Always ensure the temperature of the testing air or gas,

which must be oil free, and the ambient temperature are

as close as possible. It is advisable to allow a settling

down period of approximately one hour depending on

the volume of the system.

Step 1 – Leak Path Test:

• The initial air test is a ‘Leak Path’ test and should be

performed at 15 KPa for a minimum of 120 minutes,

for a system with a volume up to 100 litres. An extra

20 minutes of testing time should be added for every

additional 100 litres of system volume.

•

No pressure drop is to be permitted during this test period.

Step 2 – Tightness Test:

• Once the ‘Leak Path’ test has been completed and

passed, a mechanical strength test can commence.

A maximum pressure of 300KPa, for a period of 10

minutes is recommended. We also suggest the pressure

is elevated in steps of 100KPa per 10 minutes. Again, no

pressure drop is allowed during this period. If higher

test pressures are required, pressures are to be

elevated in steps of one bar every 10 minutes.

•

The maximum operating pressure for a system carrying air

or technical gas is 1600KPa. A system intended to carry fuel

gas is rated at a maximum operating pressure of 500KPa.

•

If during any testing a pressure drop is detected, then the

testing process should be halted, and the location of the

leak identied and remedied. A report should be made

and kept of the initial failed test. Once the fault has been

corrected, the whole pressure test process should be

re-commenced from the beginning.

TESTING & COMMISSIONING

When water tting installations are complete, it is essential

to ush with water before use to remove dust, debris and

ux residues, in accordance with the relevant plumbing

installation code.

Drinking water installations should be tested and

inspected in accordance with the code for leaks and

remedial action taken if necessary.

KemPress® ttings maintain earth continuity without

the need for additional continuity straps.

CERTIFICATION & TESTING

KemPress® has achieved WRAS certication and the

Australian watermark certication. The ttings have

undergone a rigorous testing program including:

