Directory

Ⅰ

.Overview..................................................................................................................................................................................................... 2

Ⅱ

Features..................................................................................................................................................................................................... 2

Ⅲ

.Motherboard parameters...........................................................................................................................................................................3

Ⅳ

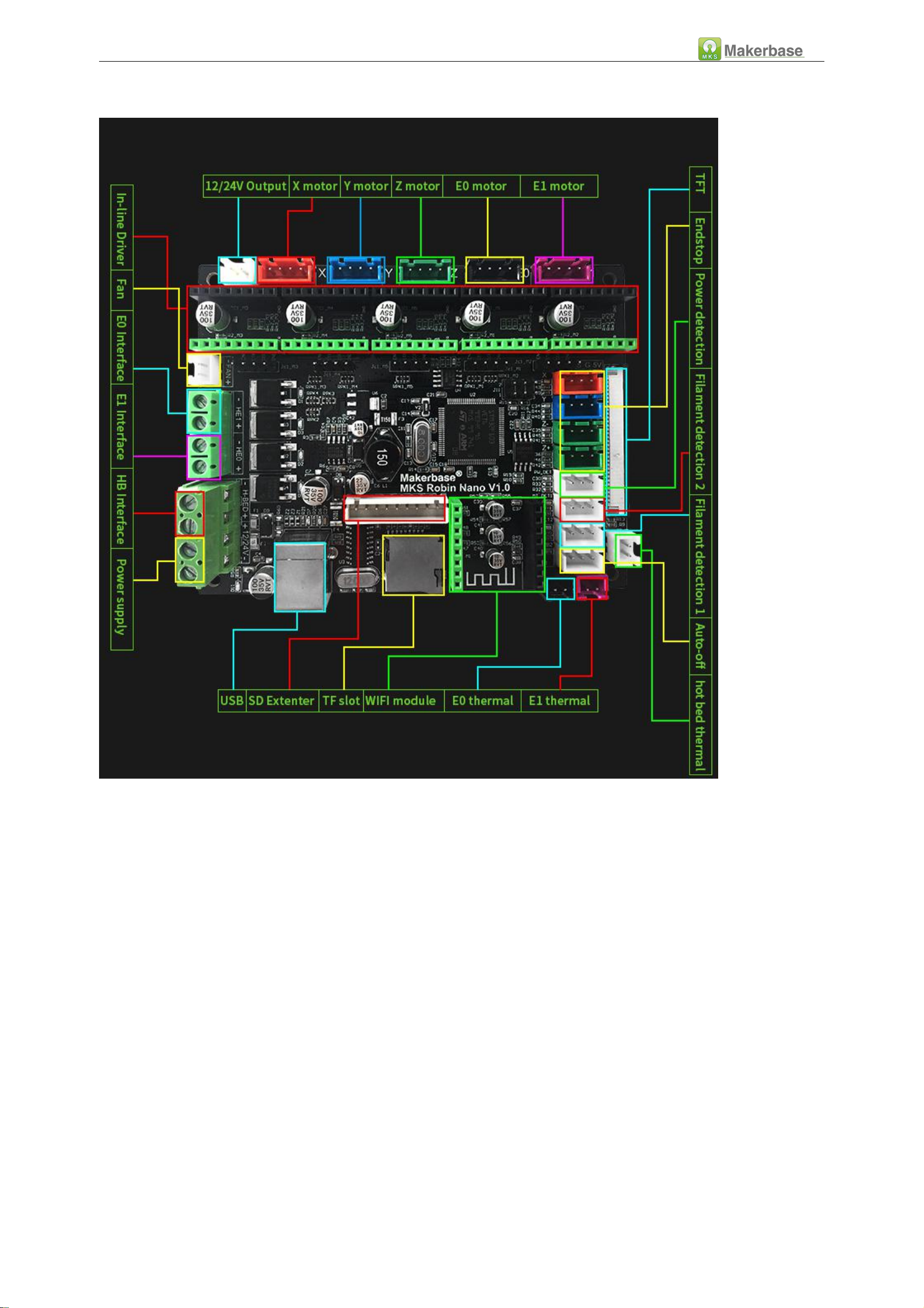

.Port Instructions..........................................................................................................................................................................................4

