Operating Instructions for Hydraulic hose swage machine G20/G32

Page 3of 17

1. About these Instructions and symbol descriptions

The information in these Operating Instructions is labelled as follows:

Warning of personal injury or environmental damage.

Warning of property damage.

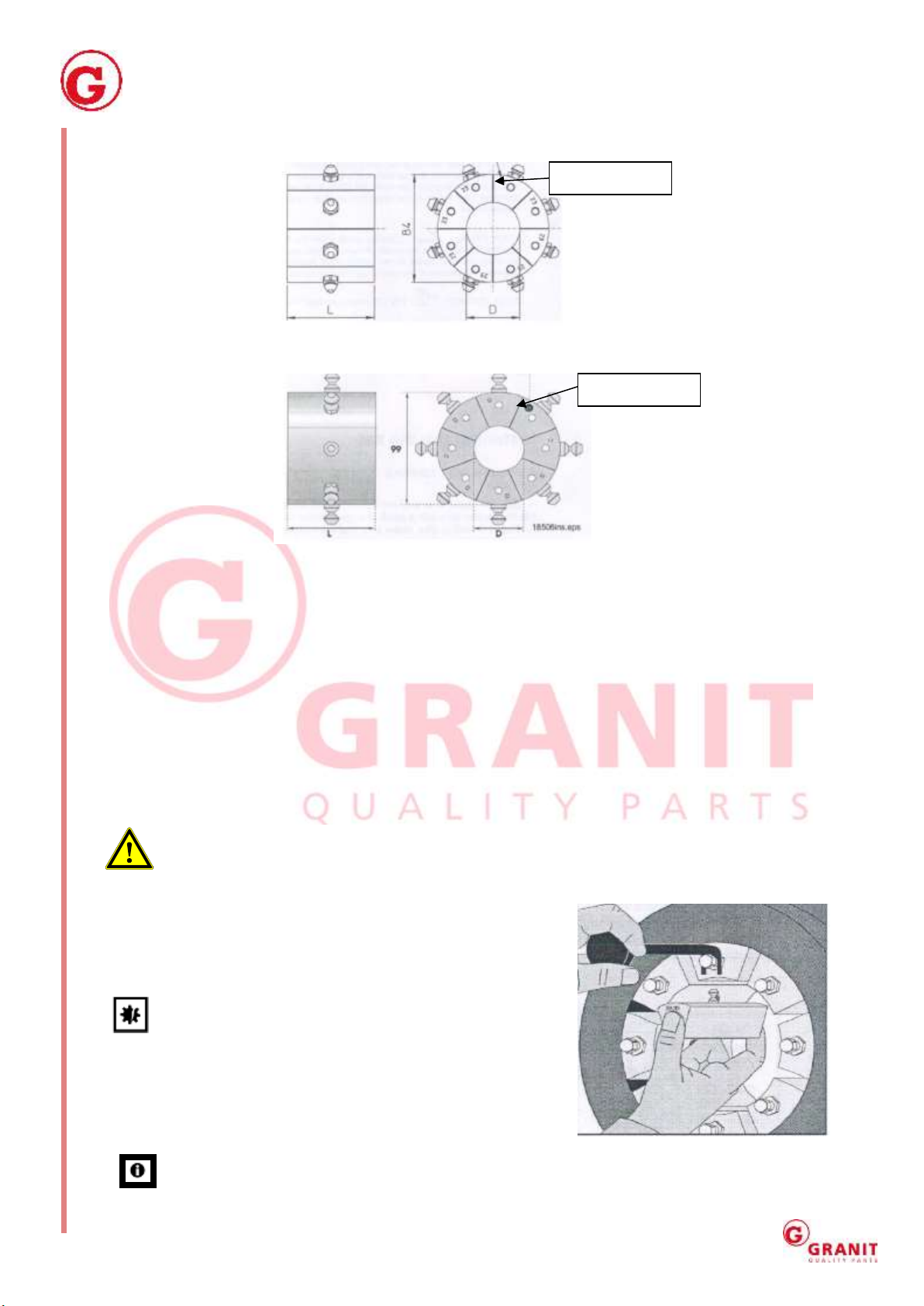

Numbers in illustrations (1, 2, 3 ...) refer to the corresponding numbers in brackets (1), (2), (3) ...

in the text next to the item numbers in the tables.

Instructions for which the order must be followed are numbered (1, 2, 3, ...)

Lists are marked with a dot (●, ●, ...)

2. Safety and accident prevention rules

2.1 General safety instructions

These operating instructions were prepared so that you can work safely with the equipment.

People who are not familiar with these instructions should not perform these actions.

Read these Operating Instructions thoroughly before use. Pay particular attention to the safety

instructions.

These Operating Instructions are intended for people with basic technical knowledge in using

equipment such as that described here.

If you have no experience with such equipment, you should first get assistance from experienced

persons.

Keep all supplied documents with the equipment for future reference if required. Keep the

purchase receipt for any warranty claims.

If you lend or sell the equipment, supply all documentation with it.

Observe the operating and maintenance instructions found in this manual.

Children should be supervised to ensure that they do not play with the equipment.

Mechanical maintenance should be performed at the prescribed intervals and in the prescribed

scope.

Following maintenance work, all dismantled protective devices must be properly reinstalled. The

protective devices and their protective functions should be inspected by a competent person

before using the machine.

Defective equipment must be repaired promptly in order to minimize the extent of damage and

avoid endangering the safety of the equipment.

The presses should only be used and operated under the conditions laid down in these operating

instructions.

Retrofits, changes or modifications to the equipment are strictly prohibited. They require

consultation with and written approval by the manufacturer.

If during operation (residual) hazards and risks become apparent which are not described in this

manual, the operator is obliged to report this to the manufacturer.

Never work or reach between or on moving pressing tools.

Do not change the settings of the safety components. Before each use check for proper

functioning, especially the hydraulic oil level, and check for possible leaks.

Liquid under high pressure can cause severe or fatal injury! In case of injury contact a physician

immediately!

Before working on the hydraulic system de-pressurize the system!