Contents

1Purpose.....................................................................................................4

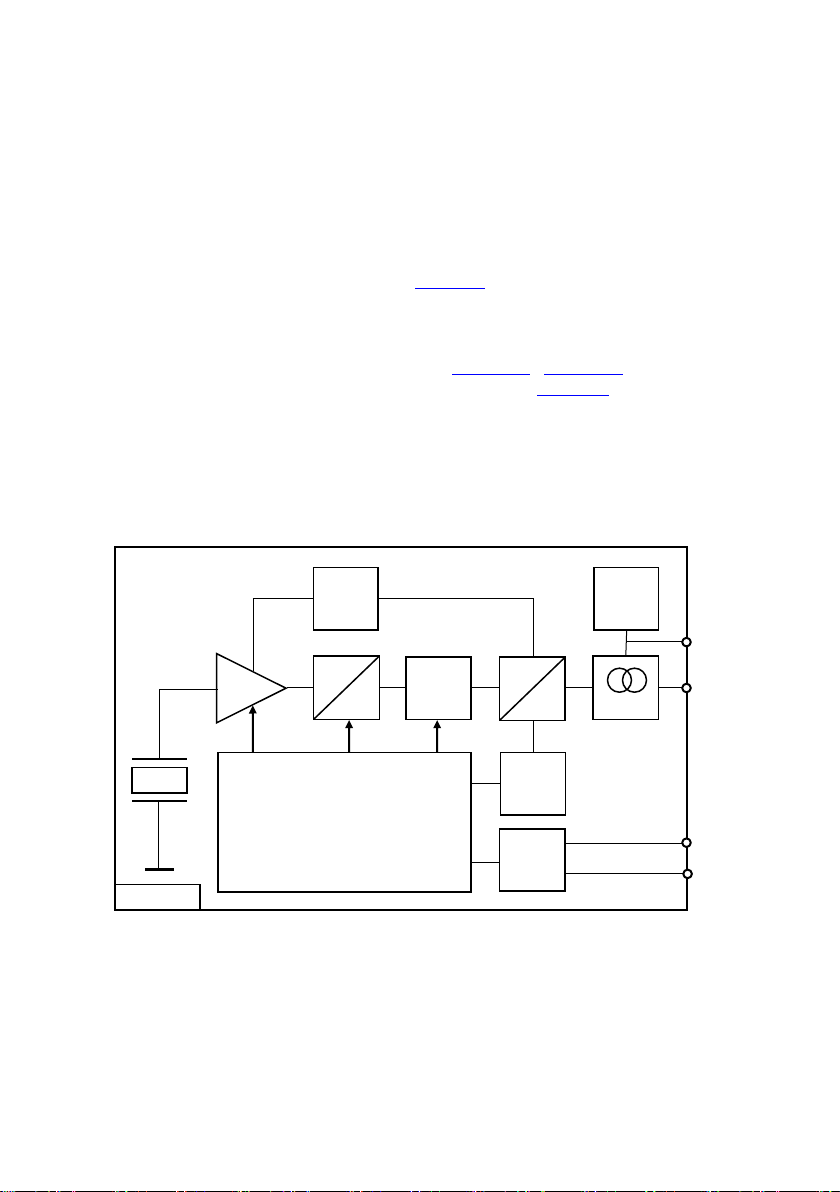

2Function....................................................................................................4

3Type Selection..........................................................................................5

3.1 Frequency Range (HP, LP).................................................................5

3.2 Measuring Range................................................................................6

3.3 Type Code ..........................................................................................6

4Sensor Operation.....................................................................................7