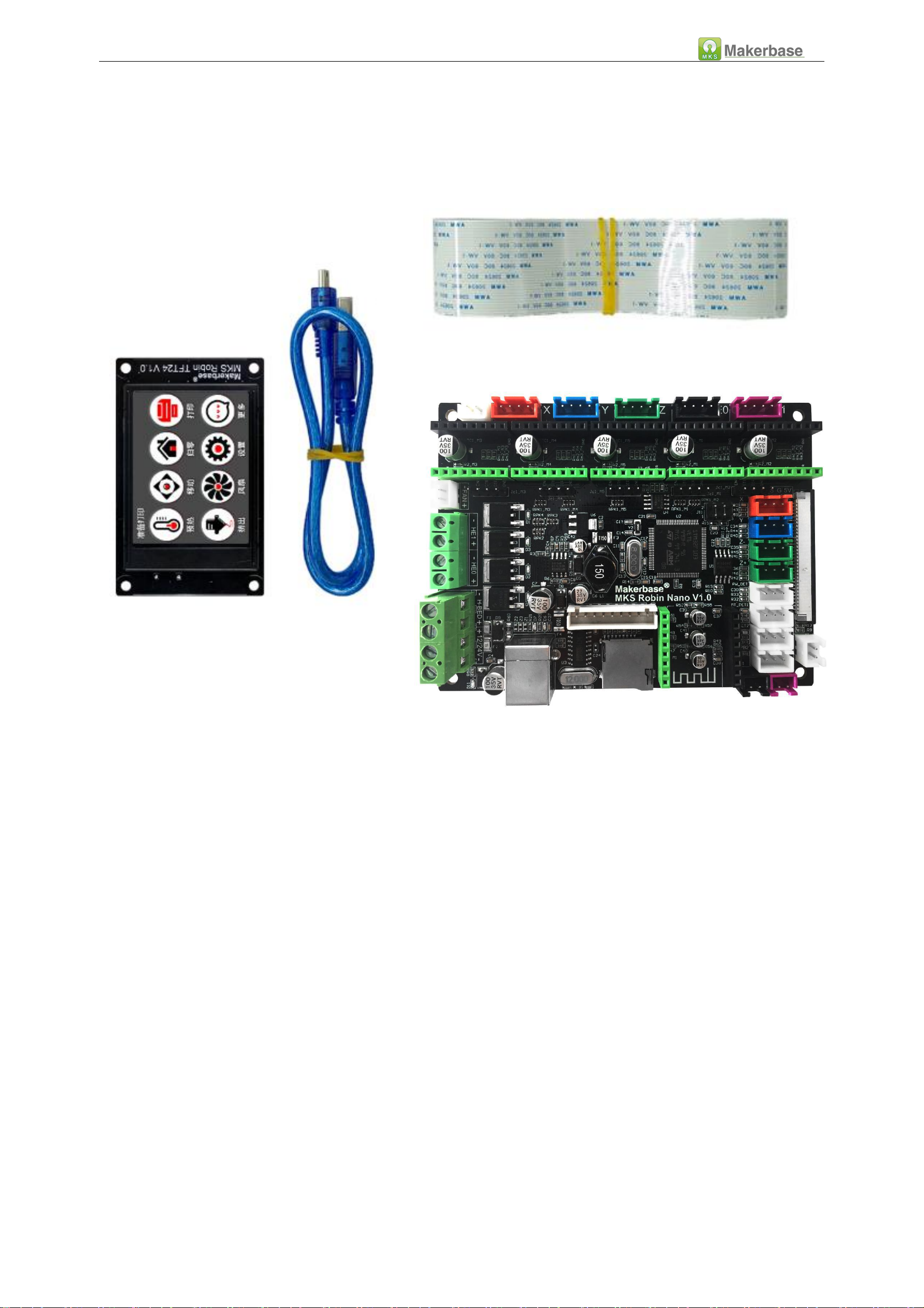

4.1 MKS Robin Nano Front view............................................................................................................................................................. 4