• Prototype testing

- burst pressure

• Watermark testing

- Water tightness

- Strength of fabrication

- Strength of joint assembly

- Pull-out strength

- Thermal cycling

• Material in contact with drinking water

• Press testing every product in the range

• Press testing every tool and Jaw

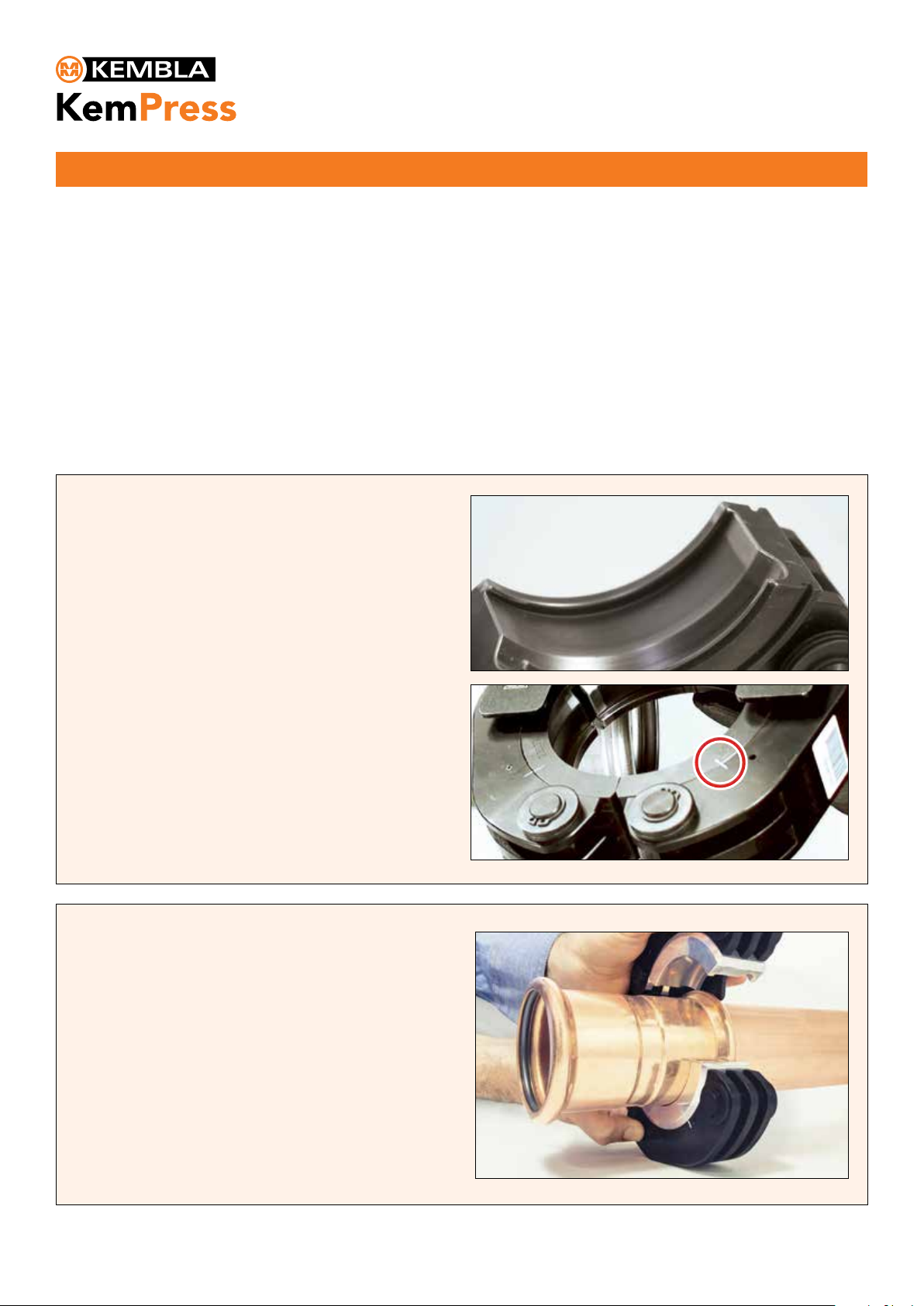

O-RING

The O-ring is pre-lubricated and should be protected

from contamination by foreign objects to avoid

damaging the integrity of the product (for example

copper lings when cutting copper tubes).

Water applications use an EPDM (Ethylene Propylene

Diene Monomer) O-ring. This O-ring is suitable for

standard water applications designated below.

For hot water temperatures exceeding 120oC please

contact Kembla Hong Kong for guidance.

The pre-lubricated O-ring has passed the materials

on contact with drinking water certication in Australia

and through WRAS.

WATER FITTINGS

Application Pressure Temperature

KPa oC

Hot & Cold Potable Water 1600 120

Chilled water 1600 -25

Rainwater installations 1600 Ambient

Vacuum - 80 Ambient

Domestic re sprinkler systems 1600 Ambient

Compressed air installations (oil free) 1600 70

5

®

Page 1of 34

Australian Certification Services P ty Ltd ABN 37 121 022 366

POBox 627 Jannali, NSW 2226 AUSTRALIA

www.certificationservices.com.au

Certificate Number: 23087

IssueDate: 22nd May 2017

Issue:02 Revision: 02

Level 1

Certificate of Conformity

Australian Certification Services Pty Ltd grants to the WaterMark User:

Metal Manufactures Ltd

Trading as MM Kembla

the right to use the WaterMark as shown above in conjunction with the Certificate No. on product/s as identified in the

WaterMark Schedule and as listed on the WaterMark database www.abcb.gov.au/ Product-Certification/WaterMark-

Certification-Scheme which have been shown to comply with the relevant Standard/s and level of certi fication referred

to below. The WaterMark User is granted a licence to use the WaterMark subject to the rules governing the use of the

WaterMark.

Metallic Press Fit Fittings

KemPress® Copper KemPress® Stainless

AS 3688:2005 Amdt 1 2006 Water supply—Metallicfittings and end connectors

AS 3688:2016 Water supply and gas systems

—Metallic fittings and end

Certificate No.: 23087

This certificate remains the property of Australian Certification Servic es Pty Ltd

WaterMark Level 1 certification is a conformity assessment scheme based on ISO Guide 67 (system 5)

Certificate No.

Secretary

This certifies that

has had the undermentioned product examined, tested and found,

when correctly installed, to comply with the requirements of the

United Kingdom Water Supply (Water Fittings) Regulations and

Scottish Water Byelaws.

The certificate by itself is not evidence of a valid WRAS Approval. Confirmation ofthe current

status of an approval must be obtained from the WRAS Directory (www.wras.co.uk/directory)

The product so mentioned will be valid until the end of:

Chairman, Product Assessment Group

June2017

MM KEMBLA

KEMPRESS RANGE OF PRESS-FIT TRANSITION FITTINGS

January 2024

1901708

Certificate No.

Secretary

This certifies that

has had the undermentioned product examined, tested and found,

when correctly installed, to comply with the requirements of the

United Kingdom Water Supply (Water Fittings) Regulations and

Scottish Water Byelaws.

The certificate by itself is not evidence of a valid WRAS Approval. Confirmation ofthe current

status of an approval must be obtained from the WRAS Directory (www.wras.co.uk/directory)

The product so mentioned will be valid until the end of:

Chairman, Product Assessment Group

June2017

MM KEMBLA

KEMPRESS COPPER PRESS-FIT FITTINGS

January 2024

1901707