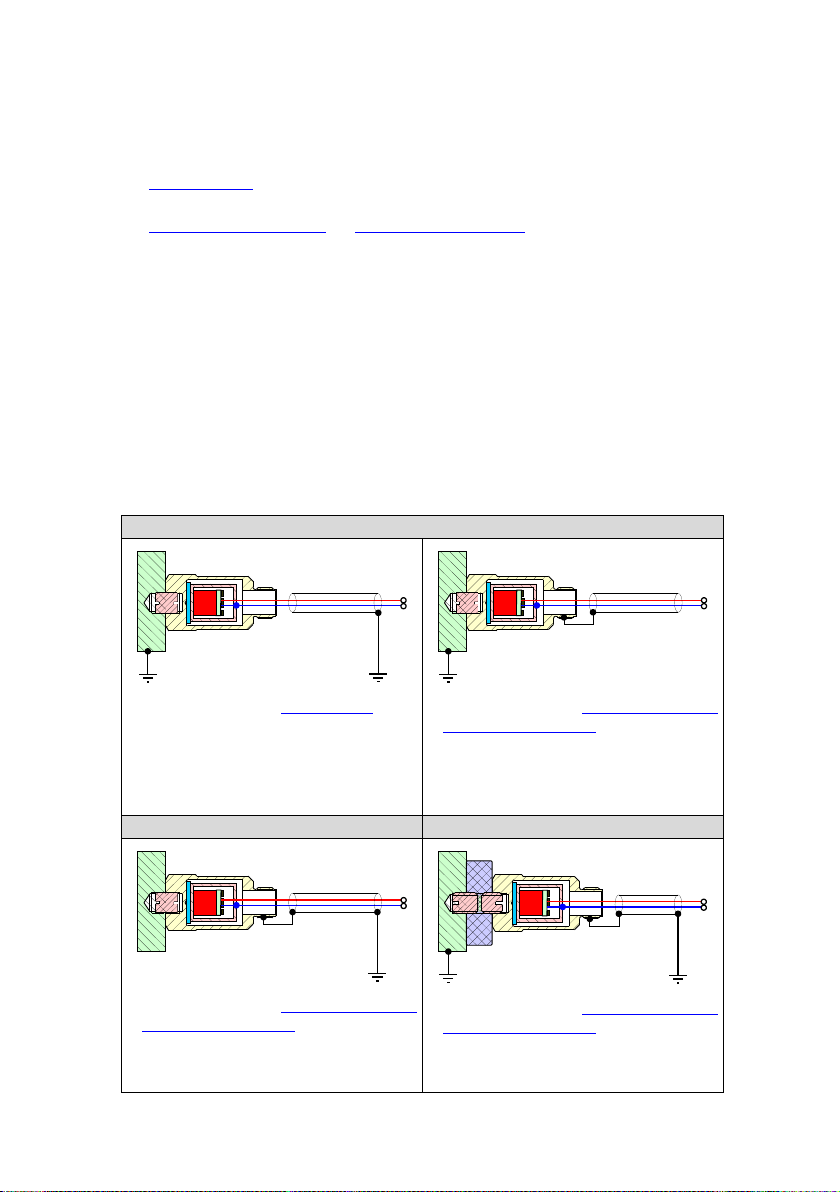

4.1 Sensor Mounting.................................................................................7

4.2 Sensor Connection .............................................................................7

4.2.1 Connection to the Loop Supply..................................................7

4.2.2 Sensor Cable.............................................................................8

4.2.3 Grounding Concept....................................................................8

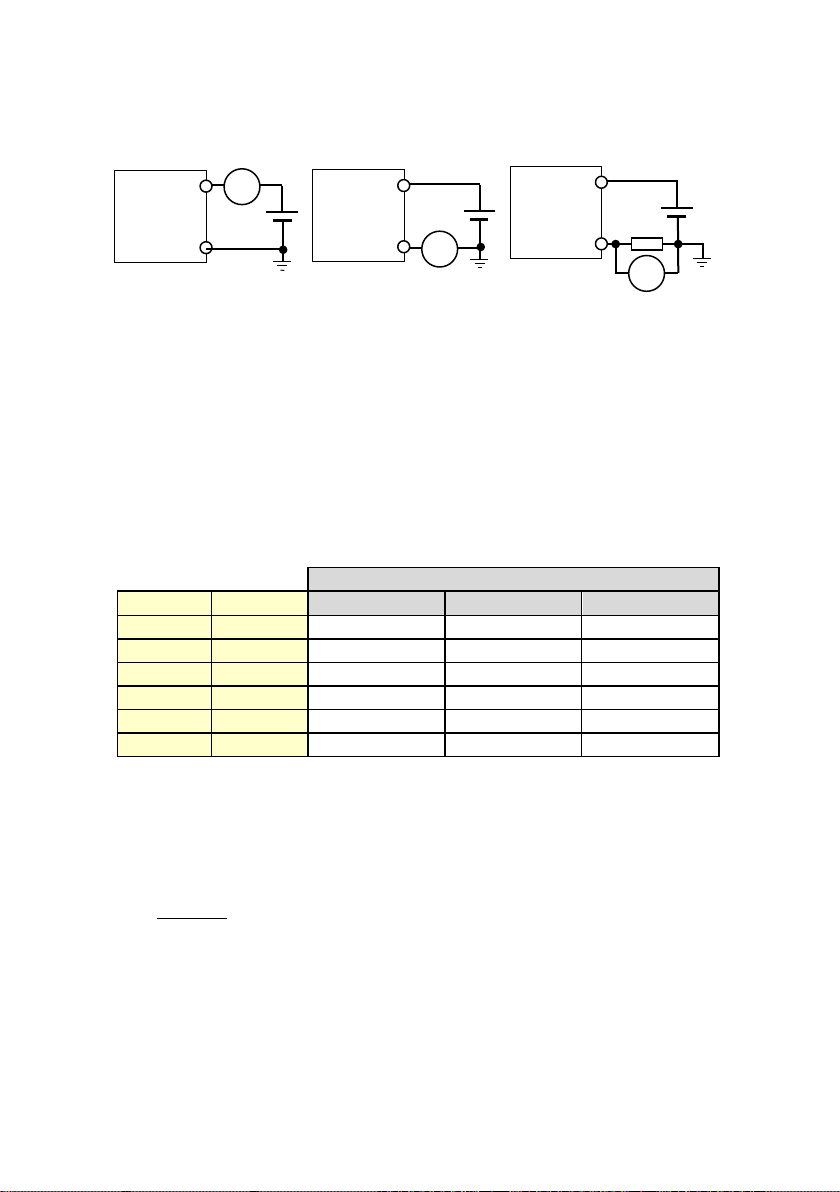

4.3 Connection of the Measuring Device..................................................9

4.3.1 Maximum Load Resistance RL...................................................9

4.4 Sensor Self-Test...............................................................................10

4.5 Measuring Mode...............................................................................10

4.5.1 Sensitivity Bi.............................................................................10

4.5.2 Calculation of Acceleration and Velocity..................................10

4.5.3 Offset Current and Noise .........................................................11

4.5.4 Linear Measuring Range xmin…xmax .........................................11

4.5.5 Maximum Dynamic Range.......................................................12

4.6 Overload Display...............................................................................12

4.7 Averaging Filter.................................................................................12

4.7.1 Number of Averages N.............................................................12

