Key Features

• Safe handling with slip-proof rubberised housing

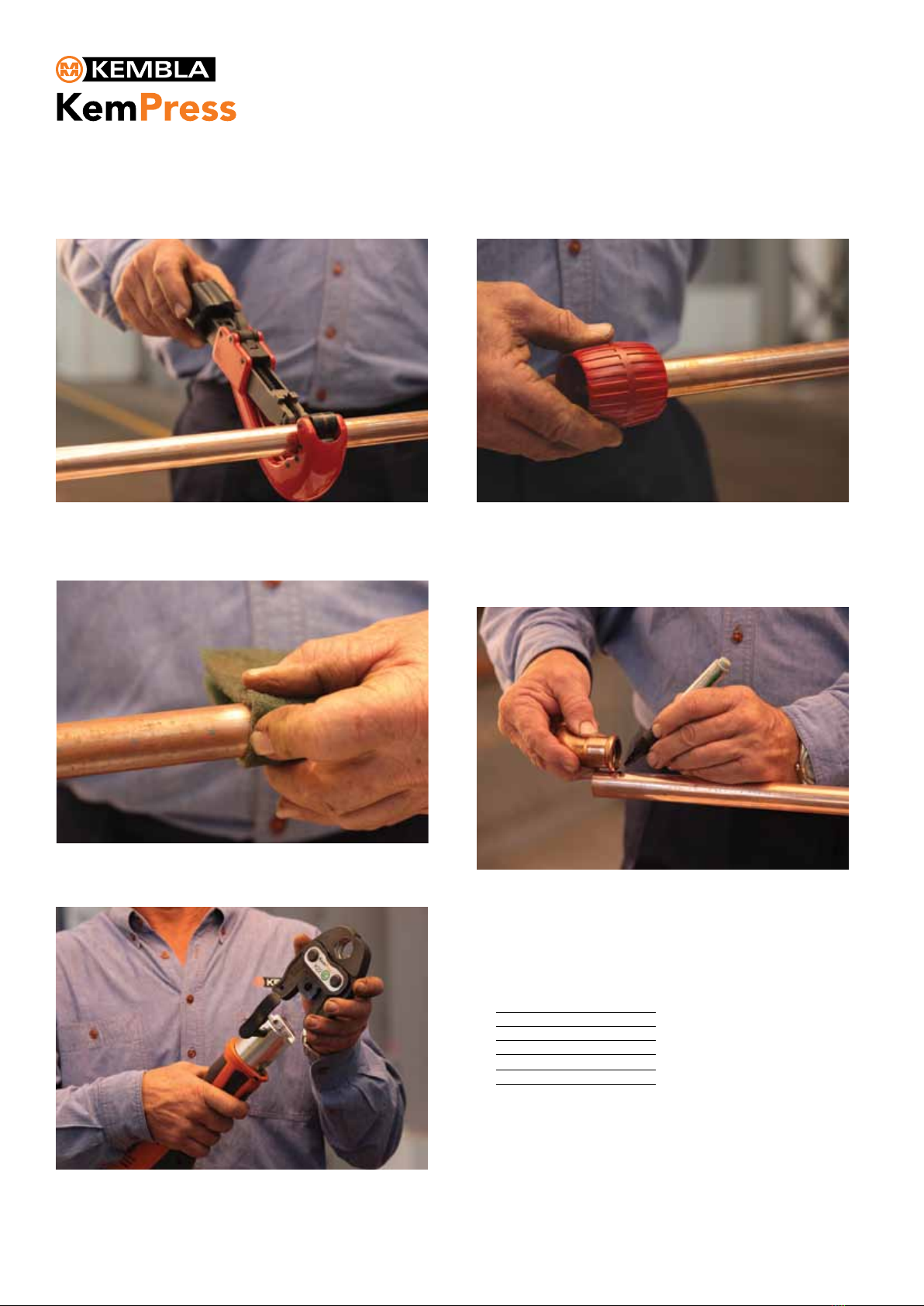

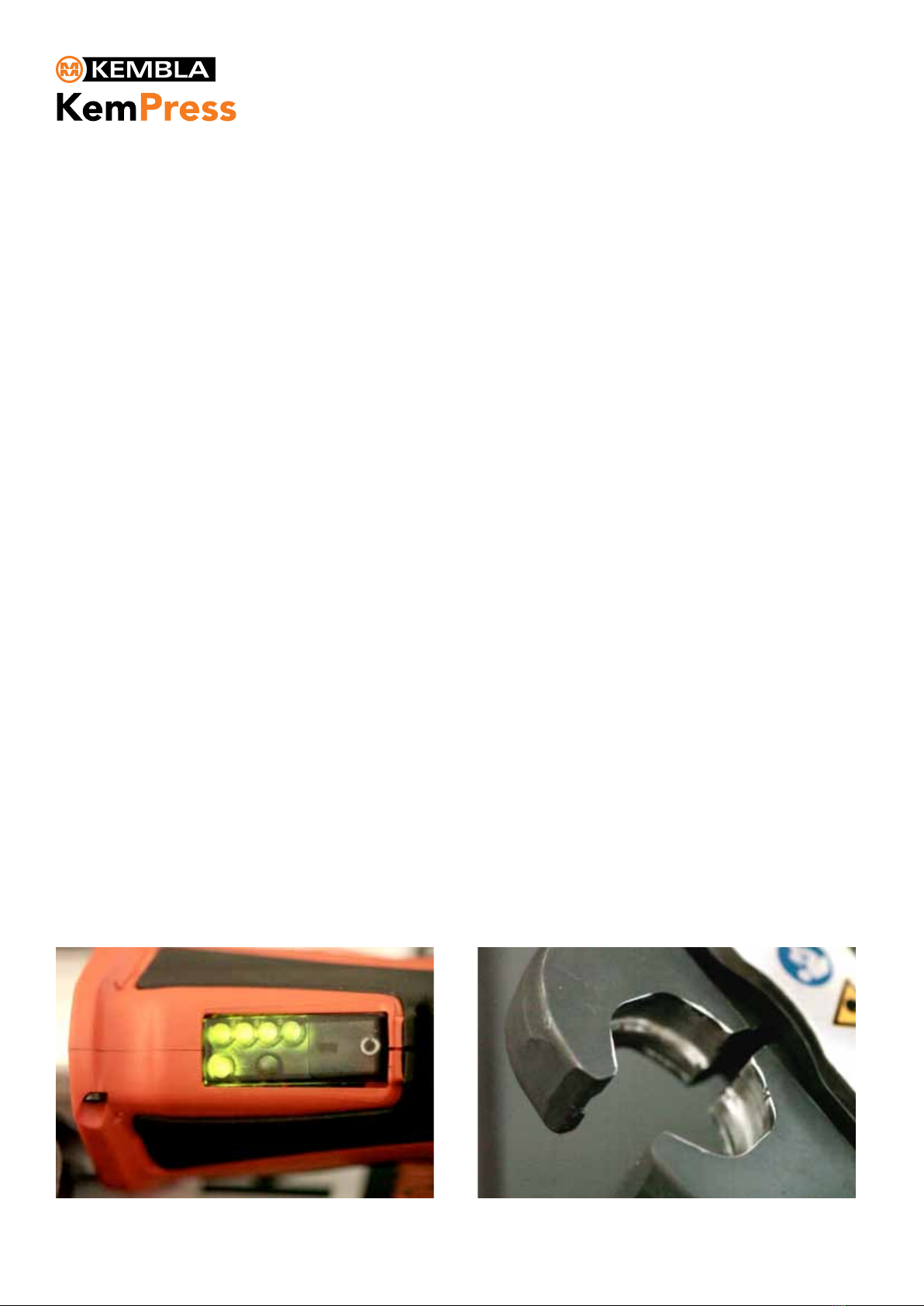

• Signals if press not completed correctly

-

Immediately

after the pressing cycle a green lights shows if the required

pressing force was achieved, a red light if not

• Automatic press cycle. Once it starts, it will automatically

complete. (manual override)

• Electronic log book allows for quick and precise

analysis of errors for servicing and repair

• Electronic monitoring of the jaw locking

bolt and visual error indicator (KPL)

• When you reach the maximum number of presses

before a service is required a warning light flashes.

The machine will not close down enabling you to

complete the job in hand.

• Redundant switch-off

• Rotatable head (KPSA)

Tool Operation

Holding the tool securely, press and hold the start button for

2 seconds to begin the automatic press cycle (the green LED

will go out). Release the start button and continue to hold the

tool securely. The green LED will light when the press cycle is

complete. To cancel the automatic press cycle press and hold

the release button on the side of the tool until the tool turns off.

If the red LED lights up, press the start button. If the tool does

not run, call Kembla Hong Kong for advice. If the red and

green LEDs flash alternately, the tool is ready for a service,

contact Kembla Hong Kong Customer Service Centre.

The tool will turn off automatically after 30 minutes of no use.

Turn the tool ON by quickly pressing and releasing the start

button and open the jaws around the fitting.

Tool Maintenance

