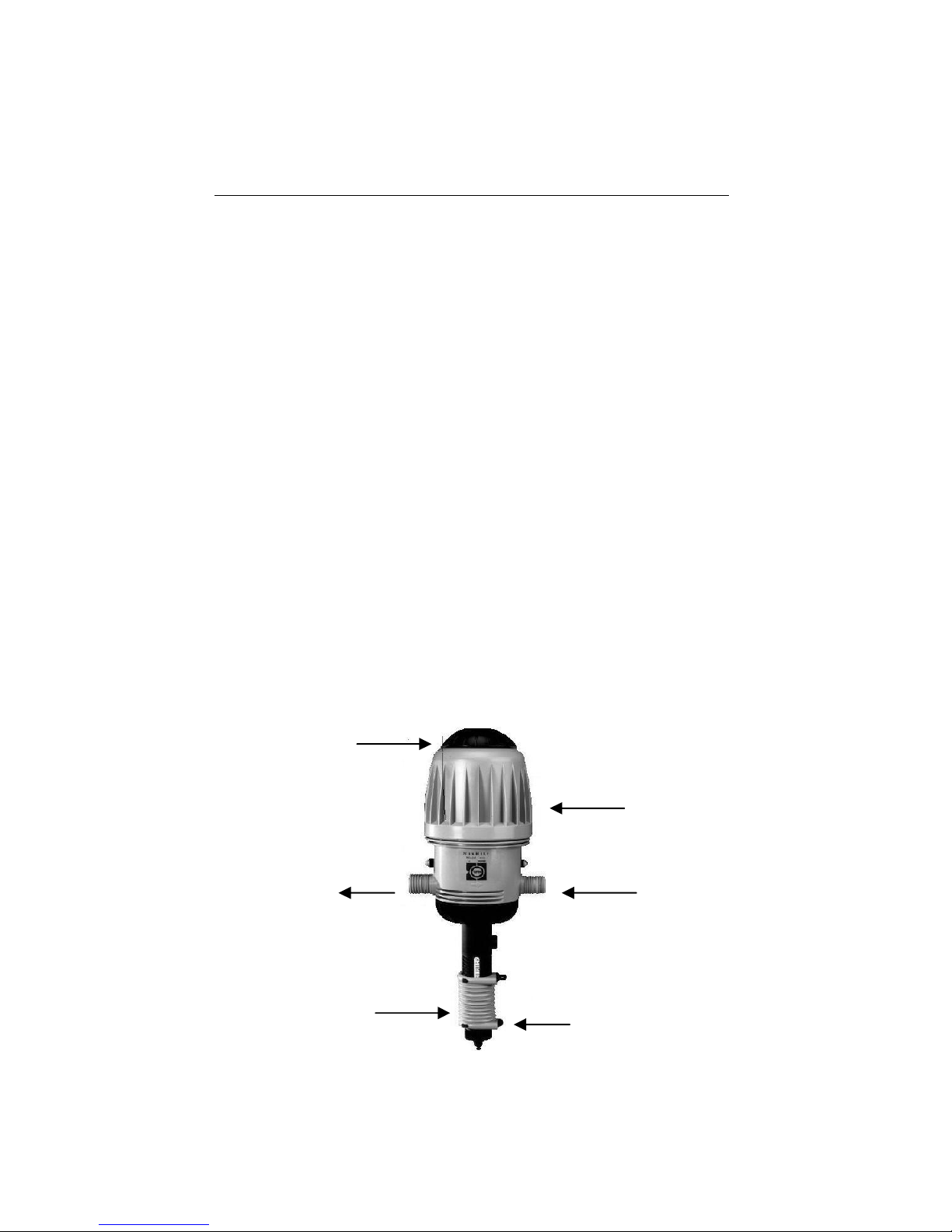

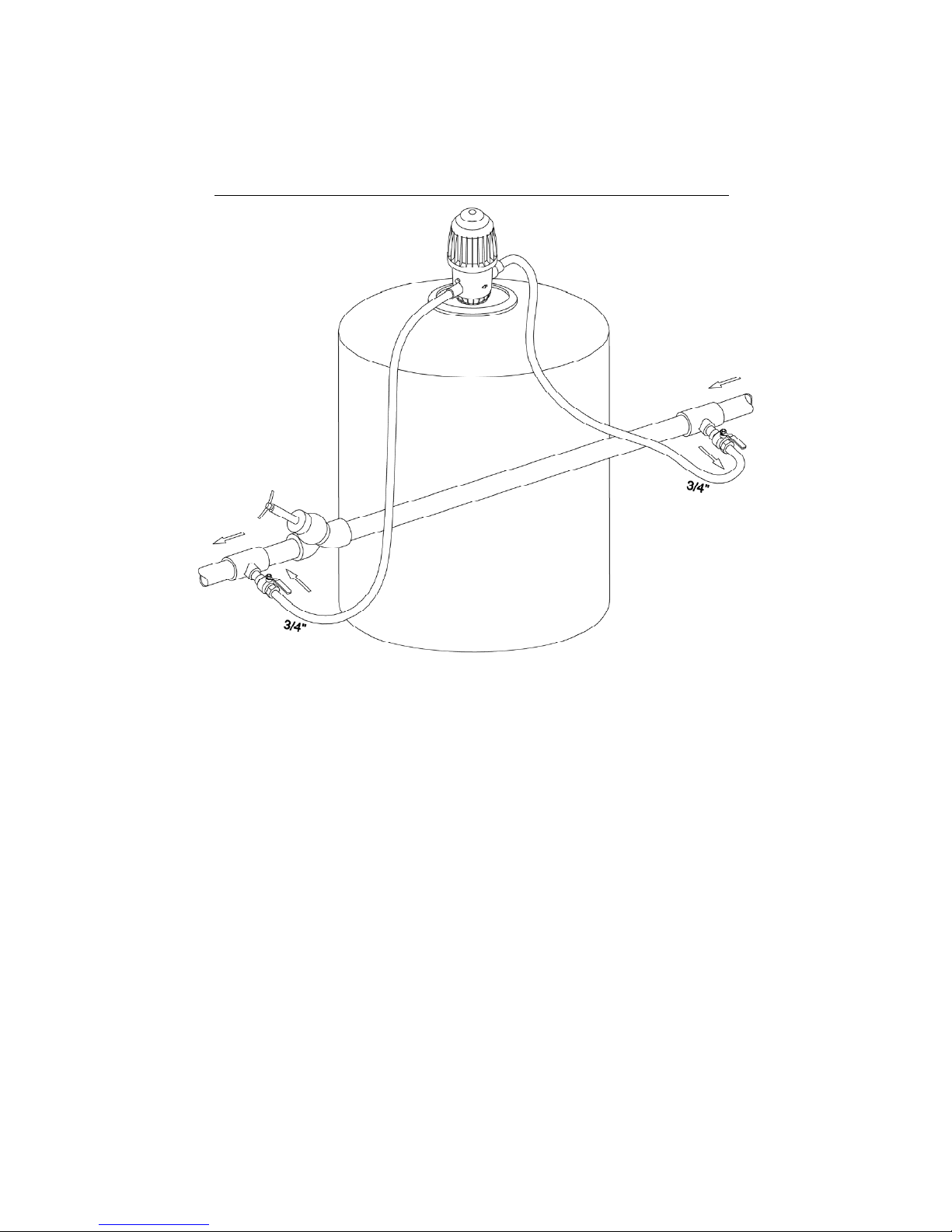

The MixRite inlet and outlet are ¾" BSPT male thread.

The additive tank should be placed beneath the MixRite.