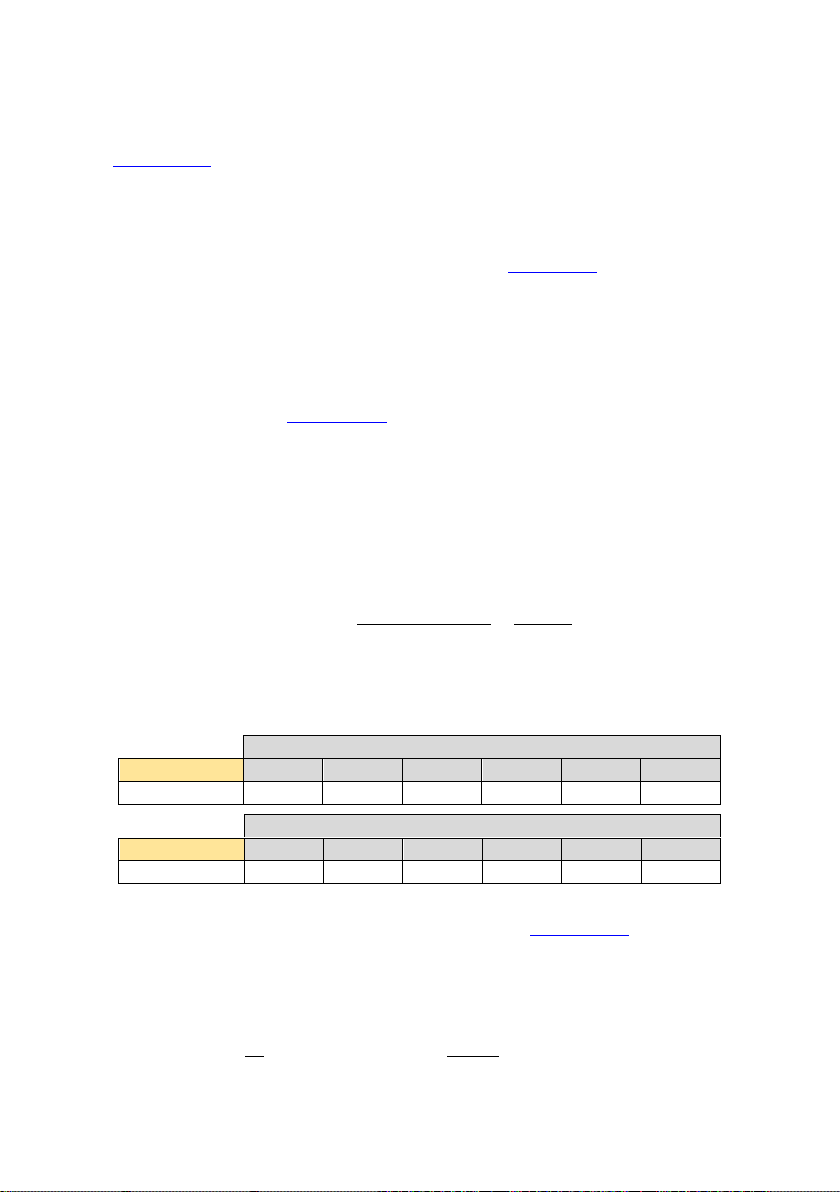

4.7.2 Settling Time T.........................................................................13

4.8 Total accuracy...................................................................................13

4.9 Error Messages.................................................................................14

4.9.1 Steps to Fix a LOOP Error.......................................................14

5Technical Data........................................................................................15

5.1 Technical Characteristics of the 4-20mA Signal Conditioning...........15

5.2 Electrical Characteristics...................................................................15

5.3Mechanical Characteristics...............................................................15

5.4 Environmental Characteristics ..........................................................15

5.5 Type Tables......................................................................................16

5.5.1 Acceleration, RMS ...................................................................16

5.5.2 Acceleration, PEAK..................................................................17

5.5.3 Velocity, RMS ..........................................................................18

5.5.4 Velocity, PEAK.........................................................................18

Limited Warranty........................................................................................19

Declaration of Conformity.........................................................................19