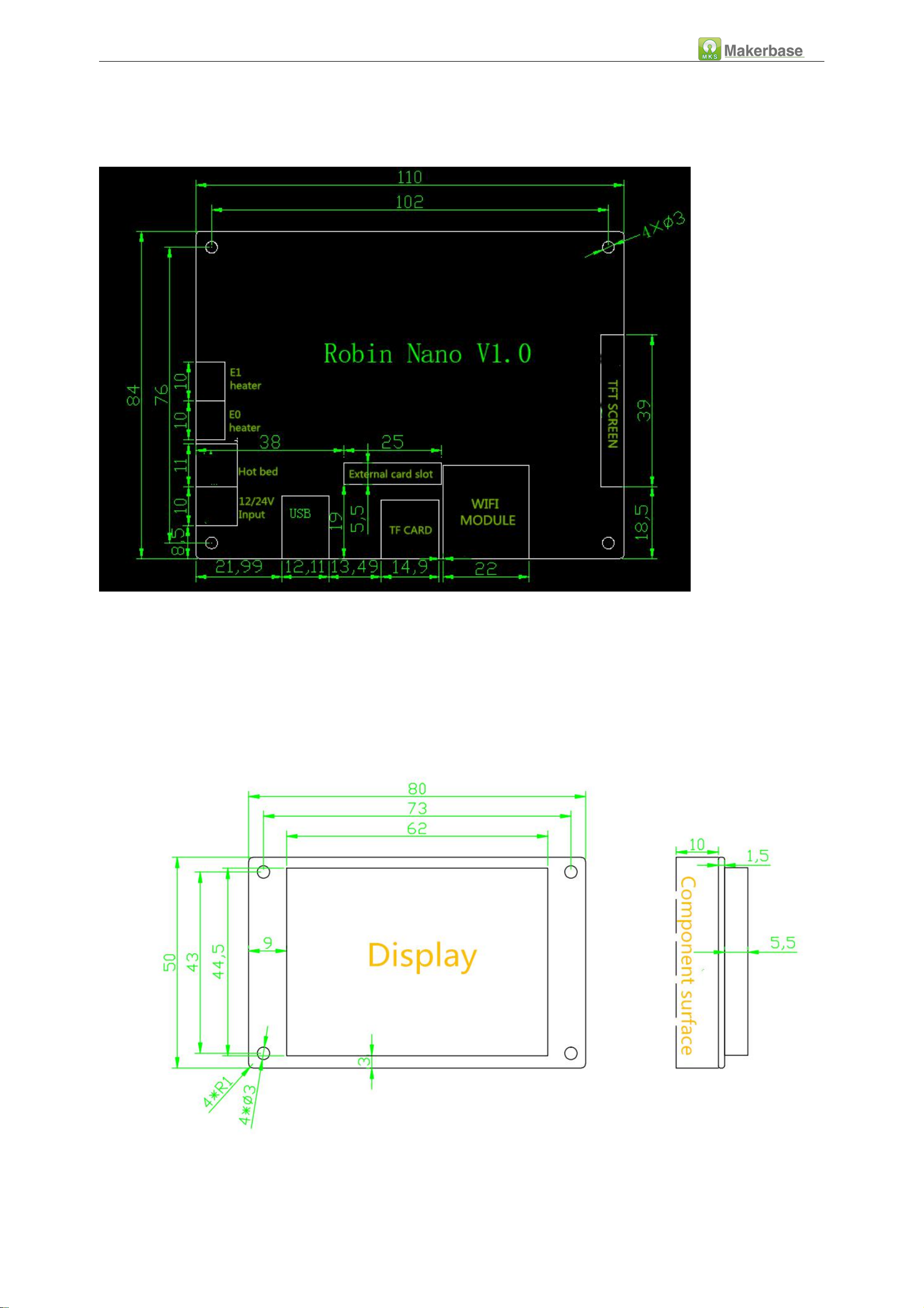

4.2 MKS Robin Nano Installation Dimensional Drawing.........................................................................................................................5

