CHAPTER 3 PROPULSION SYSTEM

- 10 - 34z

INTRO - THE TOP 10 CAUSES OF ENGINE FAILURE

It doesn’t happen often and if you’re familiar with the most common causes of engine failure you can cut

down on the chances of a breakdown. As an introductory to this chapter, we want to familiarize you with

this list of causes, compiled by Motorboating Magazine (February 2006). Here are the Top Ten to be

aware of:

1. NO FUEL: This is probably less of a problem on a fuel-efficient MJM than on other boats, but lack of

owner attention to fuel consumption is the primary culprit for engine failure. A boat’s fuel tank can be

nearly dry as a bone – even when the gauge claims there’s a 1/4 of a tank left. This makes sense when

you realize that at cruising speed, the gauge shows the tanks reading higher than when the boat is at

rest. A good rule of thumb is to never pass a fuel dock (no matter what the price) if your gauge is showing

less than 1/3 full.

1b. AIR IN FUEL LINE: If air gets drawn into the fuel lines because of either a small leak in a fuel line

connection or the Racor Filter lid gasket/filter basket tabs have interfered with the lid being secured fully,

you may find the engine will turn over, but won’t start. Check the Racor to insure the fuel level is within

an inch of the top. Check the engine owner manual for the location of a manual primer pump.

1c. COMPUTER SETTING: On the Yanmar electronic engines, we’ve encountered several instances

where after shutting down the engine for several hours (on a picnic); it was only possible to start the

engine after many tries or not at all. The problem was that the setting that determines the amount of fuel

to be injected into the engine upon starting was not set high enough.

2. DIRTY FUEL: Engine problems are caused by dirt and water in the fuel. Debris, stirred up from the

bottom of the tank by wave action, is drawn into the fuel line and clogs the fuel filter element. Starved for

fuel, the engine begins to run poorly, and then not at all. Water in the fuel can drive you mad. Moisture

condenses out of the highly humid air on the inside walls of a fuel tank, then runs down into the fuel.

Water can also be introduced at the fuel dock from a contaminated fuel supply. Fuel floats on top of

water and the fuel pick ups are near the bottom of the tank. A fuel/water separator protects against this

by handily extracting the water. Check the bowl daily and drain off the accumulated water. For severe

contamination, use a fuel drying additive.

3. FUEL BUGS: Diesel engines suffer from microbial bugs growing in the fuel. If left unchecked, these

critters clog filters. If you leave the same diesel fuel in the tank for any length of time, a fuel conditioner

similar to that supplied with your boat by the builder will kill the bugs and break up any hydrocarbon

residue into particles that will burn completely in the combustion process.

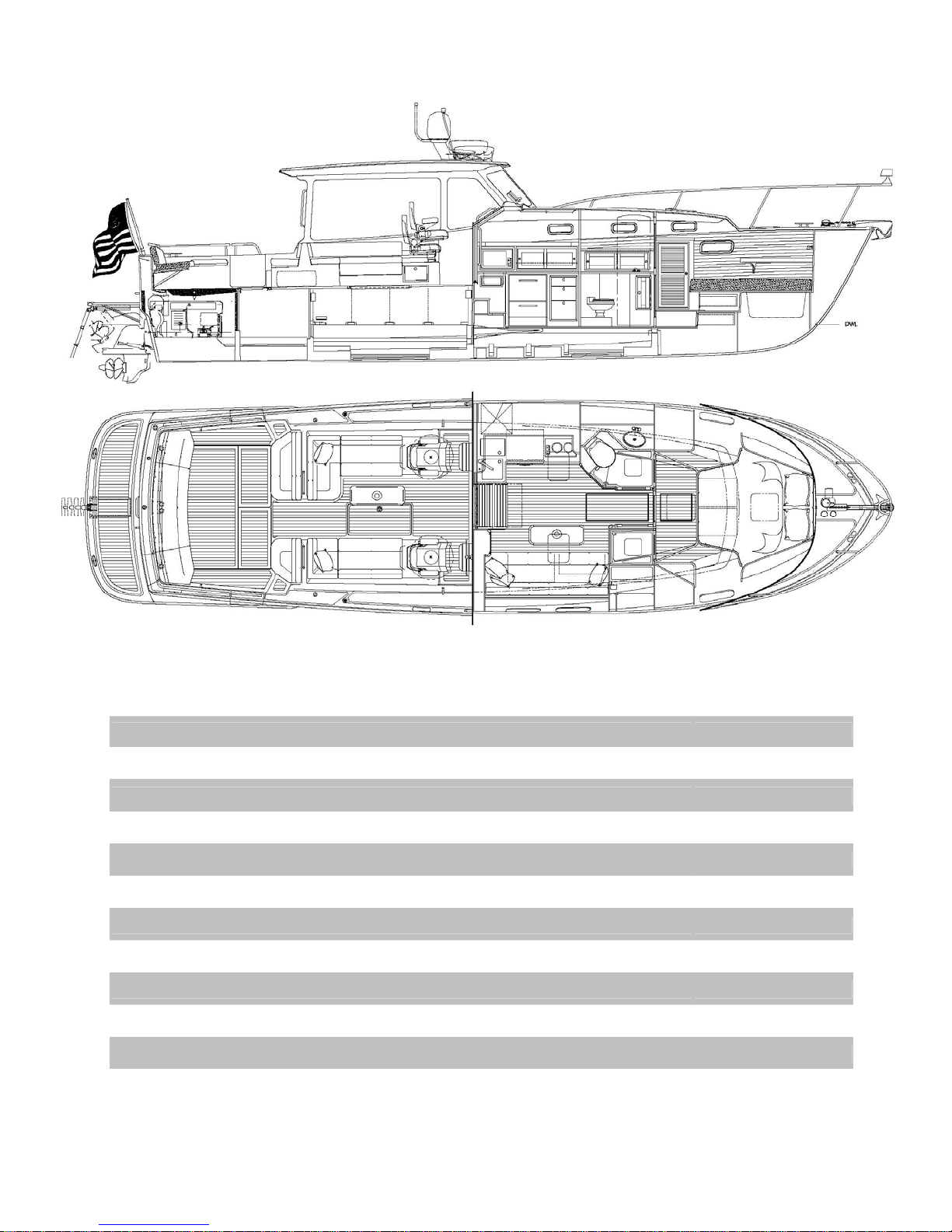

4. TIRED/DAMAGED WATER PUMP IMPELLER: As boats age or if

an engine isn’t operated for a long period of time, a worn-out circulating

water pump is another engine killer. Impeller blades are commonly

made of a rubberized material that stiffens or distorts over time and can

break off entirely, reducing coolant flow and clogging the heat

exchanger. Periodic engine maintenance procedures can prevent this

problem. A spare is provided in the Yanmar Spares Kit. Shown at right

is an impeller that would have soon failed. It was discovered, then

replaced during the 50-hour inspection on a 29z that had not been run

for 11 months. Another cause for impeller disintegration is running the

engine with the raw water intake shut off. By the time that the overheating is discovered and you shut

down the engine, the impeller may already have been destroyed or damaged. This happened on a 34z

when the operator forgot to be sure that the raw water intake valve was in the proper position.

5. HARD HOSE: Another issue to be concerned about with older boats. As water intake hoses age,

they lose their resiliency and collapse under suction, causing a restriction in the flow of engine coolant.

This results in over-heating.