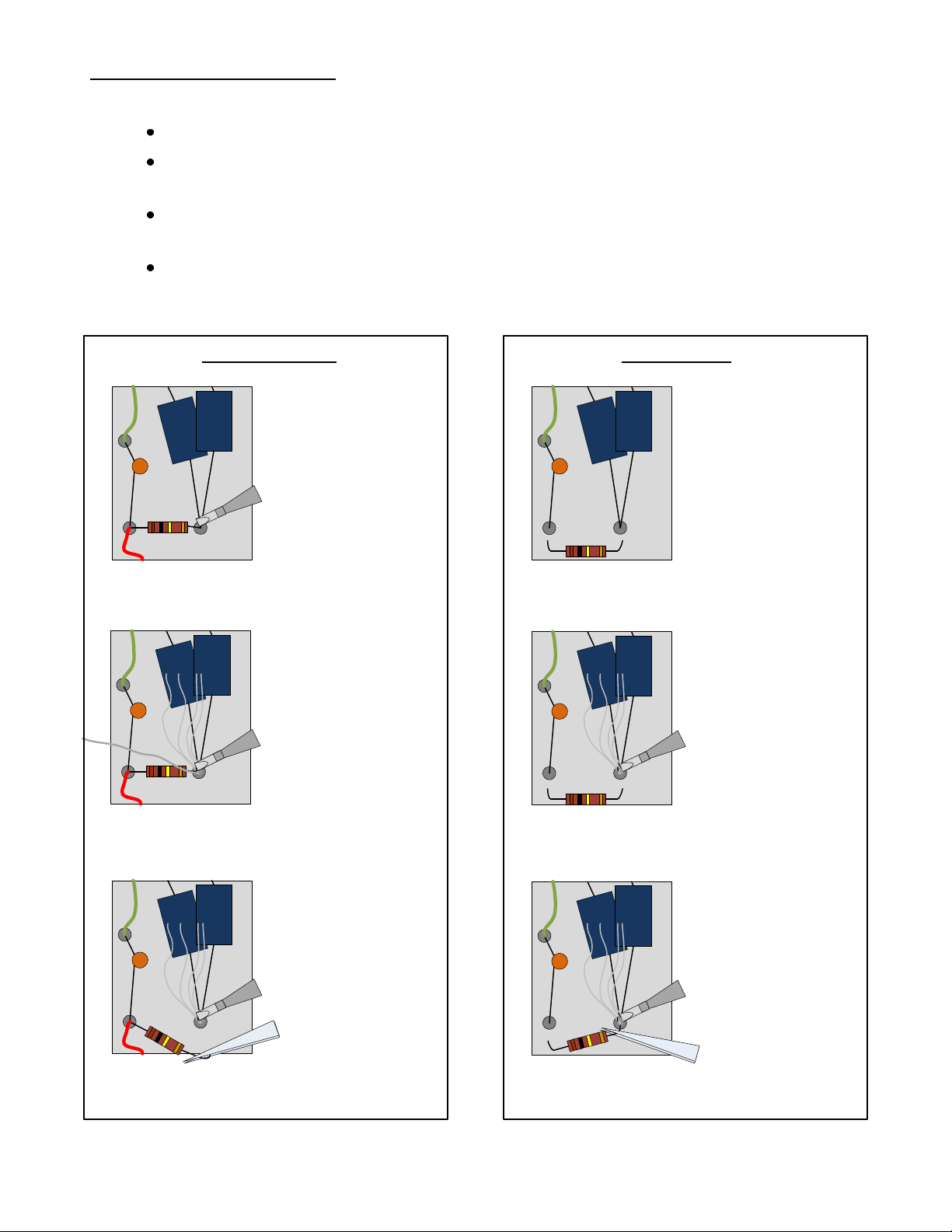

Soldering Tips (solder lugs)

