9

TOOL OPERATION PROCEDURE

Only crimp dies and accessories designed and

manufactured by BURNDY®are recommended for

use with the BURNDY®MD6 HYTOOLTM. Use of non-

BURNDY®, non-conforming products with the BURNDY®

MD6 HYTOOLTM shall be deemed abuse and will void

the warranty.

Call BURNDY®Technical Services at 1-800-346-4175,

with any application questions if in doubt.

1. Select the proper dies for the connector to be crimped.

(Refer to the BURNDY®Master Catalog.)

2. Check die recommendation chart for compatibility with

MD6. If recommended, refer to catalog and chart for

number of crimps required for proper installation.

3. Install dies in jaws making certain that they are

properly secured by the spring loaded, positive lock,

die buttons.

4. IMPORTANT - To help minimize hand and arm

fatigue and perceived handle force during use, it is

recommended to hold the MD6 HYTOOLTM with your

hands at the end of the handles.

5. Insert conductor into the connector and align the

tool and die on the connector. Start in the center for

splices and “H” frames, and on the end, nearest the

pad, for terminals.

6. Operate the tool by closing, and allowing, the handle

butt/stop blocks to touch. Normally a “pop” will be

heard as the tool goes over center after the crimp

is made.

7. Continue crimping the connector until the correct

number of crimps have been completed. Work from

the center to the outer edges for splices and “H” frame

connectors, alternating sides if possible, for the best

compression connection.

8. Reposition tool for next crimp, if required. Unless non-

bowing dies are used, it is recommended that the tool

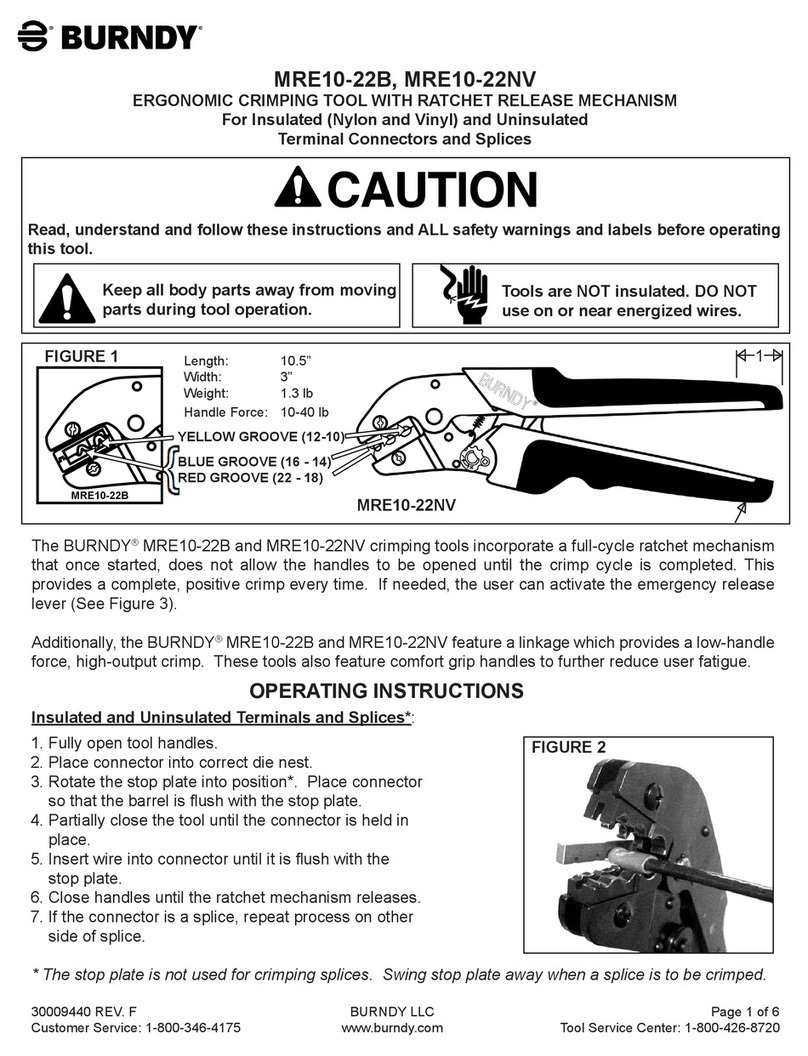

TOOL VARIATIONS:

MD6 Standard MD6 with permanent “BG (5/8”) and

“D3” grooves.

be rotated 90° for each adjacent crimp on large splice

connections.

CARE & MAINTENANCE

Your MD6 TYPE HYTOOLTM has been thoroughly tested

and lubricated by the factory. Extended trouble-free

service can be assured by following these simple steps:

1. Keep the tool clean at all times. Remove dirt, debris,

and other foreign substances from external surfaces

daily, to help prevent corrosion and damage to the

tool and mechanism.

2. Lightly lubricate every two (2) months with a good

grade machine oil in between the handle pivots and

all rubbing surfaces as needed.

3. Store the tool in either the optional tool bag or metal

carry case, when not in use. Keep in a dry, moisture

free area.

CLEANING RECOMMENDATIONS:

1. Spray jaws with CHEM-CleanTM, or equivalent, solvent

to loosen contaminants.

2. Using a stiff fiber brush, (never metal) remove

contaminants in and around jaw mechanism and

allow solvent to drain o tool.

3. Use air nozzle to remove any solvent residue.

4. Lubricate according to Care & Maintenance

instructions.

MD6-6 “Snub-Nose” variation of MD6 has a

permanent “D3” groove in jaw.

Recommended for use where space for

tool jaw is limited.

MD6-37 Permanent 161,162,163, & 171 dies

MD6-38 Permanent K, BG, & C dies in jaw