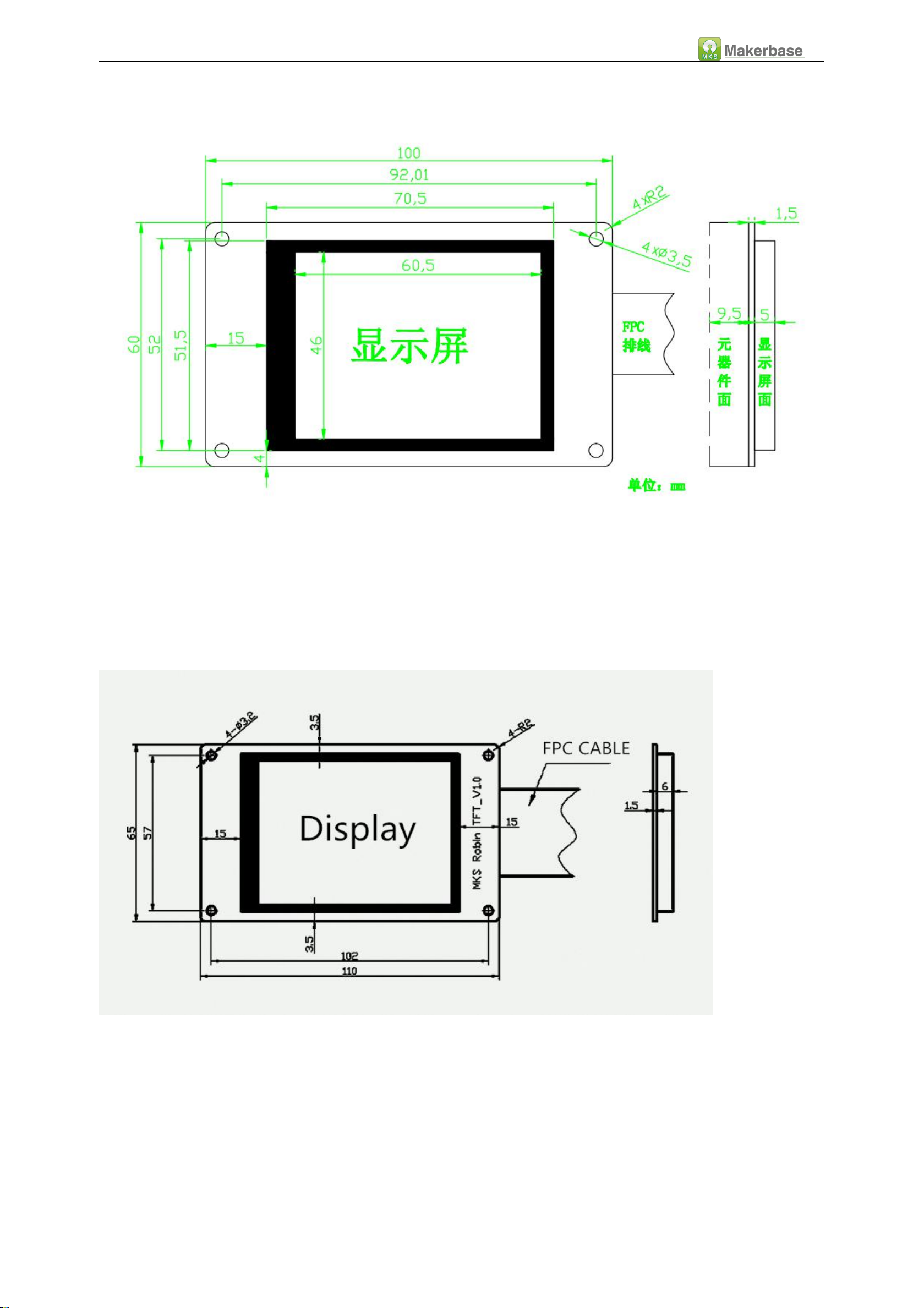

4.3 MKS Robin TFT(2.4inches,2.8inches,3.2inches) Installation Dimensional Drawing.......................................................................... 5

4.4 MKS Robin Nano System connection diagram..................................................................................................................................7

4.5 Driver and motherboard wiring diagram (note the driving direction, do not insert the reverse)........................................................ 8

Ⅴ

.Firmware Upgrade Instructions................................................................................................................................................................11

5.1 The ways to get the MKS Robin Nano Latest Firmware................................................................................................................ 11

5.2 The methods for updating the firmware........................................................................................................................................ 11

Ⅵ

. USB driver Installation.......................................................................................................................................................................... 12

Ⅶ

. Machine parameters and function configuration................................................................................................................................ 13

7.1 Basic settings

(

Important, must be set

)

..................................................................................................................................... 13

7.2 Function setting............................................................................................................................................................................14

7.3 Delta Settings................................................................................................................................................................................. 15

7.4 Bed Leveling Setting....................................................................................................................................................................... 16

7.4.1 Manual leveling....................................................................................................................................................................16

7.4.2 Auto leveling........................................................................................................................................................................ 16

7.5 Filament change function...............................................................................................................................................................17

7.6 Filament Detecting.........................................................................................................................................................................18

7.7 Power off recovery......................................................................................................................................................................... 18

7.8 Auto off after print finish function..................................................................................................................................................19

7.9 Breakpoints recovery......................................................................................................................................................................19

Ⅷ

. The network printing function................................................................................................................................................................. 20

8.1 The introduction of printing mode................................................................................................................................................. 20

8.2 Cloud Print Mode........................................................................................................................................................................... 21

8.3 LAN Print mode.............................................................................................................................................................................. 25

8.4 AP print mode................................................................................................................................................................................ 28

8.5 Model Library Web site..................................................................................................................................................................... 30

Ⅸ

.TFT touch Screen User interface configuration......................................................................................................................................31

9.2 . Steps................................................................................................................................................................................................32

9.3 Name of logo and button picture..................................................................................................................................................... 33

Ⅹ

. Technical Support and Guarantee..........................................................................................................................................................39