Carry out basic inspection of the pressing device and jaws prior

to each use to ensure they are clean and free from debris and

dirt. The pressing jaws should be visually inspected to ensure

there are no cracks. If there are any cracks in the pressing jaws,

do not use them, as there is risk of the jaws shattering and

potential injury from flying fragments. It is recommended to

always wear appropriate eye protection whenever using the

pressing device. When inspecting the pressing jaws, also ensure

that there are no foreign material deposits and that the contours

of the jaw surfaces are in order. Failure to do this may result in

damage to the jaws and/or the pressing device. Always remove the

battery before performing regular cleaning and maintenance work.

The pressing device, jaws and batteries must be serviced at

least within 40,000 presses. Failure to have the required services

carried out may affect the warranty.

Tool Service Program

The Kembla Hong Kong tool service and repair program

is easy, ensures minimal down time and provides known

maximum costs for repairs. The key components of the

program include:

•

Replacement tools available while your tool is being

serviced/repaired

•

Maximum repair price guarantee: the cost won’t exceed

our maximum repair price and if the cost of repair is less,

you only get charged that amount

•

No fix, no charge

•

Up to 12 months warranty on repairs

Any service or repair of the KemPress

®

pressing tool or jaws,

requiring opening the device, or mechanical repairs, shall only

be carried out by MM Kembla or their authorised agent.

Failure to do so may void the warranty.

11

®