iii EDH0387En1020 — 09/18

BG Series Goniometric Cradles

Table of Contents

Warranty .................................................................................................................ii

EC Declaration of Conformity...............................................................................v

Definitions and Symbols.......................................................................................vi

Warnings ...............................................................................................................vii

Caution .................................................................................................................viii

1.0 — Introduction.................................................................................1

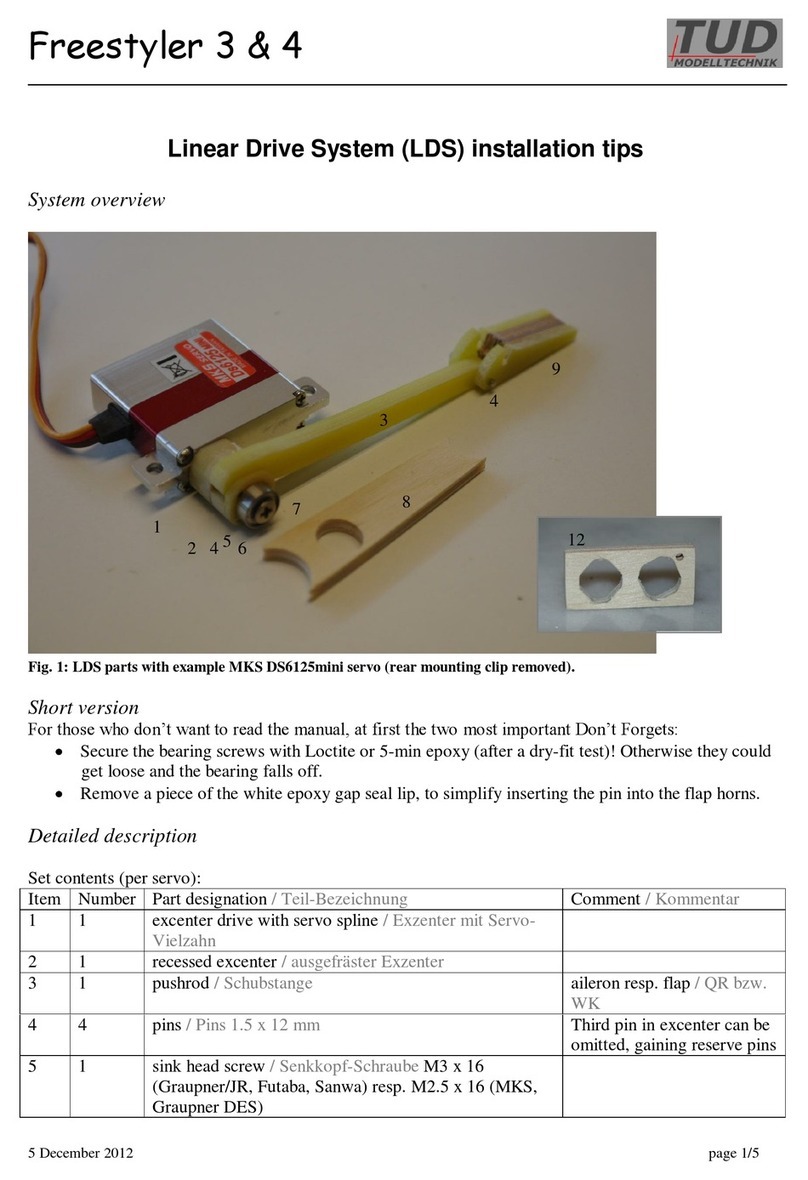

2.0 — Description ...................................................................................2

2.1 Design Details ............................................................................................2

3.0 — Characteristics............................................................................3

3.1 Definitions..................................................................................................3

3.2 Mechanical Specifications .......................................................................4

3.3 Load Specification Definitions.................................................................4

3.4 Load Characteristics and Stiffness .........................................................4

3.5 Goniometric Cradle Weights ...................................................................5

4.0 — Drives and Motors ....................................................................5

4.1 Stepper Drive Versions ............................................................................5

4.2 DC-Servo Drive Versions ..........................................................................6

4.3 Sensor osition..........................................................................................7

4.4 Feedback Signal osition .........................................................................8

4.5 BGS inouts ...............................................................................................9

4.6 MSCABLE-3 Cable......................................................................................9

4.7 BGM inouts ............................................................................................10

4.8 MCAB-3 Cable ..........................................................................................10

5.0 — Connection to Newport Controllers ..............................11

5.1 Warnings on Controllers ........................................................................11

5.2 Connection...............................................................................................12

5.3 Cables .......................................................................................................12

5.4 MSCABLE-3 Cable....................................................................................12

5.5 MCAB-3 Cable ..........................................................................................13

6.0 — Connection to non Newport Electronics.....................14

6.1 Connections.............................................................................................14