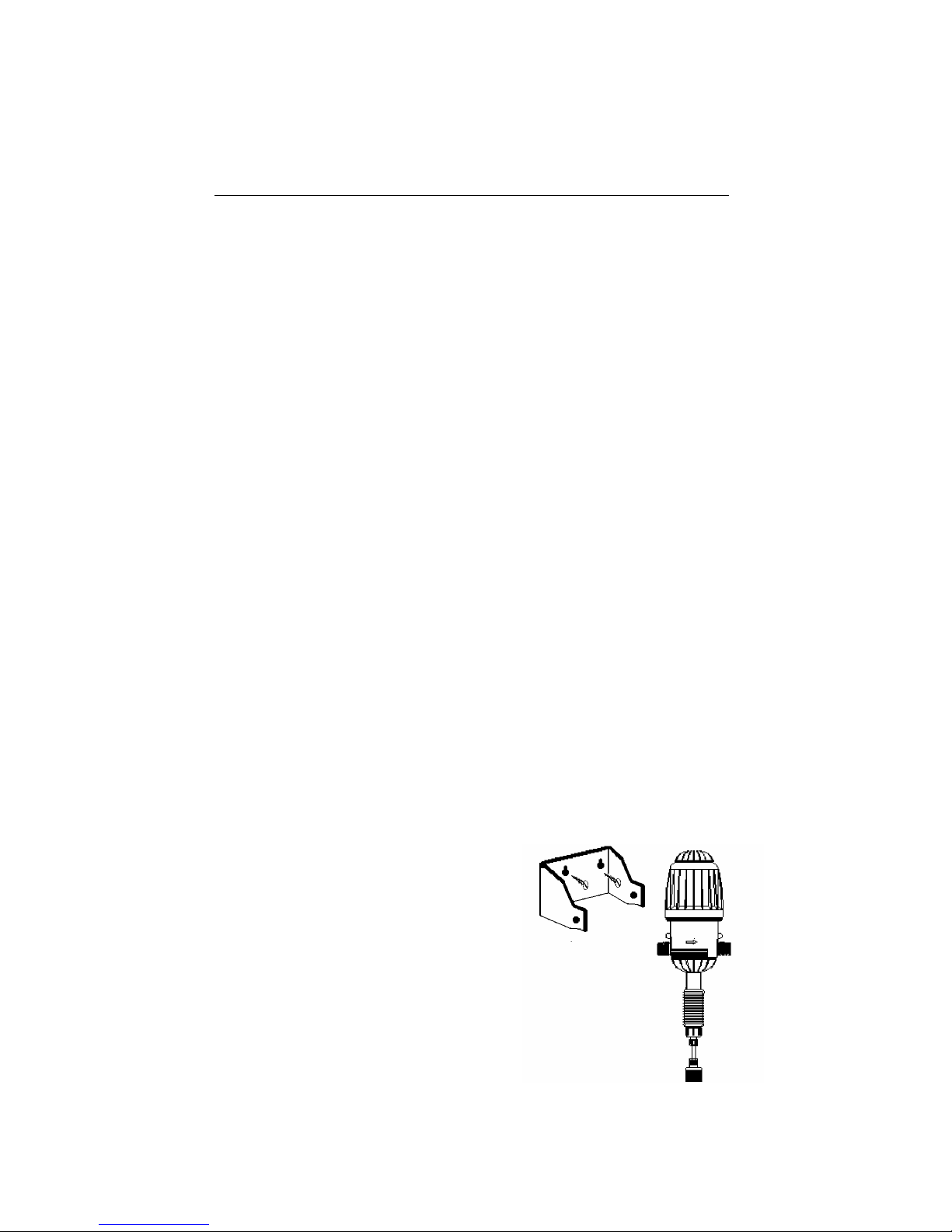

Mounting the MixRite

1. Prepare the MixRite site.

The MixRite intake and outlet must

reach the intake and outlet pipes.

The MixRite must be positioned above

the liquid additives container.