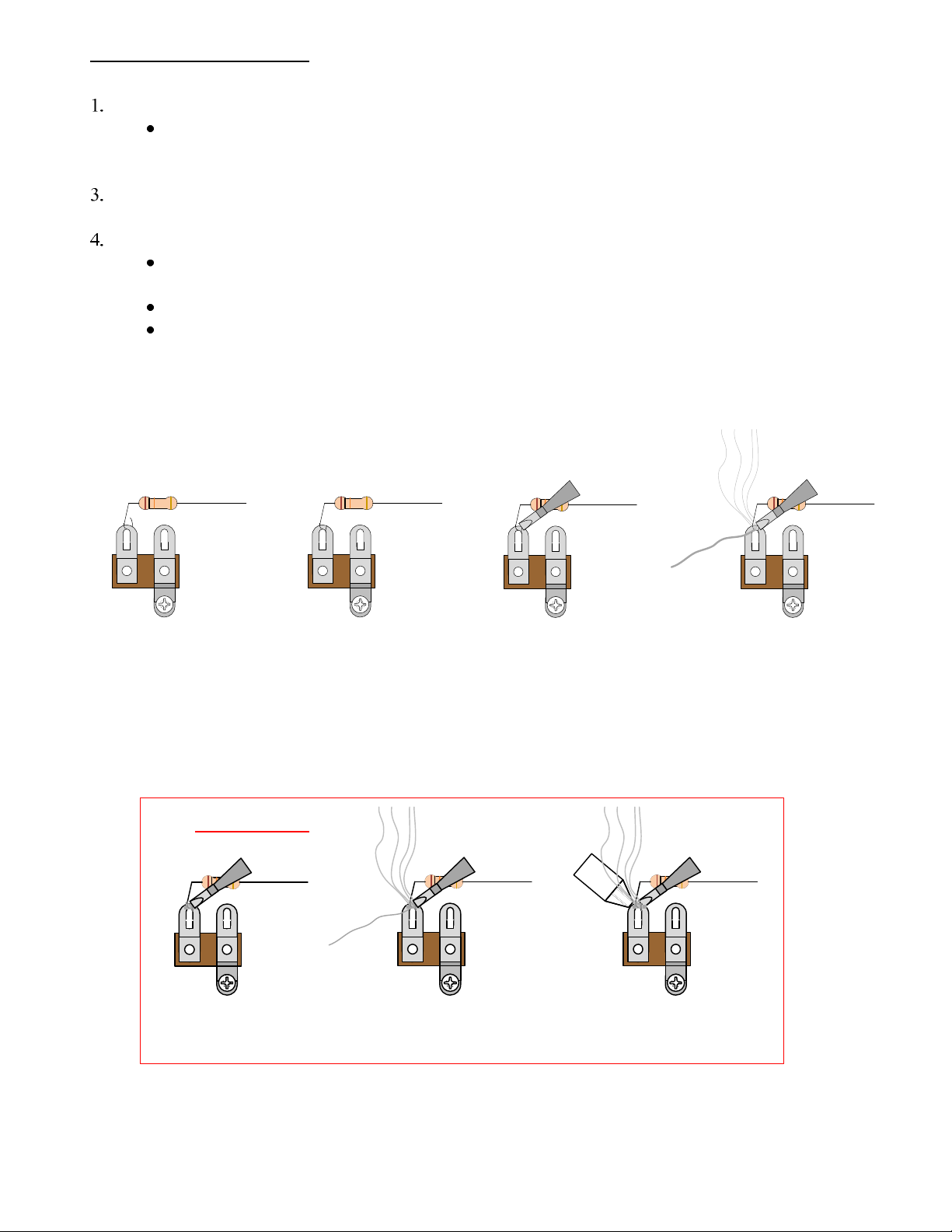

Bend the component lead or wire ending and wrap it around the connection point.

Make sure it is not too close to a neighboring component which could cause an

unintended connection.

2. Wrap the component lead so that it can hold itself to the connection point.

Touch the soldering iron to both the component lead and the connection point allowing both to

warm up just before applying the solder to them.

Be sure to adequately cover both component lead and connection point with melted solder.

Remove the soldering iron from your work and allow the solder joint to cool. (The

solder joint should be shiny and smooth after solidifying.)

Cut off any excess wire or component leads with cutting pliers.

Clean the soldering iron's tip by wiping it across the wet sponge again after making the

solder joint.

1. Bend the component lead

and rap it around the

connection point.

2. Wrap the component lead

so that it can hold itself to the

connection point.

3. Heat up both component

lead and connection point ith

the soldering iron.

4. Apply solder to both

component lead and

connection point.

2. Apply fresh solder to mix in

ith old solder joint

1. Heat up old solder joint

ith the soldering iron.

3. Use a de-soldering tool to

remove the old solder joint

hile it is heated.

De-Soldering Tip

8