INTRODUCTION ..........................................................................................................................................................5

DESCRIPTION OF THE MANUAL'S BASIC CONTENTS .....................................................................................................5

1INFORMATION ABOUT THE MANUAL..................................................................................................................5

1.1 UPDATES TO THE MANUAL...................................................................................................................................5

1.2 COPYRIGHT...........................................................................................................................................................6

1.3 WARRANTY...........................................................................................................................................................6

1.4 TERMS OF DELIVERY .............................................................................................................................................6

1.5 JURISDICTION.......................................................................................................................................................6

1.6 TRANSPORTING THE WHEELBARROW SPRAYER...................................................................................................6

1.7 PACKAGING ..........................................................................................................................................................7

2INFORMATION ABOUT THE WHEELBARROW SPRAYER........................................................................................7

2.1 WHEELBARROW SPRAYER IDENTIFICATION.........................................................................................................7

2.2 INTENDED USES....................................................................................................................................................7

2.3 DESCRIPTION........................................................................................................................................................8

2.4 TECHNICAL DATA AND COMPONENT IDENTIFICATION ........................................................................................8

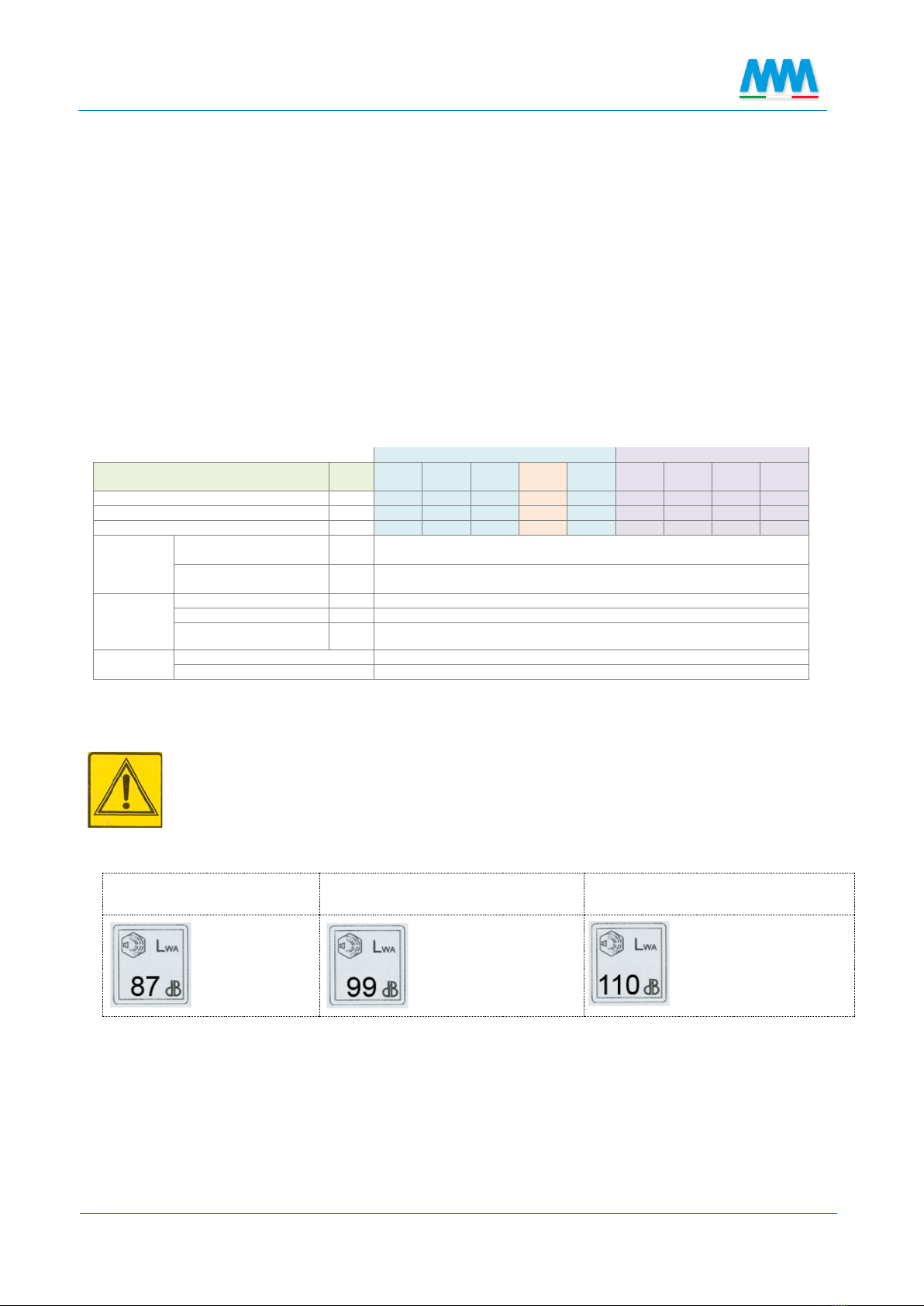

2.5 NOISE LEVELS........................................................................................................................................................8

2.6 SAFETY STANDARDS AND USES NOT PERMITTED .................................................................................................9

2.7 ELECTRIC MOTORS (BATTERY, 230V AND 400V).................................................................................................11

2.7.1 SAFE USE OF THE MOTOR, BATTERY AND BATTERY CHARGER......................................................................11

2.8 SAFETY SIGNAGE ................................................................................................................................................12

2.8.1 LOCATION OF THE PICTOGRAMS ON THE WHEELBARROW SPRAYER ...........................................................12

2.8.2 SAFETY AND DESCRIPTION PICTOGRAM LABELS............................................................................................13

3PLANT PROTECTION PRODUCTS........................................................................................................................14

3.1 ENVIRONMENTAL PROTECTION.........................................................................................................................14

4WHEELBARROW SPRAYER FUNCTIONALITY.......................................................................................................15

4.1 WATER CIRCUIT SCHEME....................................................................................................................................15

4.2 DESCRIPTION OF THE MACHINE .........................................................................................................................15

4.3 COMPONENT POSITIONING ...............................................................................................................................17

4.3.1 TANK ..............................................................................................................................................................18

4.3.2 SUCTION FILTER .............................................................................................................................................18

4.3.3 PRESSURE REGULATOR ..................................................................................................................................18

4.3.4 PUMP (see the attached use and maintenance handbook)...........................................................................19

4.3.5 MOTOR (see the attached use and maintenance handbook) ........................................................................19

4.3.6 LEVER LANCE..................................................................................................................................................19

4.3.7 HOSE REEL (optional) .....................................................................................................................................19

4.3.8 BOOM (optional)............................................................................................................................................20

5WHEELBARROW SPRAYER FUNCTIONALITY.......................................................................................................20

5.1 WHEELBARROW SPRAYER ASSEMBLY ................................................................................................................20

5.1.1 MOUNTING THE WHEELS...............................................................................................................................21

5.1.2 DRAWBAR ASSEMBLY (4-wheel models)........................................................................................................21

5.1.3 HOSE REEL ASSEMBLY (OPTIONAL)................................................................................................................21

5.1.4 BOOM ASSEMBLY (OPTIONAL).......................................................................................................................22

5.2 FILLING THE TANK...............................................................................................................................................22

5.3 HAND WASH TANK (OPTIONAL) .........................................................................................................................23

5.4 BATTERY OPERATED MODELS.............................................................................................................................24