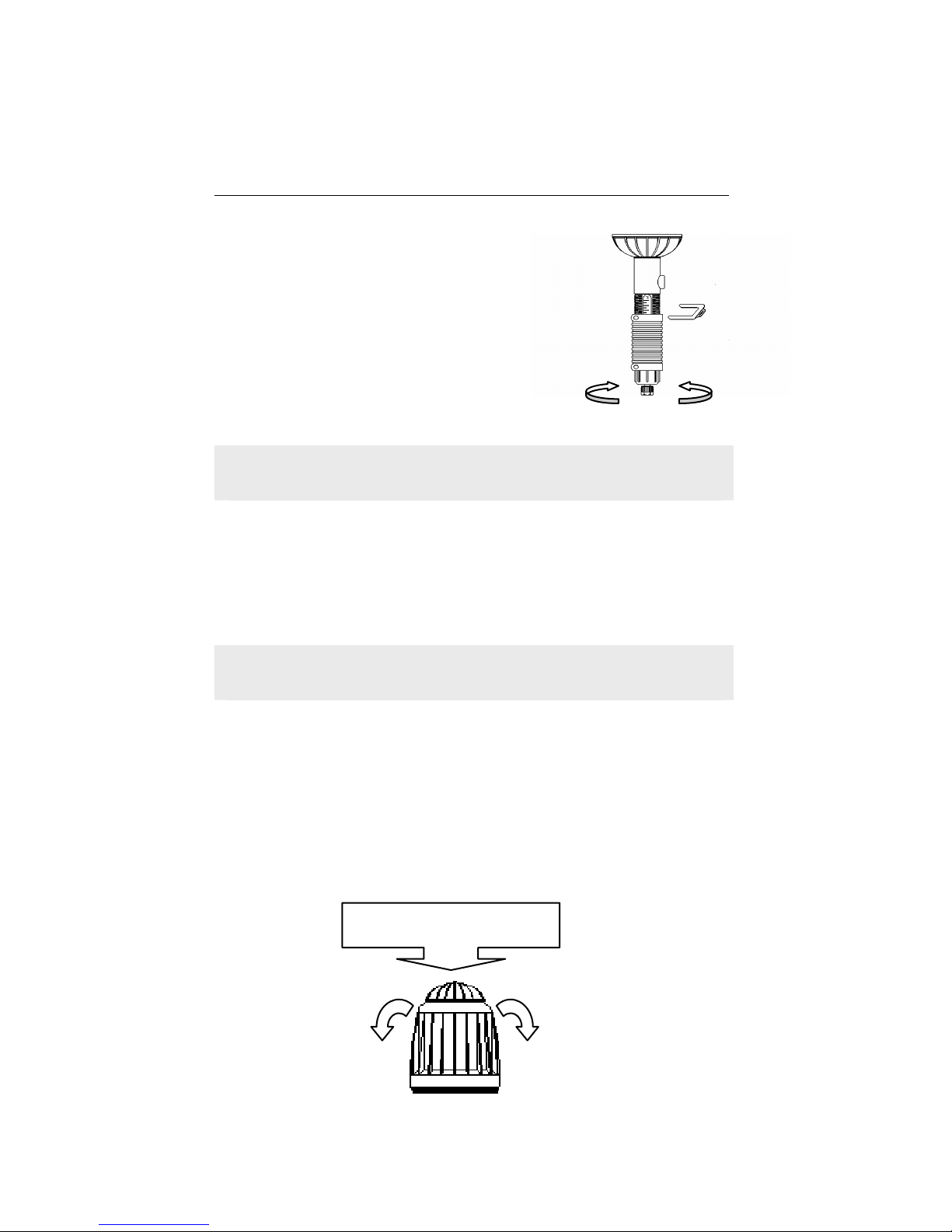

2. Screw the MixRite bracket onto a wall or

any stable vertical base.

3. Press the MixRite onto the bracket.

The nipples on the MixRite must click

into the holes in the side of bracket.